1edb1baa8c99d0fbbbcf72087d30d73d.ppt

- Количество слайдов: 33

Breaking the Supply Chain Mergers & Acquisitions

The Ailing Economy 61% of M & A fail to achieve expectations

Why are M & A’s Disappointing Share Holders? n Adverse economic times n Extremely complex n Synergy plan lacking

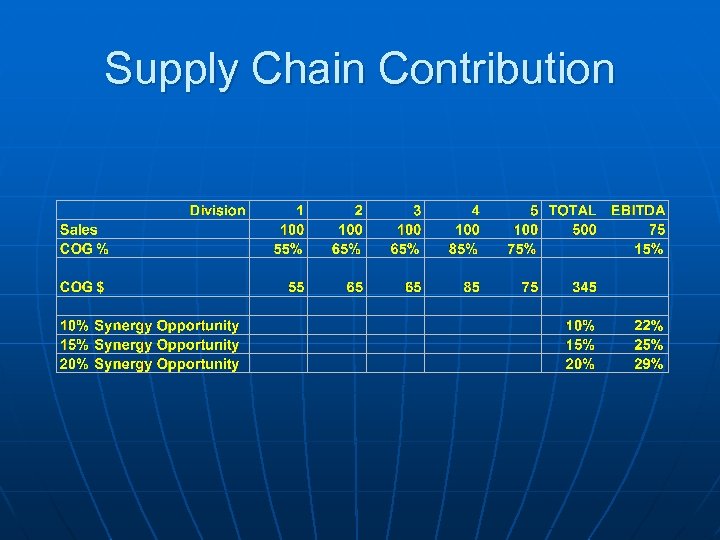

Supply Chain Contribution

Synergy Focus 4. SG&A Products Market Penetration Plants and Resources 5. Supply Chain – Why? 1. 2. 3.

Five Reasons Supply Chain is Last Considered To Be Administrative Complex Silos SC Synergies Don’t Understand Opportunities PBD

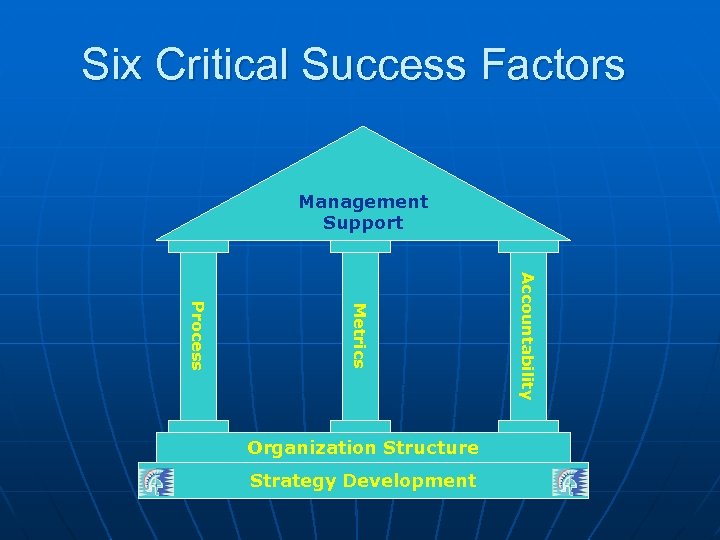

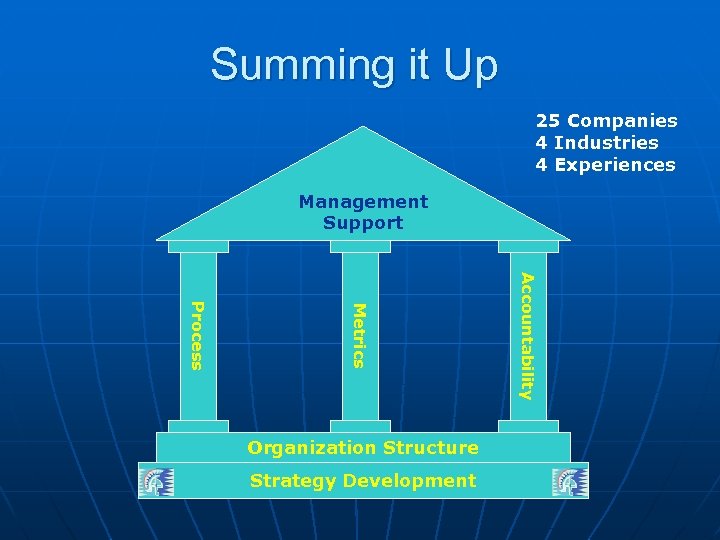

Six Critical Success Factors Management Support Strategy Development Accountability Metrics Process Organization Structure

Management Support Creating lasting synergies

Keys to Management Support n n n Confront cultural boundaries. Commit the needed resources. Support decisions for the better of the whole. Develop company-wide adrenalin. Provide tools needed.

Strategy Outside In Look

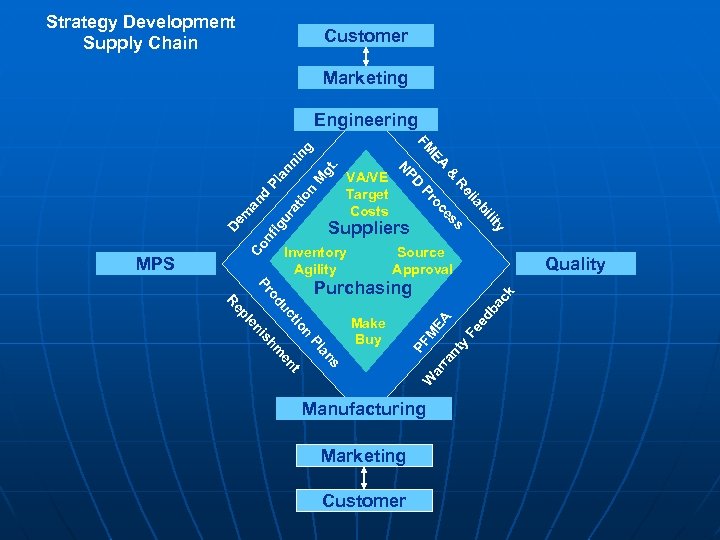

Strategy Development Supply Chain Customer Marketing Engineering n M gt . ng an ni Pl ra tio Source Approval Quality Customer ac k ed b y Fe EA M W t Manufacturing Marketing ra nt s en an Pl Make Buy ar n tio uc m sh i en pl Re od Pr Purchasing PF d ig u y nf lit bi m an lia ss Suppliers Inventory Agility Re ce o Pr Co & D De EA FM NP MPS VA/VE Target Costs

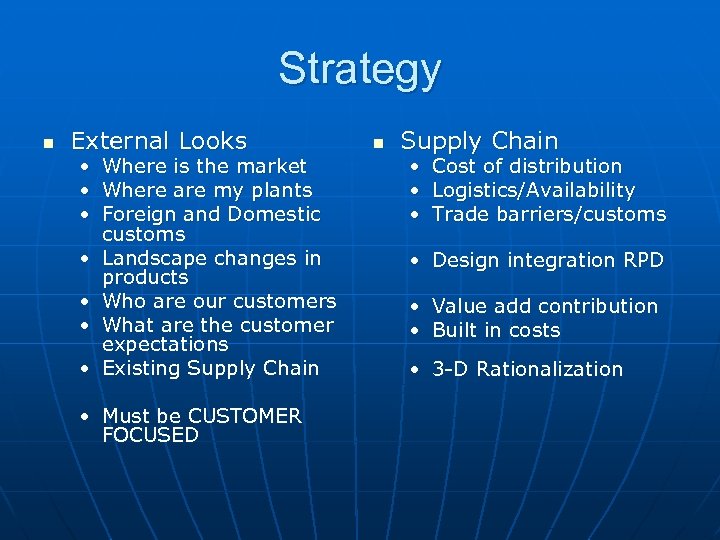

Strategy n External Looks • Where is the market • Where are my plants • Foreign and Domestic customs • Landscape changes in products • Who are our customers • What are the customer expectations • Existing Supply Chain • Must be CUSTOMER FOCUSED n Supply Chain • Cost of distribution • Logistics/Availability • Trade barriers/customs • Design integration RPD • Value add contribution • Built in costs • 3 -D Rationalization

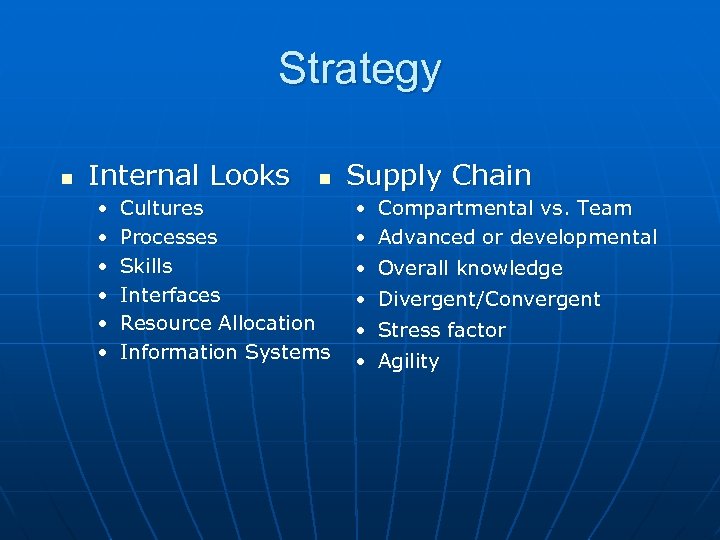

Strategy n Internal Looks • • • n Cultures Processes Skills Interfaces Resource Allocation Information Systems Supply Chain • • • Compartmental vs. Team Advanced or developmental Overall knowledge • Divergent/Convergent • Stress factor • Agility

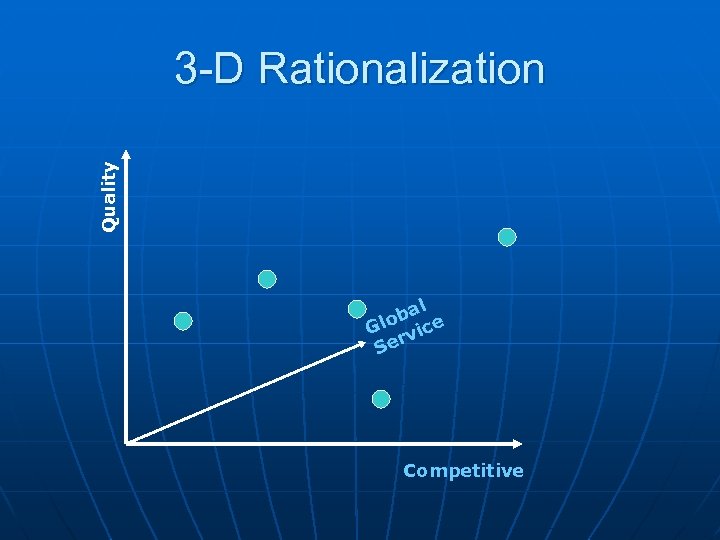

Quality 3 -D Rationalization al ob ce Gl vi r Se Competitive

Organization De-construction & Supply Chain Abyss

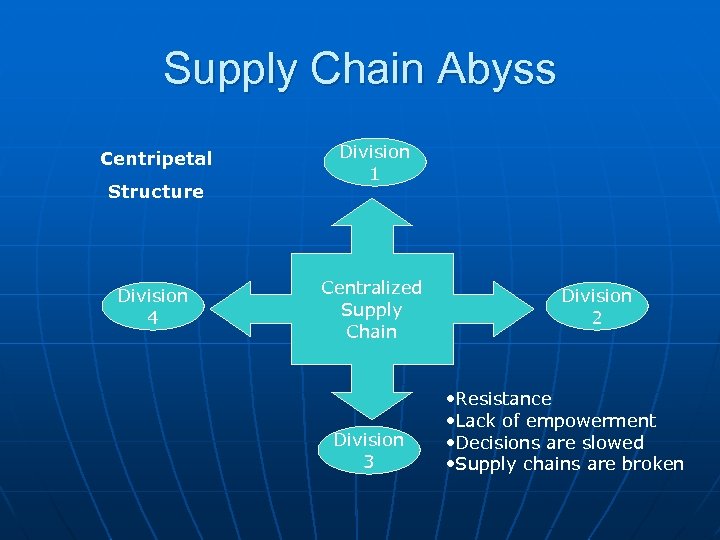

Supply Chain Abyss Centripetal Structure Division 4 Division 1 Centralized Supply Chain Division 3 Division 2 • Resistance • Lack of empowerment • Decisions are slowed • Supply chains are broken

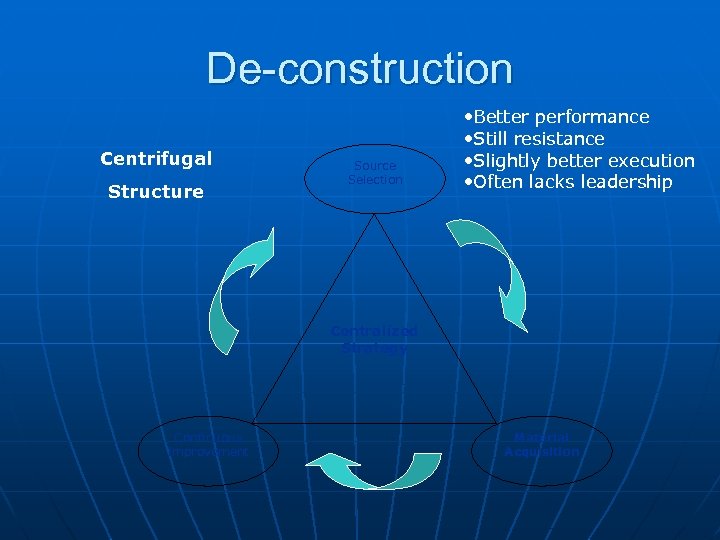

De-construction Centrifugal Structure Source Selection • Better performance • Still resistance • Slightly better execution • Often lacks leadership Centralized Strategy Continuous Improvement Material Acquisition

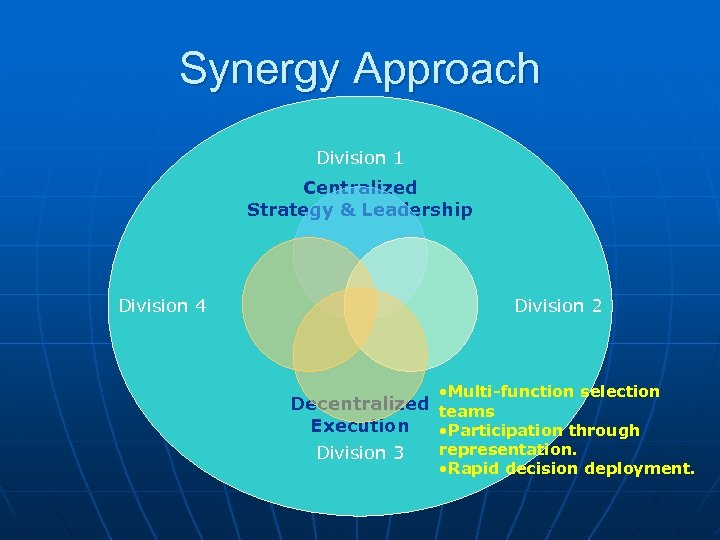

Synergy Approach Division 1 Centralized Strategy & Leadership Division 4 Division 2 • Multi-function selection Decentralized teams Execution • Participation through representation. Division 3 • Rapid decision deployment.

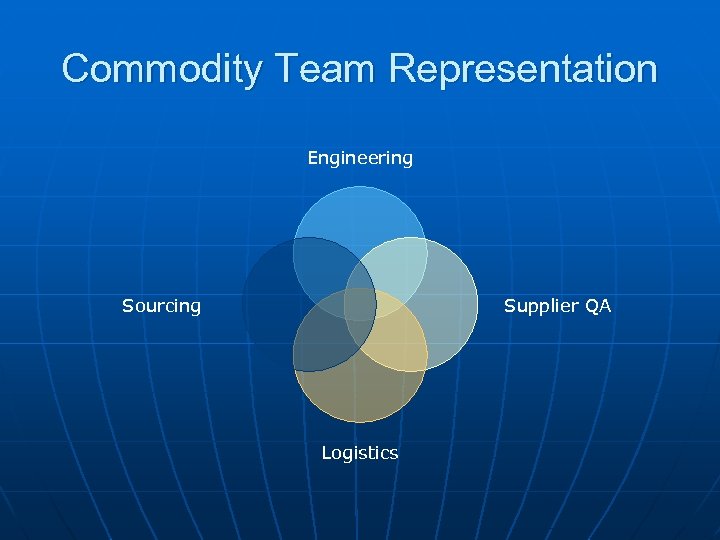

Commodity Team Representation Engineering Sourcing Supplier QA Logistics

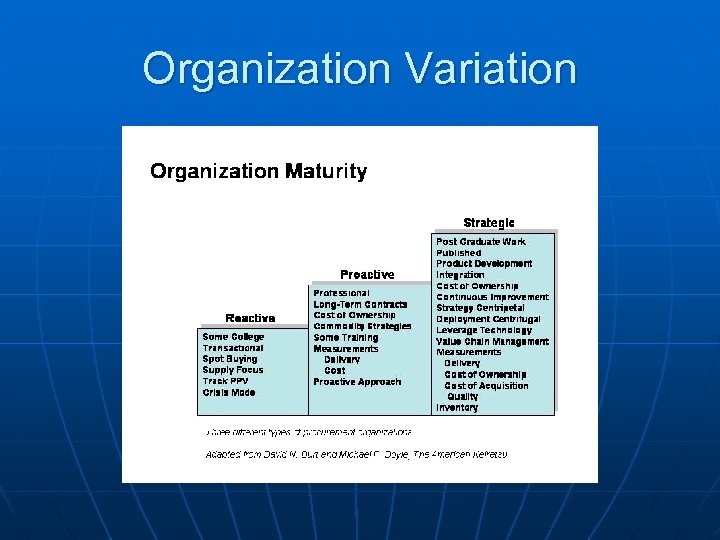

Organization Variation

Key to Organization Success Tell me and I will forget, show me and I may remember, involve me and I will care.

Accountability

Accountability Vs. Responsibility • The team must be accountable for the same things. • Team must be part of the decision process. • Performance must be measurable. • All parties must be resigned to the target. • There must be a plan to support the what. • Communication of expectations. Who What When How

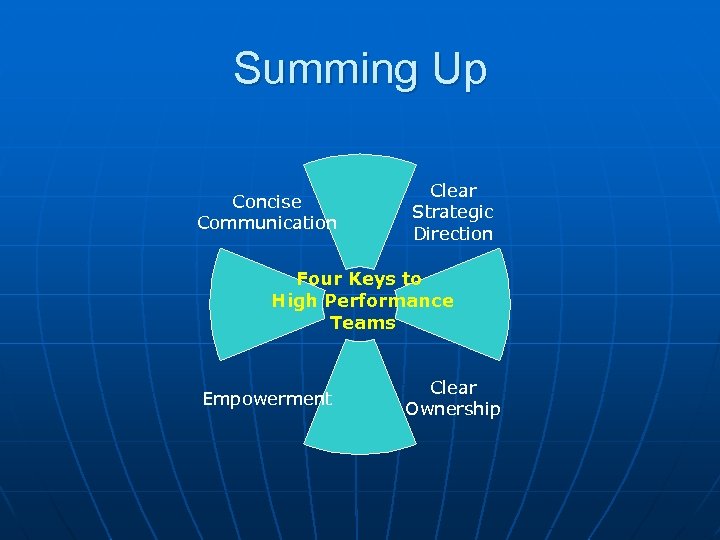

Summing Up Concise Communication Clear Strategic Direction Four Keys to High Performance Teams Empowerment Clear Ownership

Supply Chain Metrics

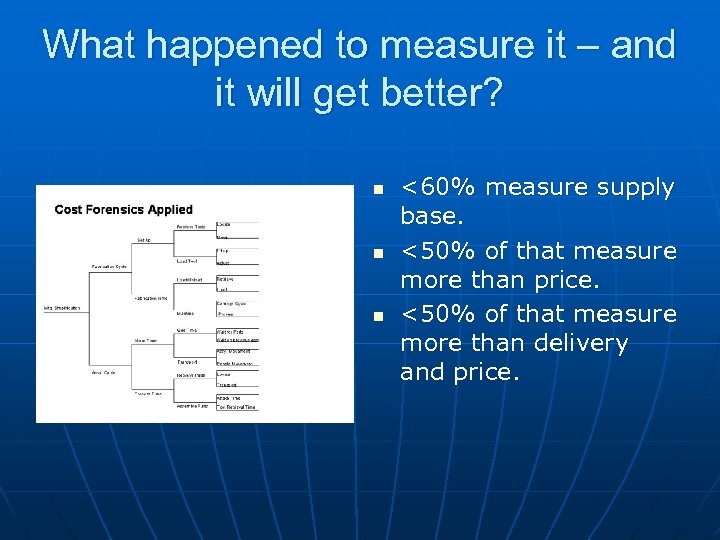

What happened to measure it – and it will get better? n n n <60% measure supply base. <50% of that measure more than price. <50% of that measure more than delivery and price.

Typical Corporate Metrics Issues n n n Not all divisions measure performance. Not all divisions measure equally. Lacks wealth equilibrium. Division IT systems lack flexibility. No time to measure. Conversion costs.

Supply Chain Processes

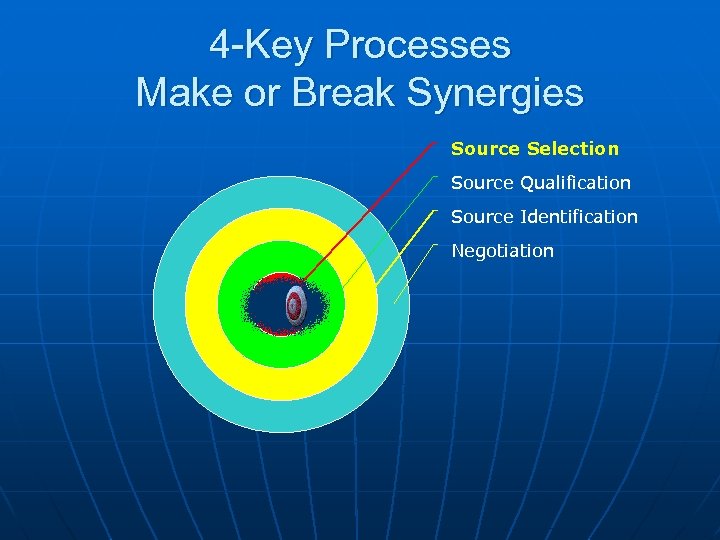

4 -Key Processes Make or Break Synergies Source Selection Source Qualification Source Identification Negotiation

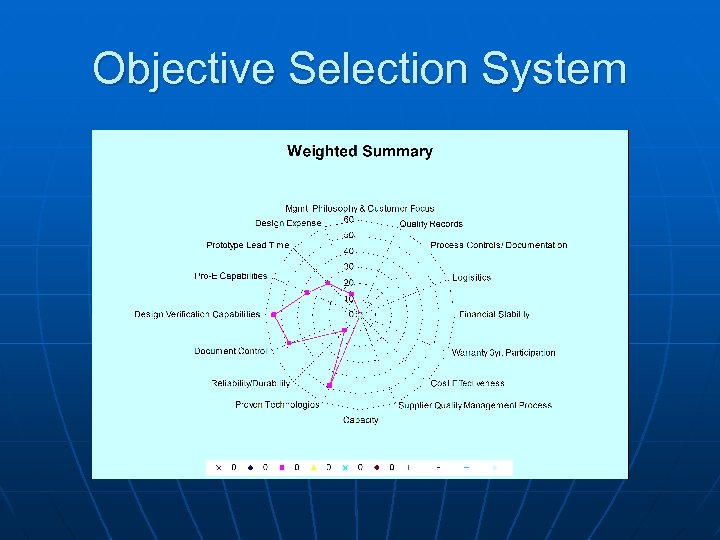

Objective Selection System

Six Key System Components n n n Objective criteria Quantifiable Unbiased appraisal Cross-division participation Cross-functional participation Clear and concise feedback

Negotiation Cost Opportunity Model % Opportunity vs. Cost Contribution % Savings Opportunity Savings Timing Margin Logistics Immediate Mfg. Cost Short Term Material Cost Designed In Cost Mid Term Conversion Costs Subtract

Summing it Up 25 Companies 4 Industries 4 Experiences Management Support Strategy Development Accountability Metrics Process Organization Structure

1edb1baa8c99d0fbbbcf72087d30d73d.ppt