d661b6ae91c99c4a88f0611b50bf0bc8.ppt

- Количество слайдов: 17

BP Experiences -- Guided Wave Radar Level Instruments Rick Stanley API SOICS April 2008

Overview • BP Inventory • Overall Experience • Design and Operation Issues − Configuration − Off Normal Behavior − Physical Design • Wish List and Path Forward 2

BP Inventory • Guided Wave Levels used at all 5 BP US Refineries − Whiting – 75 − Texas City – 50+ − Cherry Point – 40+ − Carson -- 60 • Services − Propane storage bullets − Cooling towers − Process levels − Interfaces • Overall experience is good, but there are problem applications − Configuration issues − Post startup adjustments − Consistency and reliability of measurements 3

Understanding Configuration • Many Choices – difficult to make the right ones • Manufacturer guidelines haven’t been that effective − Contractors incompletely specify configuration − Deeper understanding of application requirements • Understanding of what the choices mean and how they interact is experience that we are only now getting • Some areas of difficulty − Null zone and hold off − Dielectric selection − Thresholds − Out of range behavior − Fault behavior 4

Some Real Examples • Carson 2008 Turnaround – Installed about 40 Guided Wave Levels • Shop testing – water fill • Manufacturer tech support on site multiple times • Some installation difficulties • Several head swaps prior to startup • Despite a lot of effort, we were adjusting things prior to and during startup • Post TAR – Almost all GWR are reading OK and are stable – but it took a lot of work to get there • We seem to have more difficulties than Tx. C and Whiting have had, but distance has a way of dulling experiences. Everyone has successes and problem applications 5

Hold Off, Blocking Distance and Null Zone • Several heads had to be remote mounted due to clearance • Extension of cable from probe to head lead to mis-interpretation of parameter adjustments required • Initial operation resulted in end of probe not detected faults • Faults forced output to 100% even at zero level • Consultation with factory resulted in correction of parameters • Problem was fixed, but at cost of operations confidence • 3 Services with dual GWR – pulled one and replaced with DP 6

Dielectric • Instruments require careful dielectric selection – process design basis may not be right • Example -- DEA contactor − Instrument set for high dielectric (water based) − During startup hydrocarbon overfill into DEA contactor − Magnetic float indicated 4”, DP indicated 30” and guided wave indicated 0. − Guided wave had been indicating up until hydrocarbon carry over − Corrected dielectric for hydrocarbon – revealed actual level of about 50” − Left at hydrocarbon dielectric and seems to be working since • Similar issues to be expected in flare KO drums and similar places why water and hydrocarbon may exist 7

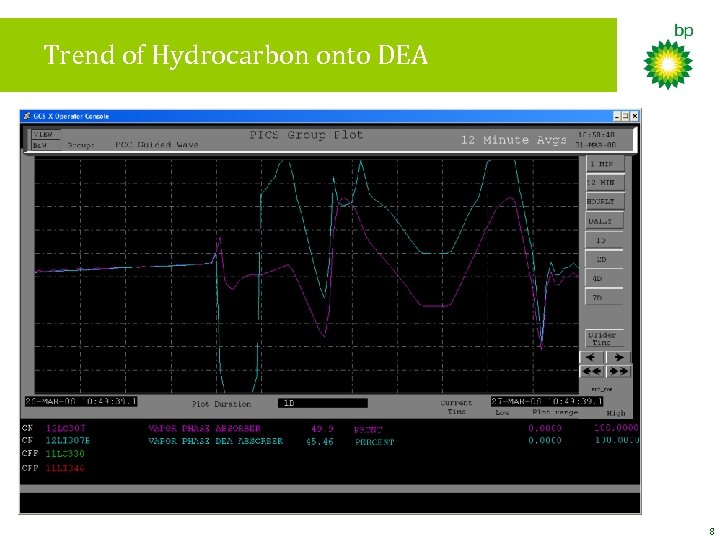

Trend of Hydrocarbon onto DEA 8

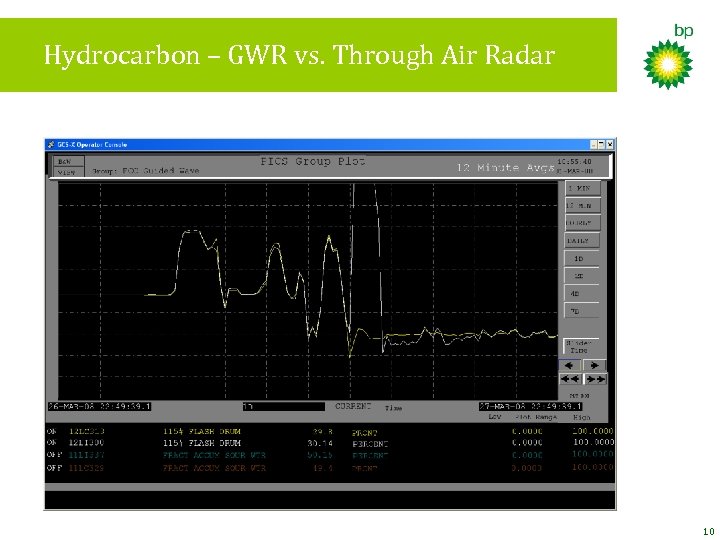

Threshold • Appropriate thresholds for detection of level surface aren’t always constant • Auto-sense functions can lead to erroneous levels • Hydrocarbon level in flash drum − Guided wave and through the air radar tracked very well − Guided wave went to 100% - Investigation found that threshold had been lost. Reset to manual threshold and they have been tracking since • Empty Drum − Threshold set to automatic – result was spikes in level even though drum was empty − Set to fixed threshold, but still having issues with empty drum − Had to adjust thresholds differently on parallel services 9

Hydrocarbon – GWR vs. Through Air Radar 10

Out of Range Behavior • Experiencing problems with instruments when level is outside probe range • Want signal to stay at 0% when level falls below probe or configured range and 100% when level increases beyond probe or configured range • Having difficulty getting reliable behavior in empty vessels • Instruments appear to be going into fault, which drives the signal to its configured fault output – this means a low level can indicate as a high level • Need reliable and predictable out of range performance. 11

Installation • External Chambers − GRW manufacturers were generally not planning on getting into the chamber business. − Users view has been to buy these like displacers – complete assemblies with chambers • Attempts at response have been mixed. Design development and fabrication quality − Materials − Basic design − Welding quality • Recent projects have resorted to piping fabricators or local fabrication 12

Installation • Guided wave installations often don’t have platforms • View of heads is limited or not possible – operations hasn’t been happy about that • Need a means of relocating display to grade without affecting radar path • Long rods are subject to being bent when being removed or reinstalled. 13

Documentation • Guided wave specification form • Baseline configuration for common applications − Hydrocarbon level − Mixed service level − Interface − Water − Dry vessel • Configuration data storage − Manufacturer’s programs − AMS or similar systems 14

We Know What These GWR’s are. Doing : -) 15

Wish List – Path Forward • Use of GWR has generally been quite successful and well accepted • Some services still need work and have impacted the attitudes of those who own them • Effectiveness of manufacturer support is still spotty − On site support is needed for commissioning of any quantity − Even with on site support we have still had performance issues • Successful implementation requires careful attention to device applications and post startup review and adjustment. Not particularly tolerant of error. Right now the commissioning labor per installation is high • Steep learning curve, but we think we are over most of it. • Still concern over some services, especially dry vessels or widely varying process conditions. 16

Conclusions • Guided Wave Radars are not simple but they do work (eventually) • They aren’t always predictable when first commissioned • They take more work than Specific Gravity based devices • We will be developing much more defined practices − Specification and configuration requirements − Checkout and commissioning procedures • We will continue to use the technology, but will run into resistance if we try to eliminate traditional SG based devices − Operations doesn’t always understand SG devices will be inaccurate − But…. . It does give them a signal even if its wrong. • It will take time to develop comfort that people have with the old technologies 17

d661b6ae91c99c4a88f0611b50bf0bc8.ppt