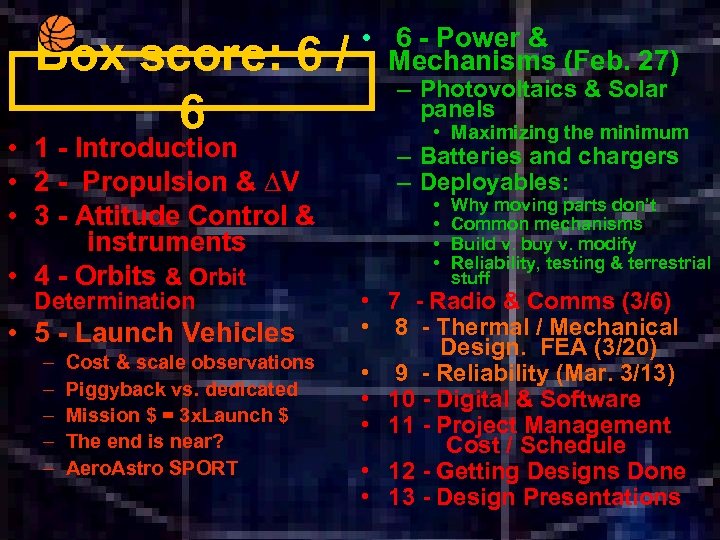

Box score: 6 / 6 • 1 - Introduction • 2 - Propulsion & ∆V • 3 - Attitude Control & instruments • 4 - Orbits & Orbit Determination • 5 - Launch Vehicles – – – Cost & scale observations Piggyback vs. dedicated Mission $ = 3 x. Launch $ The end is near? Aero. Astro SPORT • 6 - Power & Mechanisms (Feb. 27) – Photovoltaics & Solar panels • Maximizing the minimum – Batteries and chargers – Deployables: • • Why moving parts don’t Common mechanisms Build v. buy v. modify Reliability, testing & terrestrial stuff • 7 - Radio & Comms (3/6) • 8 - Thermal / Mechanical Design. FEA (3/20) • 9 - Reliability (Mar. 3/13) • 10 - Digital & Software • 11 - Project Management Cost / Schedule • 12 - Getting Designs Done • 13 - Design Presentations

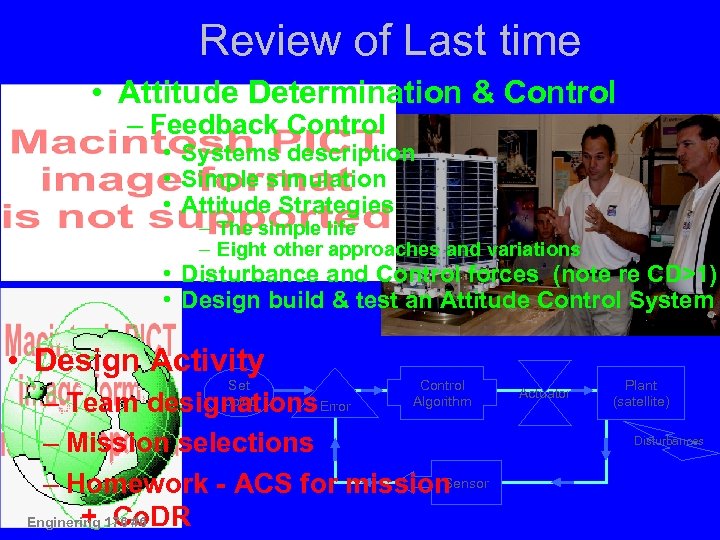

Review of Last time • Attitude Determination & Control – Feedback Control • Systems description • Simple simulation • Attitude Strategies – The simple life – Eight other approaches and variations • Disturbance and Control forces (note re CD>1) • Design build & test an Attitude Control System • Design Activity Set point Control Algorithm – Team designations. Error – Mission selections Sensor – Homework - ACS for mission + Co. DR Enginering 176 #6 Actuator Plant (satellite) Disturbances

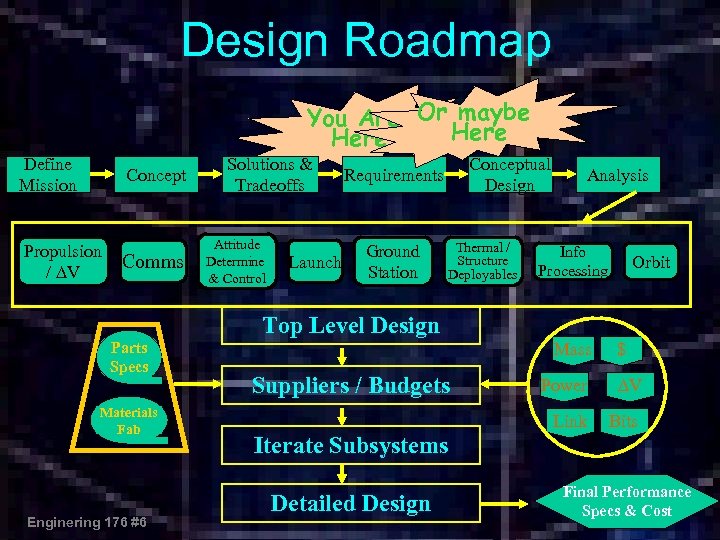

Design Roadmap You Are Or maybe Here Define Mission Concept Propulsion / ∆V Comms Solutions & Tradeoffs Attitude Determine & Control Launch Conceptual Design Requirements Ground Station Thermal / Structure Deployables Analysis Info Processing Orbit Top Level Design Parts Specs Materials Fab Enginering 176 #6 Mass Suppliers / Budgets $ Power ∆V Link Bits Iterate Subsystems Detailed Design Final Performance Specs & Cost

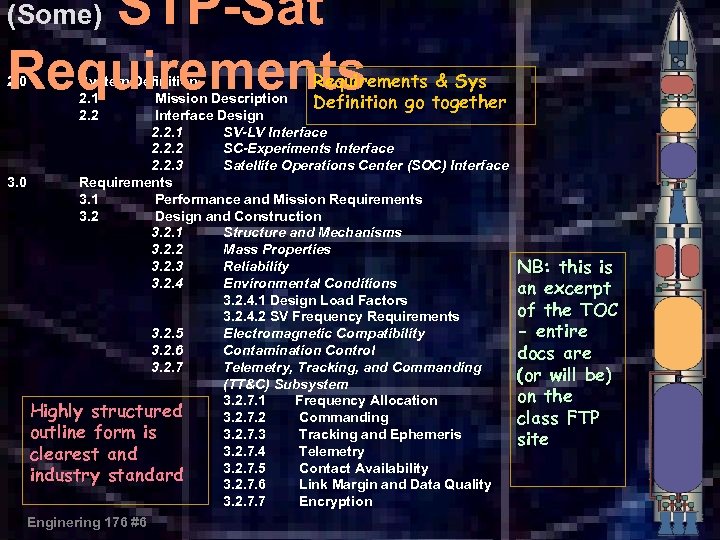

STP-Sat Requirements (Some) System Definition Requirements & Sys 2. 1 Mission Description Definition go together 2. 2 Interface Design 2. 2. 1 SV-LV Interface 2. 2. 2 SC-Experiments Interface 2. 2. 3 Satellite Operations Center (SOC) Interface 3. 0 Requirements 3. 1 Performance and Mission Requirements 3. 2 Design and Construction 3. 2. 1 Structure and Mechanisms 3. 2. 2 Mass Properties 3. 2. 3 Reliability 3. 2. 4 Environmental Conditions 3. 2. 4. 1 Design Load Factors 3. 2. 4. 2 SV Frequency Requirements 3. 2. 5 Electromagnetic Compatibility 3. 2. 6 Contamination Control 3. 2. 7 Telemetry, Tracking, and Commanding (TT&C) Subsystem 3. 2. 7. 1 Frequency Allocation Highly structured 3. 2. 7. 2 Commanding outline form is 3. 2. 7. 3 Tracking and Ephemeris 3. 2. 7. 4 Telemetry clearest and 3. 2. 7. 5 Contact Availability industry standard 3. 2. 7. 6 Link Margin and Data Quality 3. 2. 7. 7 Encryption 2. 0 Enginering 176 #6 NB: this is an excerpt of the TOC - entire docs are (or will be) on the class FTP site

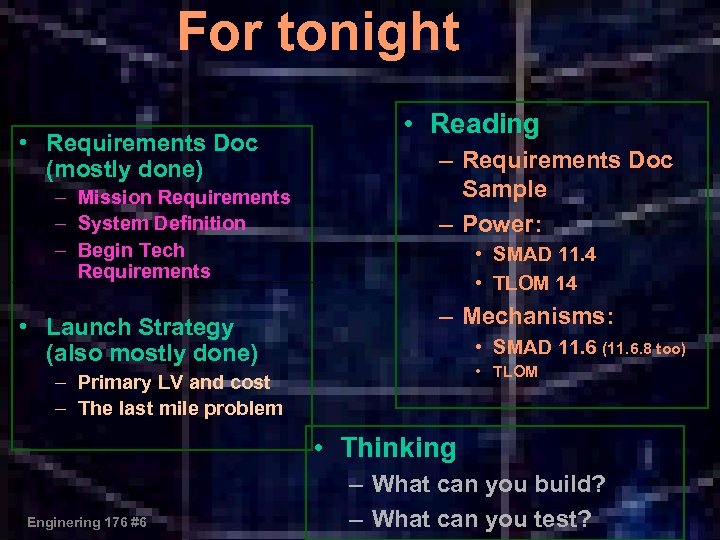

For tonight • Requirements Doc (mostly done) – Mission Requirements – System Definition – Begin Tech Requirements • Launch Strategy (also mostly done) • Reading – Requirements Doc Sample – Power: • SMAD 11. 4 • TLOM 14 – Mechanisms: • SMAD 11. 6 (11. 6. 8 too) • TLOM – Primary LV and cost – The last mile problem • Thinking Enginering 176 #6 – What can you build? – What can you test?

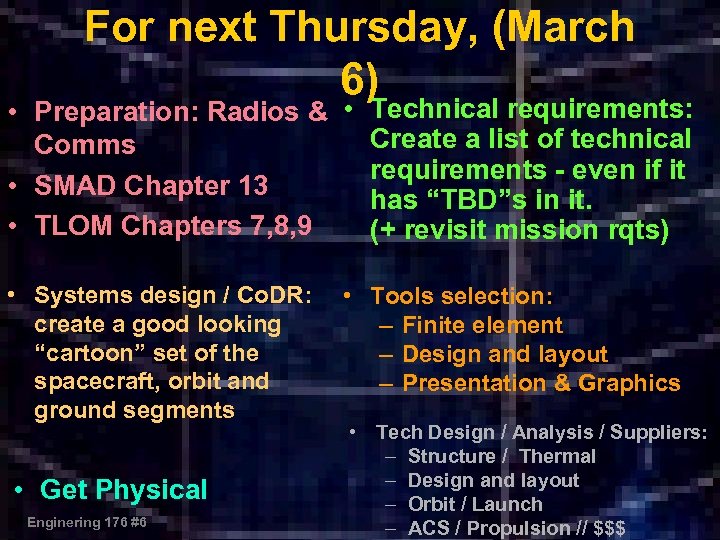

For next Thursday, (March 6) • Preparation: Radios & • Technical requirements: Create a list of technical Comms requirements - even if it • SMAD Chapter 13 has “TBD”s in it. • TLOM Chapters 7, 8, 9 (+ revisit mission rqts) • Systems design / Co. DR: create a good looking “cartoon” set of the spacecraft, orbit and ground segments • Get Physical Enginering 176 #6 • Tools selection: – Finite element – Design and layout – Presentation & Graphics • Tech Design / Analysis / Suppliers: – Structure / Thermal – Design and layout – Orbit / Launch – ACS / Propulsion // $$$

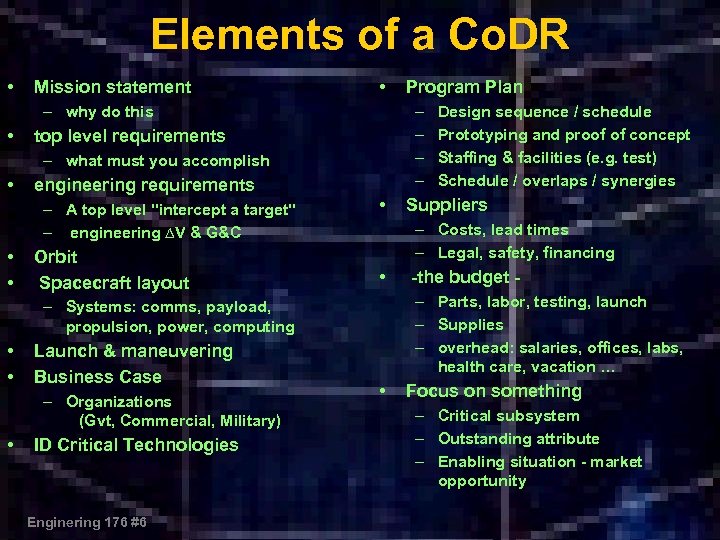

Elements of a Co. DR • Mission statement • – why do this • – – top level requirements – what must you accomplish • engineering requirements – A top level "intercept a target" – engineering ∆V & G&C • • Orbit Spacecraft layout • Launch & maneuvering Business Case – Organizations (Gvt, Commercial, Military) • ID Critical Technologies Enginering 176 #6 Design sequence / schedule Prototyping and proof of concept Staffing & facilities (e. g. test) Schedule / overlaps / synergies Suppliers – Costs, lead times – Legal, safety, financing • -the budget – Parts, labor, testing, launch – Supplies – overhead: salaries, offices, labs, health care, vacation … – Systems: comms, payload, propulsion, power, computing • • Program Plan • Focus on something – Critical subsystem – Outstanding attribute – Enabling situation - market opportunity

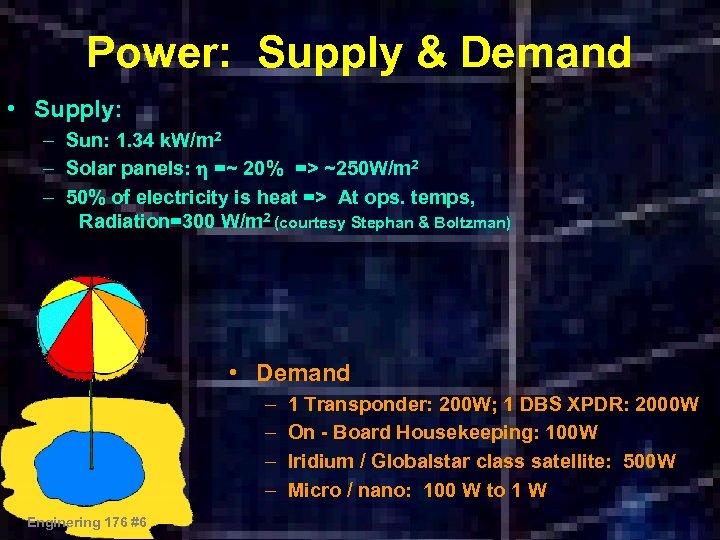

Power: Supply & Demand • Supply: – Sun: 1. 34 k. W/m 2 – Solar panels: h =~ 20% => ~250 W/m 2 – 50% of electricity is heat => At ops. temps, Radiation=300 W/m 2 (courtesy Stephan & Boltzman) • Demand – – Enginering 176 #6 1 Transponder: 200 W; 1 DBS XPDR: 2000 W On - Board Housekeeping: 100 W Iridium / Globalstar class satellite: 500 W Micro / nano: 100 W to 1 W

Design Driver: Power • Increased Demands for Power: – Higher bandwidth – Wide coverage area (10 x BW = 10 x P) (5 x area = 5 x P) • Increased supply of Power: – PV efficiency now 25% may increase to 30% – Li-Ion Battery may transition to sulfur sodium (2 x mass efficiency, or not) – Digital Charge circuits (a few % savings) – Sharper antenna patterns: – Small GS antenna (1/10 th diameter = 100 x P) Enginering 176 #6 (a few % savings in power) – New array deployment (potential 2 x to 100 x)

Small v. Big approaches to Power • Small – Commercial Ni. Cads (but relatively larger fraction of total mass) – Fixed, Body mounted cells (small V÷A => volume, not W, limit) => passive thermal • Big – Mil Spec Batteries – Large Deployable, articulated solar arrays – Large Volume / Area: => Heat matters => heaters / heat pipes / radiators Enginering 176 #6

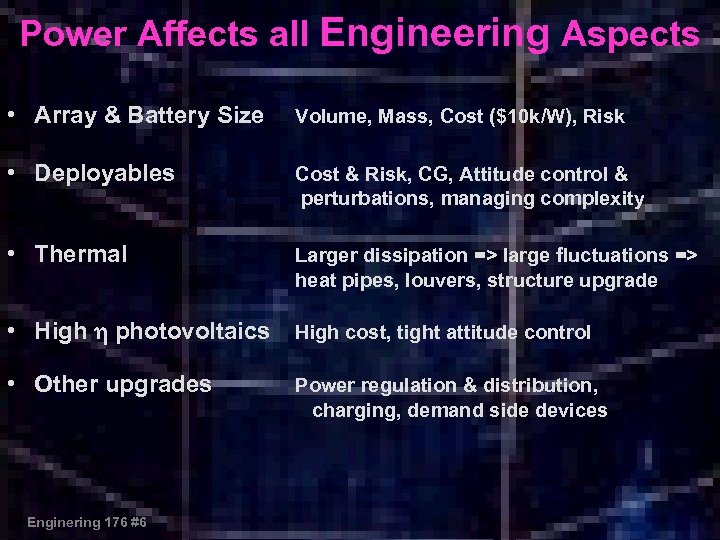

Power Affects all Engineering Aspects • Array & Battery Size Volume, Mass, Cost ($10 k/W), Risk • Deployables Cost & Risk, CG, Attitude control & perturbations, managing complexity • Thermal Larger dissipation => large fluctuations => heat pipes, louvers, structure upgrade • High h photovoltaics High cost, tight attitude control • Other upgrades Power regulation & distribution, charging, demand side devices Enginering 176 #6

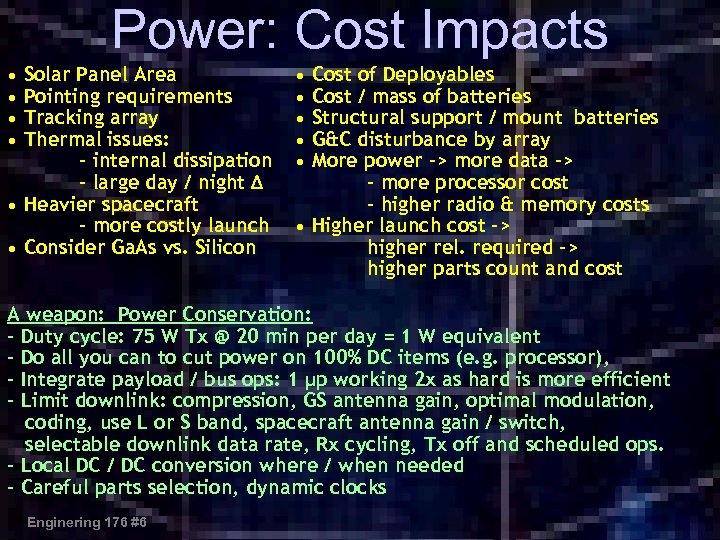

Power: Cost Impacts • Solar Panel Area • Pointing requirements • Tracking array • Thermal issues: - internal dissipation - large day / night ∆ • Heavier spacecraft - more costly launch • Consider Ga. As vs. Silicon • Cost of Deployables • Cost / mass of batteries • Structural support / mount batteries • G&C disturbance by array • More power -> more data -> - more processor cost - higher radio & memory costs • Higher launch cost -> higher rel. required -> higher parts count and cost A weapon: Power Conservation: - Duty cycle: 75 W Tx @ 20 min per day = 1 W equivalent - Do all you can to cut power on 100% DC items (e. g. processor), - Integrate payload / bus ops: 1 µp working 2 x as hard is more efficient - Limit downlink: compression, GS antenna gain, optimal modulation, coding, use L or S band, spacecraft antenna gain / switch, selectable downlink data rate, Rx cycling, Tx off and scheduled ops. - Local DC / DC conversion where / when needed - Careful parts selection, dynamic clocks Enginering 176 #6

Rechargeable Battery Options Enginering 176 #6

Battery Charging Enginering 176 #6

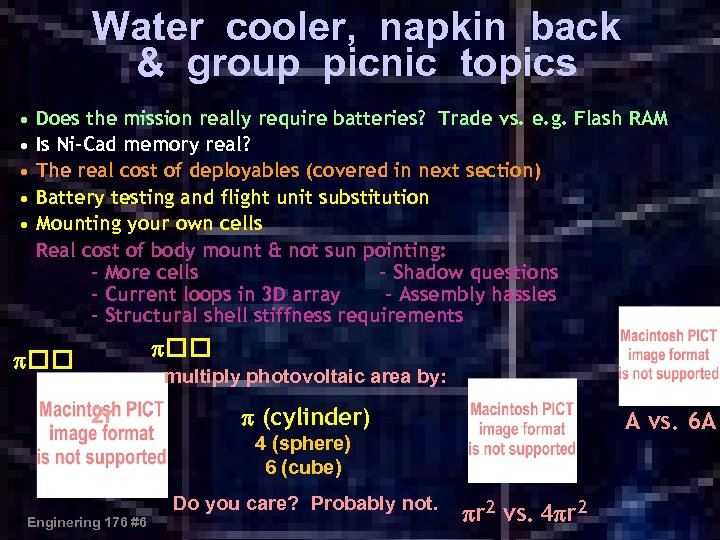

Water cooler, napkin back & group picnic topics • Does the mission really require batteries? Trade vs. e. g. Flash RAM • Is Ni-Cad memory real? • The real cost of deployables (covered in next section) • Battery testing and flight unit substitution • Mounting your own cells • Real cost of body mount & not sun pointing: - More cells - Shadow questions - Current loops in 3 D array - Assembly hassles - Structural shell stiffness requirements multiply photovoltaic area by: 2 r (cylinder) A vs. 6 A 4 (sphere) 6 (cube) Do you care? Probably not. Enginering 176 #6 r 2 vs. 4 r 2

Design for Solar Power Example: Equatorial Earth Oriented Enginering 176 #6

Power Budget and Power System Design Enginering 176 #6

Potential Paradigm Breakers • Advanced deployables – Inflatables – Flexible photovoltaics • • Power beaming Cooperative swarms Steerable Phased Arrays Data Compression Enginering 176 #6 L’Garde Inflatable

Astrid Spacecraft Mass total: 27 kg Mass platform: 22. 6 kg Hx. Wx. D: 290 x 450 Max Power 21. 7 W Battery: 22 Gates Ni-Cd µprocessor: 80 C 31 ACS: spin stabilized sun pointing magnetic ctrl. Thermal: Passive Control Downlink: S-band, 131 kb/s Uplink: UHF, 4. 8 kb/s Mission $: $1. 4 M inc. launch Dvt. time: 1 year Enginering 176 #6 Astrid (Swedish Space Corp)

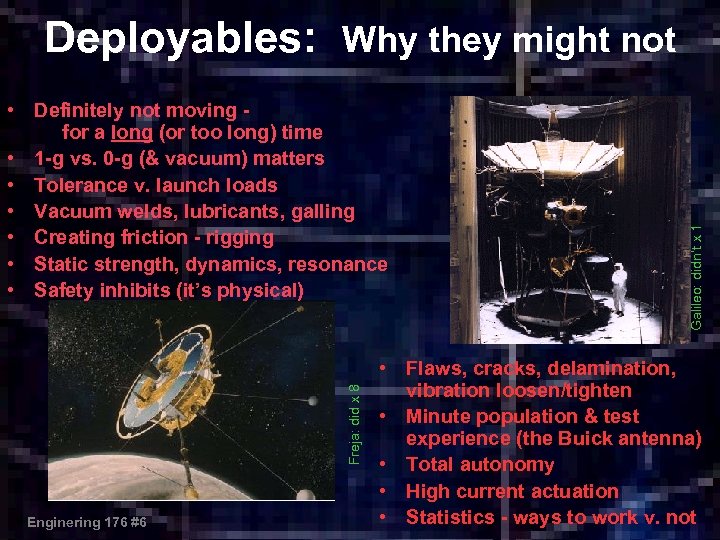

Freja: did x 8 • Definitely not moving for a long (or too long) time • 1 -g vs. 0 -g (& vacuum) matters • Tolerance v. launch loads • Vacuum welds, lubricants, galling • Creating friction - rigging • Static strength, dynamics, resonance • Safety inhibits (it’s physical) Enginering 176 #6 Galileo: didn’t x 1 Deployables: Why they might not • Flaws, cracks, delamination, vibration loosen/tighten • Minute population & test experience (the Buick antenna) • Total autonomy • High current actuation • Statistics - ways to work v. not

Common Deployables • Satellites (via Marmon rings) – Bristol Aerospace, Canada • Antennas & Radar Reflectors • Booms: gravity gradient & instrument – Spar, Canada – stacer, astromast • Solar Arrays (fixed & tracking) – Applied Solar Energy Corp. (ASEC), City of Industry, CA; – Programmed Composites, Brea, CA; – Composite Optics, Los Angles, CA) • Doors (instrument covers) • Mirrors & other optics • Rocket stages Marmon Ring Enginering 176 #6

Common Actuators • Pyrotechnic bolts and bolt cutters • Melting Wires (Israeli Aircraft Industries, Lod, Israel) • Hot Wax (not melting wax) – Starsys Research, Boulder, CO) Starsys also manufactures hinges for deploybles • Memory Metal – GSH, Santa Monica, CA • Motors and Stepper Motors • Carpenter tape – hardware stores • Sublimation (dural and others) – Du. Pont, 3 M Enginering 176 #6

Buick’s deployable antenna goes to space (the board game you can play at home) Enginering 176 #6

Two Simple Questions before designing that terrestrial component into your next spacecraft • 1) Will it really be the same part? – If you change materials, lubricants, loading, mechanical support, housing, coating, wiring, microswitches. . . It isn’t the same part. – Almost any terrestrial part will require design mods for its controller, non-standard power supply, cooling, emi protection, surge reduction, structural upgrades… • 2) How much will it cost to get around the game board? – – – – Specs and shopping: Reengineer with new materials: Lubrication, heat sinking, thermal model: DC/DC converters, surge & EMI suppression: New housing, brackets & structural analysis: Rebuild n units for test, spares, inspection & learning: Test program including 100, 000 vacuum ops, + 10 inspections and rebuilds • Total - assuming nothing goes wrong (not always a good assumption) Enginering 176 #6 $10 k $50 k $75 k $50 k $40 k $50 k $325 k

Death, Taxes and. . . Enginering 176 #6

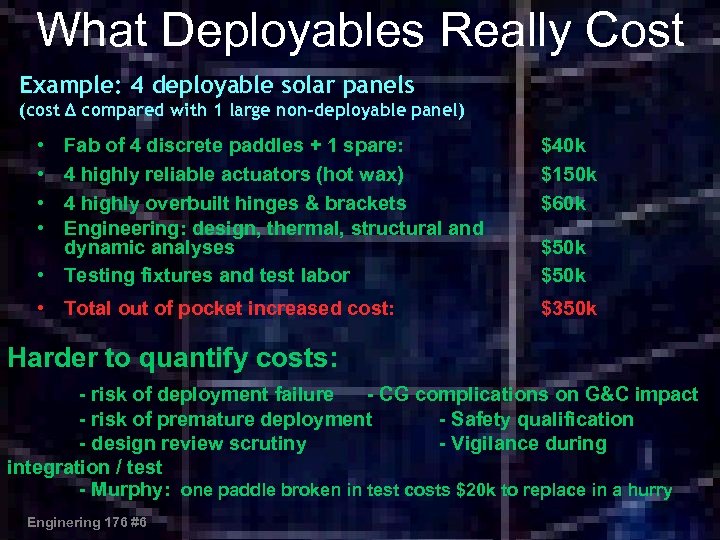

What Deployables Really Cost Example: 4 deployable solar panels (cost ∆ compared with 1 large non-deployable panel) • • Fab of 4 discrete paddles + 1 spare: 4 highly reliable actuators (hot wax) 4 highly overbuilt hinges & brackets Engineering: design, thermal, structural and dynamic analyses • Testing fixtures and test labor $40 k $150 k $60 k • Total out of pocket increased cost: $350 k $50 k Harder to quantify costs: - risk of deployment failure - CG complications on G&C impact - risk of premature deployment - Safety qualification - design review scrutiny - Vigilance during integration / test - Murphy: one paddle broken in test costs $20 k to replace in a hurry Enginering 176 #6

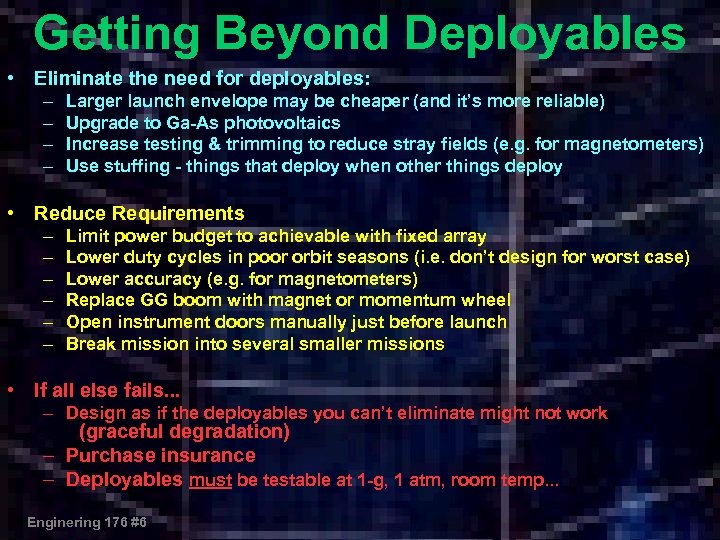

Getting Beyond Deployables • Eliminate the need for deployables: – – Larger launch envelope may be cheaper (and it’s more reliable) Upgrade to Ga-As photovoltaics Increase testing & trimming to reduce stray fields (e. g. for magnetometers) Use stuffing - things that deploy when other things deploy • Reduce Requirements – – – Limit power budget to achievable with fixed array Lower duty cycles in poor orbit seasons (i. e. don’t design for worst case) Lower accuracy (e. g. for magnetometers) Replace GG boom with magnet or momentum wheel Open instrument doors manually just before launch Break mission into several smaller missions • If all else fails. . . – Design as if the deployables you can’t eliminate might not work (graceful degradation) – Purchase insurance – Deployables must be testable at 1 -g, 1 atm, room temp. . . Enginering 176 #6

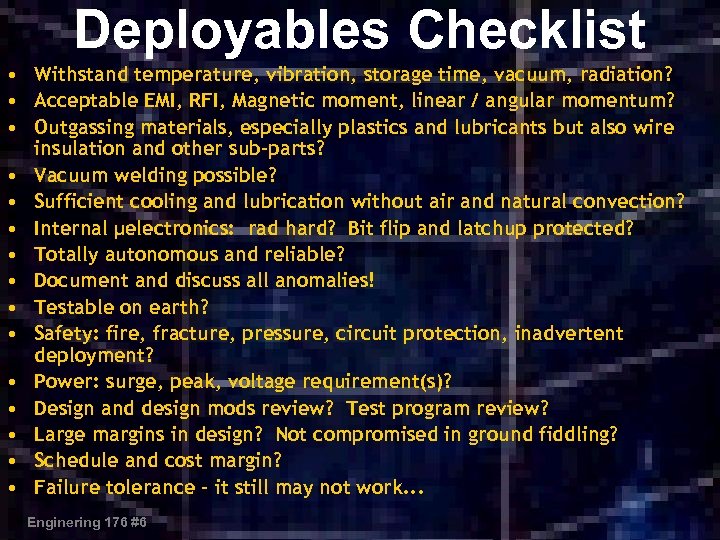

Deployables Checklist • Withstand temperature, vibration, storage time, vacuum, radiation? • Acceptable EMI, RFI, Magnetic moment, linear / angular momentum? • Outgassing materials, especially plastics and lubricants but also wire insulation and other sub-parts? • Vacuum welding possible? • Sufficient cooling and lubrication without air and natural convection? • Internal µelectronics: rad hard? Bit flip and latchup protected? • Totally autonomous and reliable? • Document and discuss all anomalies! • Testable on earth? • Safety: fire, fracture, pressure, circuit protection, inadvertent deployment? • Power: surge, peak, voltage requirement(s)? • Design and design mods review? Test program review? • Large margins in design? Not compromised in ground fiddling? • Schedule and cost margin? • Failure tolerance - it still may not work. . . Enginering 176 #6

Deployables Spec • Performance Applied torque or force, speed, accuracy, preload, angular momentum (eg mirror) • Weight / Power Allocations from system design spec • Envelope & interfaces Mech. & electrical interface, dimensions bolt patterns, interface regions. . . • Environments Number of cycles, duration exposure to environments -> parts, materials, lubes… • Lifetime (op/non) # operating cycles, duration exposure • Structure Strength, fatigue life, stiffness • Reliability Allocation from system rel. spec - may drive specific approach & redundancy Enginering 176 #6

Freja • Magnetospheric research • Launched October, 1992 • 214 kg, 2. 2 m diameter • Development cost: $23 M Freja Facts: • 8 science instruments; • deployed 6 wire booms (L=1 to 15 meters) • deployed 1 m and 2 m fixed boom • spacecraft separation: 4 pyro bolts plus standard marmon ring; • Orbit insertion: 2 Thiokol Star engines • Start: 8/87; shipped to Gobi Desert 8/92 • High “Q” passive thermal design; • Everything worked! (and still is working). Enginering 176 #6 Freja (Swedish Space Corp)

Galileo Launched Oct. ‘ 89 • Mass: 2. 5 Mg • NASA JPL • Galileo HGA Info: • Development cost about $1. 5 B • HGA loss dropped data rate by 104 • Failure caused by loss of lubricant, probably during several cross-country truck shipments (note similarity to Pegasus failure during HETE / SAC-B launch • Deployable failure caused by poor lubrication - or by misjudgement of environment? Enginering 176 #6

Enginering 176 #6

• Terrestrial Stuff that works in Space Electronic Components: – ICs, transistors, resistors, capaciters (beware of electrolytic), relays • Electronic devices – Vivitar photo strobe, timers, DC/DC Converters, many sensors • Ni-Cad batteries – with selection and test. Li-ion are also being flown • Carpenter Tape – has never failed • Laptop computers, calculators – in Shuttle environment • Stacer Booms – but rebuilt with new materials - imperfect performance on orbit • Hard disc – in enclosure - but why bother? • People, monkeys, dogs, algae, bees. . . Enginering 176 #6