8f937e4c39a553ab67747b96875a7f2e.ppt

- Количество слайдов: 33

Blanco Clean Room – CDR This is the final release: 13 Jun 09 Review: 15 June 2009 Brooke Gregory 1

Requirements • Clean – Class 10, 000 – 100? • Enough room: – NEWFIRM – 15’ x 20’ (down from 20’ x 20’ orig. ) – DECam – 12’ x 20’ Tom Diehl’s PPT • ESD – Materials - static dissipative – Humidity >~40% 2

Main Features • • Area – 14. 5 x 20. 5 ft plus gowning area Wall panels – static dissipative PVC Floor – Antistatic vinyl tile 50% FFU ceiling coverage Use Coudé as plenum Positive pressure in Coudé Air-locked pass-through Controlled humidity - >35% 3

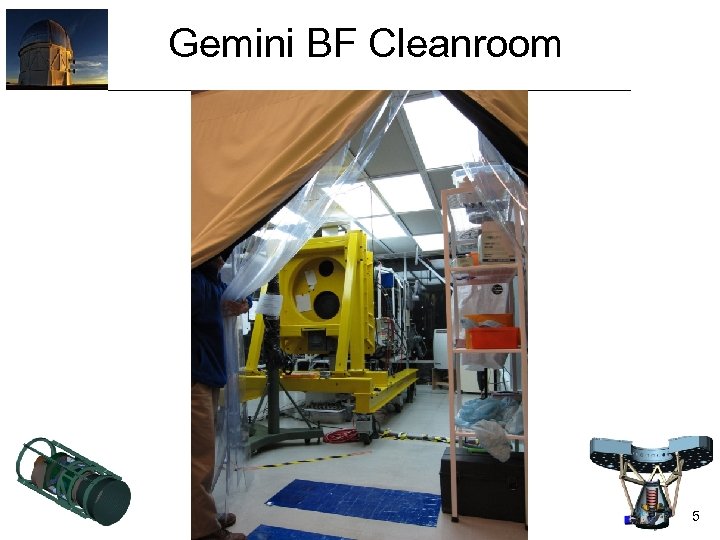

An example • • • Gemini’s Base Facility Cleanroom Same area as what we are proposing 7 FFUs No gowning area Uses main room as plenum Performance ? 4

Gemini BF Cleanroom 5

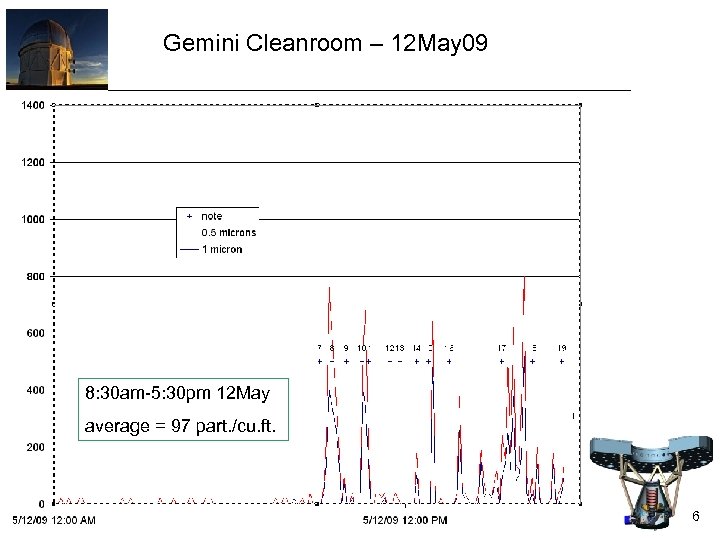

Gemini Cleanroom – 12 May 09 8: 30 am-5: 30 pm 12 May average = 97 part. /cu. ft. 6

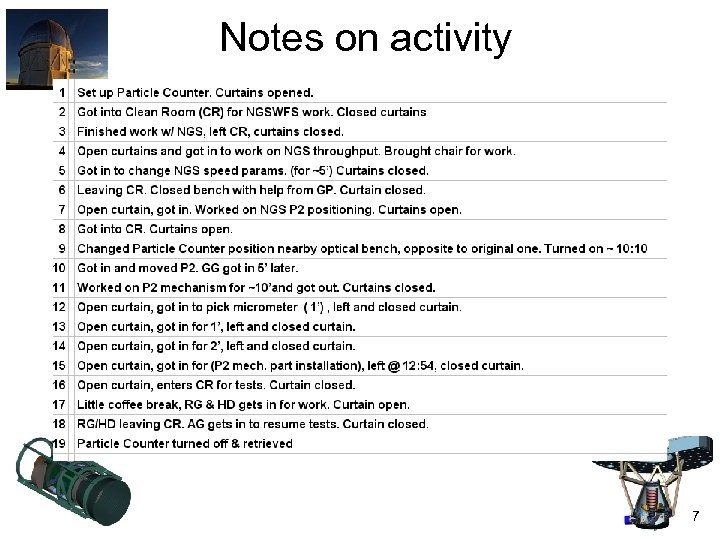

Notes on activity 7

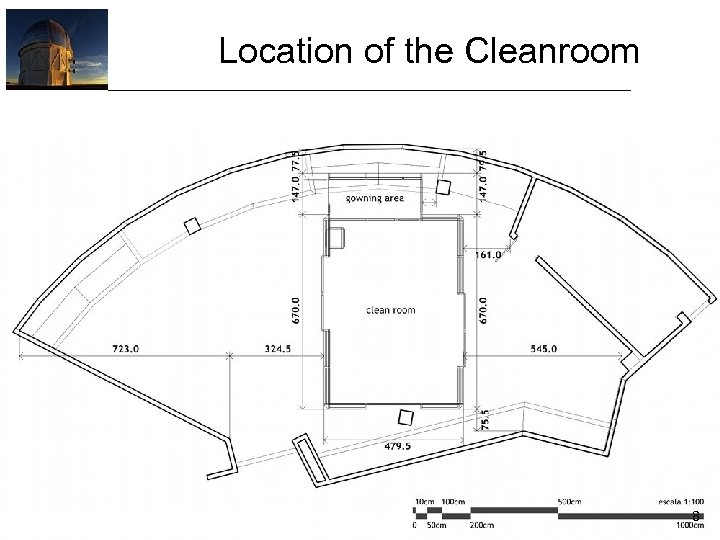

Location of the Cleanroom 8

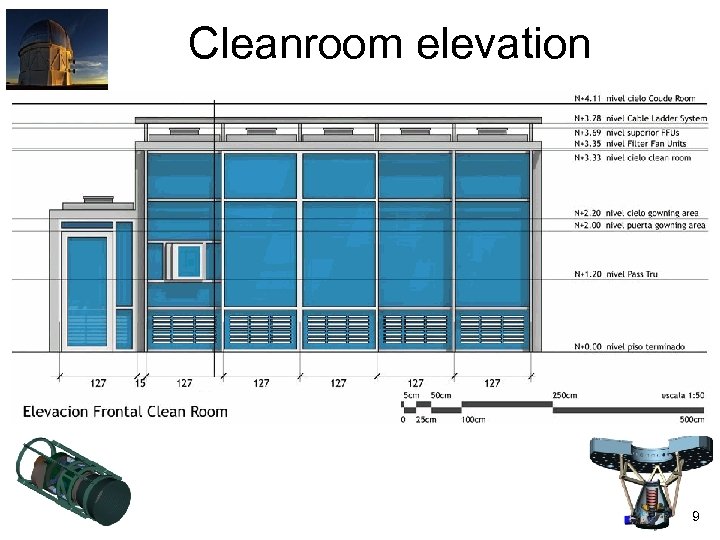

Cleanroom elevation 9

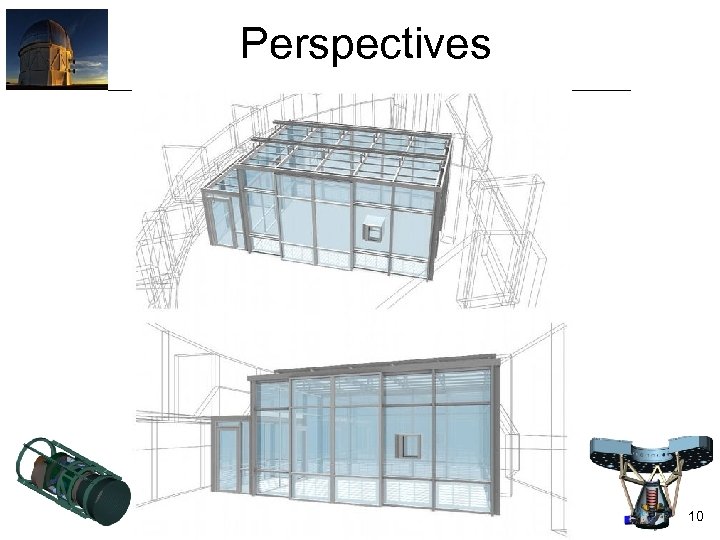

Perspectives 10

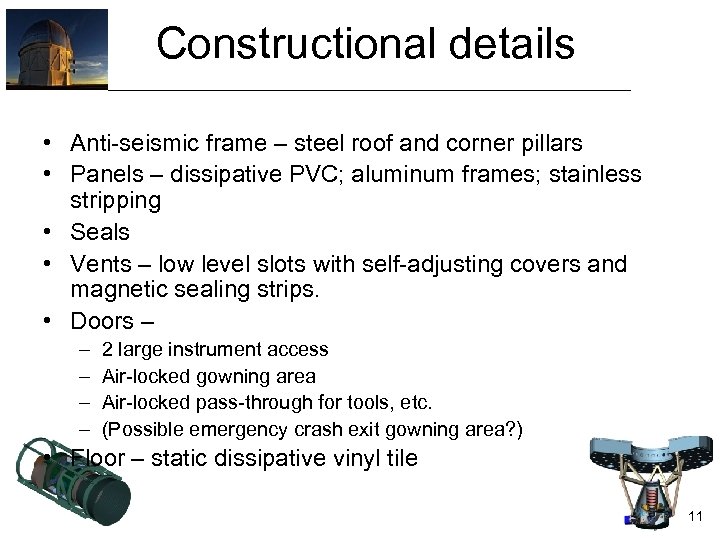

Constructional details • Anti-seismic frame – steel roof and corner pillars • Panels – dissipative PVC; aluminum frames; stainless stripping • Seals • Vents – low level slots with self-adjusting covers and magnetic sealing strips. • Doors – – – 2 large instrument access Air-locked gowning area Air-locked pass-through for tools, etc. (Possible emergency crash exit gowning area? ) • Floor – static dissipative vinyl tile 11

Construction - movie 12

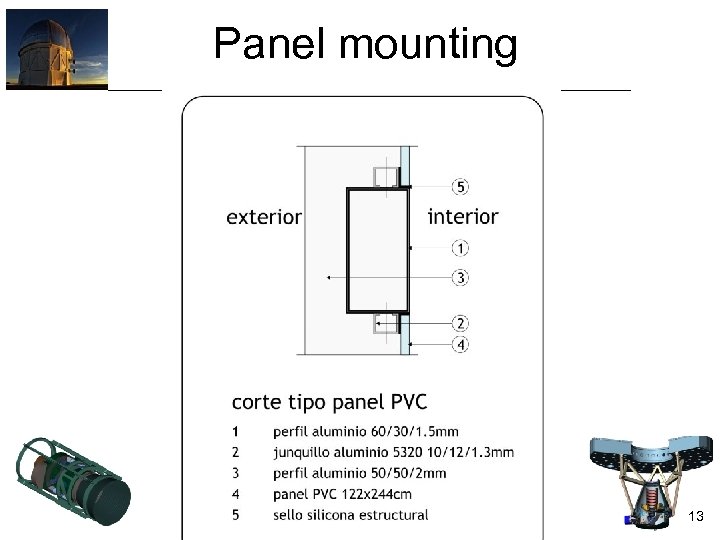

Panel mounting 13

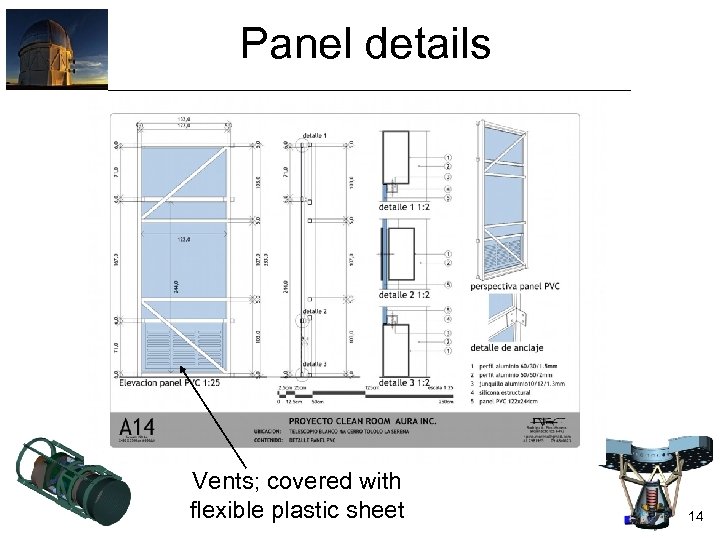

Panel details Vents; covered with flexible plastic sheet 14

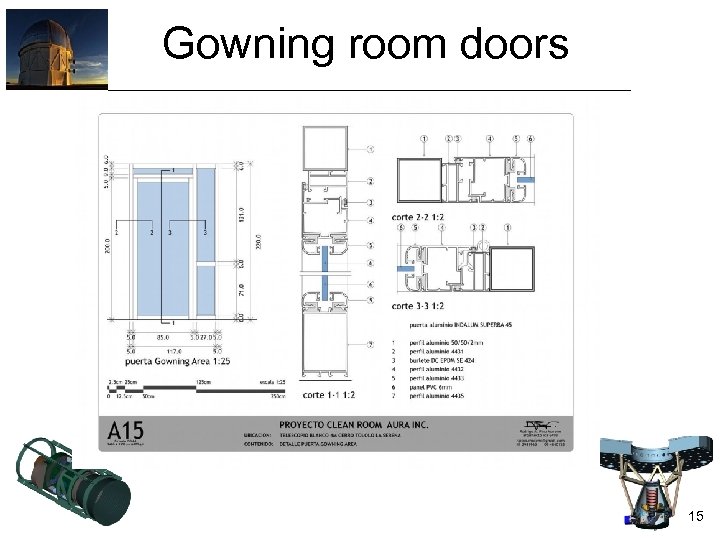

Gowning room doors 15

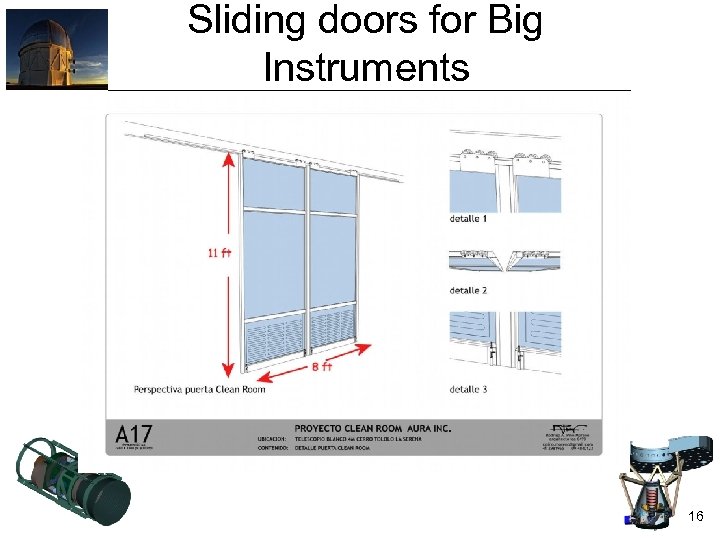

Sliding doors for Big Instruments 16

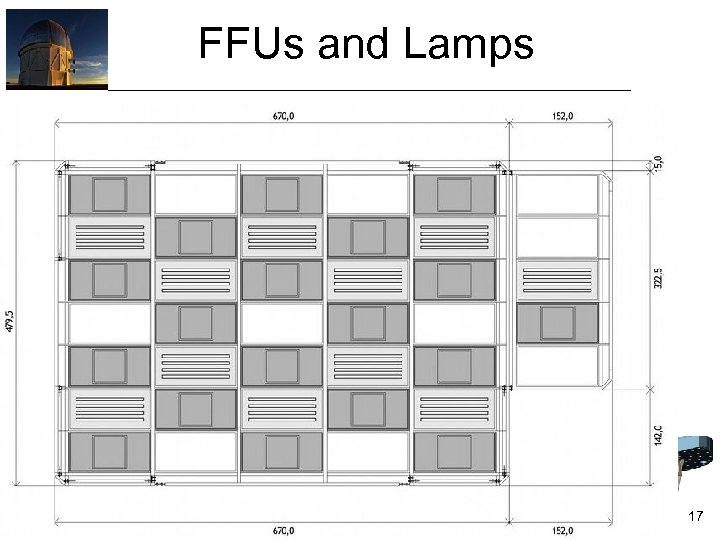

FFUs and Lamps 17

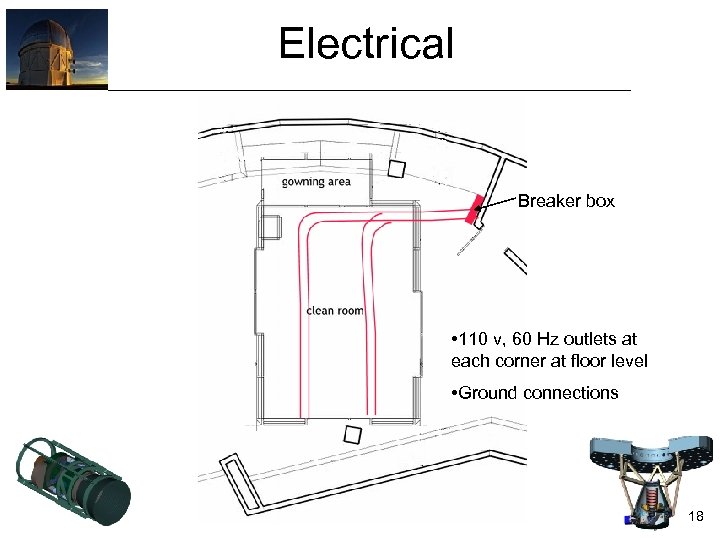

Electrical Breaker box • 110 v, 60 Hz outlets at each corner at floor level • Ground connections 18

Cleanroom in Coudé Intentionally left blank. (It is always good that one’s intentions be less than 100% clear. ) 19

Preparations to Coudé • Remove all spectrograph pillars (done) • Prepare floor: floor will be ground to eliminate relief between main concrete segments (small area). Then grouted. • Prepare ceiling (remove interfering lamps; tape holes) 20

Flooring Requirements: – ESD safe – Clean(able) – Load-resistant Solution chosen: – – – Staticworx: 3 mm, solid vinyl tile over grouted concrete ESD characteristic: ANSI ESDS 20. 20 standard Load – 2500 lbs/sq. in. Steel Transition ramp Installed by AOSS in cleanroom structure 21

Fabrication and Assembly • Welded steel modules pre-fabbed by contractor: pillars and roof modules • Modules brought to Coudé • Panel vents pre-cut • Cable trays incorporated in roof sections – Cabling of roof sections done in Coudé on floor • Pillars cemented to floor, joined to roof sections (bolted joints); • Roof installed on pillars and beams between them • FFUs, lamps, installed on roof and connected to cables • Panels, fixed and on doors, installed 22

ESD Management • Room construction – Panels – static dissipative PVC – Floor – static dissipative vinyl tile, connected to ground • Humidity – automatic control; implementation in Coudé modifications • Station tooling (TBD) ionizers, table mats, grounding lines, monitors 23

Seismic Performance The roof of the clean room weighs about 1 ton. The structure needs to be stronger than the typical all-aluminum room. We did not have the engineering resource to investigate the solutions in-house. The solution was to contract out the analysis of the requirements and the architectural solution to Rodrigo Pino and Co. 24

Seismic analysis • Performed by Ingenieria CRAM Ltda. , Concepcion; report received. • Proposed structure and then analyzed the structure, based on very conservative assumptions. • Acceleration assumed: 0. 4 g • Maximum stress on each member of the structure computed and shown to be below safe limits. 25

Operations Model • Cleanroom normally off: vents will be sealed, doors locked, humidifier and all but one ventilator will be off. • Coudé will be at positive pressure (this is new). A fan/filter inlet to the Coudé will be constantly acting. (Requires periodic filter maintenance). • Procedure for cleanroom use, depending on nature of use: – – – Un-lock necessary doors Un-block vents Turn on FFUs and lamps and dust monitors Possible wipe down of cleanroom Turn on humidifier and space heaters (if required) Wait until dust-counter reading has settled to a steady state and, depending on application, humidity has reached appropriate level 26

Tools and furniture • A 3 ton gantry crane will be ordered; 1. 5 ton hoist • More tools are not proposed in this presentation. • Rehearsal at Fermilab will lead to good input on tools. • We propose to solicit suggestions from both teams. • Our philosophy is to minimize the use of the clean room. We will also be providing lab space in the Coudé room or in Las Tacas. 27

Approximate Milestones • • • 15 June - Review 16 June - Issue requisitions 17 June - Start floor preparations 17 June - Start clearing Coudé 1 July - Steel arrives, Benjamin starts fabrication 8 July - Move wall of Coudé 16 July - All materials arrive 17 August - Coudé ready for Cleanroom installation 17 August - Assembly begins 17 September - Cleanroom complete 28

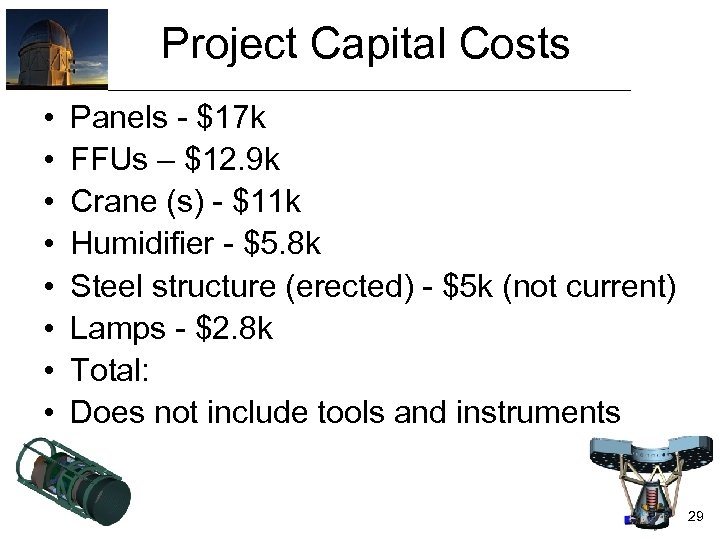

Project Capital Costs • • Panels - $17 k FFUs – $12. 9 k Crane (s) - $11 k Humidifier - $5. 8 k Steel structure (erected) - $5 k (not current) Lamps - $2. 8 k Total: Does not include tools and instruments 29

END • Some extra slides follow. 30

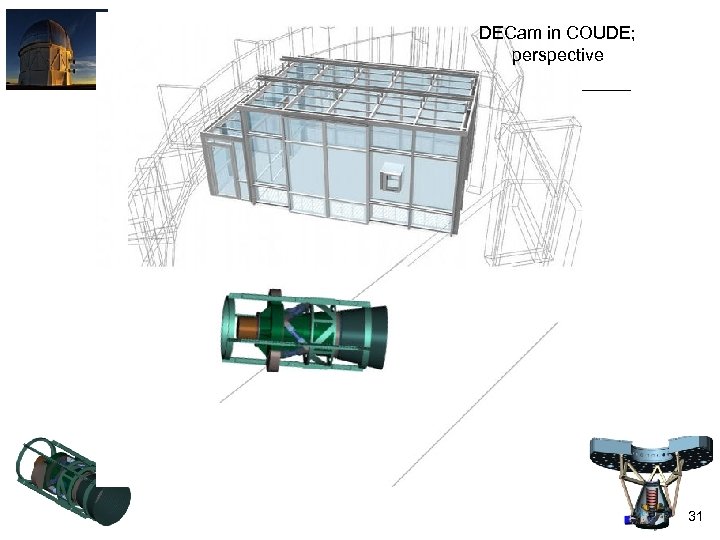

DECam in COUDE; perspective 31

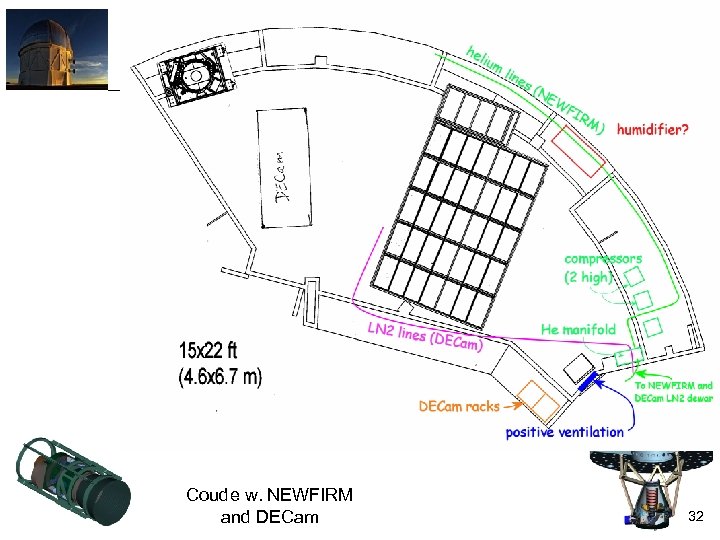

Coude w. NEWFIRM and DECam 32

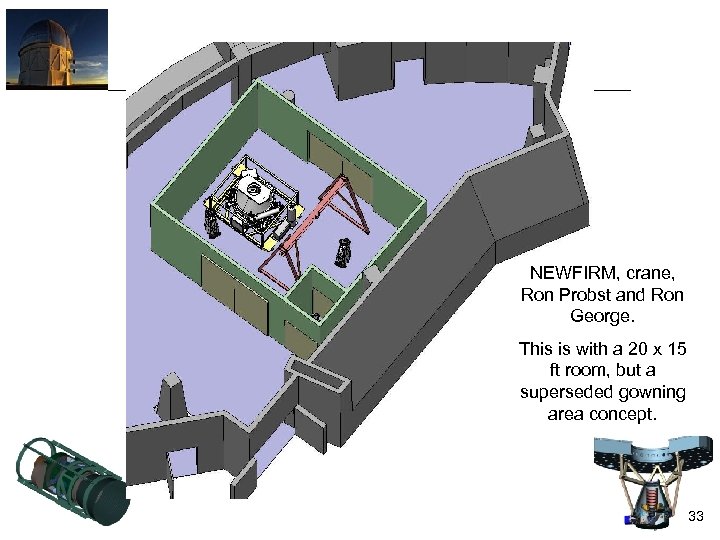

NEWFIRM, crane, Ron Probst and Ron George. This is with a 20 x 15 ft room, but a superseded gowning area concept. 33

8f937e4c39a553ab67747b96875a7f2e.ppt