RDBVMAH Biotech forages.pptx

- Количество слайдов: 56

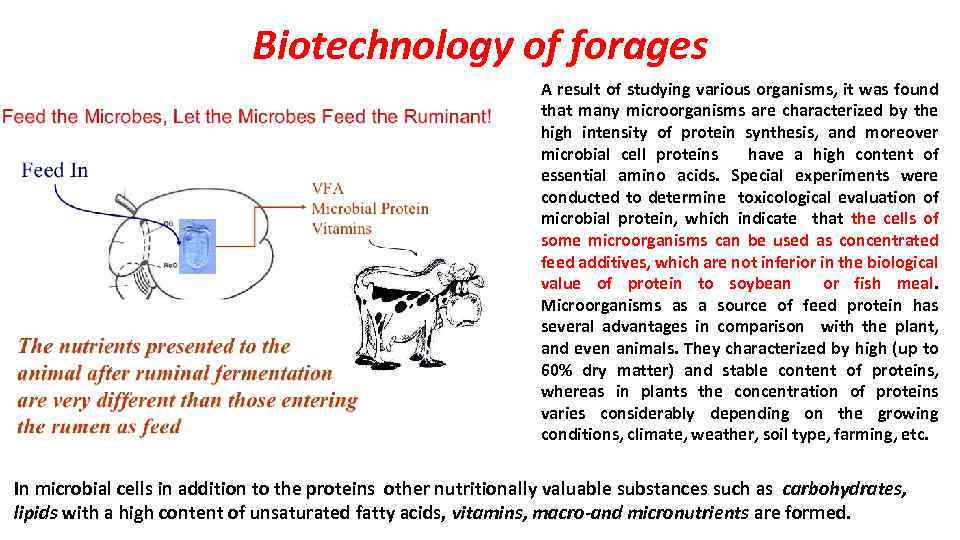

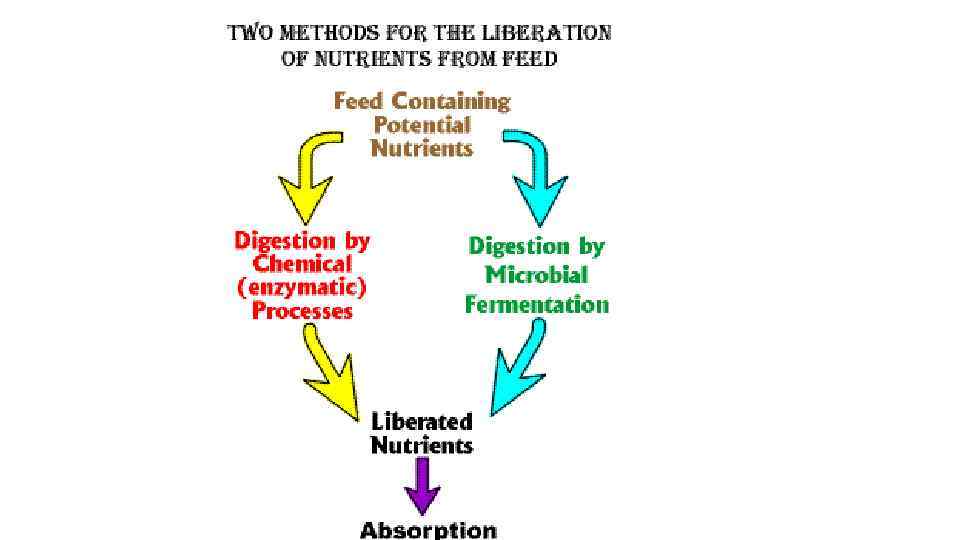

Biotechnology of forages A result of studying various organisms, it was found that many microorganisms are characterized by the high intensity of protein synthesis, and moreover microbial cell proteins have a high content of essential amino acids. Special experiments were conducted to determine toxicological evaluation of microbial protein, which indicate that the cells of some microorganisms can be used as concentrated feed additives, which are not inferior in the biological value of protein to soybean or fish meal. Microorganisms as a source of feed protein has several advantages in comparison with the plant, and even animals. They characterized by high (up to 60% dry matter) and stable content of proteins, whereas in plants the concentration of proteins varies considerably depending on the growing conditions, climate, weather, soil type, farming, etc. In microbial cells in addition to the proteins other nutritionally valuable substances such as carbohydrates, lipids with a high content of unsaturated fatty acids, vitamins, macro-and micronutrients are formed.

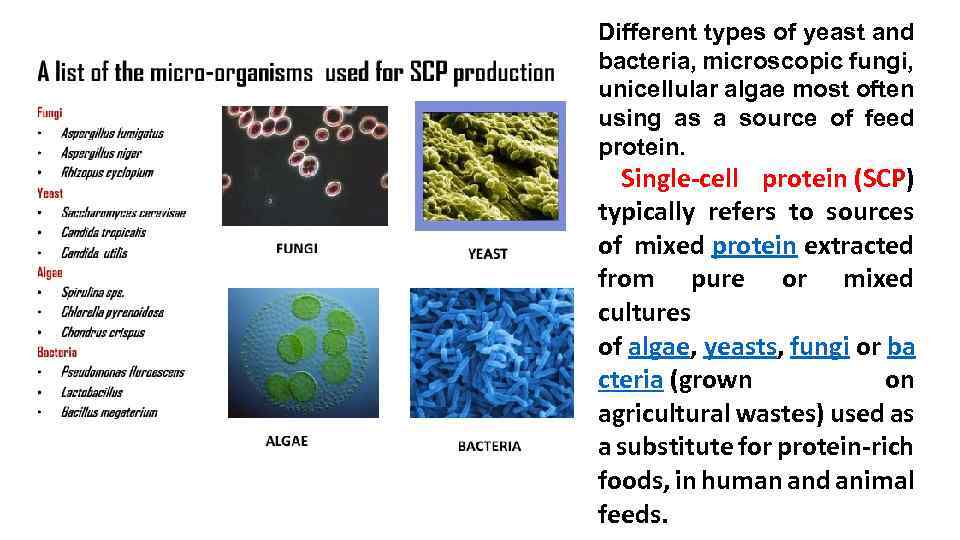

Different types of yeast and bacteria, microscopic fungi, unicellular algae most often using as a source of feed protein. Single-cell protein (SCP) typically refers to sources of mixed protein extracted from pure or mixed cultures of algae, yeasts, fungi or ba cteria (grown on agricultural wastes) used as a substitute for protein-rich foods, in human and animal feeds.

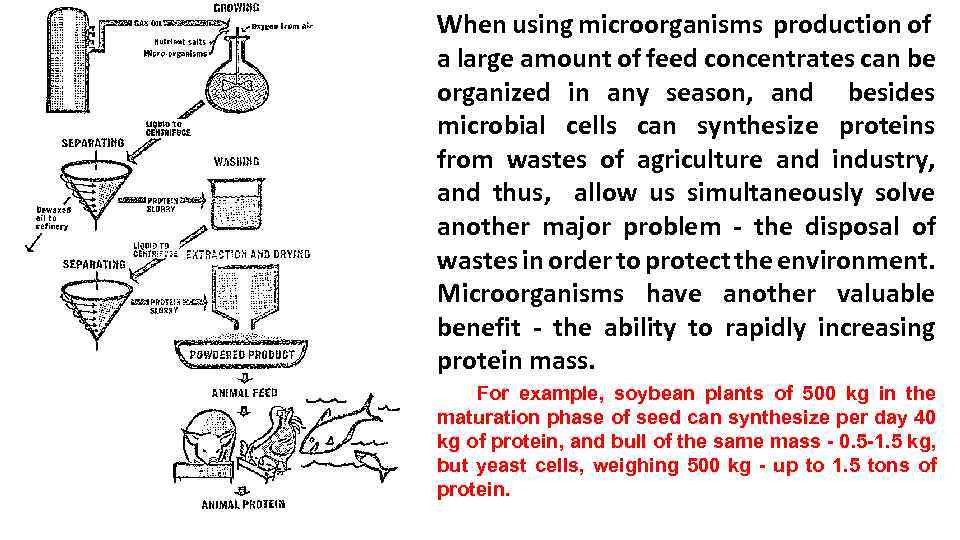

When using microorganisms production of a large amount of feed concentrates can be organized in any season, and besides microbial cells can synthesize proteins from wastes of agriculture and industry, and thus, allow us simultaneously solve another major problem - the disposal of wastes in order to protect the environment. Microorganisms have another valuable benefit - the ability to rapidly increasing protein mass. For example, soybean plants of 500 kg in the maturation phase of seed can synthesize per day 40 kg of protein, and bull of the same mass - 0. 5 -1. 5 kg, but yeast cells, weighing 500 kg - up to 1. 5 tons of protein.

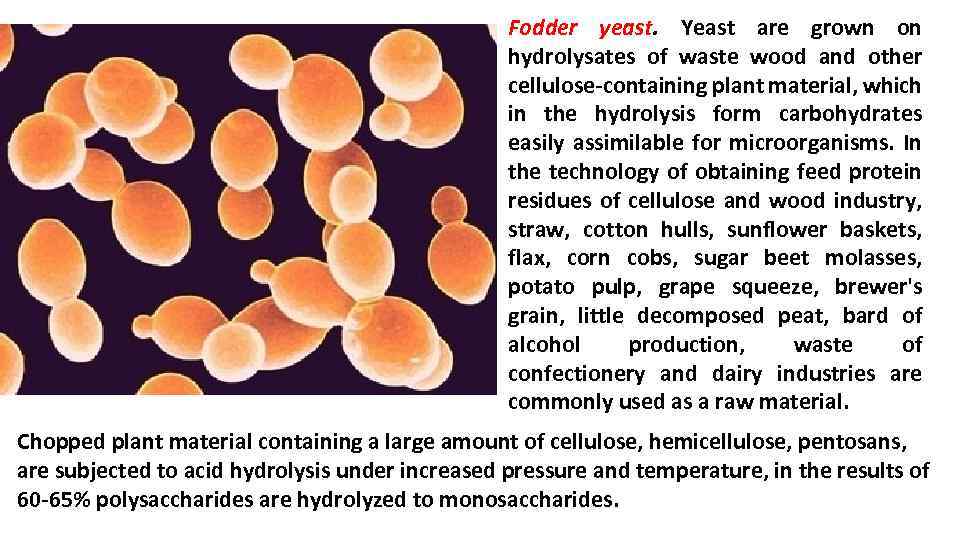

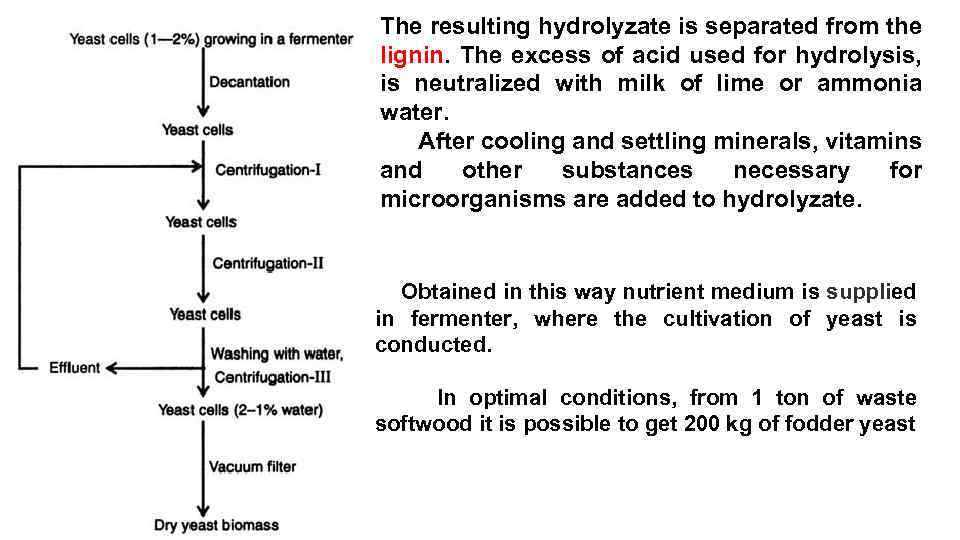

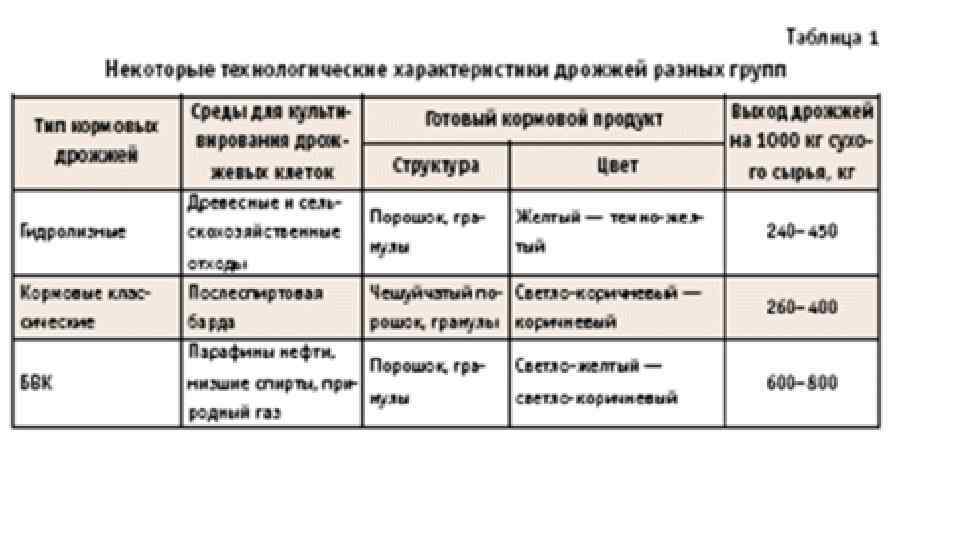

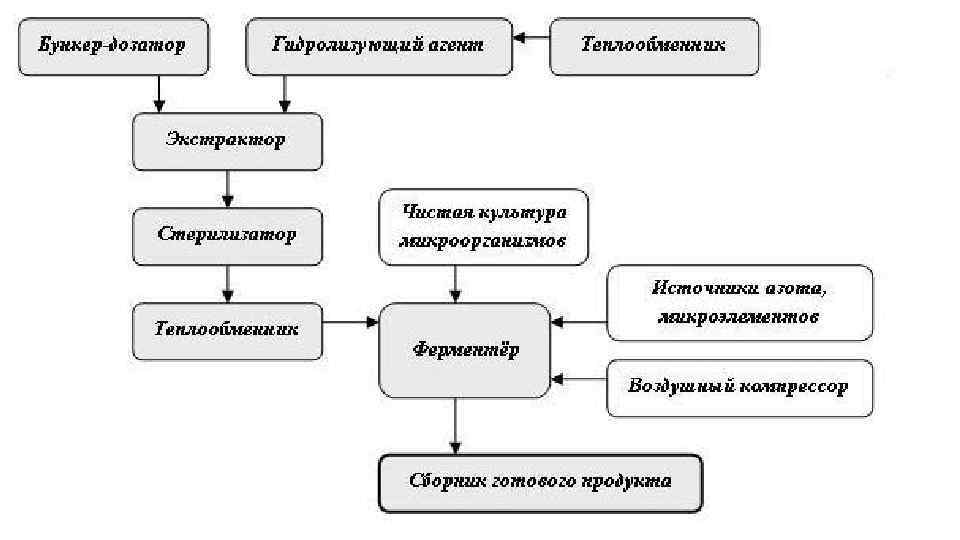

Fodder yeast. Yeast are grown on hydrolysates of waste wood and other cellulose-containing plant material, which in the hydrolysis form carbohydrates easily assimilable for microorganisms. In the technology of obtaining feed protein residues of cellulose and wood industry, straw, cotton hulls, sunflower baskets, flax, corn cobs, sugar beet molasses, potato pulp, grape squeeze, brewer's grain, little decomposed peat, bard of alcohol production, waste of confectionery and dairy industries are commonly used as a raw material. Chopped plant material containing a large amount of cellulose, hemicellulose, pentosans, are subjected to acid hydrolysis under increased pressure and temperature, in the results of 60 -65% polysaccharides are hydrolyzed to monosaccharides.

The resulting hydrolyzate is separated from the lignin. The excess of acid used for hydrolysis, is neutralized with milk of lime or ammonia water. After cooling and settling minerals, vitamins and other substances necessary for microorganisms are added to hydrolyzate. Obtained in this way nutrient medium is supplied in fermenter, where the cultivation of yeast is conducted. In optimal conditions, from 1 ton of waste softwood it is possible to get 200 kg of fodder yeast

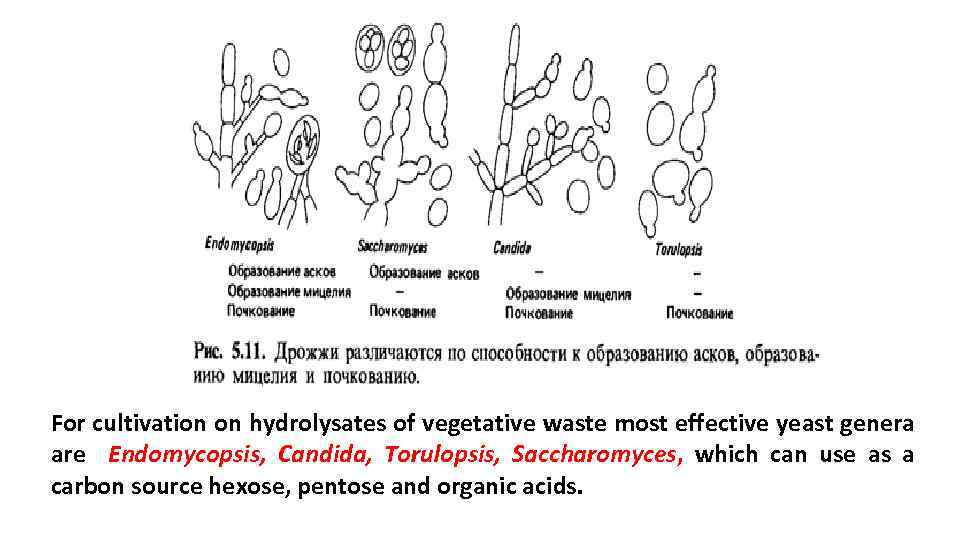

For cultivation on hydrolysates of vegetative waste most effective yeast genera are Endomycopsis, Candida, Torulopsis, Saccharomyces, which can use as a carbon source hexose, pentose and organic acids.

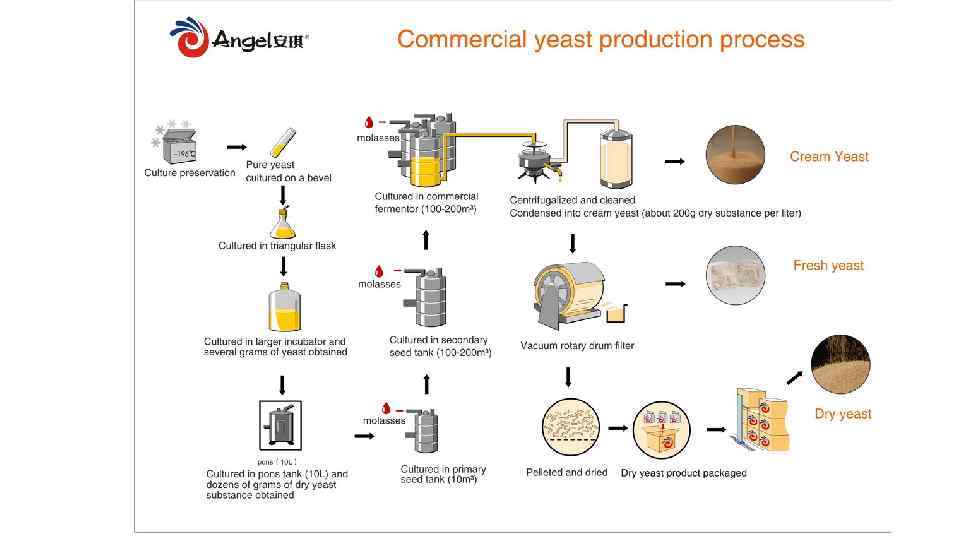

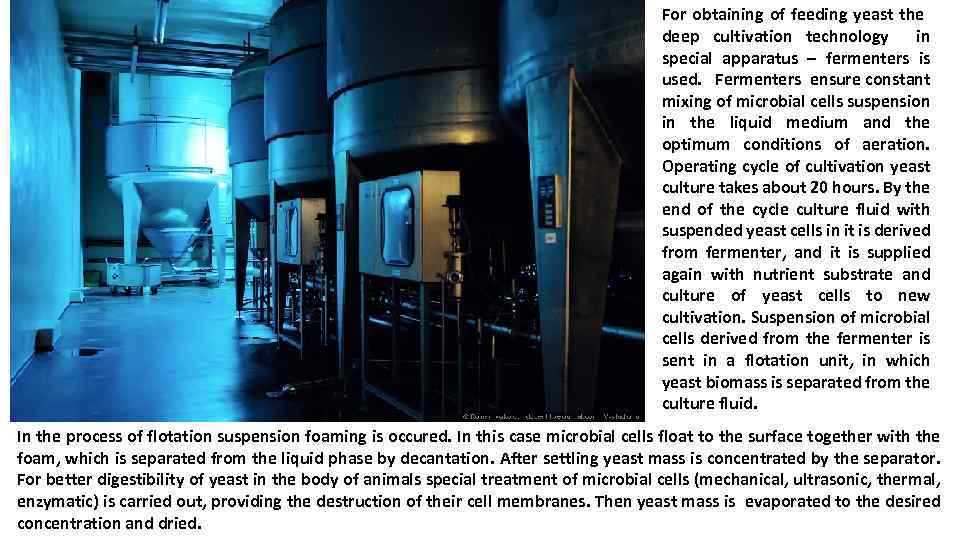

For obtaining of feeding yeast the deep cultivation technology in special apparatus – fermenters is used. Fermenters ensure constant mixing of microbial cells suspension in the liquid medium and the optimum conditions of aeration. Operating cycle of cultivation yeast culture takes about 20 hours. By the end of the cycle culture fluid with suspended yeast cells in it is derived from fermenter, and it is supplied again with nutrient substrate and culture of yeast cells to new cultivation. Suspension of microbial cells derived from the fermenter is sent in a flotation unit, in which yeast biomass is separated from the culture fluid. In the process of flotation suspension foaming is occured. In this case microbial cells float to the surface together with the foam, which is separated from the liquid phase by decantation. After settling yeast mass is concentrated by the separator. For better digestibility of yeast in the body of animals special treatment of microbial cells (mechanical, ultrasonic, thermal, enzymatic) is carried out, providing the destruction of their cell membranes. Then yeast mass is evaporated to the desired concentration and dried.

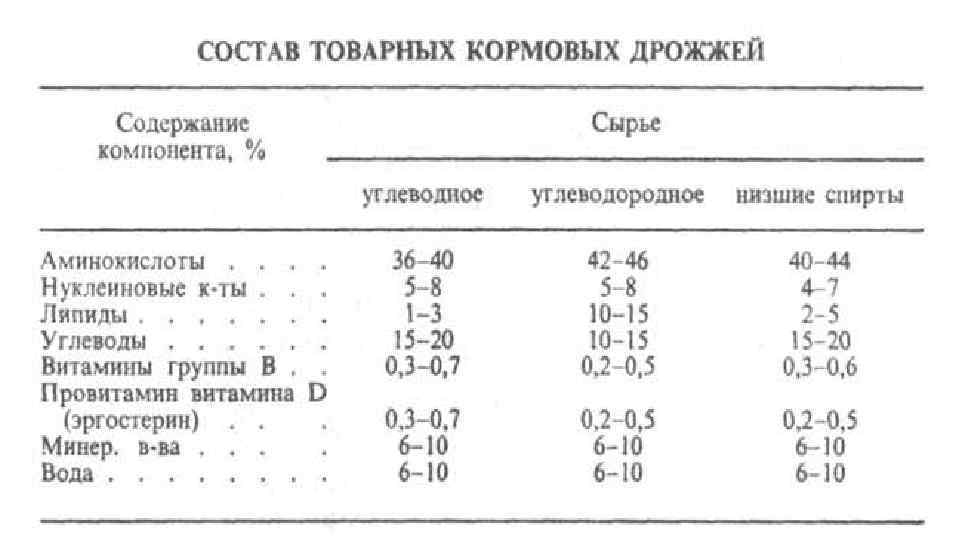

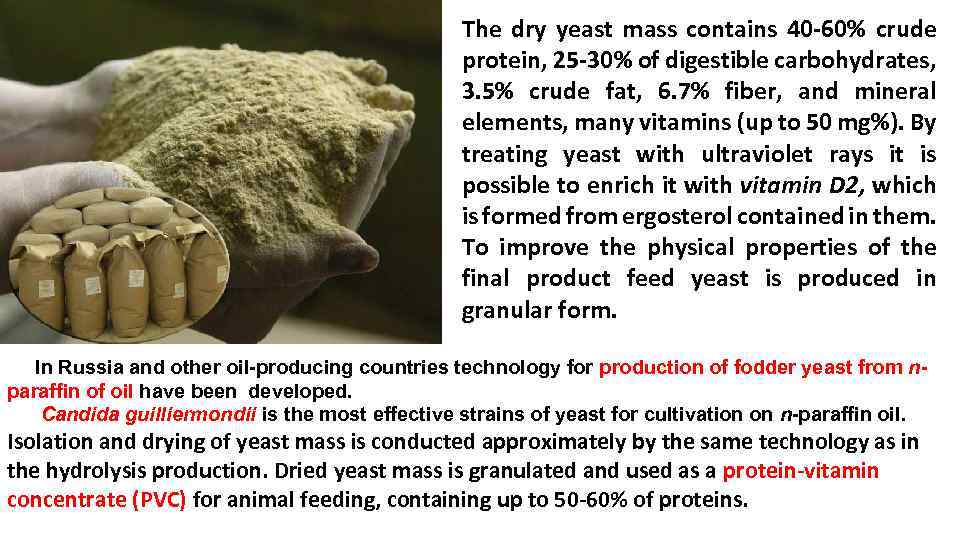

The dry yeast mass contains 40 -60% crude protein, 25 -30% of digestible carbohydrates, 3. 5% crude fat, 6. 7% fiber, and mineral elements, many vitamins (up to 50 mg%). By treating yeast with ultraviolet rays it is possible to enrich it with vitamin D 2, which is formed from ergosterol contained in them. To improve the physical properties of the final product feed yeast is produced in granular form. In Russia and other oil-producing countries technology for production of fodder yeast from nparaffin of oil have been developed. Candida guilliermondii is the most effective strains of yeast for cultivation on n-paraffin oil. Isolation and drying of yeast mass is conducted approximately by the same technology as in the hydrolysis production. Dried yeast mass is granulated and used as a protein-vitamin concentrate (PVC) for animal feeding, containing up to 50 -60% of proteins.

Protein concentrates from bacteria. Bacterial proteins containing crude protein about 60 -80% by dry weight are also important forage. There are more than 30 species of bacteria, which can be used as a valuable source of feed protein. Bacteria are able to increase biomass several times faster than yeast cells and in the protein of bacteria contains much more sulfurcontaining amino acids owing to what it has a higher biological value than the protein of yeast. Various gaseous products (natural and associated gas, gas condensate, etc. ), lower alcohols (methanol and ethanol), hydrogen are serving as a carbon source for the bacteria. Methylococcus most often are grown on gas nutrient media and under optimal conditions can utilize up to 85 -90% methane.

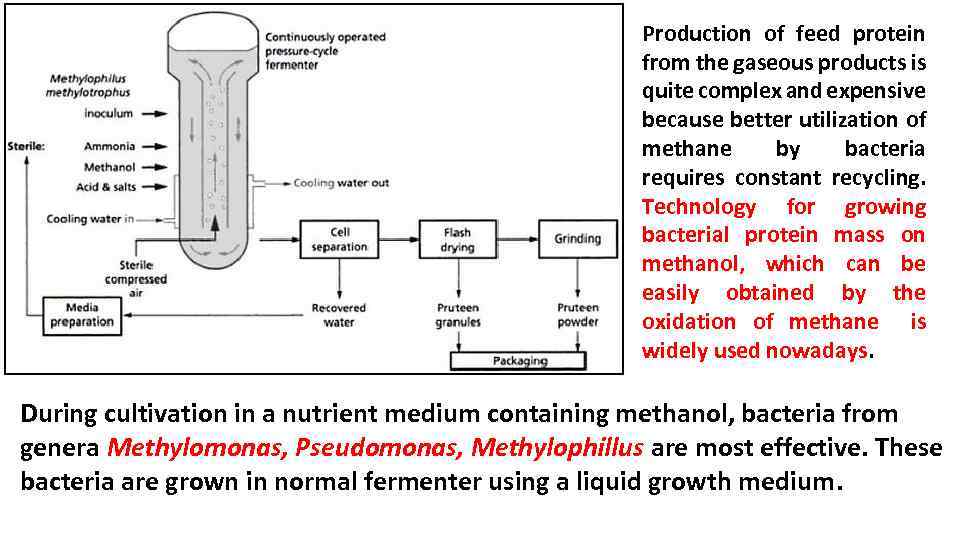

Production of feed protein from the gaseous products is quite complex and expensive because better utilization of methane by bacteria requires constant recycling. Technology for growing bacterial protein mass on methanol, which can be easily obtained by the oxidation of methane is widely used nowadays. During cultivation in a nutrient medium containing methanol, bacteria from genera Methylomonas, Pseudomonas, Methylophillus are most effective. These bacteria are grown in normal fermenter using a liquid growth medium.

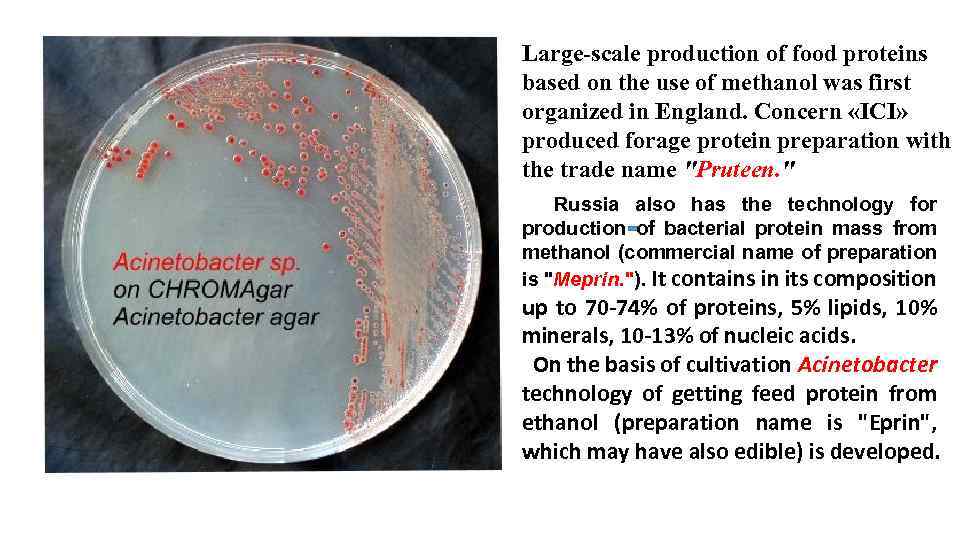

Large-scale production of food proteins based on the use of methanol was first organized in England. Concern «ICI» produced forage protein preparation with the trade name "Pruteen. " Russia also has the technology for production of bacterial protein mass from methanol (commercial name of preparation is "Meprin. "). It contains in its composition up to 70 -74% of proteins, 5% lipids, 10% minerals, 10 -13% of nucleic acids. On the basis of cultivation Acinetobacter technology of getting feed protein from ethanol (preparation name is "Eprin", which may have also edible) is developed.

Hydrogen-oxidizing bacteria are characterized by high intensity of synthesis of proteins that can accumulate in their cells up to 80% crude protein of dry matter. These bacteria use the energy of the oxidation of hydrogen for carbon dioxide utilization, and some strains also for the assimilation of atmospheric nitrogen. Hydrogen-Gas atmosphere for the cultivation of bacteria usually contains 70 -80% of hydrogen, 20 -30% of oxygen and 35% of carbon dioxide. High efficiency of growing in such gaseous medium have bacteria of the genera Pseudomonas, Alcaligenes, Achromobacter, Corinebacterium etc. Hydrogen for the production of protein mass is usually obtained from water by it electrolysis (electrolysis) or photochemical decomposition. Carbon dioxide can be used from any industrial waste gas industries, as well as flue gas, which simultaneously solves the problem of cleaning the gas medium. Production of feed protein on the basis of hydrogen-oxidizing bacteria can also be arranged near the chemical plants, where by-product hydrogen is formed.

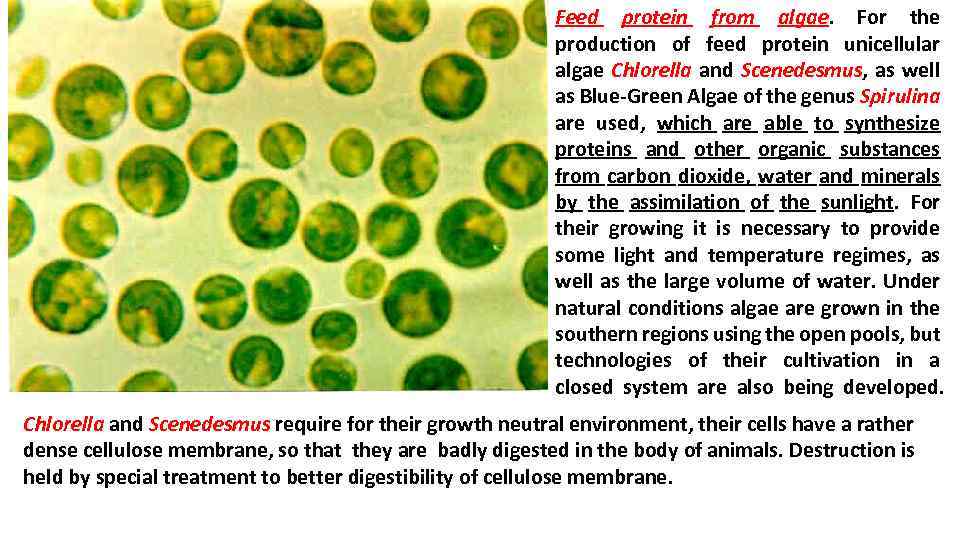

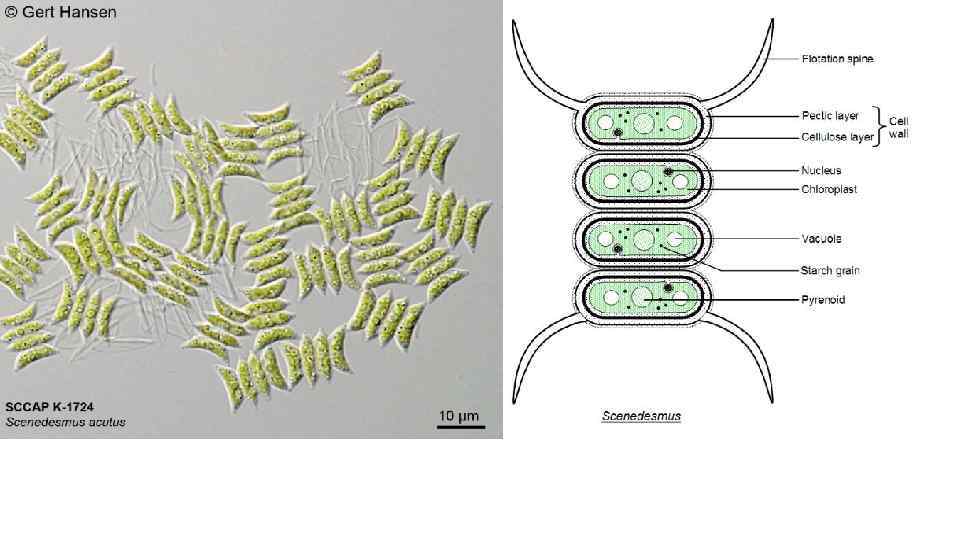

Feed protein from algae. For the production of feed protein unicellular algae Chlorella and Scenedesmus, as well as Blue-Green Algae of the genus Spirulina are used, which are able to synthesize proteins and other organic substances from carbon dioxide, water and minerals by the assimilation of the sunlight. For their growing it is necessary to provide some light and temperature regimes, as well as the large volume of water. Under natural conditions algae are grown in the southern regions using the open pools, but technologies of their cultivation in a closed system are also being developed. Chlorella and Scenedesmus require for their growth neutral environment, their cells have a rather dense cellulose membrane, so that they are badly digested in the body of animals. Destruction is held by special treatment to better digestibility of cellulose membrane.

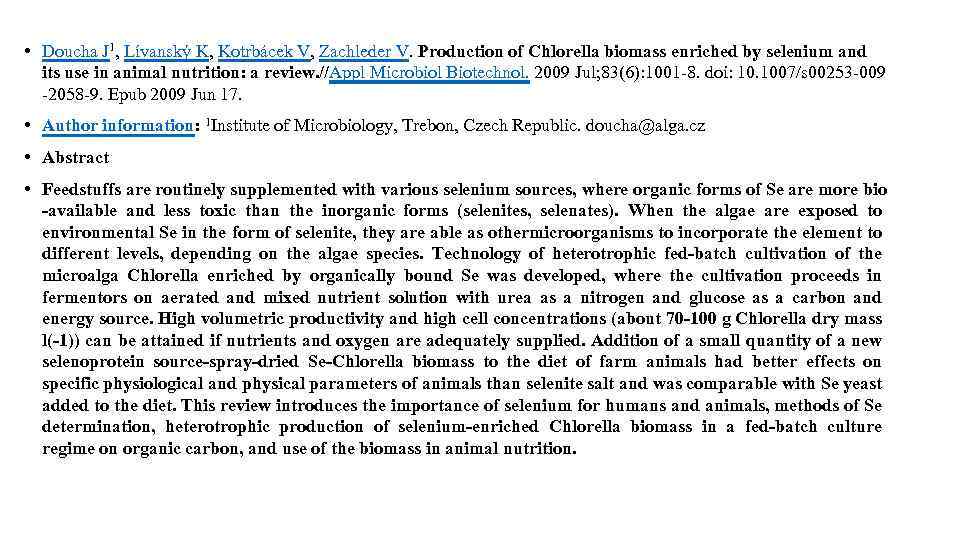

• Doucha J 1, Lívanský K, Kotrbácek V, Zachleder V. Production of Chlorella biomass enriched by selenium and its use in animal nutrition: a review. //Appl Microbiol Biotechnol. 2009 Jul; 83(6): 1001 -8. doi: 10. 1007/s 00253 -009 -2058 -9. Epub 2009 Jun 17. • Author information: 1 Institute of Microbiology, Trebon, Czech Republic. doucha@alga. cz • Abstract • Feedstuffs are routinely supplemented with various selenium sources, where organic forms of Se are more bio -available and less toxic than the inorganic forms (selenites, selenates). When the algae are exposed to environmental Se in the form of selenite, they are able as othermicroorganisms to incorporate the element to different levels, depending on the algae species. Technology of heterotrophic fed-batch cultivation of the microalga Chlorella enriched by organically bound Se was developed, where the cultivation proceeds in fermentors on aerated and mixed nutrient solution with urea as a nitrogen and glucose as a carbon and energy source. High volumetric productivity and high cell concentrations (about 70 -100 g Chlorella dry mass l(-1)) can be attained if nutrients and oxygen are adequately supplied. Addition of a small quantity of a new selenoprotein source-spray-dried Se-Chlorella biomass to the diet of farm animals had better effects on specific physiological and physical parameters of animals than selenite salt and was comparable with Se yeast added to the diet. This review introduces the importance of selenium for humans and animals, methods of Se determination, heterotrophic production of selenium-enriched Chlorella biomass in a fed-batch culture regime on organic carbon, and use of the biomass in animal nutrition.

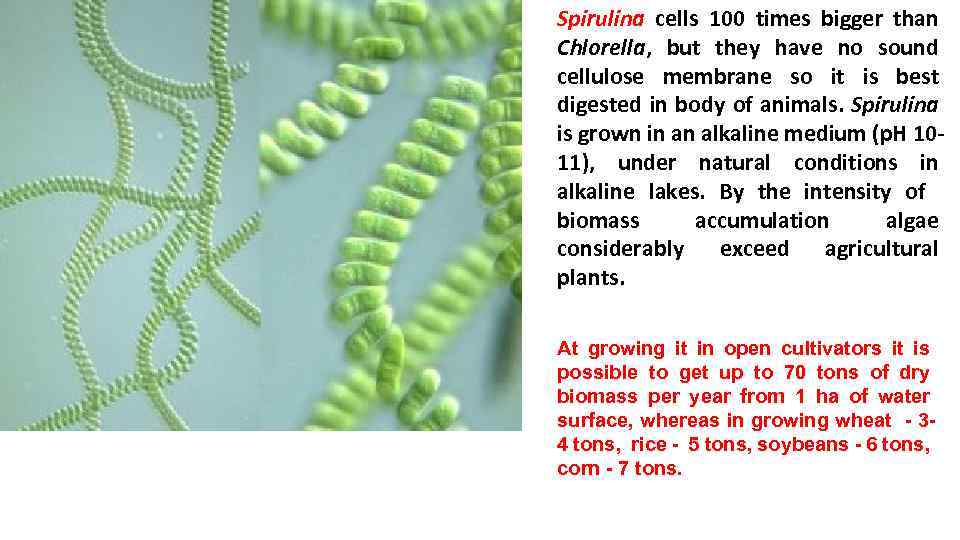

Spirulina cells 100 times bigger than Chlorella, but they have no sound cellulose membrane so it is best digested in body of animals. Spirulina is grown in an alkaline medium (p. H 1011), under natural conditions in alkaline lakes. By the intensity of biomass accumulation algae considerably exceed agricultural plants. At growing it in open cultivators it is possible to get up to 70 tons of dry biomass per year from 1 ha of water surface, whereas in growing wheat - 34 tons, rice - 5 tons, soybeans - 6 tons, corn - 7 tons.

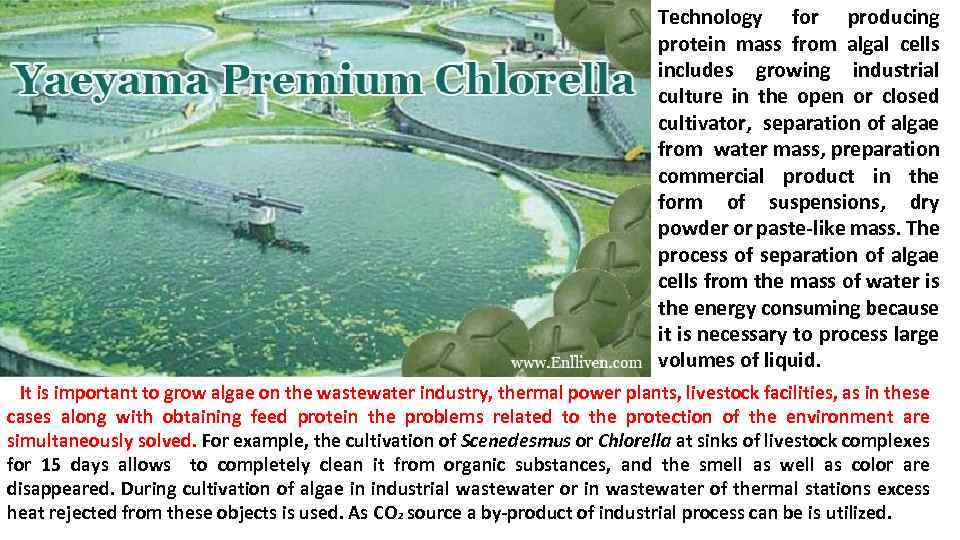

Technology for producing protein mass from algal cells includes growing industrial culture in the open or closed cultivator, separation of algae from water mass, preparation commercial product in the form of suspensions, dry powder or paste-like mass. The process of separation of algae cells from the mass of water is the energy consuming because it is necessary to process large volumes of liquid. It is important to grow algae on the wastewater industry, thermal power plants, livestock facilities, as in these cases along with obtaining feed protein the problems related to the protection of the environment are simultaneously solved. For example, the cultivation of Scenedesmus or Chlorella at sinks of livestock complexes for 15 days allows to completely clean it from organic substances, and the smell as well as color are disappeared. During cultivation of algae in industrial wastewater or in wastewater of thermal stations excess heat rejected from these objects is used. As CO 2 source a by-product of industrial process can be is utilized.

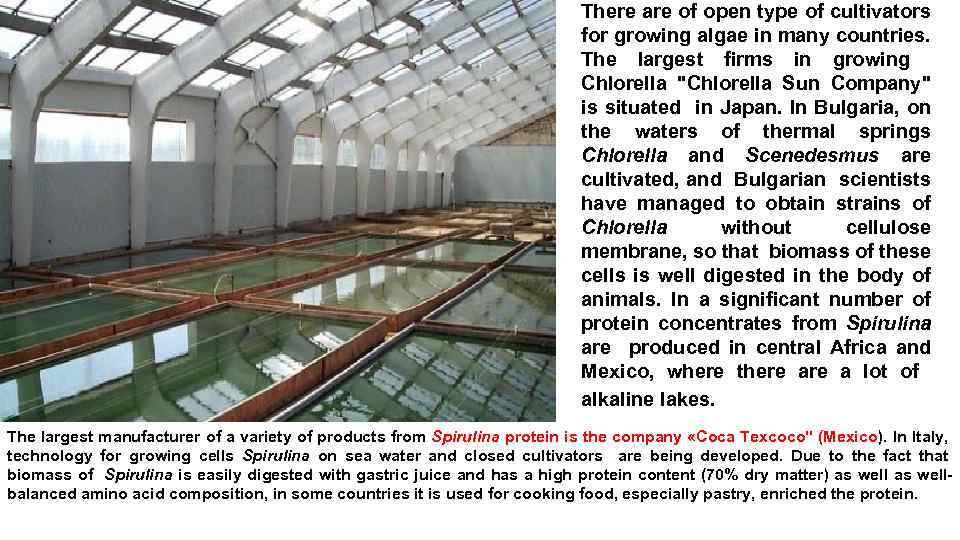

There are of open type of cultivators for growing algae in many countries. The largest firms in growing Chlorella "Chlorella Sun Company" is situated in Japan. In Bulgaria, on the waters of thermal springs Chlorella and Scenedesmus are cultivated, and Bulgarian scientists have managed to obtain strains of Chlorella without cellulose membrane, so that biomass of these cells is well digested in the body of animals. In a significant number of protein concentrates from Spirulina are produced in central Africa and Mexico, where there a lot of alkaline lakes. The largest manufacturer of a variety of products from Spirulina protein is the company «Coca Texcoco" (Mexico). In Italy, technology for growing cells Spirulina on sea water and closed cultivators are being developed. Due to the fact that biomass of Spirulina is easily digested with gastric juice and has a high protein content (70% dry matter) as wellbalanced amino acid composition, in some countries it is used for cooking food, especially pastry, enriched the protein.

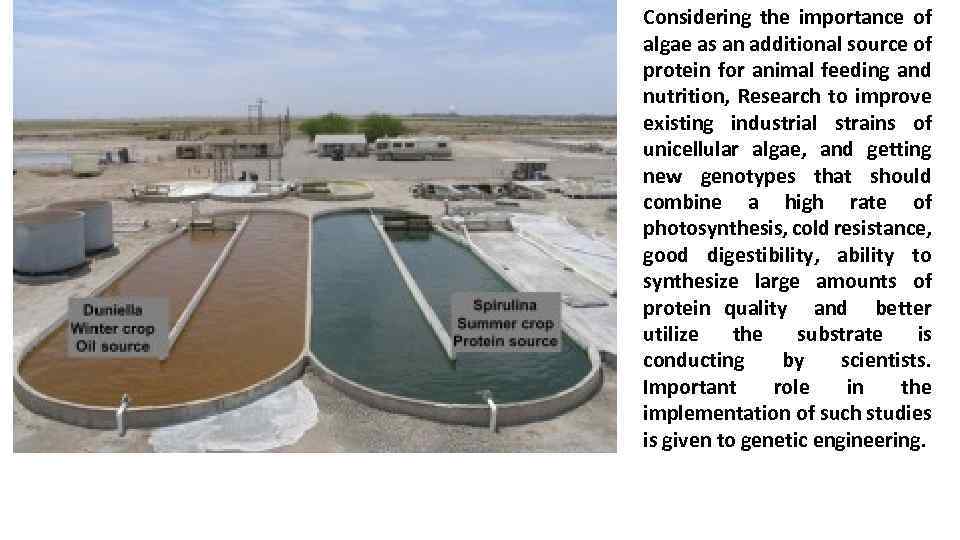

Considering the importance of algae as an additional source of protein for animal feeding and nutrition, Research to improve existing industrial strains of unicellular algae, and getting new genotypes that should combine a high rate of photosynthesis, cold resistance, good digestibility, ability to synthesize large amounts of protein quality and better utilize the substrate is conducting by scientists. Important role in the implementation of such studies is given to genetic engineering.

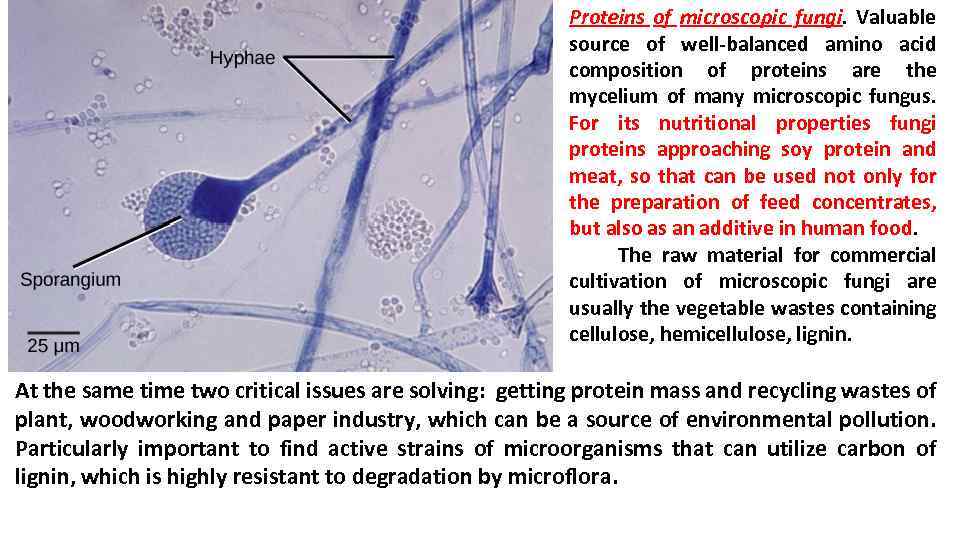

Proteins of microscopic fungi. Valuable source of well-balanced amino acid composition of proteins are the mycelium of many microscopic fungus. For its nutritional properties fungi proteins approaching soy protein and meat, so that can be used not only for the preparation of feed concentrates, but also as an additive in human food. The raw material for commercial cultivation of microscopic fungi are usually the vegetable wastes containing cellulose, hemicellulose, lignin. At the same time two critical issues are solving: getting protein mass and recycling wastes of plant, woodworking and paper industry, which can be a source of environmental pollution. Particularly important to find active strains of microorganisms that can utilize carbon of lignin, which is highly resistant to degradation by microflora.

Currently in the process of studies, the fast-growing non-toxic strains of the meso-and thermophilic fungi from the genera Penicilium, Aspergillus, Fusarium, Trichoderma for industrial cultivation are selected. Mycelium cells of these fungi have a thin cell wall owing to what it is a very well-digested in the gastrointestinal tract of animals. They contain in their composition complex of aromatic substances rich in vitamins and easily digestible lipids.

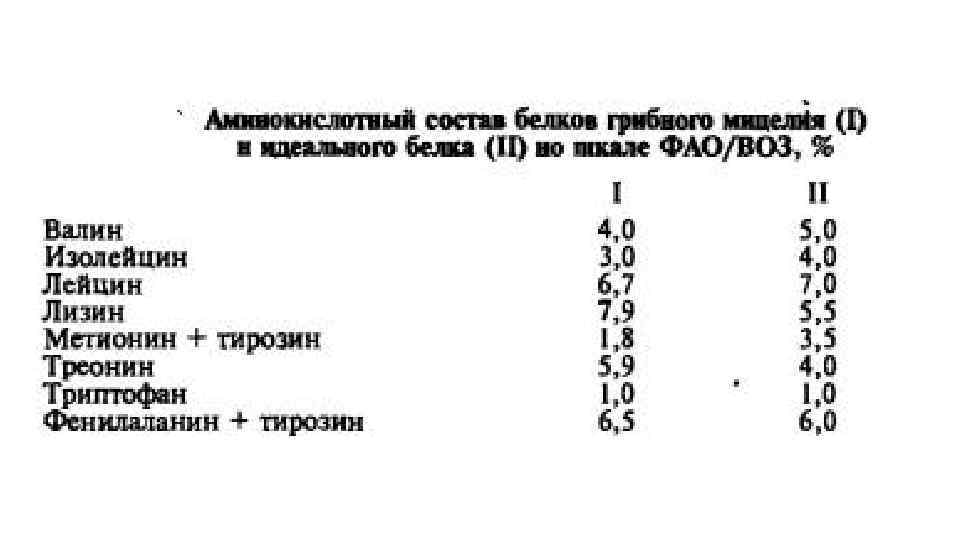

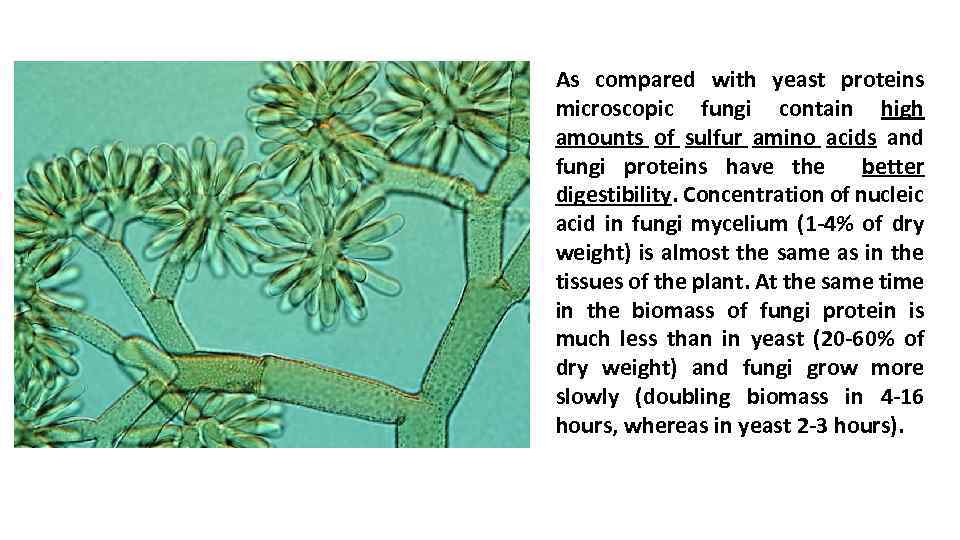

As compared with yeast proteins microscopic fungi contain high amounts of sulfur amino acids and fungi proteins have the better digestibility. Concentration of nucleic acid in fungi mycelium (1 -4% of dry weight) is almost the same as in the tissues of the plant. At the same time in the biomass of fungi protein is much less than in yeast (20 -60% of dry weight) and fungi grow more slowly (doubling biomass in 4 -16 hours, whereas in yeast 2 -3 hours).

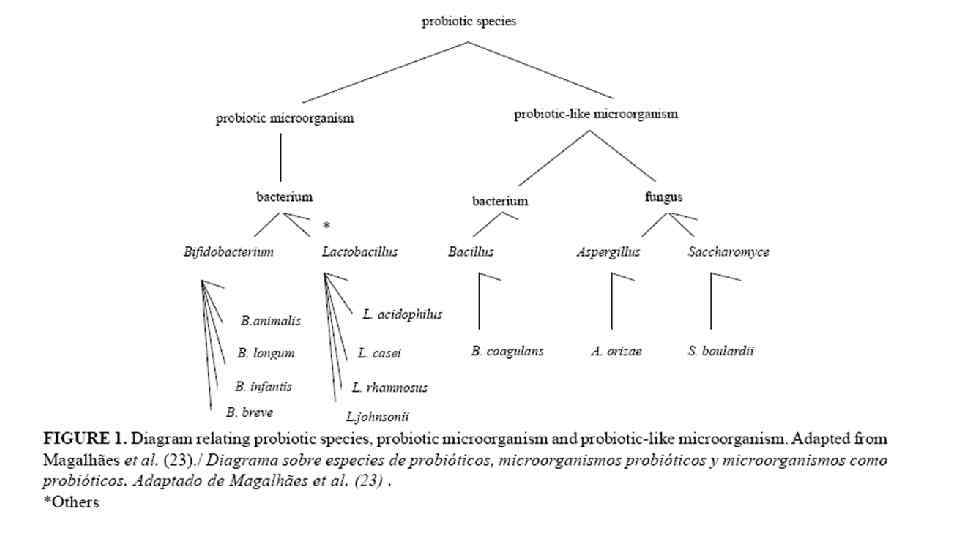

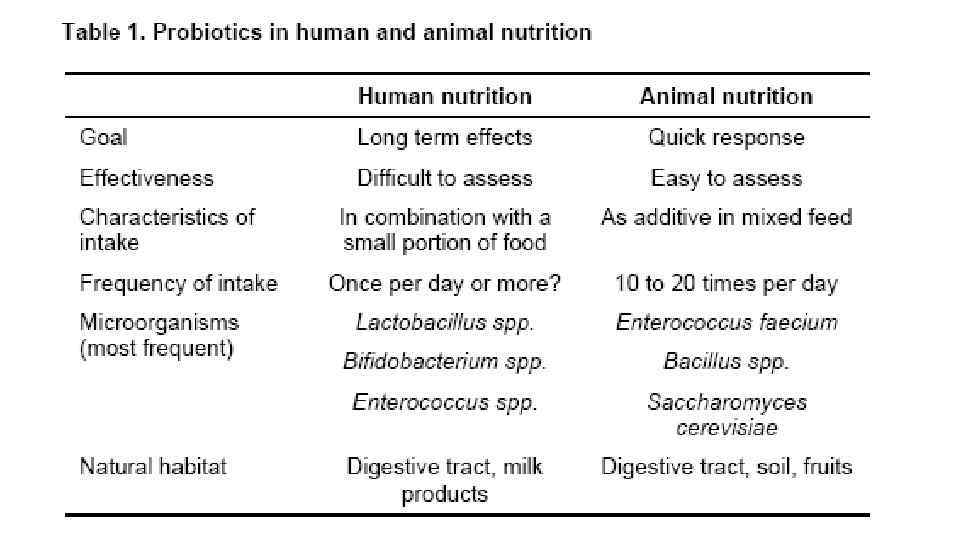

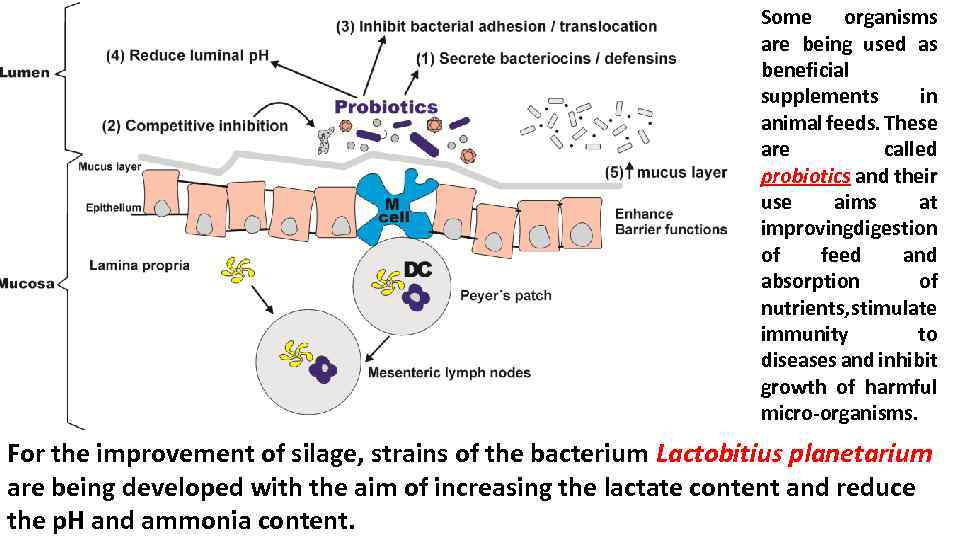

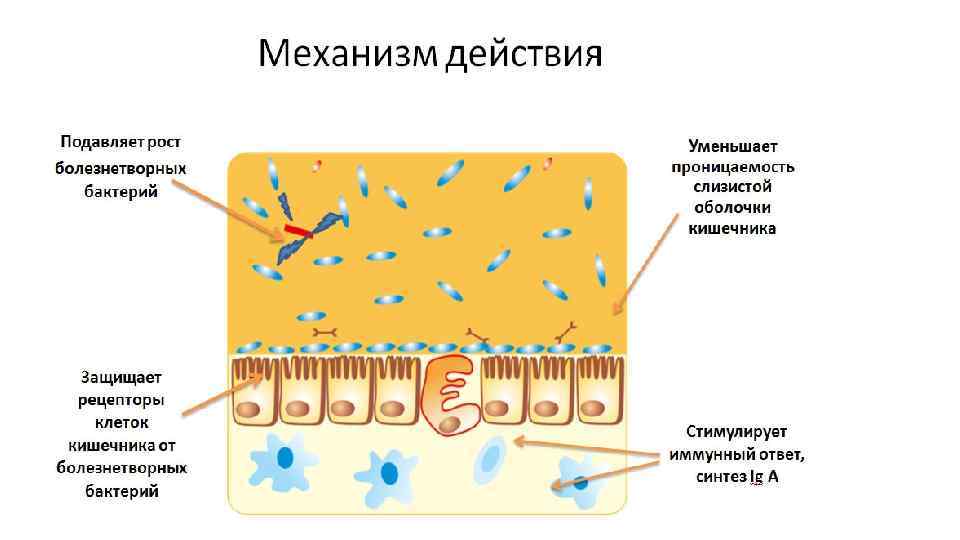

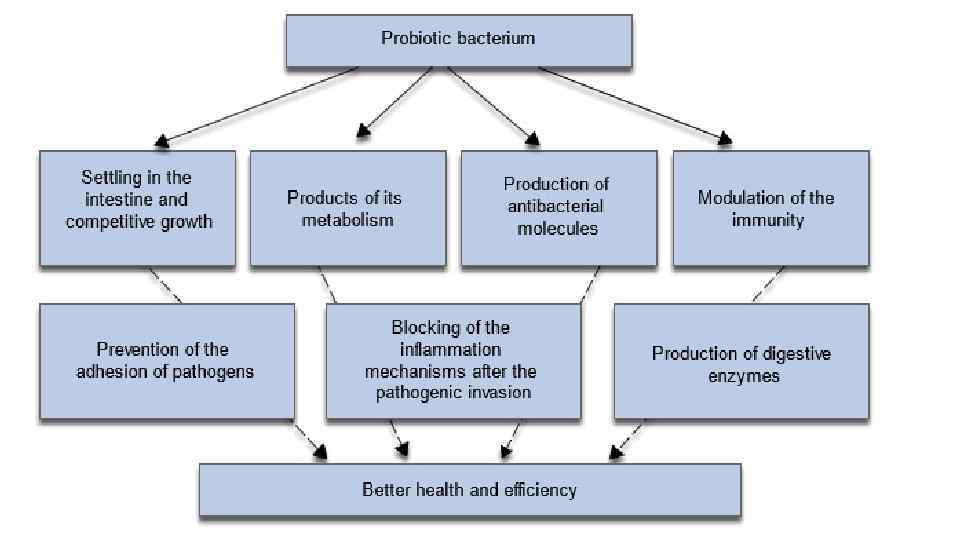

Certain microorganisms are of great interest as probiotics. Probiotics are biological products containing live microorganisms - symbionts of humans and animals that have the ability to restore the disturbed microecology of organisms. These include Bifidobacteria, Lactobacilli, Streptococci, etc. , which are present in the body at birth. In veterinary practice for the development of probiotics, besides the genera of bacteria, yeast and fungi (Saccharomyces cerevisiae, Candida pintolonesi, Aspergillus niger, Asp. oryzae) are also used. The raw materials used for the preparation of culture media, must be harmless to humans and animals. Main substrate is skimmed milk and hydrolysed milk. The biomass of microbial symbionts is concentrated by separators, further components of supporting medium during storage are introduced (gelatin, sugar, skim milk), then it filled into ampoules or vials and aliquots are lyophilized.

Some organisms are being used as beneficial supplements in animal feeds. These are called probiotics and their use aims at improving igestion d of feed and absorption of nutrients, stimulate immunity to diseases and inhibit growth of harmful micro-organisms. For the improvement of silage, strains of the bacterium Lactobitius planetarium are being developed with the aim of increasing the lactate content and reduce the p. H and ammonia content.

In the technologies of creation of probiotics lactic acid bacteria, bacilli and others are mainly used. For example, Bactolakt (Japan) includes Lactobacillus rhamnosum, Lactobacillus casei, Lactobacillus faecium; Linex (Russia) consist of Lactobacillus, Bifidobacterium, Streptococcus; Biosoprina (Ukraine) has in its content Bacillus sibtilis, Bacillus cereus.

Borchers AT 1, Selmi C, Meyers FJ, Keen CL, Gershwin ME. Probiotics and immunity. //J Gastroenterol. 2009; 44(1): 26 -46. doi: 10. 1007/s 00535 -008 -2296 -0. Epub 2009 Jan 22. Author information: Department of Nutrition, Allergy and Clinical Immunology, University of California at Davis, CA, USA. Abstract Probiotics are defined as live microorganisms that, when administered in adequate amounts, confer a health benefit on the host, including the gastrointestinal tract. While this beneficial effect was originally thought to stem from improvements in the intestinal microbial balance, there is now substantial evidence that probiotics can also provide benefits by modulating immune functions. In animal models, probiotic supplementation is able to provide protection from spontaneous and chemically induced colitis by downregulating inflammatory cytokines or inducing regulatory mechanisms in a strain-specific manner. In animal models of allergen sensitization and murine models of asthma and allergic rhinitis, orally administered probiotics can strain-dependently decrease allergen-specific Ig. E production, in part by modulating systemic cytokine production. Certain probiotics have been shown to decrease airway hyperresponsiveness and inflammation by inducing regulatory mechanisms. Promising results have been obtained with probiotics in the treatment of human inflammatory diseases of the intestine and in the prevention and treatment of atopic eczema in neonates and infants. However, the findings are too variable to allow firm conclusions as to the effectiveness of specific probiotics in these conditions.

Bermudez-Brito M 1, Plaza-Díaz J, Muñoz-Quezada S, Gómez-Llorente C, Gil A. Probiotic mechanisms of action. //Ann Nutr Metab. 2012; 61(2): 160 -74. doi: 10. 1159/000342079. Epub 2012 Oct 2. Author information: Department of Biochemistry and Molecular Biology II, Institute of Nutrition and Food Technology José Mataix, Biomedical Research Center, University of Granada, Armilla, Spain. Abstract Probiotics are live microorganisms that provide health benefits to the host when ingested in adequate amounts. The strains most frequently used as probiotics include lactic acid bacteria and bifidobacteria. Probiotics have demonstrated significant potential as therapeutic options for a variety of diseases, but the mechanisms responsible for these effects have not been fully elucidated yet. Several important mechanisms underlying the antagonistic effects of probiotics on various microorganisms include the following: modification of the gut microbiota, competitive adherence to the mucosa and epithelium, strengthening of the gut epithelial barrier and modulation of the immune system to convey an advantage to the host. Accumulating evidence demonstrates that probiotics communicate with the host by pattern recognition receptors, such as toll-like receptors and nucleotide-binding oligomerization domain-containing protein-like receptors, which modulate key signaling pathways, such as nuclear factor-ĸB and mitogenactivated protein kinase, to enhance or suppress activation and influence downstream pathways. This recognition is crucial for eliciting measured antimicrobial responses with minimal inflammatory tissue damage. A clear understanding of these mechanisms will allow for appropriate probiotic strain selection for specific applications and may uncover novel probiotic functions. The goal of this systematic review was to explore probiotic modes of action focusing on how gut microbes influence the host.

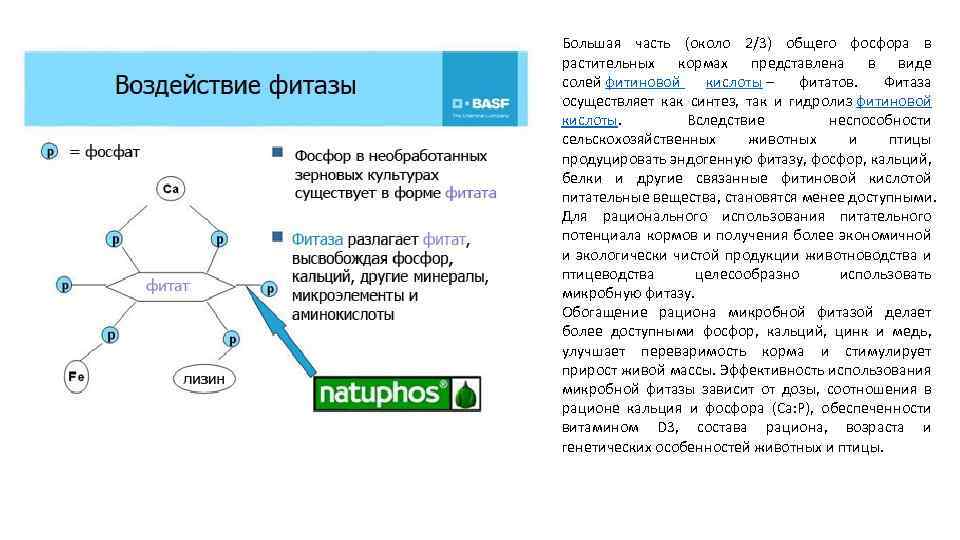

Большая часть (около 2/3) общего фосфора в растительных кормах представлена в виде солей фитиновой кислоты – фитатов. Фитаза осуществляет как синтез, так и гидролиз фитиновой кислоты. Вследствие неспособности сельскохозяйственных животных и птицы продуцировать эндогенную фитазу, фосфор, кальций, белки и другие связанные фитиновой кислотой питательные вещества, становятся менее доступными. Для рационального использования питательного потенциала кормов и получения более экономичной и экологически чистой продукции животноводства и птицеводства целесообразно использовать микробную фитазу. Обогащение рациона микробной фитазой делает более доступными фосфор, кальций, цинк и медь, улучшает переваримость корма и стимулирует прирост живой массы. Эффективность использования микробной фитазы зависит от дозы, соотношения в рационе кальция и фосфора (Са: Р), обеспеченности витамином D 3, состава рациона, возраста и генетических особенностей животных и птицы.

Dersjant-Li Y 1, Awati A, Schulze H, Partridge G. Phytase in non-ruminant animal nutrition: a critical review on phytase activities in the gastrointestinal tract and influencing factors. //J Sci Food Agric. 2014 Nov 8. doi: 10. 1002/jsfa. 6998. [Epub ahead of print Author information 1: Danisco Animal Nutrition, Du. Pont Industrial Biosciences, PO Box 777, Marlborough, SN 8 1 XN, UK Abstract This review focuses on phytase functionality in the digestive tract of farmed non-ruminant animals and the factors influencing in vivo phytase enzyme activity. In pigs, feed phytase is mainly active in the stomach and upper part of the small intestine, and added phytase activity is not recovered in the ileum. In poultry, feed phytase activities are mainly found in the upper part of the digestive tract, including the crop, proventriculus and gizzard. For fish with a stomach, phytase activities are mainly in the stomach. Many factors can influence the efficiency of feed phytase in the gastrointestinal tract, and they can be divided into three main groups: (i) phytase related; (ii) dietary related and (iii) animal related. Phytase-related factors include type of phytase (e. g. 3 - or 6 -phytase; bacterial or fungal phytase origin), the p. H optimum and the resistance of phytase to endogenous protease. Dietary-related factors are mainly associated with dietary phytate content, feed ingredient composition and feed processing, and total P, Ca and Na content. Animal-related factors include species, gender and age of animals. To eliminate the antinutritional effects of phytate (IP 6 ), it needs to be hydrolyzed as quickly as possible by phytase in the upper part of the digestive tract. A phytase that works over a wide range of p. H values and is active in the stomach and upper intestine (along with several other characteristics and in addition to being refractory to endogenous enzymes) would be ideal. © 2014 The Authors. Journal of the Science of Food and Agriculture published by John Wiley & Sons Ltd on behalf of Society of Chemical Industry.

Gao CQ 1, Ji C, Zhao LH, Zhang JY, Ma QG. Phytase transgenic corn in nutrition of laying hens: residual phytase activity and phytate phosphorus content in the gastrointestinal tract. //Poult Sci. 2013 Nov; 92(11): 2923 -9. doi: 10. 3382/ps. 2013 -03226 Author information: 1 State Key Laboratory of Animal Nutrition, College of Animal Science and Technology, China Agricultural University, Beijing 100193, PR China. Abstract The residual activities of transgenic corn-derived and 2 commercial microbial phytases (PA and PB) along the gastrointestinal tract (GIT) of laying hens were compared to evaluate their relative resistance to hydrolysis in the GIT when added to P-deficient diets. The treatments consisted of a negative control (NC) diet containing 0. 10 nonphytate P and an NC diet supplemented with transgenic corn-derived phytase (TCDP), PA, and PB at 500 to 5, 000 FTU/kg of diet, respectively. Seven diets were fed to Hy-Line Brown laying hens (n = 504; 8 replicates of 9 hens per treatment) for 21 d. At the end of the experiment, the hens were killed and digesta samples from the crop, proventriculus and gizzard, jejunum, and ileum were collected analyzed for residual phytase activities and phytate P content. Phytase activity in the transgenic corn was determined to be 8, 980 FTU/kg of DM. The residual phytase activities along the GIT had increased (P < 0. 01) with the addition of TCDP, PA, and PB to the NC diets. The TCDP had higher residual activity (P < 0. 05) in the crop, proventriculus and gizzard, jejunum, and ileum as compared with the PA and PB activity. There was a decrease (P < 0. 01) in the phytate P content of the digesta from all sources of phytase supplementation in the NC diets. Residual phytate P content decreased caudally along the GIT of hens. The results of this research indicate that phytase expressed in corn is as efficacious as the commercial microbial phytases (PA and PB) in P-deficient diets for the improvement of phytate P digestibility, which would eliminate the need for supplemental phytase and corn separately in laying hen diets.

He J 1, Wu AM 2, Chen D 1, Yu B 1, Mao X 1, Zheng P 1, Yu J 1, Tian G 1. Cost-effective lignocellulolytic enzyme production by Trichoderma reesei on a cane molasses medium. //Biotechnol Biofuels. 2014 Mar 24; 7: 43. doi: 10. 1186/1754 -6834 -7 -43. Institute of Animal Nutrition, Sichuan Agricultural University, Ya'an, Sichuan 625014, People's Republic of China. 2 College of Forestry, South China Agricultural University, Guangzhou 510642, People's Republic of China. Abstract BACKGROUND: Cane molasses, an important residue of the sugar industry, have the potential as a cost-effective carbon source that could serve as nutrients for industrial enzyme-producing microorganisms, especially filamentous fungi. However, the enzyme mixtures produced in such a complex medium are poorly characterized. In this study, the secretome of Trichoderma reesei grown on a cane molasses medium (CMM) as well as on a lactose-based conventional medium (LCM) were compared analyzed by using proteomics. RESULTS: In this study we show that both the CMM and LCM can serve as excellent growth media for T. reesei. The enzyme expression patterns in the two media were similar and a considerable number of the identified proteins on two-dimensional gel electrophoresis (2 -DE) gels were those involved in biomass degradation. The most abundant cellulolytic enzymes identified in both media were cellobiohydrolases (Cel 7 A/Cel 6 A) and endoglucanases (Cel 7 A/Cel 5 A) and were found to be more abundant in CMM. We also found that both media can serve as an inducer of xylanolytic enzymes. The main xylanases (XYNI/XYNIV) and xyloglucanase (Cel 74 A) were found at higher concentrations in the CMM than LCM. CONCLUSIONS: We analyzed the prevalent proteins secreted by T. reesei in the CMM and LCM. Here, we show that hydrolytic enzymes are cost-effective and can be produced on cane molasses as a carbon source which can be used to digest lignocellulolytic biomass.

Salim HM 1, Kang HK, Akter N, Kim DW, Kim JH, Kim MJ, Na JC, Jong HB, Choi HC, Suh OS, Kim WK. Supplementation of direct-fed microbials as an alternative to antibiotic on growth performance, immune response, cecal microbial population, and ileal morphology of broiler chickens. //Poult Sci. 2013 Aug; 92(8): 2084 -90. Author information: 1 Department of Animal Science, University of Manitoba, Winnipeg, Canada. Abstract An experiment was conducted to investigate the supplementation of direct-fed microbials (DFM) as an alternative to antibiotics on growth performance, immune response, cecal microbial population, and ileal morphology of broiler chickens. A total of 800 one-day-old male broiler chicks (Ross × Ross) were randomly allotted to 4 dietary treatments with 4 replicate pens per treatment (50 birds/replicate pen). The 4 dietary treatments fed for 35 d were a corn-soybean meal basal diet (control); control plus 0. 1% virginiamycin, as an antibiotic growth promoter (AGP); control plus 0. 1% direct-fed microbials that contained Lactobacillus reuteri (DFM 1); and control plus 0. 1% direct-fed microbials that contained a mixture of L. reuteri, Bacillus subtilis, and Saccharomyces cerevisiae (DFM 2). Results showed that dietary AGP and DFM supplementation significantly increased (P < 0. 05) the BW gain of broilers during 0 to 21 d. The feed intake was reduced, whereas the feed conversion was improved significantly when birds were fed DFM 2 at 0 to 7 d of age. The white blood cell and monocyte levels were significantly higher in the DFM 2 group compared with the control. In addition, feeding DFM significantly (P < 0. 05) increased the plasma immunoglobulin levels where a higher level was observed in DFM 2 compared with those of the other treatments. Neither DFM nor AGP treatments affected the cecal Lactobacillus and Salmonella content; however, cecal Escherichia coli content significantly decreased in broiler chickens fed DFM and AGP. The ileal villus height, and width and total thickness of muscularis externa were significantly increased when birds were fed DFM compared with AGP and control. These results indicate that the dietary supplementation of DFM increases the growth performance of birds at an early age, stimulates the immune response, decreases the number of E. coli, and improves the ileal morphology of broiler chickens. Thus, DFM that contained a mixture of several beneficial microorganisms could be a viable alternative to antibiotics in the broiler diets.

Tang XS 1, Shao H, Li TJ, Tang ZR, Huang RL, Wang SP, Kong XF, Wu X, Yin YL. Dietary supplementation with bovine lactoferrampin-lactoferricin produced by Pichia pastoris fed-batch fermentation affects intestinal microflora in weaned piglets. //Appl Biochem Biotechnol. 2012 Oct; 168(4): 887 -98. doi: 10. 1007/s 12010 -012 -9827 -0. Epub 2012 Aug 25 Author information: Scientific Observing and Experimental Station of Animal Nutrition and Feed Science in South-Central, Ministry of Agriculture, Hunan Provincial Engineering Research Center of Healthy Livestock, Key Laboratory of Agroecological Processes in Subtropical Region, Institute of Subtropical Agriculture, Chinese Academy of Sciences, Changsha, Hunan 410125, China. Abstract This work is aimed at investigating the effects of recombinant bovine lactoferrampin-lactoferricin (LFA-LFC) instead of chlortetracycline on intestinal microflora in weaned piglets. The high cost of peptide production from either native digestion or chemical synthesis limits the clinical application of antimicrobial peptides. The expression of recombinant peptides in yeast may be an effective alternative. In the current study, recombinant LFA-LFC was produced via fed-batch fermentation in recombinant strain Pichia pastoris (KM 71) XS 10. Uniform design U 6(6(4)) was used to optimize the fermentation conditions. The target peptide purified via cation-exchange and size-exclusion chromatography was added into the dietary of weaned piglets. After 21 days, the Lactobacilli, Bifidobacteria, and Enterobacteria in the chyme of the gut were quantified using real-time polymerase chain reaction. The results showed that approximately 82 mg of LFA-LFC was secreted into 1 L of medium under optimized conditions. Moreover, purified peptide showed strong antimicrobial activities against all the tested microorganisms. Compared with the control group, the LFA-LFC group increased the amount of Lactobacilli and Bifidobacteria (P<0. 05) in the chyme of the stomach, duodenum, jejunum, ileum, colon, and caecum. These results show that dietary supplementation with LFA-LFC can affect intestinal microflora in weaned piglets.

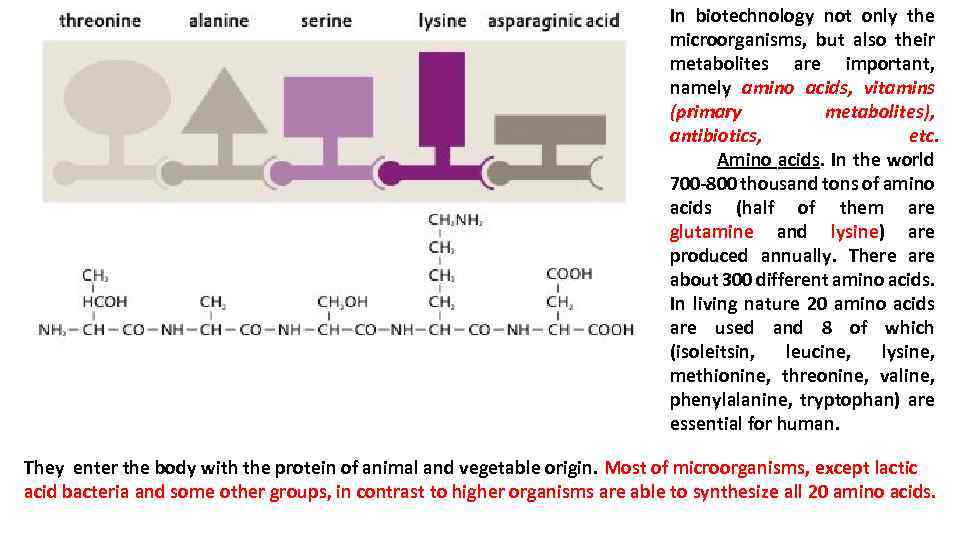

In biotechnology not only the microorganisms, but also their metabolites are important, namely amino acids, vitamins (primary metabolites), antibiotics, etc. Amino acids. In the world 700 -800 thousand tons of amino acids (half of them are glutamine and lysine) are produced annually. There about 300 different amino acids. In living nature 20 amino acids are used and 8 of which (isoleitsin, leucine, lysine, methionine, threonine, valine, phenylalanine, tryptophan) are essential for human. They enter the body with the protein of animal and vegetable origin. Most of microorganisms, except lactic acid bacteria and some other groups, in contrast to higher organisms are able to synthesize all 20 amino acids.

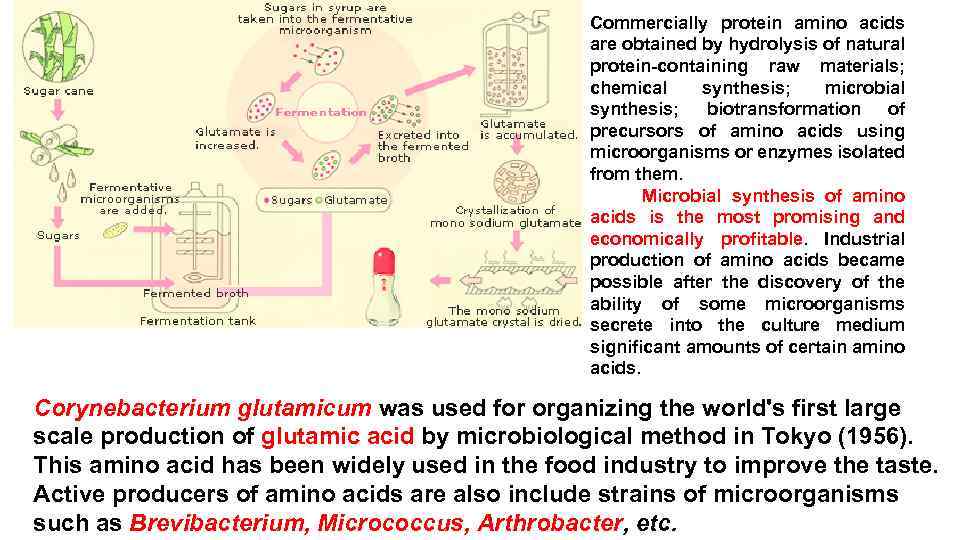

Commercially protein amino acids are obtained by hydrolysis of natural protein-containing raw materials; chemical synthesis; microbial synthesis; biotransformation of precursors of amino acids using microorganisms or enzymes isolated from them. Microbial synthesis of amino acids is the most promising and economically profitable. Industrial production of amino acids became possible after the discovery of the ability of some microorganisms secrete into the culture medium significant amounts of certain amino acids. Corynebacterium glutamicum was used for organizing the world's first large scale production of glutamic acid by microbiological method in Tokyo (1956). This amino acid has been widely used in the food industry to improve the taste. Active producers of amino acids are also include strains of microorganisms such as Brevibacterium, Micrococcus, Arthrobacter, etc.

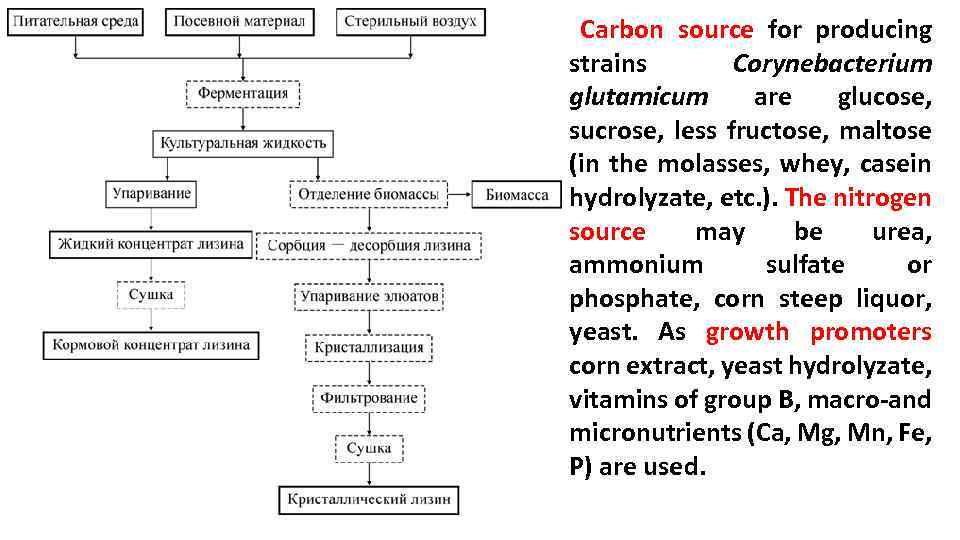

Carbon source for producing strains Corynebacterium glutamicum are glucose, sucrose, less fructose, maltose (in the molasses, whey, casein hydrolyzate, etc. ). The nitrogen source may be urea, ammonium sulfate or phosphate, corn steep liquor, yeast. As growth promoters corn extract, yeast hydrolyzate, vitamins of group B, macro-and micronutrients (Ca, Mg, Mn, Fe, P) are used.

Lysine is synthesized on an industrial scale, primarily as a feed additive. In practice lysine is obtained by deep-batch fermentation of Brevibacterium flavum and Corynebacterium glutamicum at 30 -33 ° C, p. H 7. 07. 2 within 2 -3 days. Lysine is accumulated in culture medium at the end of the exponential phase of growth. At the end of the fermentation culture liquid is separated from the cell mass. Lysine is separated from the culture fluid, mixed with filler (wheat bran, etc. ), and used as feed concentrate in granulated or liquid form.

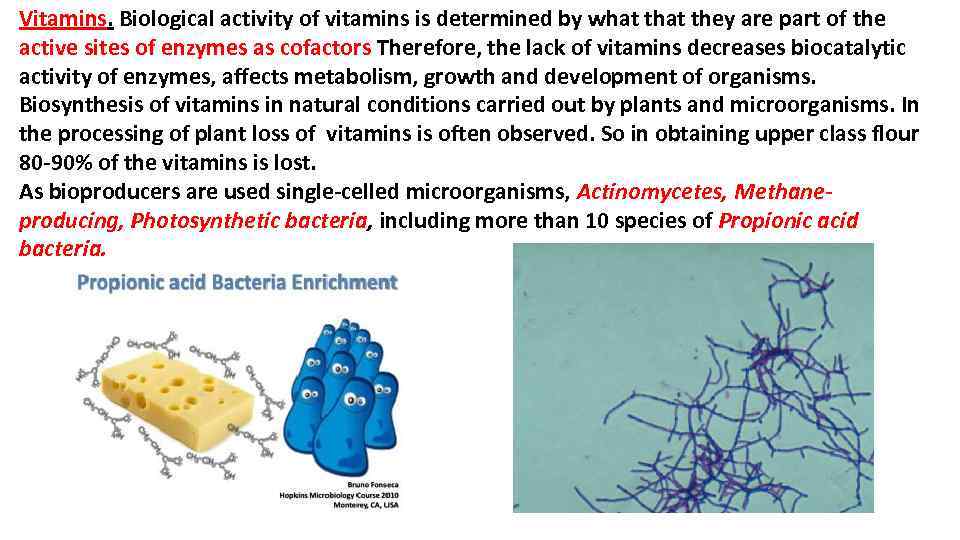

Vitamins. Biological activity of vitamins is determined by what they are part of the active sites of enzymes as cofactors Therefore, the lack of vitamins decreases biocatalytic activity of enzymes, affects metabolism, growth and development of organisms. Biosynthesis of vitamins in natural conditions carried out by plants and microorganisms. In the processing of plant loss of vitamins is often observed. So in obtaining upper class flour 80 -90% of the vitamins is lost. As bioproducers are used single-celled microorganisms, Actinomycetes, Methaneproducing, Photosynthetic bacteria, including more than 10 species of Propionic acid bacteria.

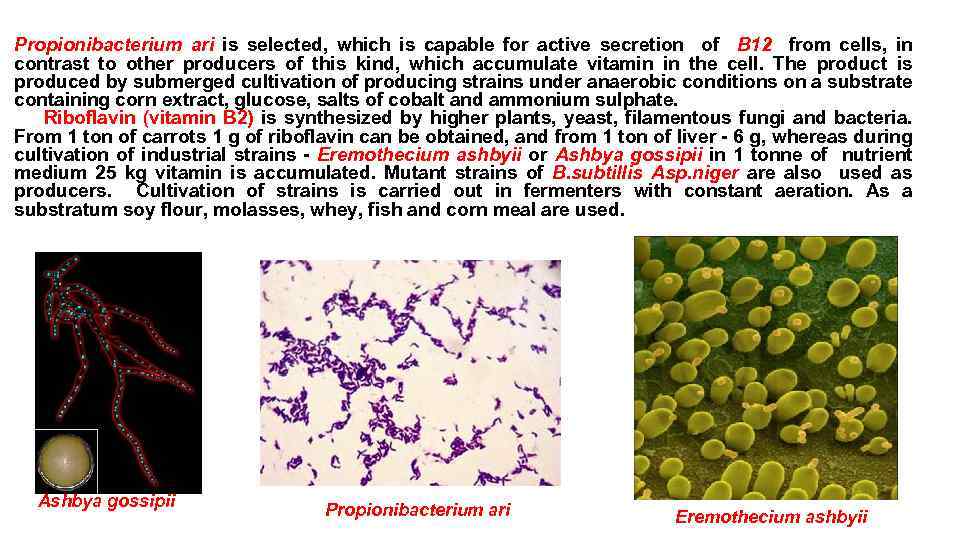

Propionibacterium ari is selected, which is capable for active secretion of B 12 from cells, in contrast to other producers of this kind, which accumulate vitamin in the cell. The product is produced by submerged cultivation of producing strains under anaerobic conditions on a substrate containing corn extract, glucose, salts of cobalt and ammonium sulphate. Riboflavin (vitamin B 2) is synthesized by higher plants, yeast, filamentous fungi and bacteria. From 1 ton of carrots 1 g of riboflavin can be obtained, and from 1 ton of liver - 6 g, whereas during cultivation of industrial strains - Eremothecium ashbyii or Ashbya gossipii in 1 tonne of nutrient medium 25 kg vitamin is accumulated. Mutant strains of B. subtillis Asp. niger are also used as producers. Cultivation of strains is carried out in fermenters with constant aeration. As a substratum soy flour, molasses, whey, fish and corn meal are used. Ashbya gossipii Propionibacterium ari Eremothecium ashbyii

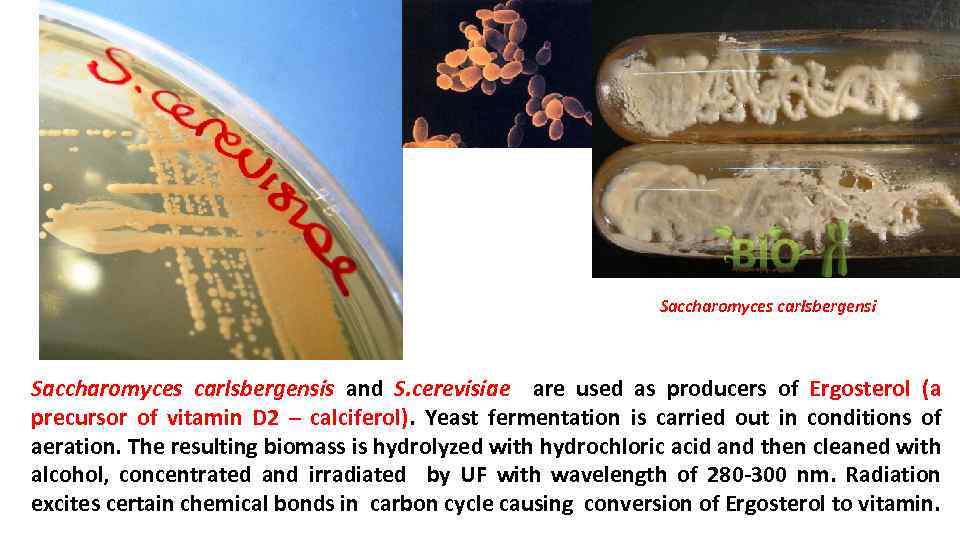

Saccharomyces carlsbergensis and S. cerevisiae are used as producers of Ergosterol (a precursor of vitamin D 2 – calciferol). Yeast fermentation is carried out in conditions of aeration. The resulting biomass is hydrolyzed with hydrochloric acid and then cleaned with alcohol, concentrated and irradiated by UF with wavelength of 280 -300 nm. Radiation excites certain chemical bonds in carbon cycle causing conversion of Ergosterol to vitamin.

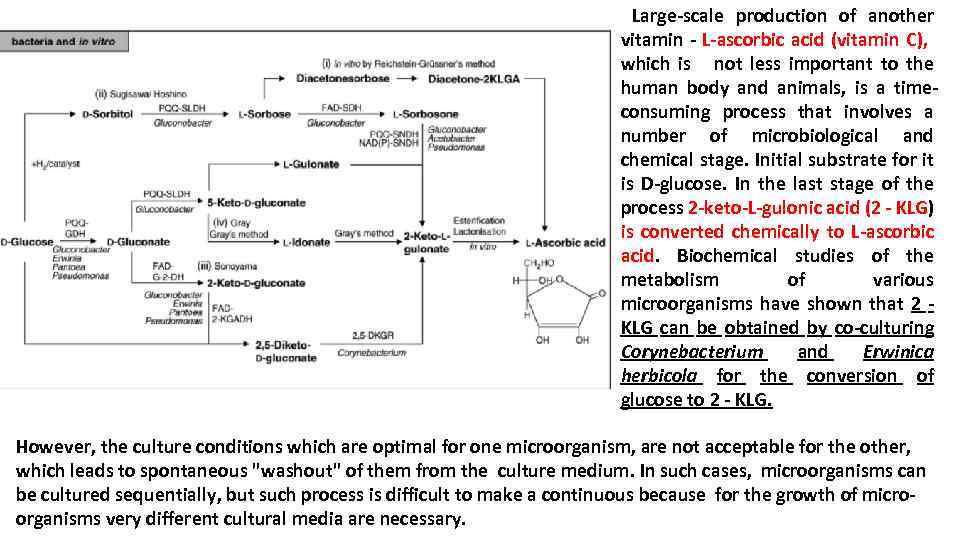

Large-scale production of another vitamin - L-ascorbic acid (vitamin C), which is not less important to the human body and animals, is a timeconsuming process that involves a number of microbiological and chemical stage. Initial substrate for it is D-glucose. In the last stage of the process 2 -keto-L-gulonic acid (2 - KLG) is converted chemically to L-ascorbic acid. Biochemical studies of the metabolism of various microorganisms have shown that 2 - KLG can be obtained by co-culturing Corynebacterium and Erwinica herbicola for the conversion of glucose to 2 - KLG. However, the culture conditions which are optimal for one microorganism, are not acceptable for the other, which leads to spontaneous "washout" of them from the culture medium. In such cases, microorganisms can be cultured sequentially, but such process is difficult to make a continuous because for the growth of microorganisms very different cultural media are necessary.

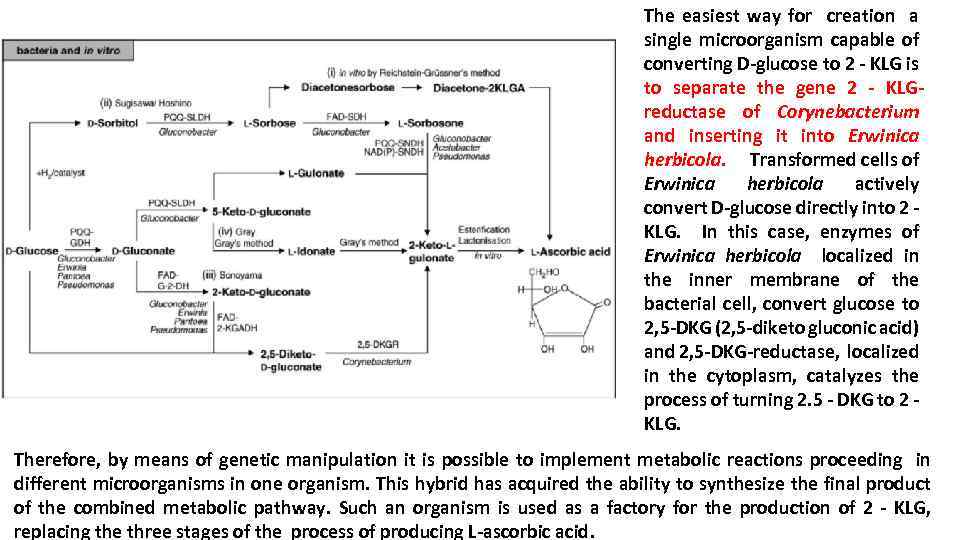

The easiest way for creation a single microorganism capable of converting D-glucose to 2 - KLG is to separate the gene 2 - KLGreductase of Corynebacterium and inserting it into Erwinica herbicola. Transformed cells of Erwinica herbicola actively convert D-glucose directly into 2 - KLG. In this case, enzymes of Erwinica herbicola localized in the inner membrane of the bacterial cell, convert glucose to 2, 5 -DKG (2, 5 -diketo gluconic acid) and 2, 5 -DKG-reductase, localized in the cytoplasm, catalyzes the process of turning 2. 5 - DKG to 2 - KLG. Therefore, by means of genetic manipulation it is possible to implement metabolic reactions proceeding in different microorganisms in one organism. This hybrid has acquired the ability to synthesize the final product of the combined metabolic pathway. Such an organism is used as a factory for the production of 2 - KLG, replacing the three stages of the process of producing L-ascorbic acid.

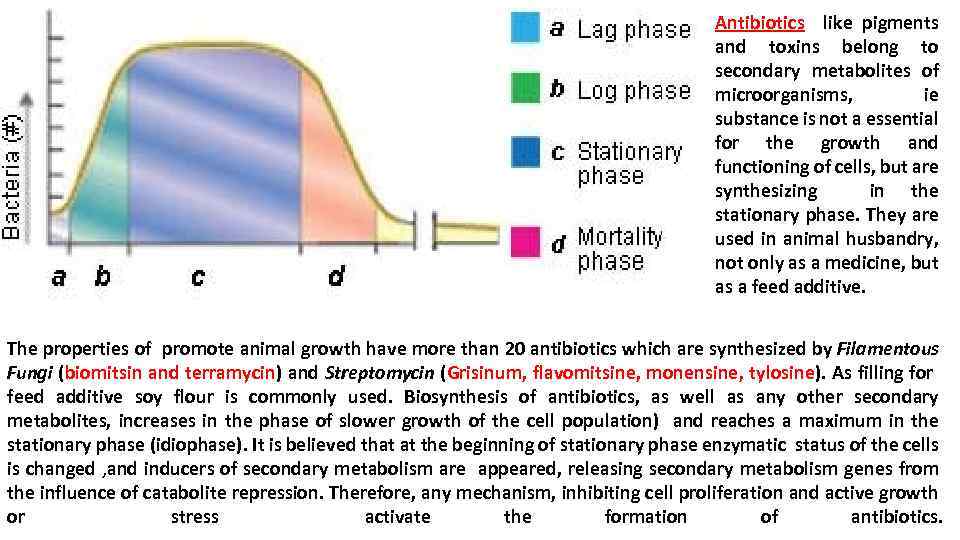

Antibiotics like pigments and toxins belong to secondary metabolites of microorganisms, ie substance is not a essential for the growth and functioning of cells, but are synthesizing in the stationary phase. They are used in animal husbandry, not only as a medicine, but as a feed additive. The properties of promote animal growth have more than 20 antibiotics which are synthesized by Filamentous Fungi (biomitsin and terramycin) and Streptomycin (Grisinum, flavomitsine, monensine, tylosine). As filling for feed additive soy flour is commonly used. Biosynthesis of antibiotics, as well as any other secondary metabolites, increases in the phase of slower growth of the cell population) and reaches a maximum in the stationary phase (idiophase). It is believed that at the beginning of stationary phase enzymatic status of the cells is changed , and inducers of secondary metabolism are appeared, releasing secondary metabolism genes from the influence of catabolite repression. Therefore, any mechanism, inhibiting cell proliferation and active growth or stress activate the formation of antibiotics.

RDBVMAH Biotech forages.pptx