b233c20eb286a758a5db0b9285cdd6fd.ppt

- Количество слайдов: 30

Bioremediation of PAHs-contaminated marsh soil by white-rot fungi Lara Valentín Carrera laralent@usc. es Chemical Engineering Department University of Santiago de Compostela July 14, 2005 Chemical Engineering Department VERTIMAR-2005

Bioremediation of PAHs by white rot fungi 1. Introduction 2. Objective 3. Screening of nine strains of white-rot fungi (WRF) 4. Time course degradation of PAHs 5. Effect of salinity on the enzymes activity 6. Slurry bioreactor 7. Conclusions July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

1. 1 What is bioremediation? July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

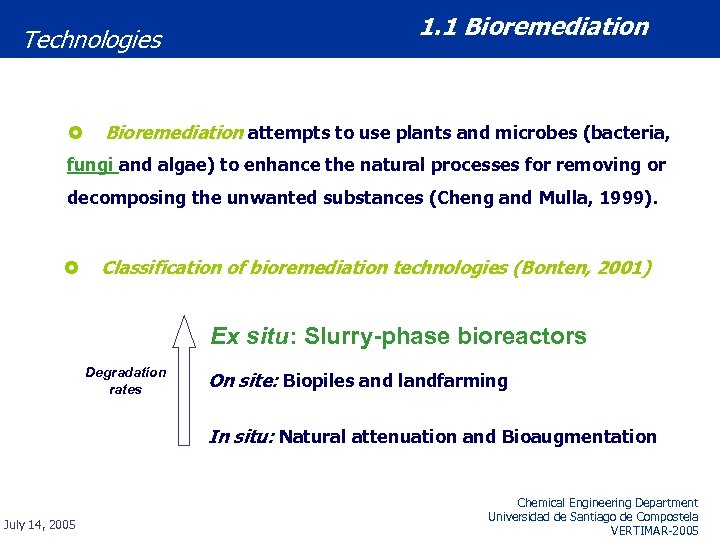

Technologies £ 1. 1 Bioremediation attempts to use plants and microbes (bacteria, fungi and algae) to enhance the natural processes for removing or decomposing the unwanted substances (Cheng and Mulla, 1999). £ Classification of bioremediation technologies (Bonten, 2001) Ex situ: Slurry-phase bioreactors Degradation rates On site: Biopiles and landfarming In situ: Natural attenuation and Bioaugmentation July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

Slurry-phase bioreactors 1. 1 Bioremediation £ Certain amount of water is added to the contaminated soil. The soil-water mixture is mixed and aerated. £ Solid content of 10 to 20 weight percentage. £ Operated continuously or semi-continuously. £ Aerobic conditions (frequently) or anaerobic. £ High contact microorganisms – contaminant. £ High mass transfer rates. £ High degradation rates. £ Constant control of the degradation process. July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

1. 2 Why white-rot fungi for bioremediation? July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

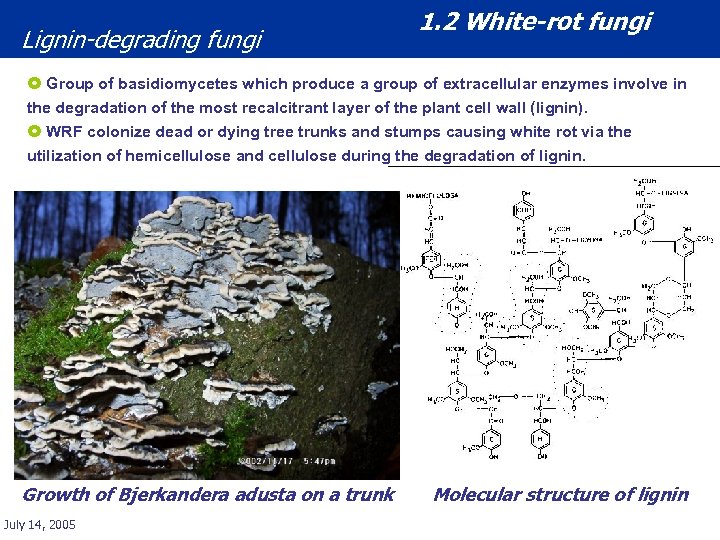

Lignin-degrading fungi 1. 2 White-rot fungi £ Group of basidiomycetes which produce a group of extracellular enzymes involve in the degradation of the most recalcitrant layer of the plant cell wall (lignin). £ WRF colonize dead or dying tree trunks and stumps causing white rot via the utilization of hemicellulose and cellulose during the degradation of lignin. Growth of Bjerkandera adusta on a trunk July 14, 2005 Molecular structure of lignin

Extracellular enzymes July 14, 2005 1. 2 White-rot fungi Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

Recalcitrant compounds July 14, 2005 1. 2 White-rot fungi Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

2. Objective July 14, 2005 Chemical Engineering Department Universidade de Santiago de Compostela VERTIMAR-2005

2. Objective £ To develop a slurry-phase bioreactor technology operated with white-rot fungi for the treatment of marine sites contaminated with fuel oil derivatives. £ The study was focused on the aromatic fraction of the fuel, especially on the PAHs since they have a recalcitrant and toxic nature. July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

3. Screening of nine strains of white-rot fungi July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

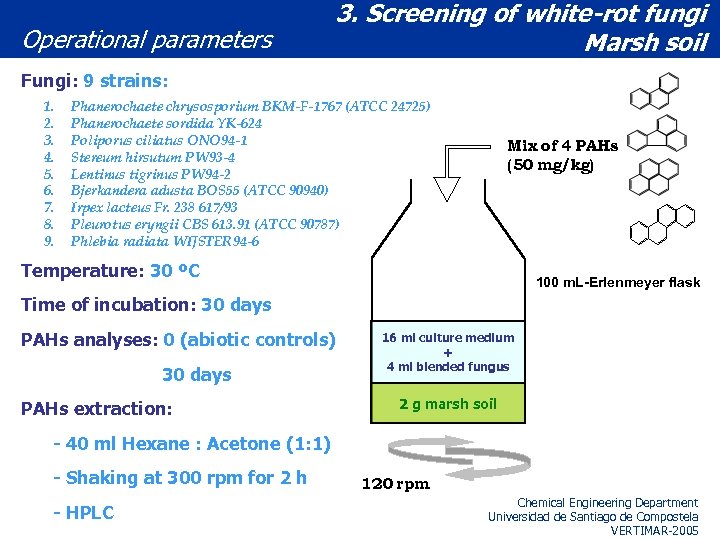

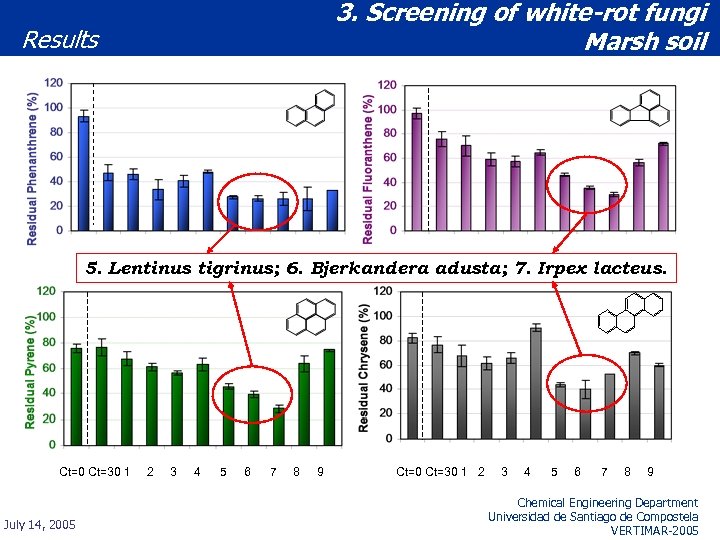

Operational parameters 3. Screening of white-rot fungi Marsh soil Fungi: 9 strains: 1. 2. 3. 4. 5. 6. 7. 8. 9. Phanerochaete chrysosporium BKM-F-1767 (ATCC 24725) Phanerochaete sordida YK-624 Poliporus ciliatus ONO 94 -1 Stereum hirsutum PW 93 -4 Lentinus tigrinus PW 94 -2 Bjerkandera adusta BOS 55 (ATCC 90940) Irpex lacteus Fr. 238 617/93 Pleurotus eryngii CBS 613. 91 (ATCC 90787) Phlebia radiata WIJSTER 94 -6 Mix of 4 PAHs (50 mg/kg) Temperature: 30 ºC 100 m. L-Erlenmeyer flask Time of incubation: 30 days PAHs analyses: 0 (abiotic controls) 30 days PAHs extraction: 16 ml culture medium + 4 ml blended fungus 2 g marsh soil - 40 ml Hexane : Acetone (1: 1) - Shaking at 300 rpm for 2 h - HPLC 120 rpm Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

3. Screening of white-rot fungi Marsh soil Results 5. Lentinus tigrinus; 6. Bjerkandera adusta; 7. Irpex lacteus. Ct=0 Ct=30 1 July 14, 2005 2 3 4 5 6 7 8 9 Ct=0 Ct=30 1 2 3 4 5 6 7 8 9 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

4. Time course degradation of PAHs July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

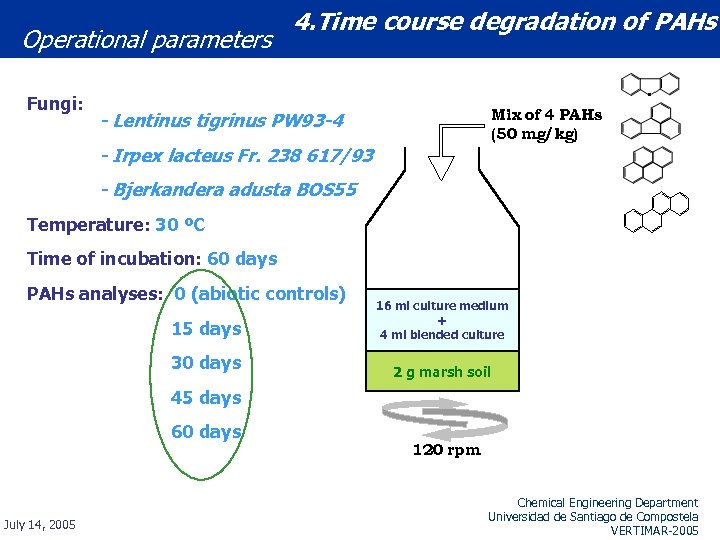

Operational parameters Fungi: 4. Time course degradation of PAHs Mix of 4 PAHs (50 mg/kg) - Lentinus tigrinus PW 93 -4 - Irpex lacteus Fr. 238 617/93 - Bjerkandera adusta BOS 55 Temperature: 30 ºC Time of incubation: 60 days PAHs analyses: 0 (abiotic controls) 15 days 30 days 16 ml culture medium + 4 ml blended culture 2 g marsh soil 45 days 60 days July 14, 2005 120 rpm Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

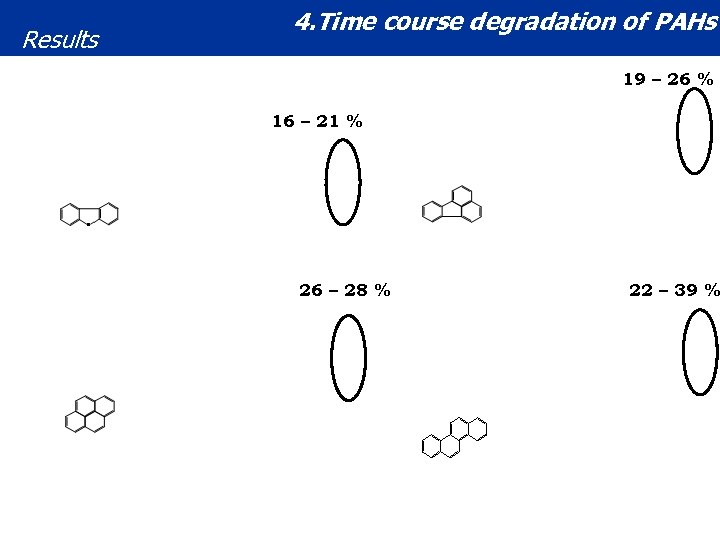

Results 4. Time course degradation of PAHs 19 – 26 % 16 – 21 % 26 – 28 % 22 – 39 %

5. Effect of salinity on the enzymes activity July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

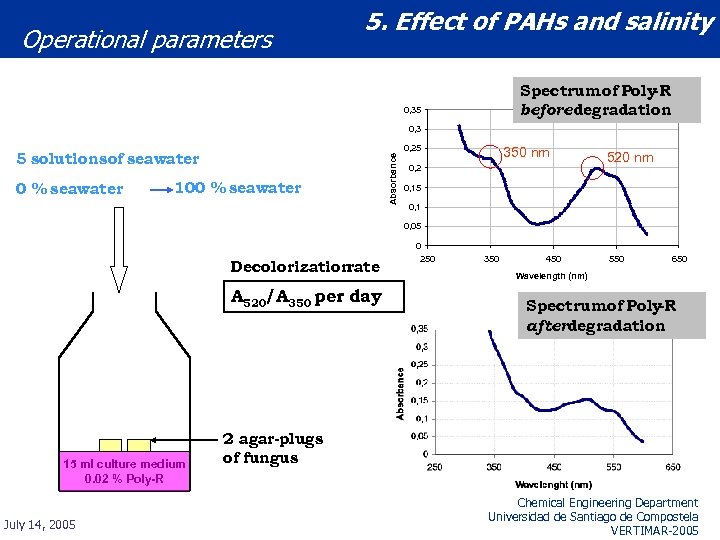

Operational parameters 5. Effect of PAHs and salinity Spectrum of Poly -R before degradation 0, 35 0, 3 0 % seawater 100 % seawater Absorbance 0, 25 5 solutionsof seawater 350 nm 0, 2 520 nm 0, 15 0, 1 0, 05 Decolorization rate A 520/A 350 per day 15 ml culture medium 0. 02 % Poly-R July 14, 2005 0 250 350 450 550 650 Wavelength (nm) Spectrum of Poly -R afterdegradation 2 agar-plugs of fungus Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

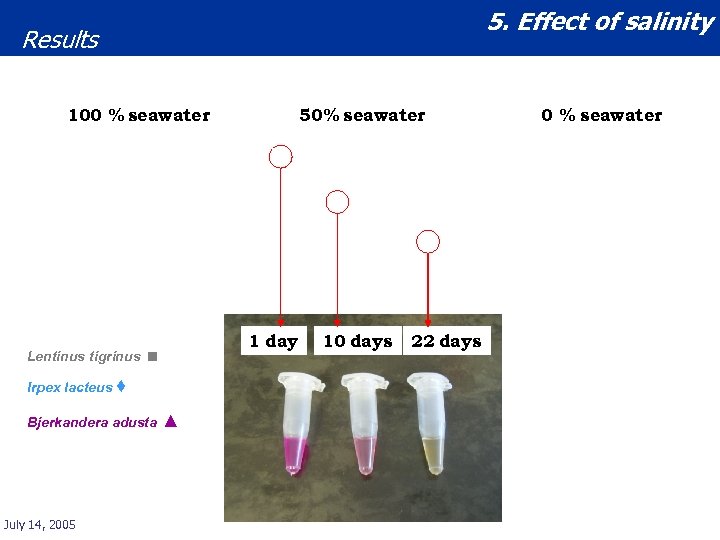

5. Effect of salinity Results 100 % seawater Lentinus tigrinus 1 day ■ Irpex lacteus ♦ Bjerkandera adusta July 14, 2005 50% seawater ▲ 10 days 22 days 0 % seawater

6. Slurry bioreactor July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

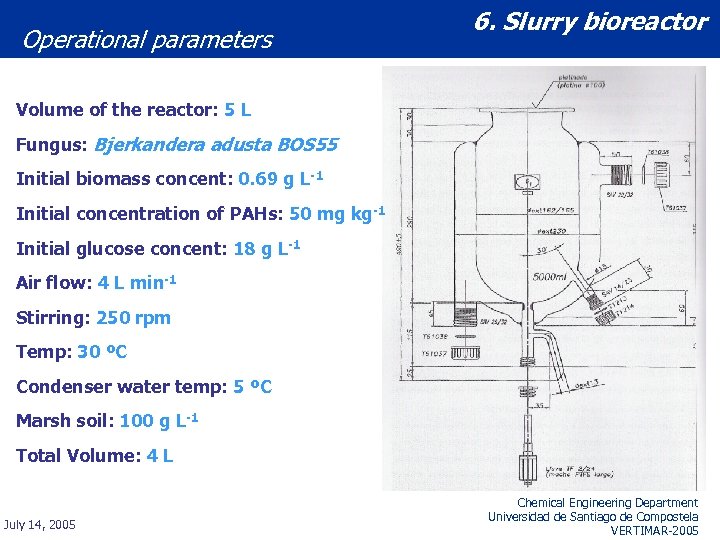

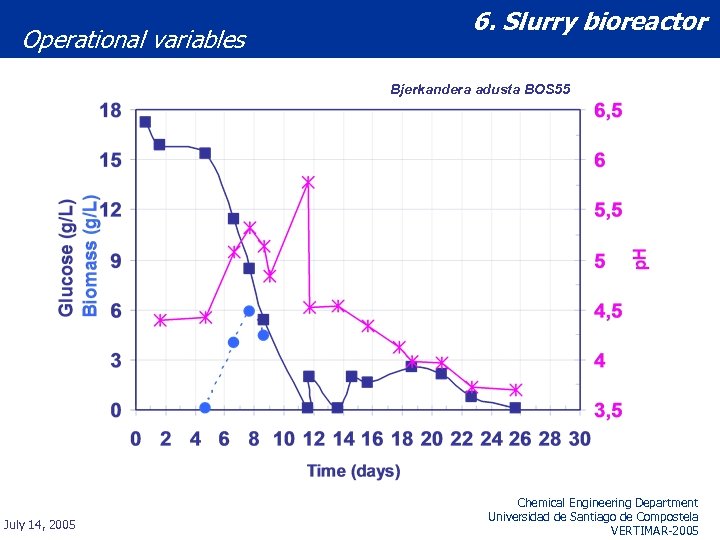

Operational parameters 6. Slurry bioreactor Volume of the reactor: 5 L Fungus: Bjerkandera adusta BOS 55 Initial biomass concent: 0. 69 g L-1 Initial concentration of PAHs: 50 mg kg-1 Initial glucose concent: 18 g L-1 Air flow: 4 L min-1 Stirring: 250 rpm Temp: 30 ºC Condenser water temp: 5 ºC Marsh soil: 100 g L-1 Total Volume: 4 L July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

Operational variables 6. Slurry bioreactor Bjerkandera adusta BOS 55 July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

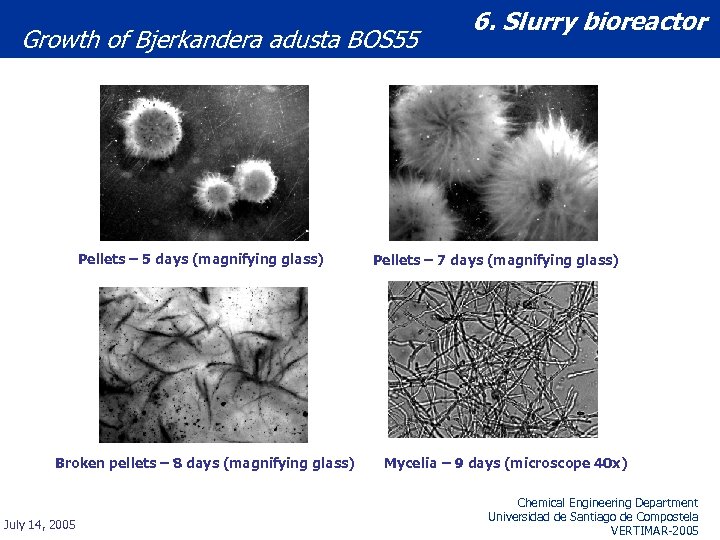

Growth of Bjerkandera adusta BOS 55 Pellets – 5 days (magnifying glass) Broken pellets – 8 days (magnifying glass) July 14, 2005 6. Slurry bioreactor Pellets – 7 days (magnifying glass) Mycelia – 9 days (microscope 40 x) Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

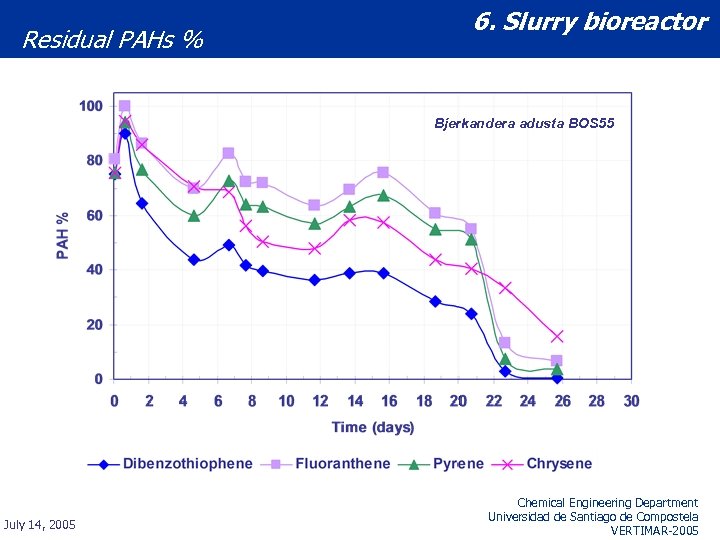

Residual PAHs % 6. Slurry bioreactor Bjerkandera adusta BOS 55 July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

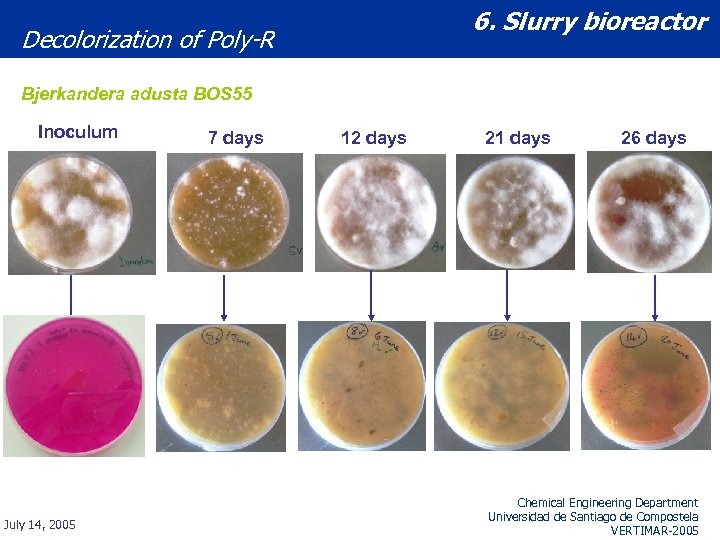

6. Slurry bioreactor Decolorization of Poly-R Bjerkandera adusta BOS 55 Inoculum July 14, 2005 7 days 12 days 21 days 26 days Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

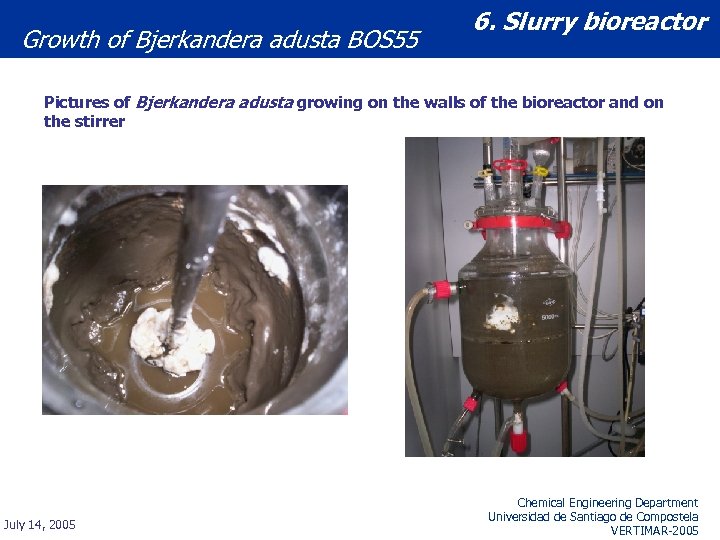

Growth of Bjerkandera adusta BOS 55 6. Slurry bioreactor Pictures of Bjerkandera adusta growing on the walls of the bioreactor and on the stirrer July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

7. Conclusions July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

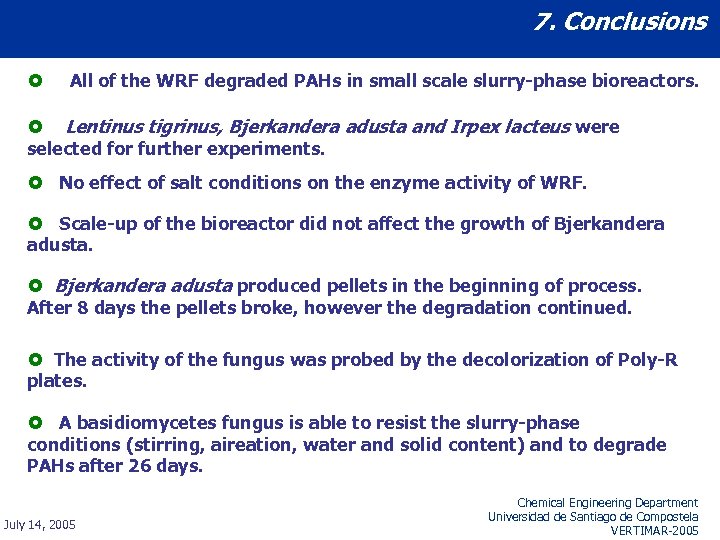

7. Conclusions £ All of the WRF degraded PAHs in small scale slurry-phase bioreactors. £ Lentinus tigrinus, Bjerkandera adusta and Irpex lacteus were selected for further experiments. £ No effect of salt conditions on the enzyme activity of WRF. £ Scale-up of the bioreactor did not affect the growth of Bjerkandera adusta. £ Bjerkandera adusta produced pellets in the beginning of process. After 8 days the pellets broke, however the degradation continued. £ The activity of the fungus was probed by the decolorization of Poly-R plates. £ A basidiomycetes fungus is able to resist the slurry-phase conditions (stirring, aireation, water and solid content) and to degrade PAHs after 26 days. July 14, 2005 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

Acknowledgements to Gumersindo Feijoo, Maria Teresa Moreira, Juan Manuel Lema, Thelmo Lú-Chau and Alanna Malcolm. CICYT: VEM 2003 -20089 -C 02 -01 Chemical Engineering Department Universidad de Santiago de Compostela VERTIMAR-2005

b233c20eb286a758a5db0b9285cdd6fd.ppt