5e895168db24adb11db065d559f0bc4f.ppt

- Количество слайдов: 46

Biomass Energy: A Crash Course Peter Flynn Poole Chair in Management for Engineers Dept. of Mechanical Engineering University of Alberta U of A Energy Club: February 2009 April 2006

Opening Thoughts Society will likely have limits on its willingness to spend given that the problem is in the future. n What we get for the dollar spent varies widely. n The head needs to help the heart get the most environmental benefit per dollar spent. n U of A Energy Club: February 2009 2

1. Biomass is Carbon Neutral n The carbon it emits is taken up in regrowth of the plant. n If the biomass was not converted, it would rot and make CO 2 anyway. n Hence, it displaces coal or oil. U of A Energy Club: February 2009 3

2. Alberta Has Lots of It n Straw and forest harvest residues are annual crops. n Straw alone could supply the next 25% of Alberta’s total power usage. U of A Energy Club: February 2009 4

2 A. And May Have Much More U of A Energy Club: February 2009 5

3. The Technology Exists Today: Power at Large Scale U of A Energy Club: February 2009 6

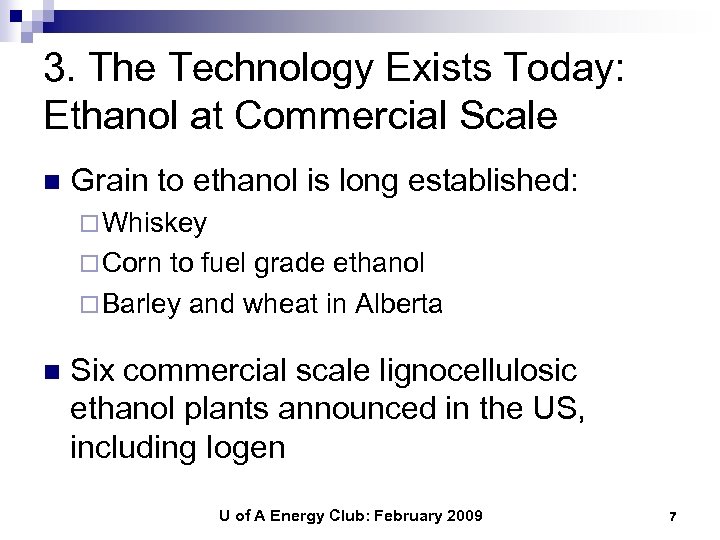

3. The Technology Exists Today: Ethanol at Commercial Scale n Grain to ethanol is long established: ¨ Whiskey ¨ Corn to fuel grade ethanol ¨ Barley and wheat in Alberta n Six commercial scale lignocellulosic ethanol plants announced in the US, including Iogen U of A Energy Club: February 2009 7

3 A. Whole Grain to Ethanol is a Poor Choice n Competition between food and fuel impacts the whole world. n Poor energy yield, high impact on soil and water quality. U of A Energy Club: February 2009 8

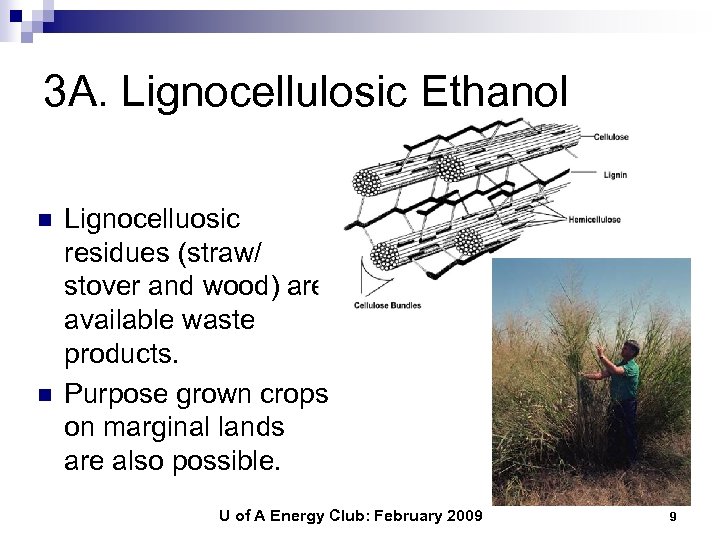

3 A. Lignocellulosic Ethanol n n Lignocelluosic residues (straw/ stover and wood) are available waste products. Purpose grown crops on marginal lands are also possible. U of A Energy Club: February 2009 9

4. Research Isn’t the Correct Prime Focus n Research can be misused as a tool to postpone difficult choices. n Technologies exist today. n Alberta has a particular need for action. U of A Energy Club: February 2009 10

5. Renewable Energy is not and never will be “Competitive” We have used fossil fuels because they are cheaper. n Competitiveness isn’t the key question: we are paying more for an environmental gain. Someone must pay. n The key objective is to buy the most greenhouse gas out of the atmosphere at the lowest extra cost. U of A Energy Club: February 2009 11

6. Technologies are Not Equal. . n The cost per unit of energy output and per tonne of avoided CO 2 eq varies widely with technology and plant size. Power from straw: ~$75 per MWh n Power from manure: ~$200 per MWh n The minimum screen for any technology is “how much grant per tonne of CO 2 avoided? U of A Energy Club: February 2009 12

And Can Be Studied in Detail n For each technology: ¨ What is the appropriate size of plant? ¨ How much CO 2 equivalent is avoided? n Life cycle analysis need not be the complicated barrier it has morphed into. ¨ How much extra does someone pay compared to a business as usual case. Minimizing extra $ per tonne of avoided emission is the right metric. U of A Energy Club: February 2009 13

7. There is an Optimum Size; it is Large n Three elements to producing useful energy from biomass: ¨ Get the biomass ¨ Move it to site ¨ Process it n Processing cost decreases with size, transport cost increases. U of A Energy Club: February 2009 14

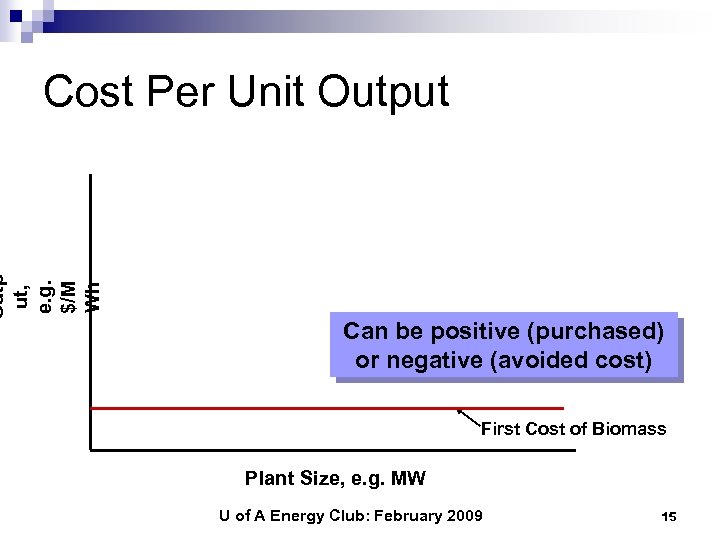

Outp ut, e. g. $/M Wh Cost Per Unit Output Can be positive (purchased) or negative (avoided cost) First Cost of Biomass Plant Size, e. g. MW U of A Energy Club: February 2009 15

Biomass Transportation by Truck n Costs include: ¨ Loading and unloading: distance fixed. ¨ Shipping: distance (scale) variable. Typical values are $5 per tonne (distance fixed) and $0. 09 per tonne km (one way) (distance variable). n Increases ~ with (scale)1/2. n U of A Energy Club: February 2009 16

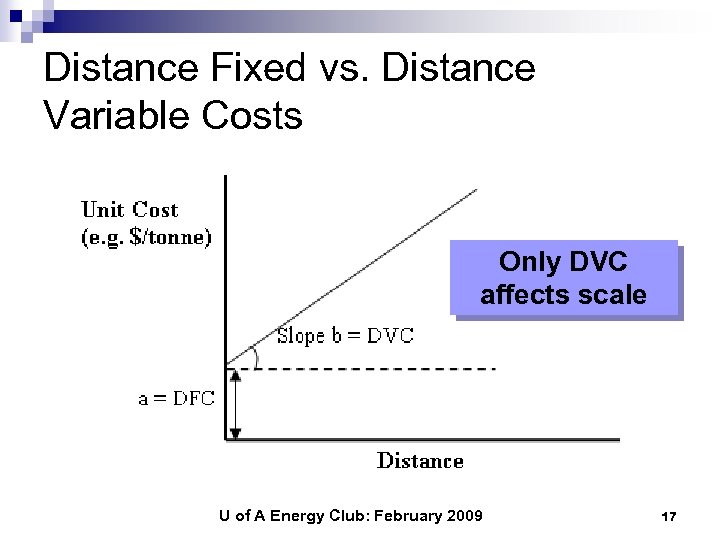

Distance Fixed vs. Distance Variable Costs Only DVC affects scale U of A Energy Club: February 2009 17

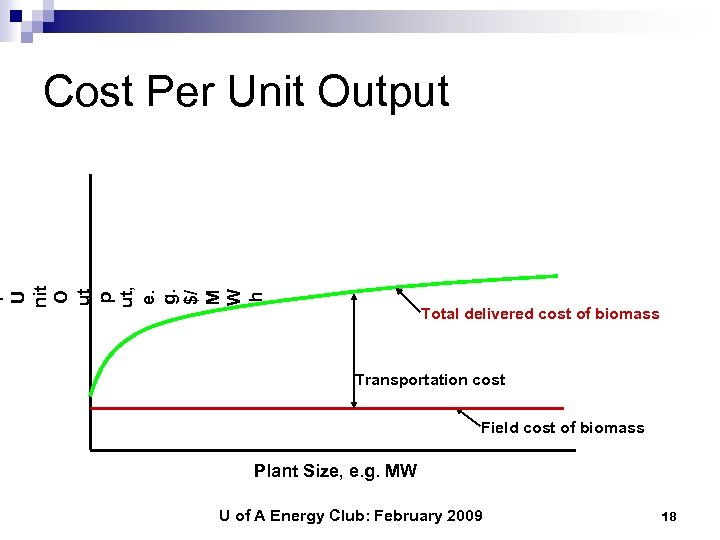

r U nit O ut p ut, e. g. $/ M W h Cost Per Unit Output Total delivered cost of biomass Transportation cost Field cost of biomass Plant Size, e. g. MW U of A Energy Club: February 2009 18

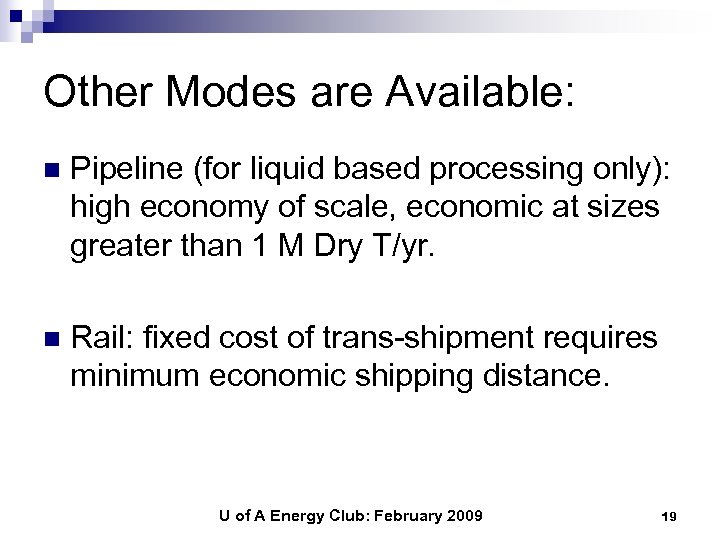

Other Modes are Available: n Pipeline (for liquid based processing only): high economy of scale, economic at sizes greater than 1 M Dry T/yr. n Rail: fixed cost of trans-shipment requires minimum economic shipping distance. U of A Energy Club: February 2009 19

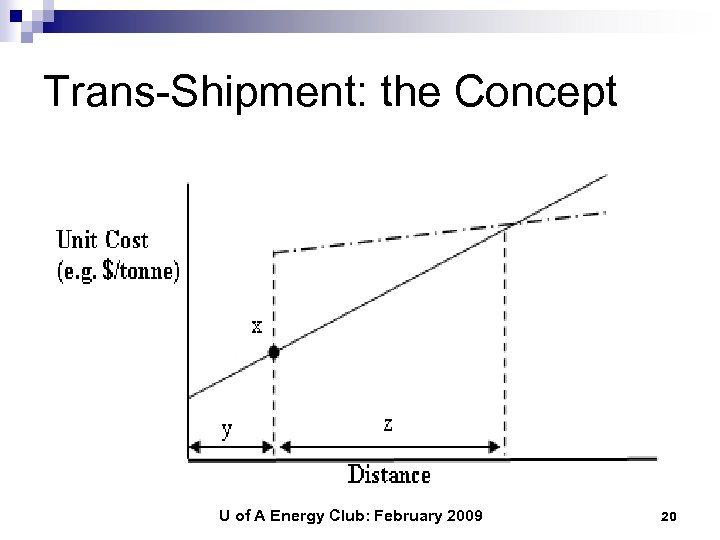

Trans-Shipment: the Concept U of A Energy Club: February 2009 20

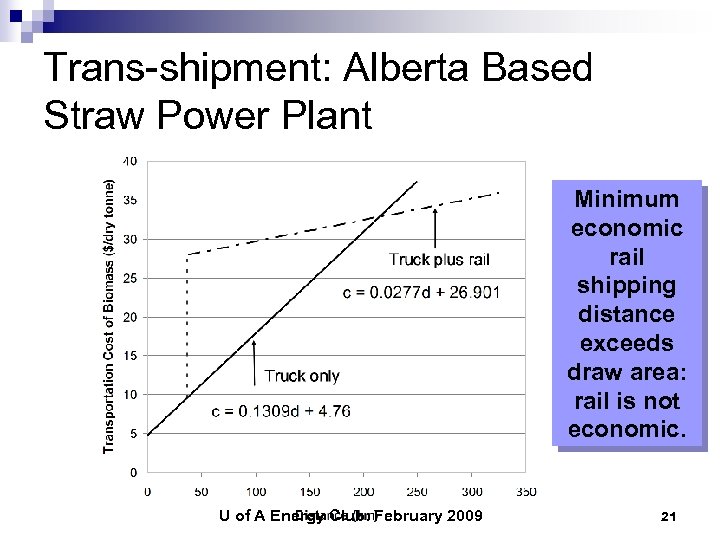

Trans-shipment: Alberta Based Straw Power Plant Minimum economic rail shipping distance exceeds draw area: rail is not economic. U of A Energy Club: February 2009 21

Biomass Processing: Use It Economy of scale in capital equipment and operating costs, typical scale factors in the range of 0. 6 to 0. 8. n All evidence is that scale factor is valid up to very large processing sizes (>500 MW); road congestion limit is the prior constraint if delivery by truck. n U of A Energy Club: February 2009 22

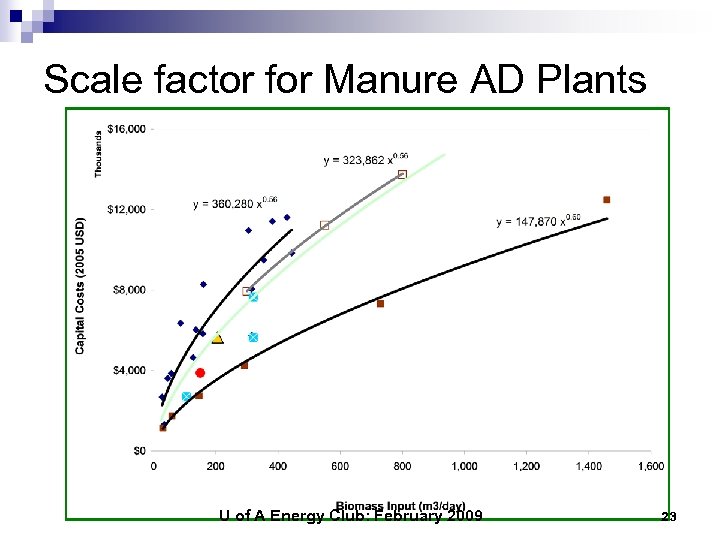

Scale factor for Manure AD Plants U of A Energy Club: February 2009 23

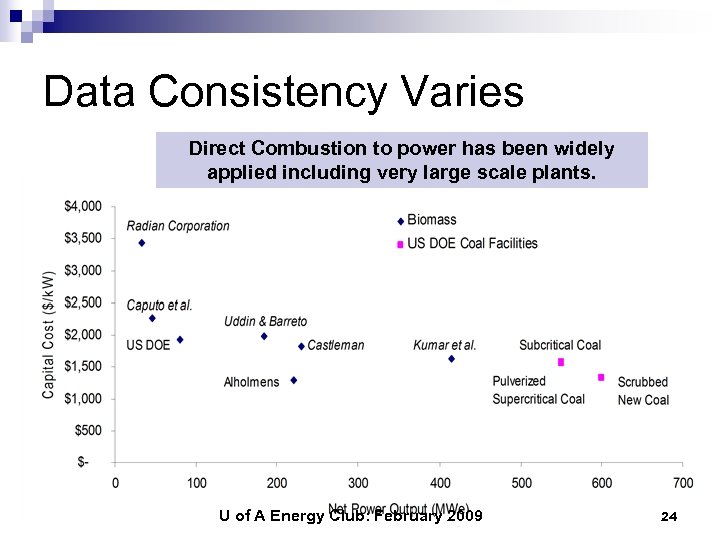

Data Consistency Varies Direct Combustion to power has been widely applied including very large scale plants. U of A Energy Club: February 2009 24

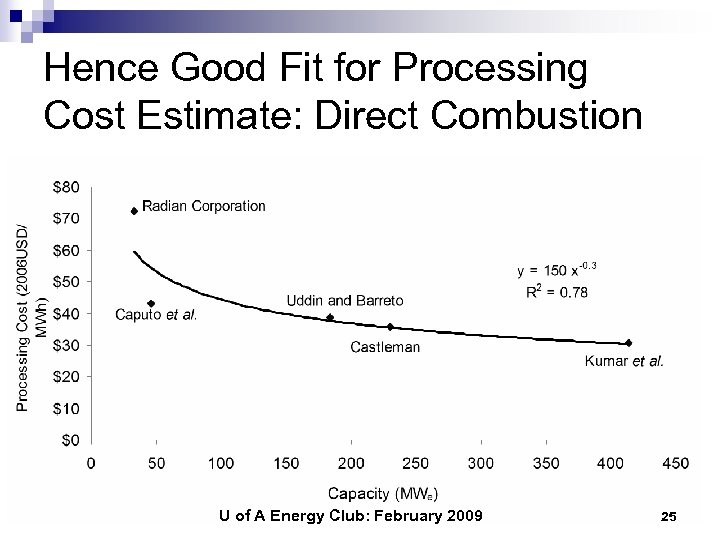

Hence Good Fit for Processing Cost Estimate: Direct Combustion U of A Energy Club: February 2009 25

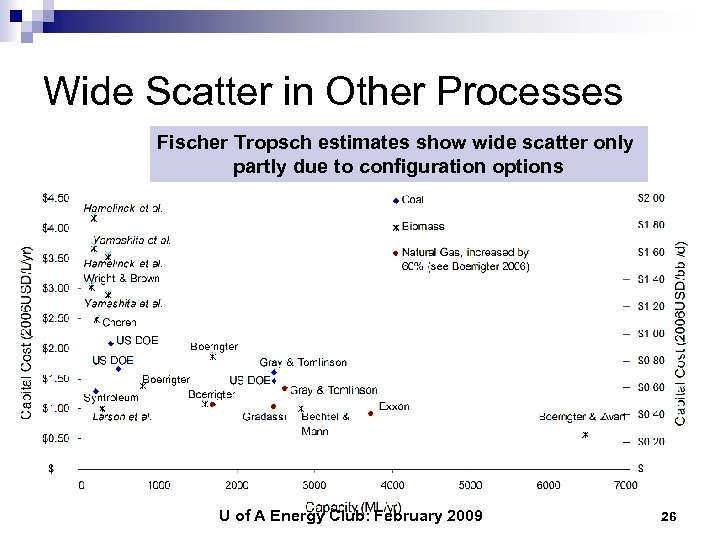

Wide Scatter in Other Processes Fischer Tropsch estimates show wide scatter only partly due to configuration options U of A Energy Club: February 2009 26

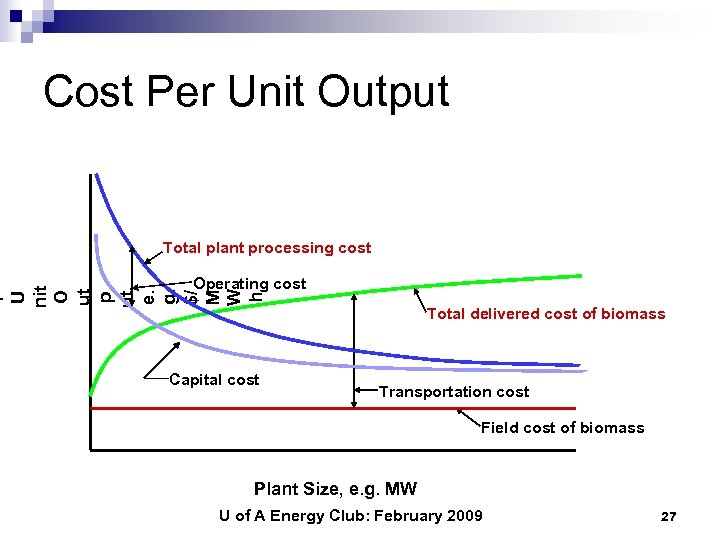

Cost Per Unit Output Total plant processing cost r U nit O ut p ut, e. g. $/ M W h Operating cost Capital cost Total delivered cost of biomass Transportation cost Field cost of biomass Plant Size, e. g. MW U of A Energy Club: February 2009 27

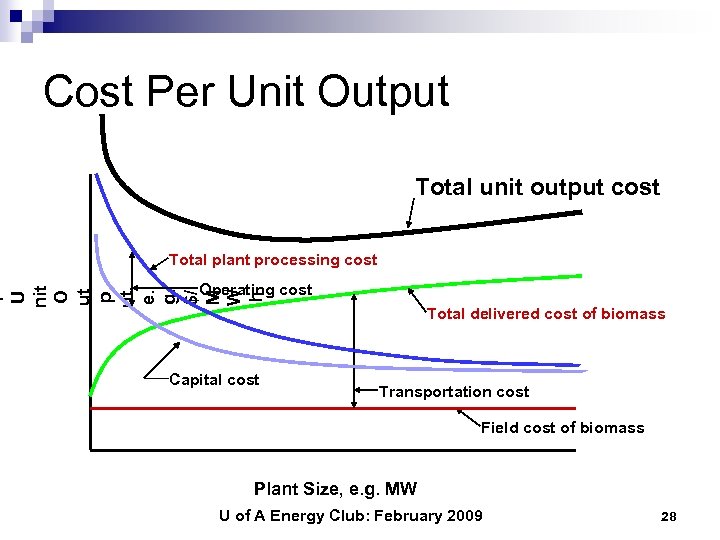

Cost Per Unit Output Total unit output cost Total plant processing cost r U nit O ut p ut, e. g. $/ M W h Operating cost Capital cost Total delivered cost of biomass Transportation cost Field cost of biomass Plant Size, e. g. MW U of A Energy Club: February 2009 28

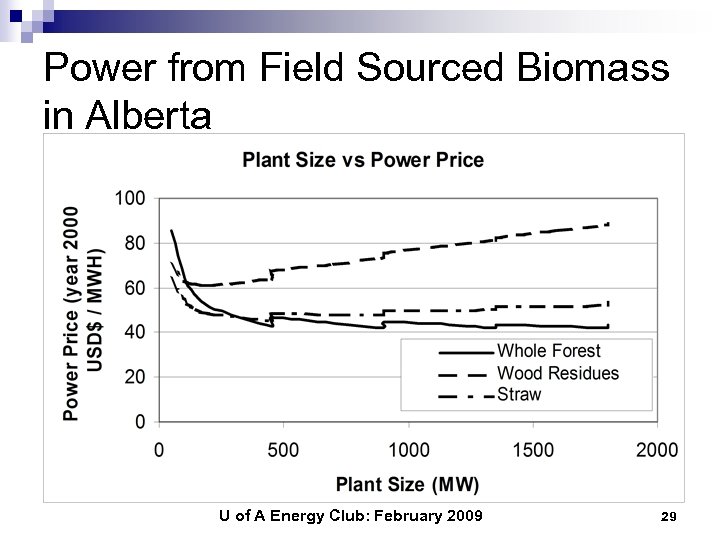

Power from Field Sourced Biomass in Alberta U of A Energy Club: February 2009 29

Optimum Size n Increases with increasing processing cost n Increases with increasing biomass availability n Is neutral to the field cost of biomass U of A Energy Club: February 2009 30

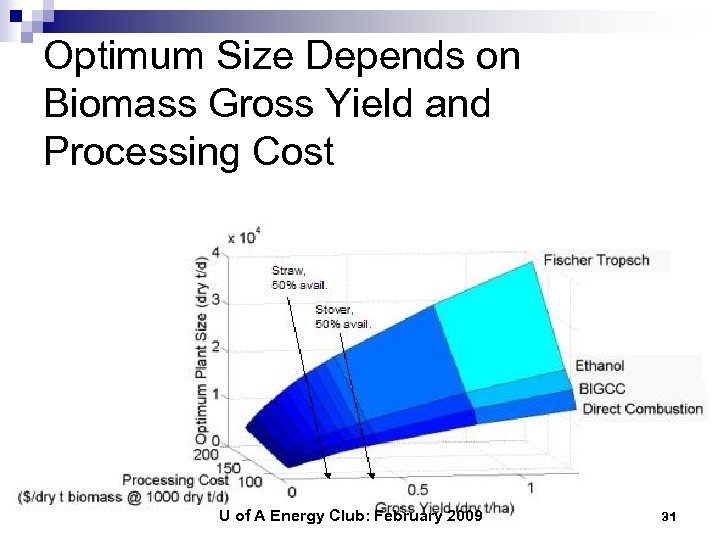

Optimum Size Depends on Biomass Gross Yield and Processing Cost U of A Energy Club: February 2009 31

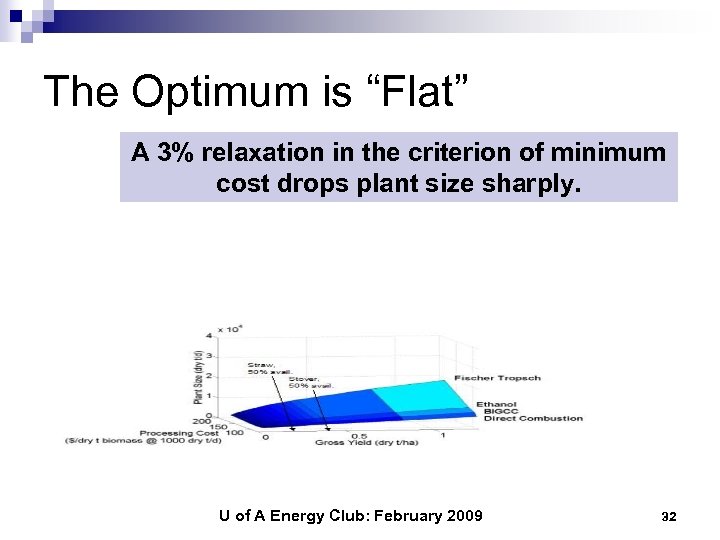

The Optimum is “Flat” A 3% relaxation in the criterion of minimum cost drops plant size sharply. U of A Energy Club: February 2009 32

50% of Optimum Size Has Minimal Impact, But the Cost Climbs Sharply Thereafter n Power from straw in Alberta: n $75 per MWh at optimum (330 MW net) n $77 per MWh at 50% of optimum n $100 per MWh at 25% of optimum n $125 per MWh at 10% of optimum n $145 per MWh at 5% of optimum U of A Energy Club: February 2009 33

Power from Field Sourced Biomass in Alberta n Straw to Power: >150 MW n FHR to Power: >100 MW n Lignocellulosic Ethanol: >3000 TPD n Power from Manure: county wide plant. U of A Energy Club: February 2009 34

8. Life Cycle Analysis of Emissions For most biomass plants the replacement of fossil fuel is the overwhelming contributor. n Processing related emissions tend to equalize. n Transport and refining are relatively small and estimates vary widely. n U of A Energy Club: February 2009 35

LCA Values, CO 2 eq Base load power vs. coal: 830 g/h. Wh, 1350 g/dry tonne of biomass. n Ethanol or diesel: 2000 – 2400 g/l, 600 g/dry tonne of biomass. n Power from manure (methane avoidance a factor): 900 g/k. Wh. n U of A Energy Club: February 2009 36

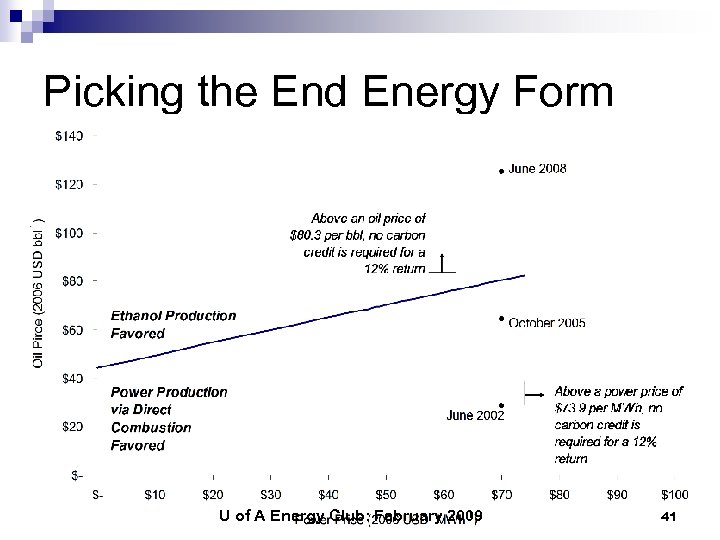

9. Put Cost and Avoided Emissions Together n How much extra does someone (the consumer or taxpayer) pay? n How much emission is avoided. n Pick the most cost effective process. U of A Energy Club: February 2009 37

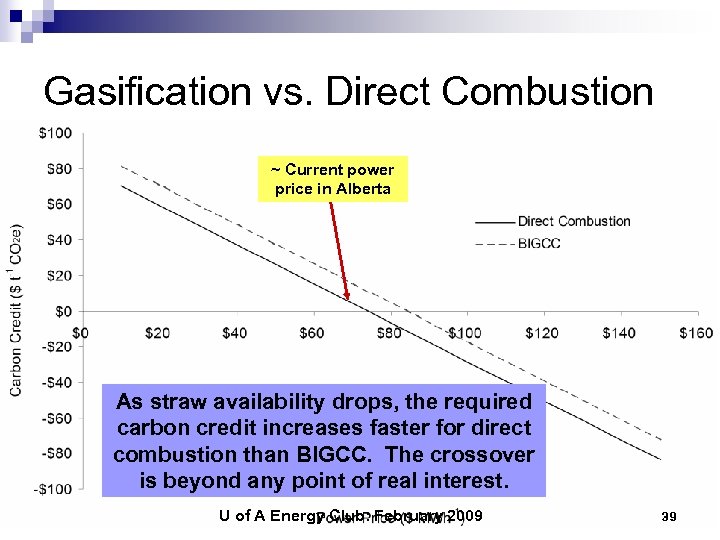

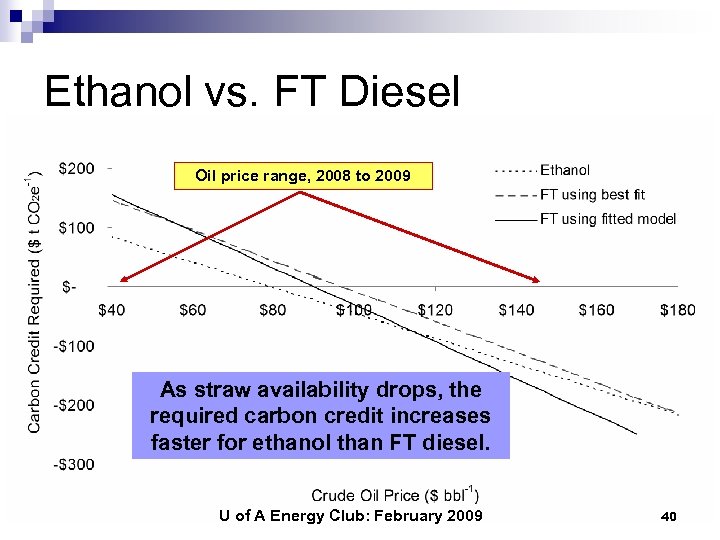

Two key technology questions For a given end form of energy, e. g. power or transportation fuel, what is the most efficient technology. (This will depend on the abundance of biomass, since low availability = higher delivered cost). n Between two end forms of energy, what should I pick. n U of A Energy Club: February 2009 38

Gasification vs. Direct Combustion ~ Current power price in Alberta As straw availability drops, the required carbon credit increases faster for direct combustion than BIGCC. The crossover is beyond any point of real interest. U of A Energy Club: February 2009 39

Ethanol vs. FT Diesel Oil price range, 2008 to 2009 As straw availability drops, the required carbon credit increases faster for ethanol than FT diesel. U of A Energy Club: February 2009 40

Picking the End Energy Form U of A Energy Club: February 2009 41

Some Cautions Some technologies are far better demonstrated than others, hence more confidence in cost. n All cost estimates rely on pre 2006 references, and hence miss the upswing in equipment and labor cost. The future of these costs is uncertain. n U of A Energy Club: February 2009 42

10. Policy Comes in Good and Bad Flavors n Jurisdictions around the world are wrestling with how to integrate a more expensive form of energy into an existing energy economy. n Some do it better than others. U of A Energy Club: February 2009 43

Bad Policy n “Man on the moon” targets obscure social costs. n Short term “up front” payments. n Higher payment to small scale projects. n Doing everything with every source (makes as much sense as making electricity from gasoline). U of A Energy Club: February 2009 44

Good Policy n Does not, for a global warming target, specify the end product of bioenergy. n Is long term n Allows competition between projects to meet a social goal at the lowest cost. n Identifies the cost per tonne of avoided CO 2 eq. U of A Energy Club: February 2009 45

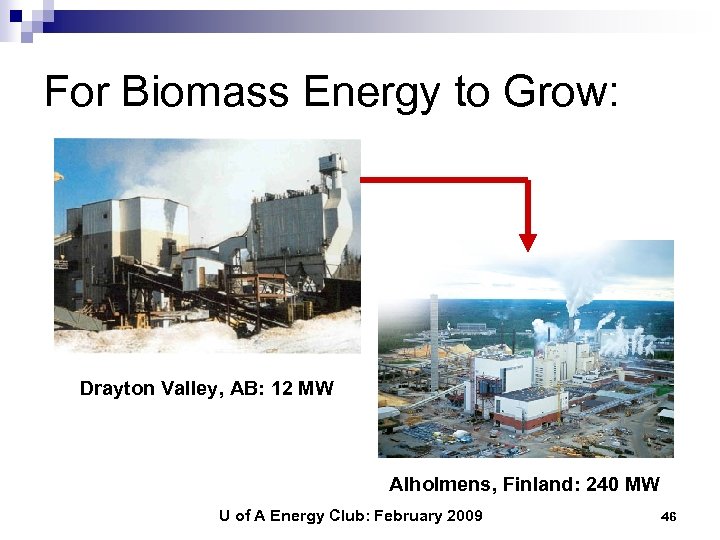

For Biomass Energy to Grow: Drayton Valley, AB: 12 MW Alholmens, Finland: 240 MW U of A Energy Club: February 2009 46

5e895168db24adb11db065d559f0bc4f.ppt