8c2c75043bbe52ca04f87280fe5defdf.ppt

- Количество слайдов: 34

Biofouling formation and remedial measures

introduction a. Biofouling is the undesirable accumulation of microorganisms, plants, algae, and/or animals on wetted structures. b. Biofouling is one of the most important problems currently facing marine technology. In the marine environment any solid surface will become fouled. c. Marine and freshwater biofouling is one of the major unsolved problems currently affecting the shipping industry and industrial aquatic processes. d. Marine biofouling commonly refers to the adverse growth of marine organisms on immersed artificial structures such as ship hulls, jetty pilings, navigational instruments, aquaculture net cages and seawater in taking pipes

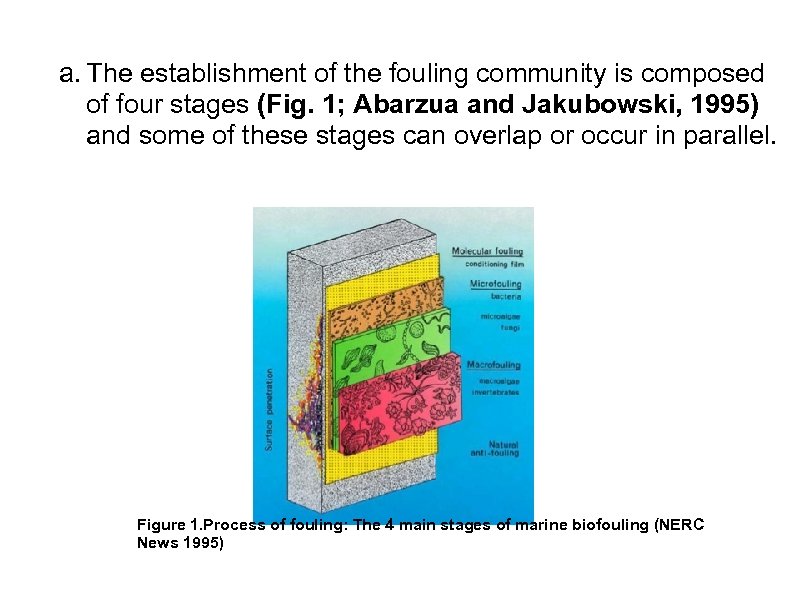

a. The establishment of the fouling community is composed of four stages (Fig. 1; Abarzua and Jakubowski, 1995) and some of these stages can overlap or occur in parallel. Figure 1. Process of fouling: The 4 main stages of marine biofouling (NERC News 1995)

Formation of biofouling a. Biofouling is not as simple a process as it sounds. Organisms do not usually simply suck onto a substrate like a suction cup. The complex process often begins with the production of a biofilm.

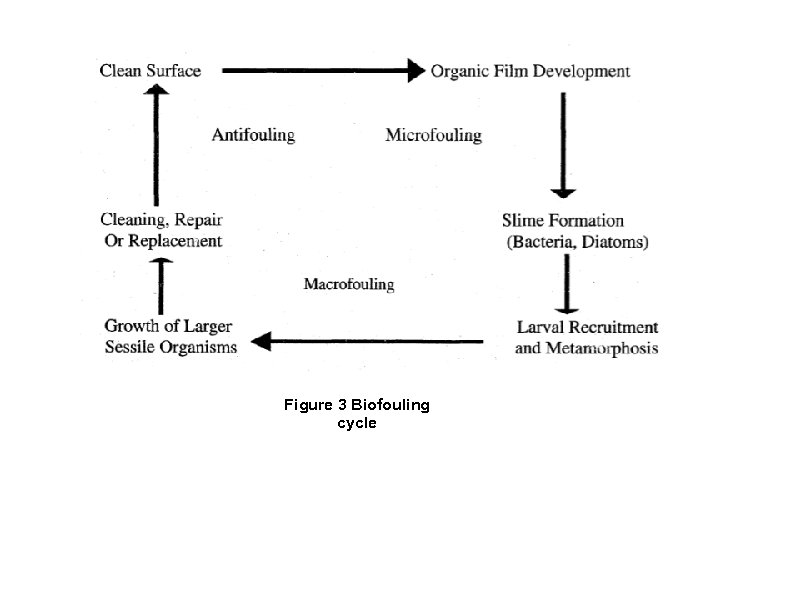

Figure 3 Biofouling cycle

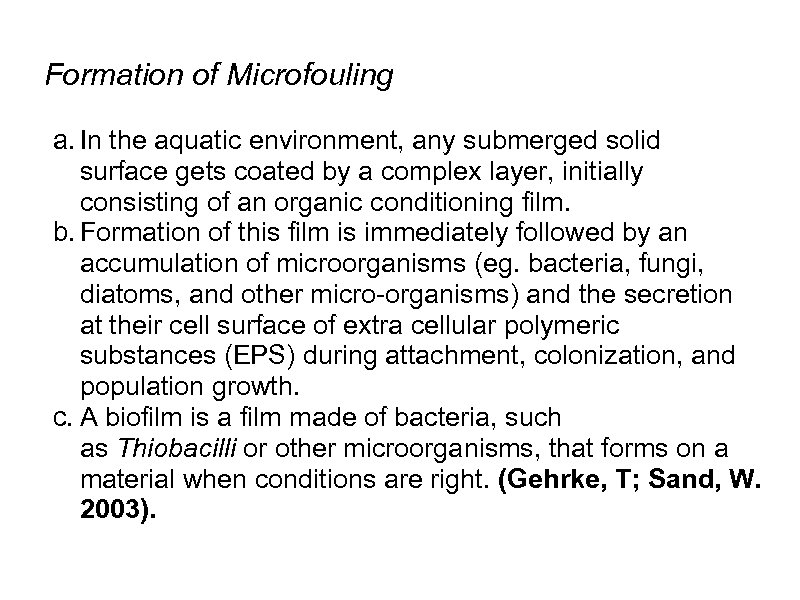

Formation of Microfouling a. In the aquatic environment, any submerged solid surface gets coated by a complex layer, initially consisting of an organic conditioning film. b. Formation of this film is immediately followed by an accumulation of microorganisms (eg. bacteria, fungi, diatoms, and other micro-organisms) and the secretion at their cell surface of extra cellular polymeric substances (EPS) during attachment, colonization, and population growth. c. A biofilm is a film made of bacteria, such as Thiobacilli or other microorganisms, that forms on a material when conditions are right. (Gehrke, T; Sand, W. 2003).

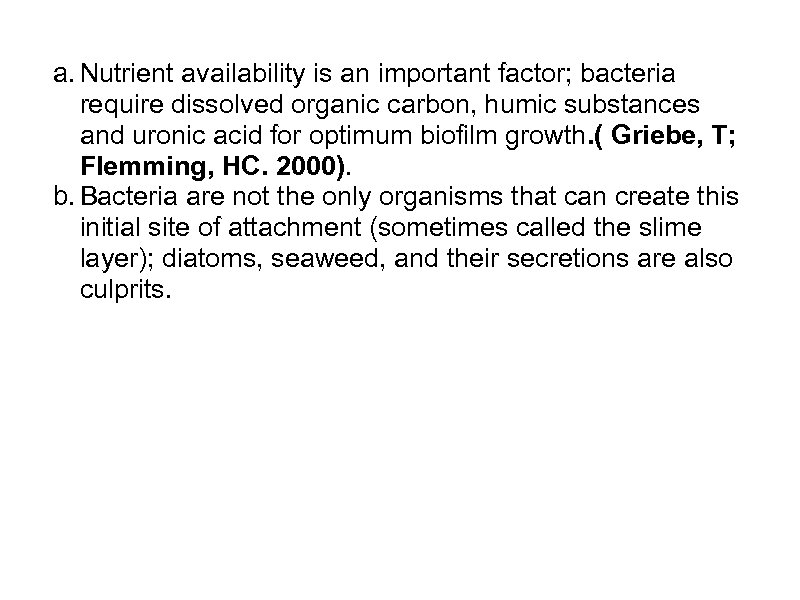

a. Nutrient availability is an important factor; bacteria require dissolved organic carbon, humic substances and uronic acid for optimum biofilm growth. ( Griebe, T; Flemming, HC. 2000). b. Bacteria are not the only organisms that can create this initial site of attachment (sometimes called the slime layer); diatoms, seaweed, and their secretions are also culprits.

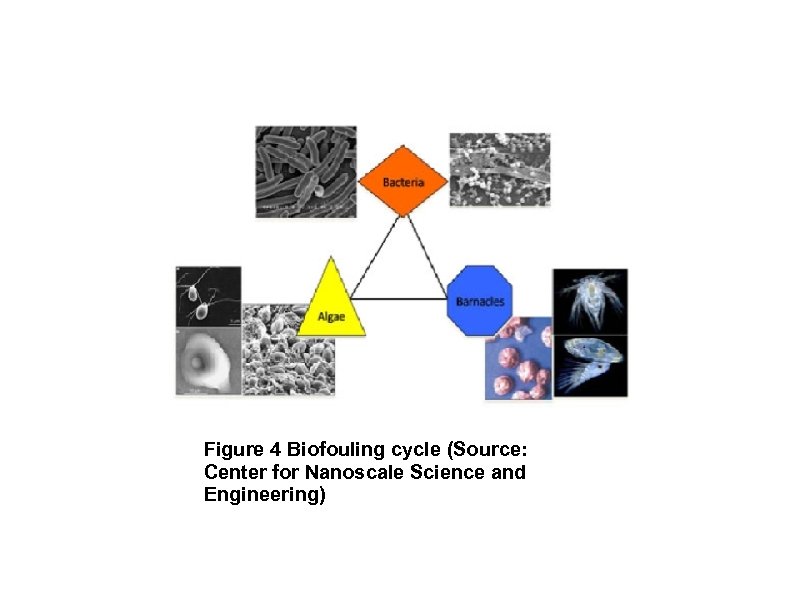

Figure 4 Biofouling cycle (Source: Center for Nanoscale Science and Engineering)

Formation of macrofouling a. A macrofouling community consisting of either 'soft fouling' or 'hard fouling’ may develop and overgrow the microfouling. b. Soft fouling comprises algae and invertebrates, such as soft corals, sponges, anemones, tunicates and hydroids. • Hard fouling comprises invertebrates such as barnacles, mussels and tubeworms, bryazons and seaweeds (Callow and Callow 2002).

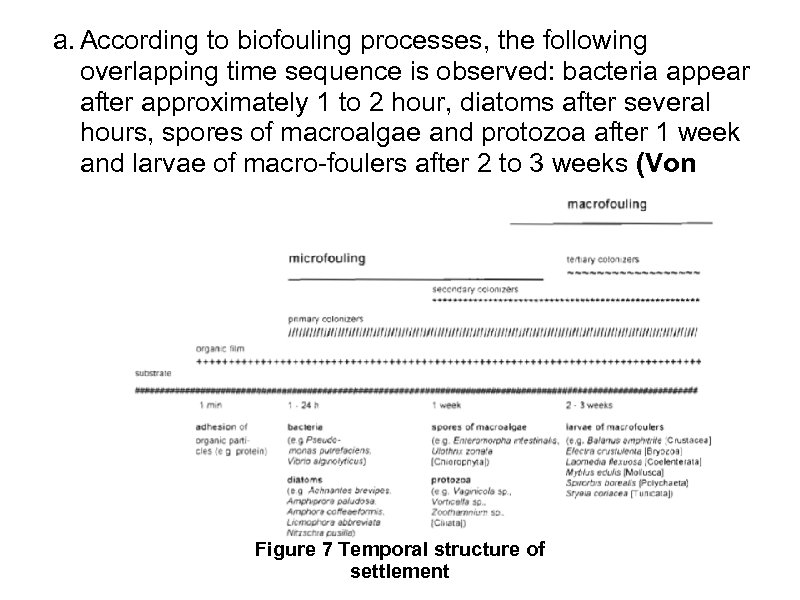

a. According to biofouling processes, the following overlapping time sequence is observed: bacteria appear after approximately 1 to 2 hour, diatoms after several hours, spores of macroalgae and protozoa after 1 week and larvae of macro-foulers after 2 to 3 weeks (Von Oertzen et al. , 1989). Figure 7 Temporal structure of settlement

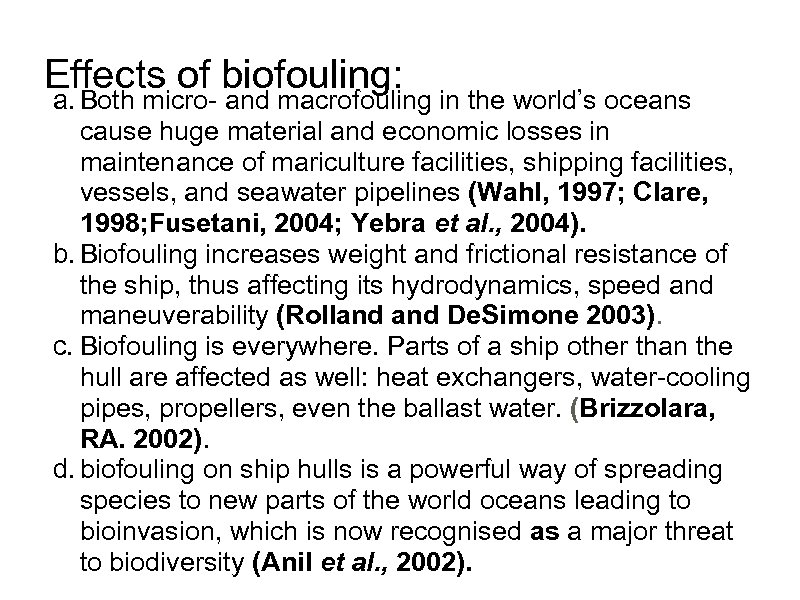

Effects of biofouling: a. Both micro- and macrofouling in the world’s oceans cause huge material and economic losses in maintenance of mariculture facilities, shipping facilities, vessels, and seawater pipelines (Wahl, 1997; Clare, 1998; Fusetani, 2004; Yebra et al. , 2004). b. Biofouling increases weight and frictional resistance of the ship, thus affecting its hydrodynamics, speed and maneuverability (Rolland De. Simone 2003). c. Biofouling is everywhere. Parts of a ship other than the hull are affected as well: heat exchangers, water-cooling pipes, propellers, even the ballast water. (Brizzolara, RA. 2002). d. biofouling on ship hulls is a powerful way of spreading species to new parts of the world oceans leading to bioinvasion, which is now recognised as a major threat to biodiversity (Anil et al. , 2002).

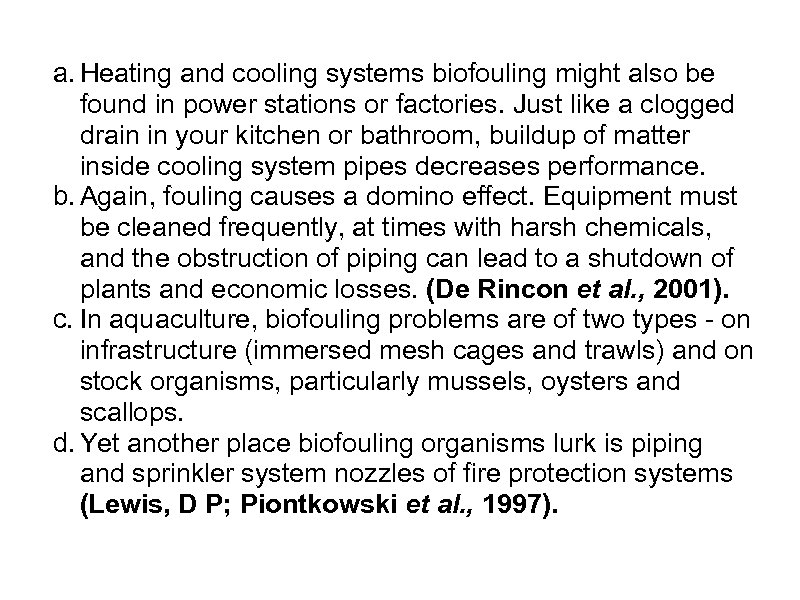

a. Heating and cooling systems biofouling might also be found in power stations or factories. Just like a clogged drain in your kitchen or bathroom, buildup of matter inside cooling system pipes decreases performance. b. Again, fouling causes a domino effect. Equipment must be cleaned frequently, at times with harsh chemicals, and the obstruction of piping can lead to a shutdown of plants and economic losses. (De Rincon et al. , 2001). c. In aquaculture, biofouling problems are of two types - on infrastructure (immersed mesh cages and trawls) and on stock organisms, particularly mussels, oysters and scallops. d. Yet another place biofouling organisms lurk is piping and sprinkler system nozzles of fire protection systems (Lewis, D P; Piontkowski et al. , 1997).

Remedial measures of Biofouling a. Physical method b. Chemical method c. Biological method

Physical method a. The simplest method for treatment of fouling is simply to remove by mechanical cleaning eg, by treatment of the fouled surface with high-pressure water jets (Granhag et al. , 2004). b. scraping

Disadvantages a. Costly b. Time consuming c. Less effective d. Not easily applicable to everywhere

Chemical method a. TBT b. Copper c. UV irritation d. Chlorination e. Titanium alloys(2 m/sec ) f. Silicone elastomers (for fast vessels)

DISADVANTAGES a. Evidence of adverse effects of TBT prompted the International Marine Organization to call for a ban on the application of TBT based antifouling paints from 2003 and the presence of such paints on the surface of ships from the year 2008. b. some want to eliminate copper-based coatings, claiming they are responsible for the same negative effects as TBT. c. These are not organism specific.

Biological method a. There may be no greater way to fight nature than with nature itself. b. The disadvantages of physical and chemical methods we need the help of natural source for producing ecofriendly antifouling compounds. c. Several kinds of natural antifouling agents that inhibit growth of fouling orgonisms have been isolated from marine organisms like bacteria (Holrnstrom et al. , 1996), marine algae (Abarzua et al. , 1999, de Nys et al. , 1996, Eng-Wilmot et al. , 1979, Gross et al. , 1991, Hellio et al. , 2002, Ishida 2000, Murakami et al. , 199 1, Wu et al. , 1998), sponges (Mokashe et al. , 1994, Thakur 2001), coelenterates (Davis et al. , 1989, Targett et al. , 1983, Targett 1988), holothurians (Mokashe et al. , 1994) and ascidians (Thakur 2001).

a. The new diterpene methoxy-ent-8(14)-pimarenely-15 -one and the three known metabolites ent-8(14)-pimarene-15 R, 16 -Diol, stigmasterol, ß-sitosterol from the mangrove plant Ceriops tagal (Chen et al. , 2008). Diterpenes from brown sea weed Canistrocarpus cervicornis also act as antifoulant metabolites (Bian co et al. , 2009). b. Diterpene from Brazilian brown alga Dictyota pfafii (Barbosa et al. , 2007). c. Two antifouling compounds 3 -methyl-N-(2 -Phenylethyl) butanamide and cyclo (D-Pro-D-Phe) from Letendraea helminthicola, a sponge associated fungus (Yang et al. , 2007). d. Vibrio biofilm formation inhibited by a marine actinomycete A 66 (You et al. , 2007). e. The sesquiterpene hydroquinone avarol was isolated from the marine sponge Dysidea avara.

a. whereas the corresponding quinone, avarone was obtained by oxidation of avarol toxic against the settlement of the cyprid stage of Balanus amphitrite, and for their growth inhibitory activity on fouling micro and macroorganisms. (Tsoukatou et al. , 2007).

conclusion a. Bio fouling remedial measures move towards nontoxic antifoulants. b. Marine lives such as corals, sponges, marine plants, and dolphins, etc. , prevent the surface of their bodies with antifouling substances without causing serious environmental problems. c. Therefore, these substances may be expected to be used, as new environmental friendly antifouling agents, especially those having highly anesthetic, repellent, and settlement inhibitory properties, etc. , without showing biocidal properties, are desirable.

a. Many of the antifouling substances are found from these marine animals, marine plants and microorganisms. b. Natural products antifoulants consist mainly of five kinds of compound such as terpenes, nitrogen-containing compounds, phenols, steroids and others. c. These are produced from sponges, corals, starfishes, mussels, algae, terrestrial plants, etc. These compounds are considered to play an important role in the antifouling mechanism of marine organisms (Omae, 2006). d. Microorganisms from the marine environment are less exploited for producing environmental friendly antifouling compounds.

a. In future, we expect to utilize some natural products, their synthetic derivatives or their mixtures as ecofriendly antifouling agents. b. Using natural methods may be more cost effective than specialized coatings, materials, or techniques. c. These industries' research might serve to overcome the still-common misconception that businesses cannot remain profitable without harming the environment. d. Research is still needed to determine the exact method of applying this knowledge.

reference a. b. c. d. e. f. g. h. i. j. k. Abarzua S, Jakubowski S, (1995) Biotechnological investigation for the prevention of biofouling. I. Biological and biochemical principles for the prevention of biofouling. Marine Ecology Progress Series, 123: 301 -312 Anderson, J M; Cima, M J; Langer, R; Shawgo, R S; Shive, M S; von Recum, H; Voskerician, G. (2003) Biocompatibility and biofouling of MEMS drug delivery devices. Biomaterials 24 (11), p. 1959 -67; Anderson, C. 2002. TBT-Free Anti-Fouling Coatings IN 2003 For Better Or For Worse? Corrosion Management vol. 40, pp. 21 -24 Baier RE (1984) Initial events in microbial film formation. In: Costlow JD, Tipper RC (eds) Marine biodeterioration: an interdisciplinary study. E & FN Spon Ltd. London, p 57 -62 Baier RE, Meyer AE, De. Palma VA, King RW, Fornalik MS (1983) Surface microfouling during the induction period. Journal of Heat Transfer-Transactions of the Asme, 105, 618 -62 Bakus GJ, Targett NM, Schulte B (1986) Chemical ecology of marine organisms: an overview. Journal of Chemical Ecology, 12: 951 -987 Barbosa, J. P. , B. G. Fleury, B. A. P. D. Gama, V. L. Teixeira, R. C. Pereira. (2007) Naturalproducts as antifoulants in the Brazilian brown alga Dictyota pfaffii (Phaeophyta, Dictyotales). Biochemical Systematics and Ecology. 35: 549 -553. Bhattarai. H. D. , Y. K. Lee, K. H. Cho, H. K. Lee, and H. W. Shin. (2006) The study of antagonistic interactions among pelagic bacteria: a promising way to coin environmental friendly antifouling compounds. Hydrobiologia. 568: 417 -423. Bianco, E. M. , R. Rogers, V. L. Teixeira, and R. C. Pereira. (2009) Antifoulant diterpenes produced by the brown seaweed Canistrocarpus cervicornis. J. Appl. Phycol. 21: 341 -346. Blidberg, DR. 1997. Solar-Powered Autonomous Undersea Vehicles. Sea Technology vol. 38, no. 12, pp. 45 -51 Bott, TR; Miller, PC. (1983) Mechanisms of Biofilm Formation on Aluminum Tubes. J. Chem. Technol. Biotechnol. 33 B, (3), 177 -184

a. Brady, RF Jr. (2003) Antifouling coatings without organotin. Journal of Protective Coatings & Linings vol. 20, no. 1, pp. 33, 34, 37 b. Burton, Dennis T; Fisher, Daniel J. (2001) Chlorine Dioxide - The State of Science, Regulatory, Environmental Issues, and Case Histories. Report Number AD-A 403858; Gunasingh Masilamoni, J; Jesudoss, KS; Nandakumar, K; Satapathy, KK; Azariah, J; Nair, KVK 2002. Lethal and sub-lethal effects of chlorination on green mussel Perna viridis in the context of biofouling control in a power plant cooling water system. Marine Environmental Research. Vol. 53, no. 1, pp. 65 -76 c. Callow ME, Callow JA. (2002) Marine biofouling: a sticky problem. The Biologist 49: 10 -14. d. Characklis WG (1981) Microbial fouling: A process analysis. In E. F. C. Somerscales and JG Knudsen (eds. ), Fouling of heat transfer equipment, Hemisphere Publ. Co. , Washington, D. C. p 251 -291 e. Cho, J. Y. , E-H. Kwon, J-S. Choi, S-Y. Hong, H-W. Shin, and Y-K. Hong. (2001) Antifouling activity of seaweed extracts on the green alga Enteromorpha prolifera and the Mussel Mytilus edulis. J. of App. Phycology. 13: 117 -125. f. Christie AO, Dalley R. (1987) Barnacle fouling and prevention. Crustacean Iss 5: 419 -433. g. Claire AS (1998) Towards nontoxic antifouling. J Mar Biotechnol 6, 3– 6 h. Costlow, J. D. , Tipper, R. C. (eds. ) Marine biodeterioration: an interdisciplinary study. Naval Institute Press, Annapolis 103 -126. i. de Nys, R. & Steinberg, P. D. (1999) Role of secondary metabolites from algae and seagrasses in biofouling control. In: Fingeman, M. , Nagabhushanam, R. & Thompson, M. F. [Eds. ] Recent Advances in Marine Biotechnology, Volume 3, Biojilms, Bioadhesion, Corrosion and Biofouling, Oxford and IBH Publishing Company Co. Pvt. Ltd. , New Delhi, pp. 237. j. De Rincon, OT; Morris, E; De Romero, M; Andrade, S. (2001) Effect of 'pelo de oso' (Garveia franciscana) on different materials in Lake Maracaibo. NACE International, Corrosion/2001 pp. 15 k. Diers, J. A. , J. J. Bowling, S. O. Duke, S. Wahyuono, M. Kelly, and M. T. Hamann. 2006. Zebra Mussel antifouling activity of the marine natural product Aaptamine and Analogs. Marine Biotech. . 8: 366 -372.

a. Diggins, TP; Baier, RE; Meyer, AE; Forsberg, RL. (2002) Potential for Selective, Controlled Biofouling by Dreissena Species to Intercept Pollutants from Industrial Effluents. Biofouling vol. 18, no. 1, pp. 29 -36 b. Dobrevsky, I; Tsvetanova, Z; Varbanov, P; Dimitrov, D; Savcheva, G. (2000) A method of biofilm monitoring in the recirculating cooling water system of a petroleum refinery plant. European Federation of Corrosion Publications (UK), vol. 29, pp. 202 -212; c. Douglas-Helders, GM; Tan, C; Carson, J; Nowak, BF. (2003) Effects of copper-based antifouling treatment on the presence of Neoparamoeba pemaquidensis Page, 1987 on nets and gills of reared Atlantic salmon (Salmo salar). Aquaculture Vol. 221, no. 1 -4, pp. 13 -22 d. de Nys, R. , Leya, T. , Maximilien, R. , Afsar, A. , Nair, P. S. R. & Steinberg, P. D. (1996) Thefor the prevention of marine biofouling 11. Blue-green algae as potential producers of biogenic agents for the growth inhibition of microfouling organisms. Bot. Mar. 42: 459 -65. e. Eng-Wilmot, D. L. , Mc. Coy, L. F. & Martin, D. F. (1979) Isolation and synergis of a red tide (Gymnodinium breve) cytolic factor(s) from cultures of Gomphosphaeria aponina. In Taylor, D. L. & Seliger, H. H. [Eds. ] Toxic dinoflagellate blooms. Elsevier, Amsterdam, pp. 35560. f. Evans SM (1999) Tributyltin pollution: the catastrophe that never happened. Marine Pollution Bulletin, 38: 629– 636. g. Faille, C; Dennin, L; Bellon-Fontaine, MN; Benezech, T. (1999) Cleanability of stainless steel surfaces soiled by Bacillus thuringiensis spores under various flow conditions. Biofouling vol. 14, no. 2, pp. 143 -151 h. Fusetani N (2004) Biofouling and antifouling. Nat Prod Rep 21, 94– 104 i. Gademann, K. , (2007) Cyanobacteria natural products for the inhibition of biofilm formation and biofouling. Chimia. 61(6): 373 -377. j. Gehrke, T; Sand, W. (2003) Interactions between microorganisms and physicochemical factors cause mic of steel pilings in harbours. NACE International, Corrosion/2003 pp. 8 k. Geiger, T. , P. Delavy, R. Hany, J. Schleuniger, and M. Zinn. 2004. Encapsulated Zosteric Acid Embedded in Poly [3 -hydroxyalkanoate] Coatings - Protection against Biofouling. Polymer Bulletin. 52: 65 -72. l. Gomez de Saravia, SG; Guiamet, PS; Videla, HA. (2001) Preventing biocorrosion without damaging the environment. Four innovative strategies. Institute of Corrosion, Corrosion Odyssey pp. 9

a. Gomez de Saravia, SG; Guiamet, PS; Videla, HA. (2001) Preventing biocorrosion without damaging the environment. Four innovative strategies. Institute of Corrosion, Corrosion Odyssey pp. 9 b. Granhag LM, Finlay JA, Jonsson PR, Callow JA, Callow ME (2004) Roughness-dependent removal of settled spores of the green alga Ulva (syn Enteromorpha) exposed to hydrodynamic forces from a water jet. Biofouling 20, 117– 122 c. Greenberg, T; Itzhak, D. (2002) Marine biofouling of titanium alloys in the coral reef environment. Corrosion/2002; Denver, CO; USA; 7 -11, 7 pp. 2002; Brown, Malcom, Jr. 1999. Atomic and Molecular Imaging of Adhesive Molecules. NASA no. 19990027847 d. Greenberg, T; Itzhak, D. (2002) Marine biofouling of titanium alloys in the coral reef environment. Corrosion/2002; Denver, CO; USA; 7 -11, 7 pp. 2002 e. Griebe, T; Flemming, HC. (2000) Biocide free antifouling strategy to protect RO-membrane from biofouling (abstract only). Invest. Tec. Pap. vol. 37, no. 146, pp 676 -677 f. Gross, E. M. , Wolk, P. & Juttner, F. (1991) Fischerellin, a new allelochemical from the freshwater cyanobacterium Fischerella muscicola. J. Phycol. 27: 686 -92. g. Hirota, H. , T. Okino, E. Yoshimura, and N. Fusetani. 1998. Five new antifouling Sesquiterpene from two marine sponges of the genus Axinyssa and the Nudibranch Phyllida pustulosa. Tetrahedron. 54: 13971 -13980. h. Hodson SL, Lewis TE, Burke CM. (1997) Biofouling of fish-cage netting: efficacy and problems of in situ cleaning. Aquaculture 152: 77 -90. i. Holmstroem, C; Egan, S; Franks, A; Mc. Cloy, S; Kjelleberg, S. (2002) Antifouling activities expressed by marine surface associated Pseudoalteromonas species. FEMS Microbiology Ecology Vol. 41, no. 1, pp. 47 -58 j. Huguenin JE, Ansiuni FJ. (1981) Marine biofouling of synthetic and metallic screens. Proceedings from Ocean 81 Conference. 16– 18 September 1981, Boston, MA 545– 549. k. Huse I, Bjordal A, Ferno A, Furevik D. (1990) The effect of shading in pen rearing of Atlantic salmon (Salmo salar). Aquacult Eng 9: 235– 244 l. Jelvestam, M; Edrud, S; Petronis, S; Gatenholm, P. (2003) Biomimetic materials with tailored surface micro-architecture for prevention of marine biofouling. Surface and Interface Analysis vol. 35, no. 2, pp. 168 -173

a. Kanagasabhapathy, M. , H. Sasaki, K. Nakajima, K. Nagata, and S. Nagata. (2005) Inhibitory activities of surface associated bacteria isolated from the marine sponge Pseudomonas purpurea. Microbes and Environments. 20(3): 178 -185. b. Kelly, SR; Jensen, PR; Henkel, TP; Fenical, W; Pawlik, JR. (2003) Effects of Caribbean sponge extracts on bacterial attachment. Aquatic Microbial Ecology Vol. 31, no. 2, pp. 175 -182 c. Kem, WR; Soti, F; Rittschof, DAF. (2003) Inhibition of barnacle larval settlement and crustacean toxicity of some hoplonemertine pyridyl alkaloids. Biomolecular Engineering Vol. 20, no. 4 -6, pp. 355 -361 d. Klassen, RD; Roberge, PR; Porter, J; Pelletier, G; Zwicker, B. (2001) On-board hypochlorite generation for biofouling control. NACE International, Corrosion/2001 pp. 11, Mar. 2001 e. Kolari, M. (2003) Attachment mechanisms and properties of bacterial biofilms on non-living surfaces. Dissertationes Biocentri Viikki Universitatis Helsingiensis 12, 129 pp f. Kwong, T. F. N. , L. Miao, X. Li, and P. Y. Qian. (2006) Novel antifouling and antimicrobialcompound from a marine-derived fungus Ampelomyces sp. Marine Biotechnology. 8: 634 -640. g. Lackenby, H. (1962) The resistance to ships with special reference to skin friction and hull surface condition. Thomas Lowe Gray Lecture. Proc. Inst. Mech. Eng. 176: l-35. h. Lewis, D P; Piontkowski, J M; Straney, R W; Knowlton, J J. (1997) Use of potassium for treatment and control of zebra mussel infestation in industrial fire protection water systems. Fire Technology 33 (4), p. 356 -71 i. Lewis, RJ; Johnson, LM; Hoagland, KD. 2002. Effects of cell density, temperature, and light intensity on growth and stalk production in the biofouling diatom Achnanthes longipes (Bacillariophyceae). Journal of Psychology Vol. 38, no. 6, pp. j. Mackie, G. L. , Lowery, P. & Cooper, C. (2000) Plasma Pulse Technology to Control Zebra Mussel Biofouling. Army Engineer Waterways Experiment Station, Vicksburg, MS. Engineer Research and Development Center, Report: ERDC-TN-ZMR-2 -22. k. Manov, D. V. , Chang, G. C. & Dickey, T. D. (2004) Methods for reducing biofouling of moored optical sensors. J. Atmos. Ocean. Tech. 21: 958 -68

a. Moring JR, Moring KA. (1975) Succession of net biofouling material and its role in the diet of pen-cultured Chinook salmon. Prog Fish-Cult 37: 27– 30. b. Muralidharan, J; Jayachandran, S. (2003) Physicochemical analyses of the exopolysaccharides produced by a marine biofouling bacterium, Vibrio alginolyticus. Process Biochemistry Vol. 38, no. 6, pp. 841 -847 Alzieu C, (1998) Tributyltin: case study of a chronic contaminant in the coastal environment. Ocean and Coastal Management, 40: 23– 36 c. Murugan, A; Ramasamy, MS. (2003) Biofouling deterrent activity of the natural product from ascidian, Distaplia nathensis. Indian journal of marine sciences, Vol. 32, no. 2, pp. 162 -164 d. Murugan, A; Ramasamy, MS. (2003) Biofouling deterrent activity of the natural product from ascidian, Distaplia nathensis. Indian journal of marine sciences, Vol. 32, no. 2, pp. 162 -164 e. Nandakumar, K. , Obika, H. , Shinozaki, T. , Ooie, T. , Utsumi, A. $ Yano, T. (2003) Pulsed laser irradiation impact on two marine diatoms Skeletonema costatum and Chetoceros gracilis. Water Res. 37: 23 1 1 - 16. f. Omae, I. , 2006. General aspects of natural products antifoulants in the environment. Env. Chem. 5: 227 -262. g. Panchal, CB; et al. (1984) Biofouling and Corrosion Studies at the Seacoast Test Facility in Hawaii, DE 84 -014643; CONF-840930 -1, 6 pp h. Panchal, CB; et al. (1984) Biofouling and Corrosion Studies at the Seacoast Test Facility in Hawaii, DE 84 -014643; CONF-840930 -1, 6 pp i. Patil JS, Kimoto H, Kimoto T, Saino T (2007) Ultraviolet radiation (UV-C): a potential tool for the control of biofouling on marine optical instruments. Biofouling , 23(4): 215 -230 j. Patil, J. S. & Anil, A. C. (2000) Epibiotic community of the horseshoe crab, Tachypleus gigas. Mar. Biol. 136: 699 -713. k. Qi, S. H. , Y. Xu, H. R. Xiong, P. Y. Qian, and S. Zhang. (2009) Antifouling and antibacterial compounds from a marine fungus Cladosporium sp. F 14. World J. Microbiol. Biotechnol. 25: 399 -406. l. Railkin, 2004 A. I. Railkin, Marine Biofouling: Colonization Processes and Defenses, CRC Press, Boca Raton, Fl, USA (2004) 303 pp. m. Rolland, J. P. & De. Simone, J. M. (2003) Synthesis and characterization of perfluoropolyether graft terpolymers for biofouling applications. Polym. Mat. Sci. Eng. 88: 606 -7.

a. Rolland, JP; De. Simone, JM. ( 2003) Synthesis and characterization of perfluoropolyether graft terpolymers for biofouling applications. Polymeric Materials Science and Engineering. vol. 88, pp. 606 -607 b. Selvin, J. , and A. P. Lipton. (2004) Antifouling activity of bioactive substances extractedfrom Holothuria scabra. Hydrobiologia. 513: 251 -253. c. Stein, J; Truby, K; Wood, CD; Takemori, M; Vallance, M; Swain, G; Kavanagh, C; Kovach, B; Schultz, M; Wiebe, D. 2003. Structure--property relationships of silicone biofouling-release coatings: effect of silicone network architecture on pseudobarnacle attachment strengths. Biofouling 19, (2), 87 -94 d. Stein, J; Truby, K; Wood, CD; Takemori, M; Vallance, M; Swain, G; Kavanagh, C; Kovach, B; Schultz, M; Wiebe, D. (2003) Structure--property relationships of silicone biofouling-release coatings: effect of silicone network architecture on pseudobarnacle attachment strengths. Biofouling 19, (2), 87 -94 e. Thakur, N. L. & Muller, W. E. G. (2004) Biotechnological potential of marine sponges. Curr. Sci. 86: 1506 -12. f. Thakur, N. L. (2001) Studies on some bioactivity aspects of selected marine organisms. Ph. D g. thesis. Goa University. h. Tsoukatou, M. , J. P. Marechal, C. Hellio, I. Novakovic, S. Tufegdzic, D. Sladic, M. J. Gasic, A. S. Clare, C. Vagias, and V. Roussis. (2007) Evaluation of the activity of the Sponge metabolites Avarol and Avarone and their synthetic derivatives against fouling micro- and macroorganisms. Molecules. 12: 1022 -1034. i. Vishwakiran Y, Anil AC, Venkat K, Sawant SS (2005) Gyrineum natator: A potential indicator of imposex along the Indian coast. Chemosphere, 62: 1718 -25. j. Von Oertzen JA, Scharf EM, Arndt EA, Sandrock Dettmann L, Holzapfel H, Rlngstorf H, Kohn H, Gunther (1989) Spezialstudie 'Alternative Antifouling Systeme' Fachbereich Biologie, Universitat Rostock k. Wahl M (1997) Living attached: aufwuchs, fouling, epibiosis. In: Fouling Organisms of the Indian Ocean: Biology and Control Technology, Nagabhushanam R, Thompson M, eds. (New Delhi: Oxford & IBH) pp 31– 84

a. Walch, M. , Mazzola, M. & Grothaus, M. (2000) Feasibility Demonstration of a Pulsed Acoustic Device for Inhibition of Biofouling in Seawater Piping. Naval Surface Warfare Center Carderock Div. , Bethesda, MD, Report: NSWCCD-TR-2000/04. b. Yang, L. H. , L. Miao, O. O. Lee, X. Li, H. Xiong, K. L. Pang, L. Vrijmoed, and P. Y. Qian. (2007) Effect of culture conditions on antifouling compound production of a sponge-associated fungus Appl. Microbiol. Biotechnol. 74: 1221 -1231. c. Yebra DM, Kiil S, Dam-Johansen K (2004) Antifoulingtechnology-past, present and future steps towards efficient and environmentally friendly antifouling coatings. Prog Org Coat 50, 75– 104 d. Younqlood, JP; Andruzzi, L; Senaratne, W; Ober, CK; Callow, JA; Finlay, JA; Callow, ME. (2003) New materials for marine biofouling resistance and release: semi-fluorinated and pegylated block copolymer bilayer coatings. Polymeric Materials Science and Engineering, vol. 88, pp. 608 -609 e. Younqlood, JP; Andruzzi, L; Senaratne, W; Ober, CK; Callow, JA; Finlay, JA; Callow, ME. (2003) New materials for marine biofouling resistance and release: semi-fluorinated and pegylated block copolymer bilayer coatings. Polymeric Materials Science and Engineering, vol. 88, pp. 608 -609 f. Zobell CE, Allen CE. (1935) The significance of marine bacteria in the fouling of submerged surfaces. J Bacteriol 29: 239 -251. Web Pages: • • W 1. http: //www. abc. net. au/rn/science/earth/stories/s 24268. htm (Australian Broadcasting Corporation, ABC Ultimo Centre, 700 Harris Street, Ultimo 2007, GPO Box 9994, Sydney NSW 2001 Australia) W 2. http: //journals. eecs. qub. ac. uk/RIA/Proc. BI/1998/PB 98 I 1/B 98106 a. html http: //www. dt. navy. mil/pao/excerpts%20 pages/1999/biofouling 4. html (Naval Surface Warfare Center, Communications Division, Bldg 1 Rm 200 M, 9500 Mac. Arthur Boulevard, West Bethesda, MD 20817 -5700) W 3. http: //www. parliament. vic. gov. au/enrc/default. htm (Level 8, 35 Spring Street, Melbourne, Victoria 3000 Australia) W 4. URL http: //vortex. weather. brockport. edu/students/joek/introduction. htm (Department of Earth Sciences, SUNY Brockport, 350 New Campus Drive, Brockport, NY 14420)

a. W 5. http: //www. parliament. vic. gov. au/enrc/default. htm (Level 8, 35 Spring Street, Melbourne, Victoria 3000 Australia) b. W 6. http: //www. poseidonsciences. com/antifouling. html The Chanin Building, Suite 2805, 122 East 42 nd Street, New York, NY, USA 10168 c. W 7. http: //marine. copper. org/1 -biofouling. html (Copper Development Association Inc. , 260 Madison Avenue, New York, NY 10016) d. W 8. http: //www. timet. com/cor-p 09. htm (Titanium Metals Corporation, 1999 Broadway, Suite 4300, Denver CO 80202) e. W 9. http: //www. scienceblog. com/community/article 1341. html (Science Blog) f. W 10. http: //www. reef. crc. org. au/publications/explore/feat 53. html (The Cooperative Research Centre for the Great Barrier Reef World Heritage Area, PO Box 772, Townsville 4810, Queensland Australia) g. W 11 http: //www. dt. navy. mil/pao/excerpts%20 pages/1999/biofouling 4. html (Naval Surface Warfare Center, Communications Division, Bldg 1 Rm 200 M, 9500

8c2c75043bbe52ca04f87280fe5defdf.ppt