519afef2300bb049e4f6f01a58c13308.ppt

- Количество слайдов: 47

BEST PRACTICES IN SUPPLY CHAIN MANAGEMENT AT ZARA BY SIYU LIU, ALFONSO IZQUIERDO AND POORANAN MURUGESAN

Agenda • Historic development of the three companies – Facts and Figures • Current state of Supply chain management organization • Current product strategy • Competitive situation • Assessment of the best practice in Supply Chain Management • Prognosis of future development • Conclusion

HISTORIC DEVELOPMENT OF THE THREE COMPANIES FACTS AND FIGURES

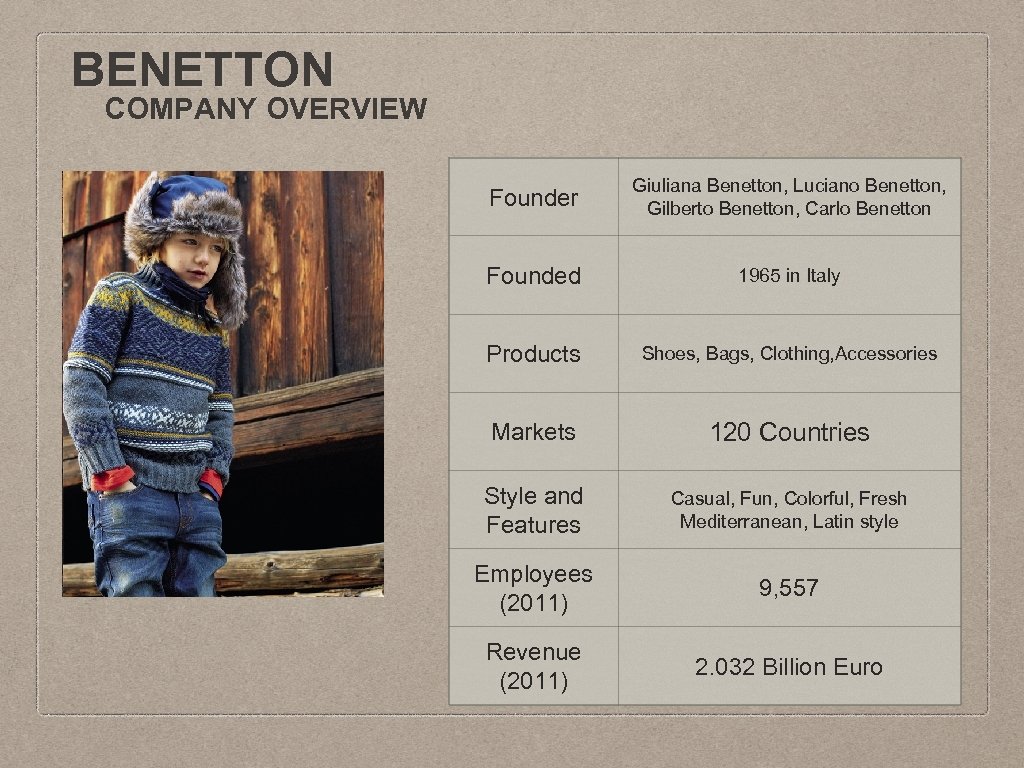

BENETTON COMPANY OVERVIEW Founder Giuliana Benetton, Luciano Benetton, Gilberto Benetton, Carlo Benetton Founded 1965 in Italy Products Shoes, Bags, Clothing, Accessories Markets 120 Countries Style and Features Casual, Fun, Colorful, Fresh Mediterranean, Latin style Employees (2011) 9, 557 Revenue (2011) 2. 032 Billion Euro

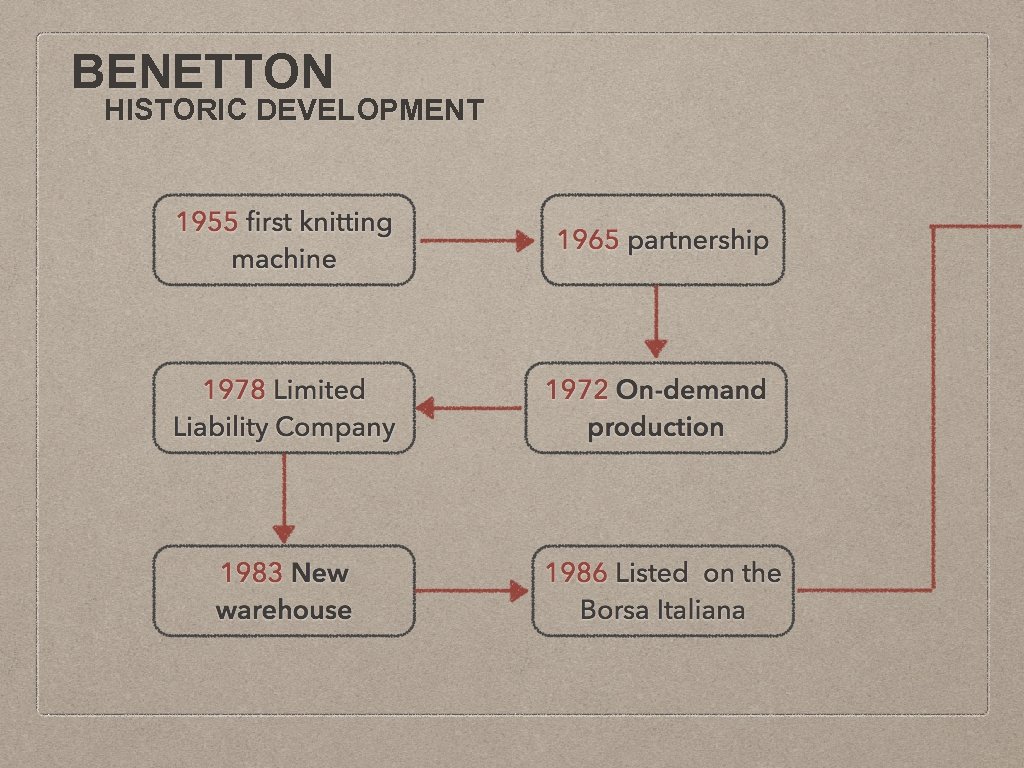

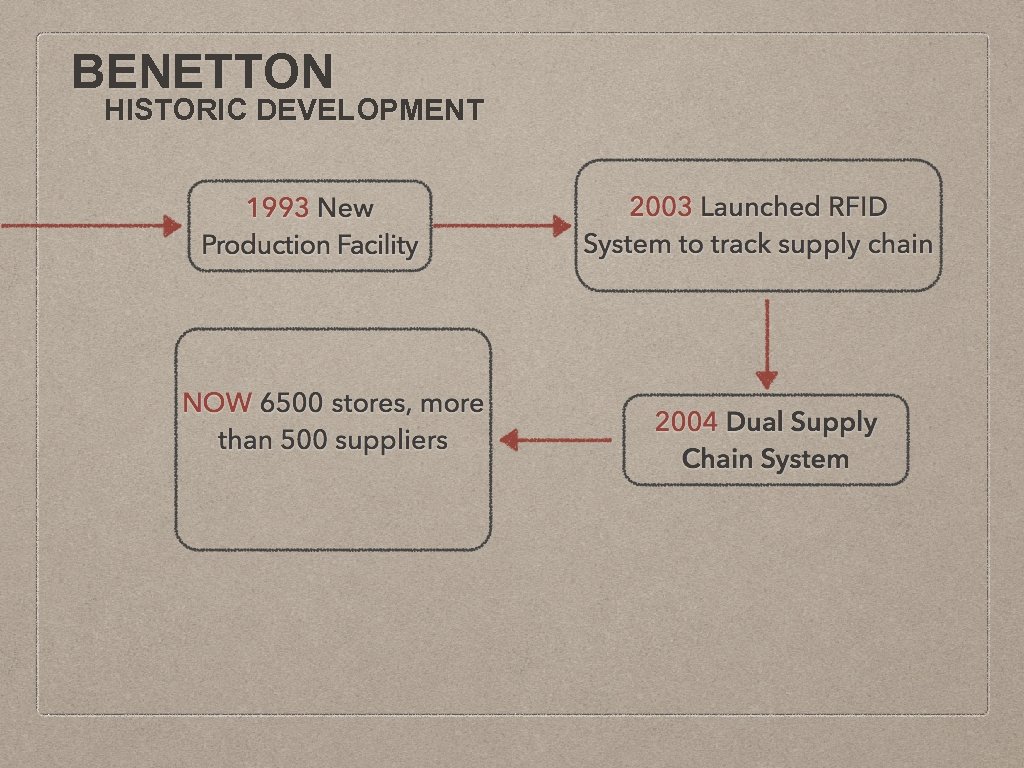

BENETTON HISTORIC DEVELOPMENT

BENETTON HISTORIC DEVELOPMENT

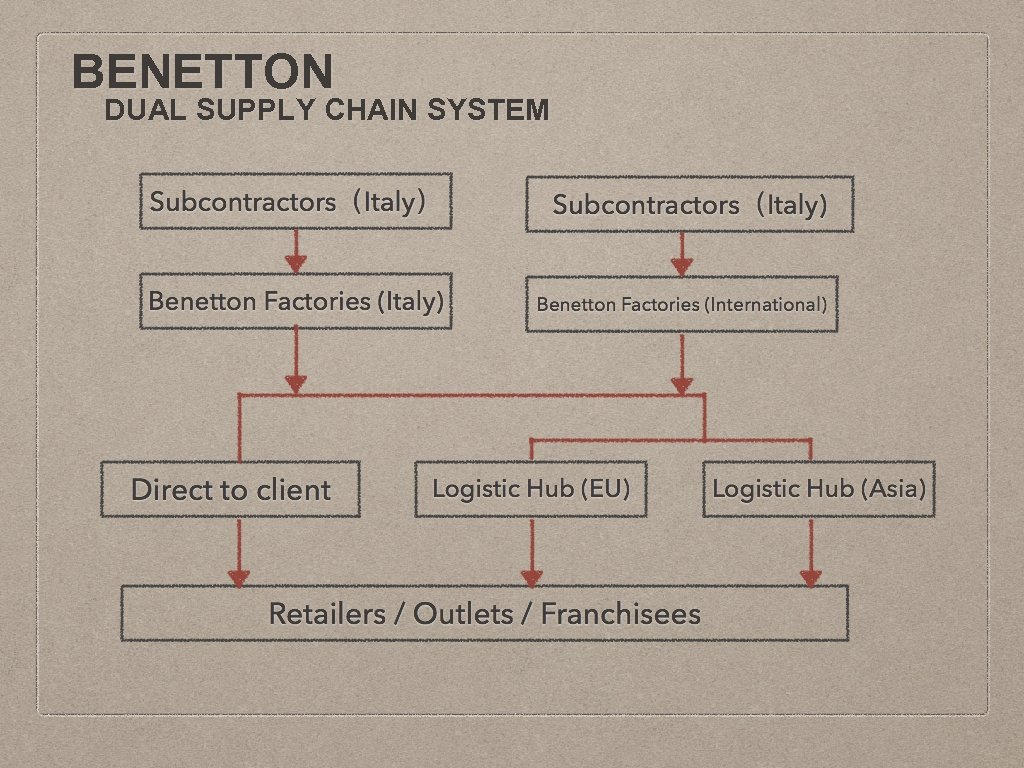

BENETTON DUAL SUPPLY CHAIN SYSTEM

HENNES & MAURITZ Founder Erling Persson Founded 1947 in Sweden Products Clothing, Accessories Markets 25 Countries Style and Features Wide range from party dresses, sport shirts to suits and other formal wears Employees (2010) 59, 440 Revenue (2010) 14. 24 Billion Euro

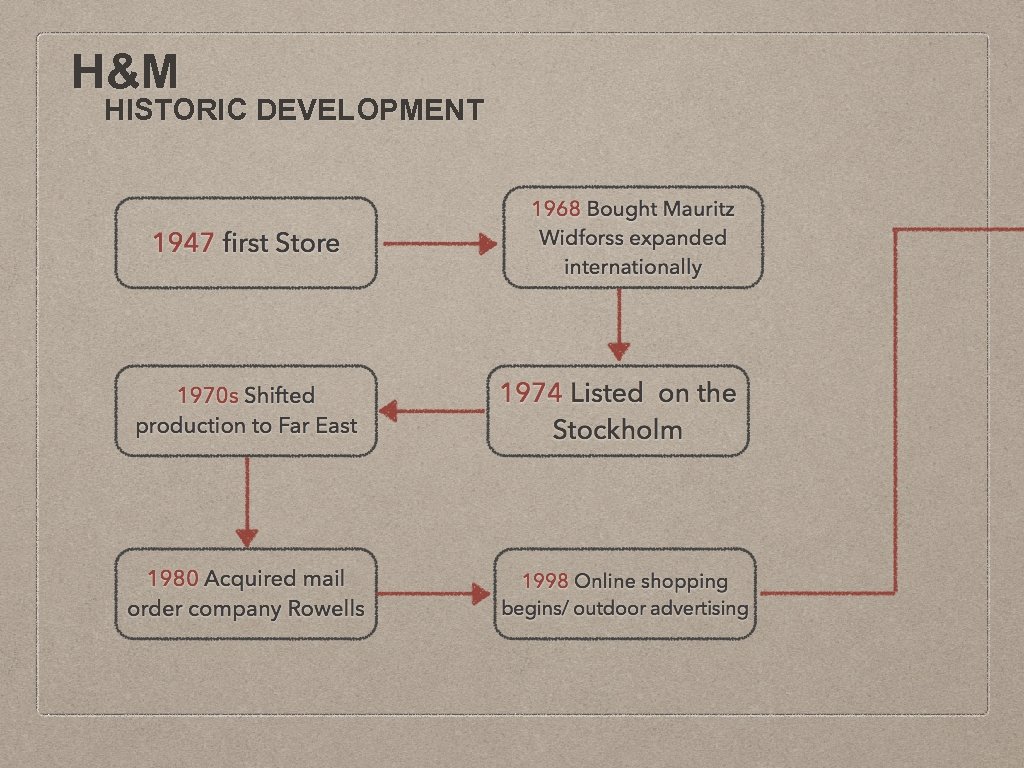

H&M HISTORIC DEVELOPMENT

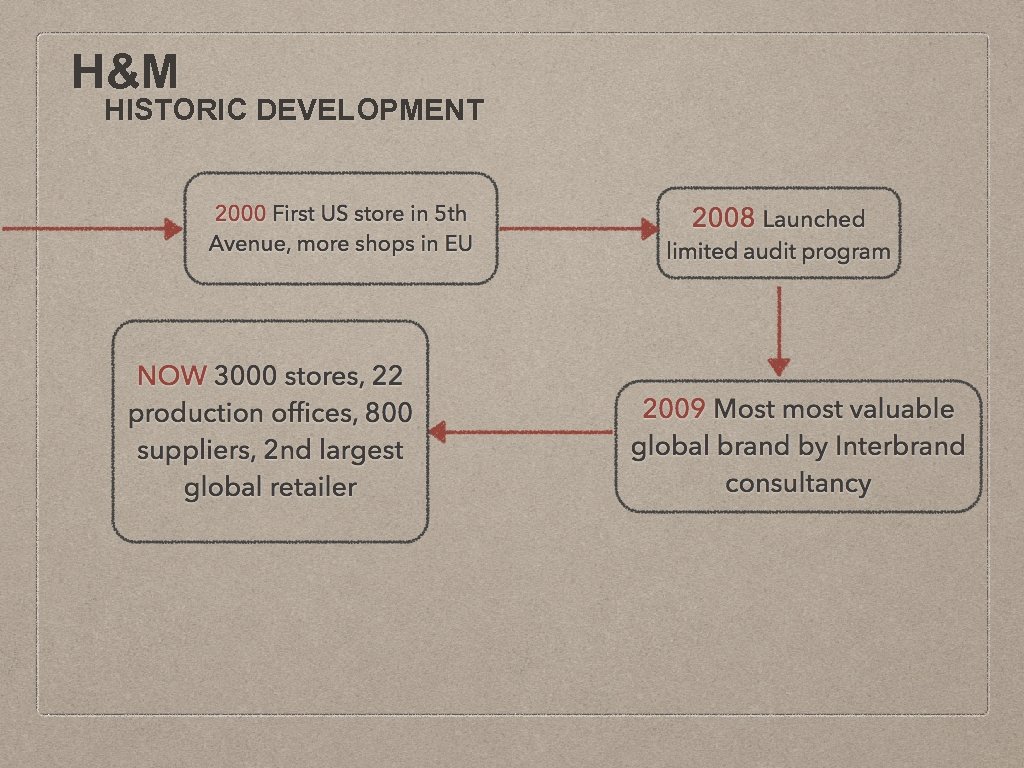

H&M HISTORIC DEVELOPMENT

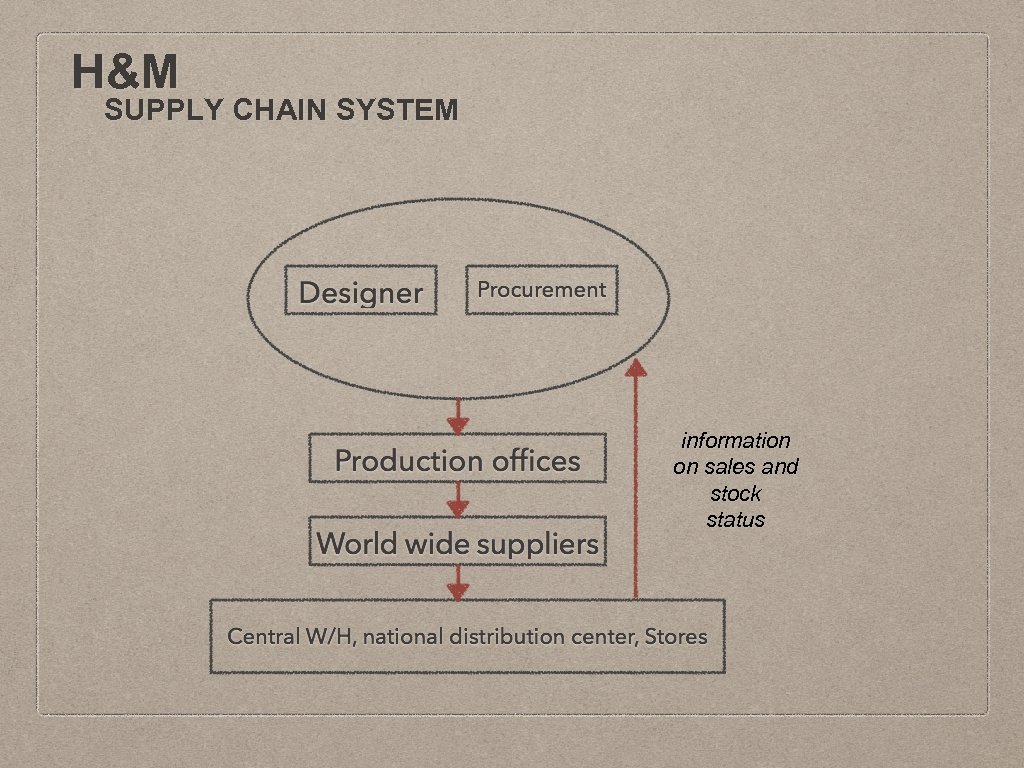

H&M SUPPLY CHAIN SYSTEM information on sales and stock status

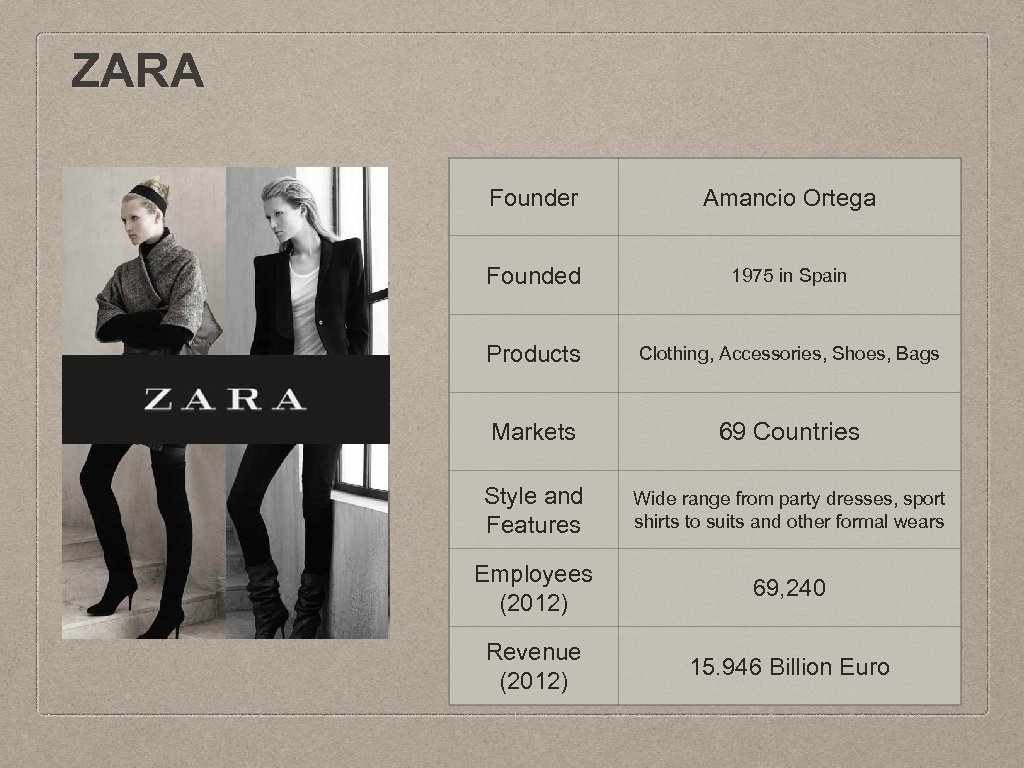

ZARA Founder Amancio Ortega Founded 1975 in Spain Products Clothing, Accessories, Shoes, Bags Markets 69 Countries Style and Features Wide range from party dresses, sport shirts to suits and other formal wears Employees (2012) 69, 240 Revenue (2012) 15. 946 Billion Euro

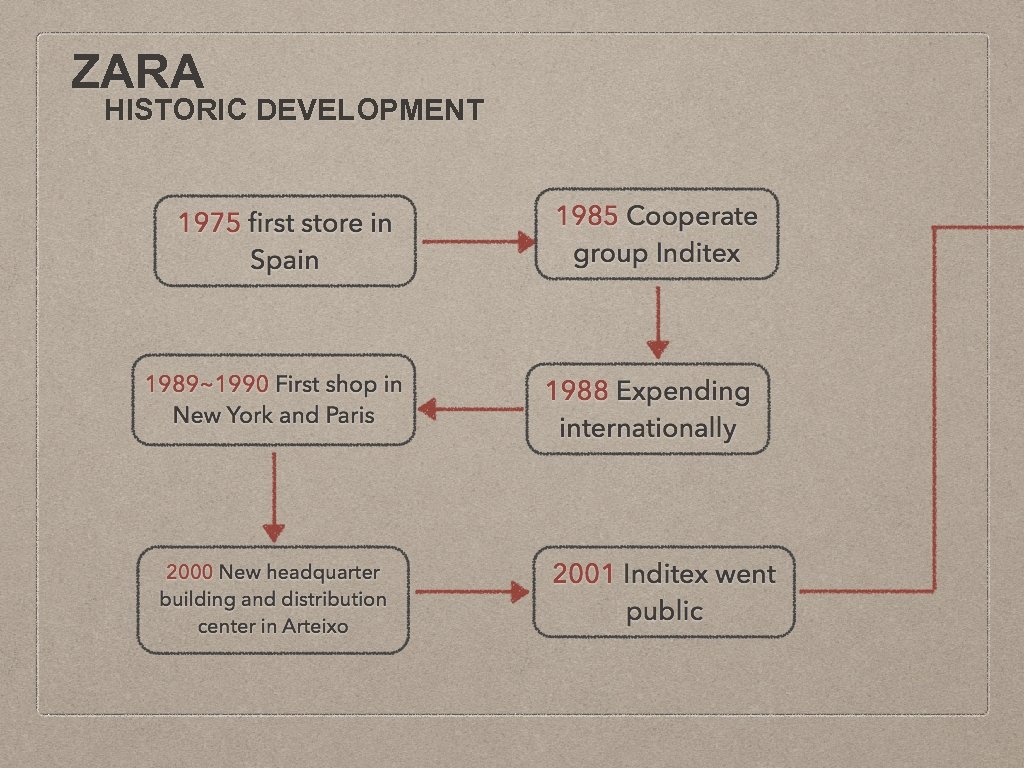

ZARA HISTORIC DEVELOPMENT

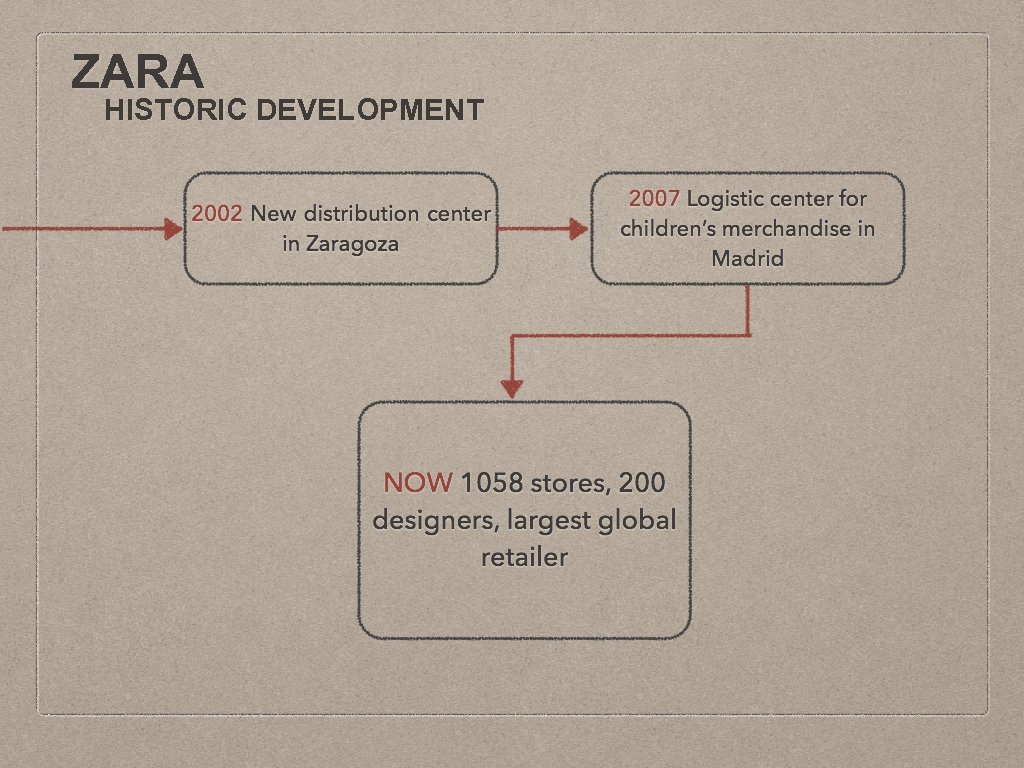

ZARA HISTORIC DEVELOPMENT

CURRENT STATE OF SUPPLY CHAIN MANAGEMENT ORGANIZATION OF ZARA

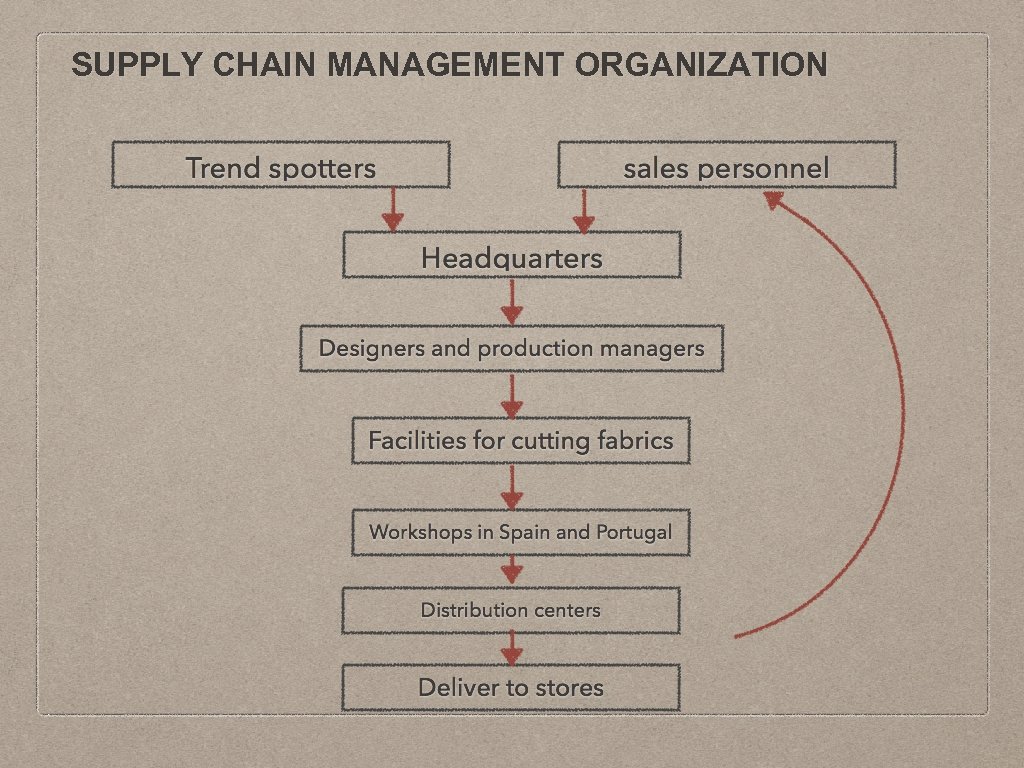

SUPPLY CHAIN MANAGEMENT ORGANIZATION

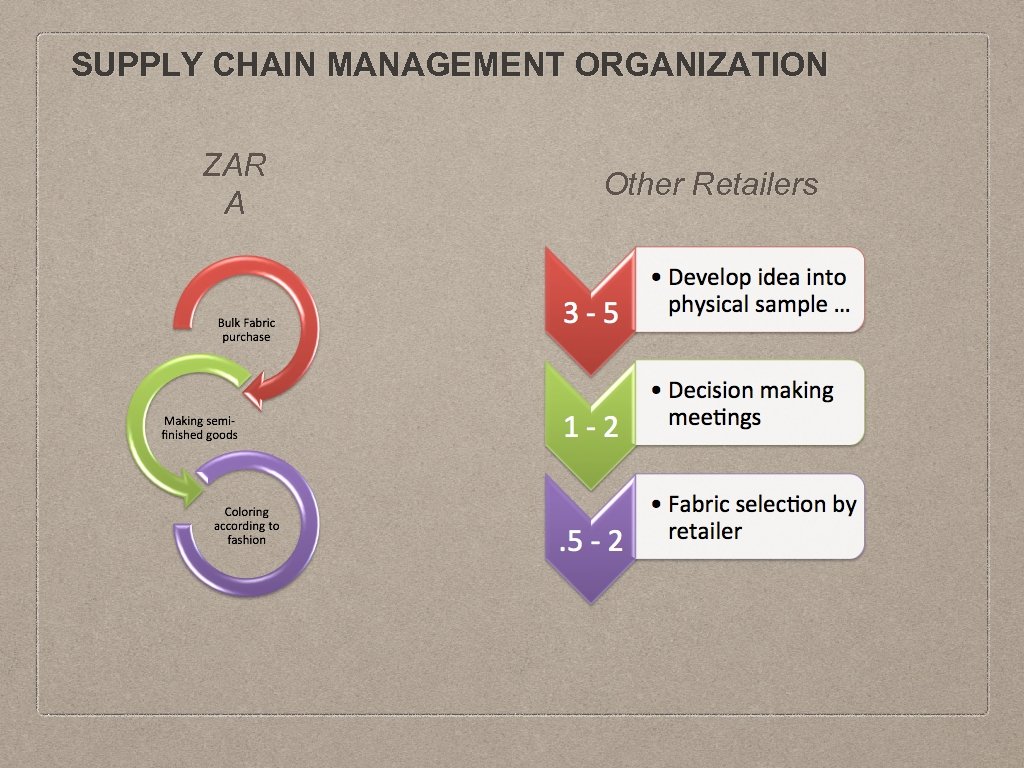

SUPPLY CHAIN MANAGEMENT ORGANIZATION ZAR A Other Retailers

Zara- Supply Chain Management

Zara- Supply Chain Management • Fast Fashion- Manufactured quickly and Sold at affordable prices • Competitors like H&M, Forever 21 followed Zara’s Fast Fashion model. • Produce and deliver in 3 weeks model. • In typical season, Zara produces 11000 different items.

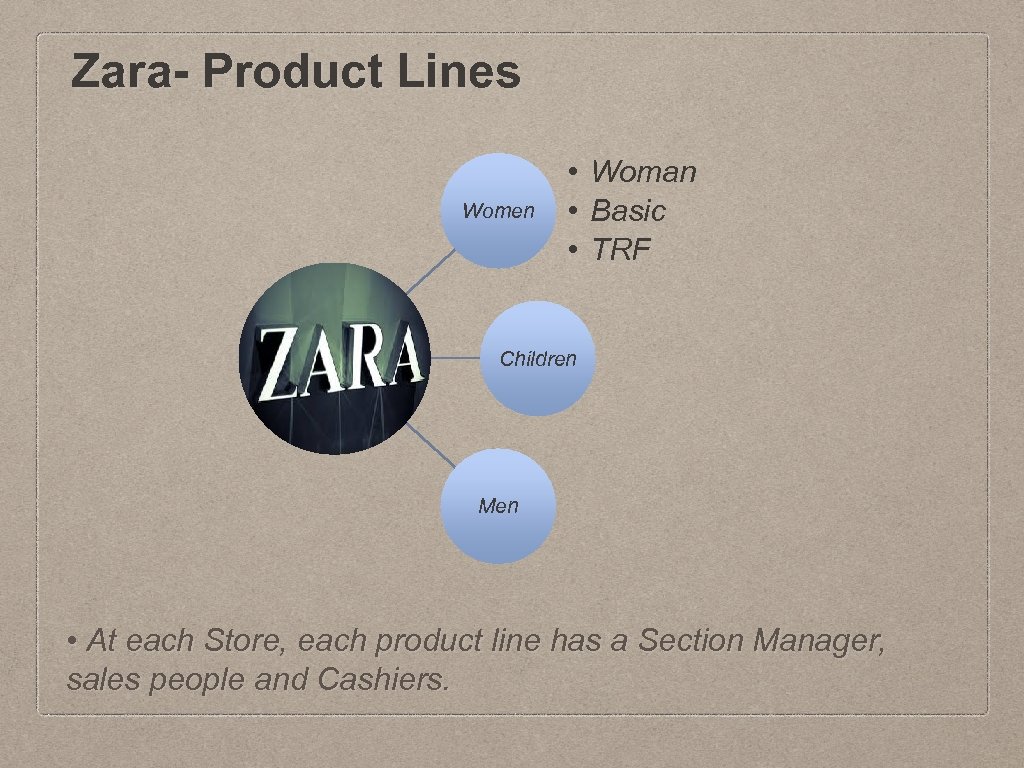

Zara- Product Lines Women • Woman • Basic • TRF Children Men • At each Store, each product line has a Section Manager, sales people and Cashiers.

Zara- Supply Chain Management Commercials Store Managers Direccion de Tiendas

Zara – Supply chain • Seasons-Autumn/winter and Spring/Summer • First designs were presented 6 months before each season • During the season, Suppliers with short lead times allowed it to introduce new designs • For basic, easy to forecast Products, Zara used cheaper suppliers with longer lead times

Zara – Supply Chain • All products came to logistic centers in Spain. • A Coruna - 50% of all Women and Men’s wear • Zaragoza – 50% of all Women and Men’s wear • Meco – All children’s wear

Zara – Order Cycle • For Every season, new collections are sent to store based on commercials. • 25000 units were sent to each store • Replenishments was ordered by section managers • Twice a week, Section manager receives offer in his or her PDA. • European stores received deliveries in 24 hours • Asian stores received deliveries in 40 hours

Zara – Supply chain Improvements • Consolidating Transport cost. • 100 Million Euro state of art logistics centre for Children’s Merchandise in Madrid • Unloading the merchandise were outsourced to logistic providers. • Attaching Alarm tags were shifted from Back room to factories.

Zara – Supply chain Improvements • Automatic replenishments of basic(10 -15%) products. • Algorithm for allocating Inventory at logistics centers to stores. • Commercials had the intelligence to find out if a manager is making mistakes.

Zara – In Store Logistics • Processing deliveries • Managing product flow between backroom and selling floor • Managing display areas and fitting rooms • Conducting physical audits.

Zara - Competitive Situation COMPETITORS • American Forever 21, Swedish Hennes & Mauritz(H&M), Japanese Uniqlo ADVANTAGES • Market Leader • High cost Supply chain management with low inventory and higher profit margins, which maximized revenues • 18% of clothes were sold in Discount sales compared to industry average of 36% • Aggressive expansion strategy

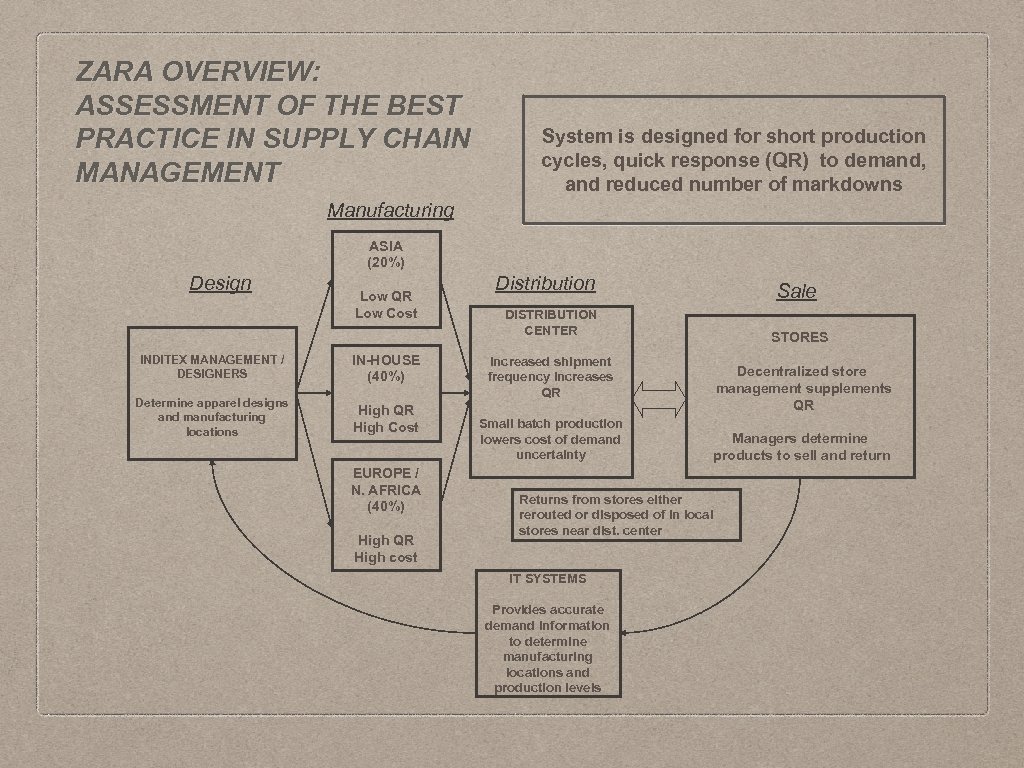

ZARA OVERVIEW: ASSESSMENT OF THE BEST PRACTICE IN SUPPLY CHAIN MANAGEMENT System is designed for short production cycles, quick response (QR) to demand, and reduced number of markdowns Manufacturing ASIA (20%) Design Low QR Low Cost INDITEX MANAGEMENT / DESIGNERS IN-HOUSE (40%) Determine apparel designs and manufacturing locations High QR High Cost EUROPE / N. AFRICA (40%) High QR High cost Distribution Sale DISTRIBUTION CENTER STORES Increased shipment frequency increases QR Small batch production lowers cost of demand uncertainty Decentralized store management supplements QR Managers determine products to sell and return Returns from stores either rerouted or disposed of in local stores near dist. center IT SYSTEMS Provides accurate demand information to determine manufacturing locations and production levels

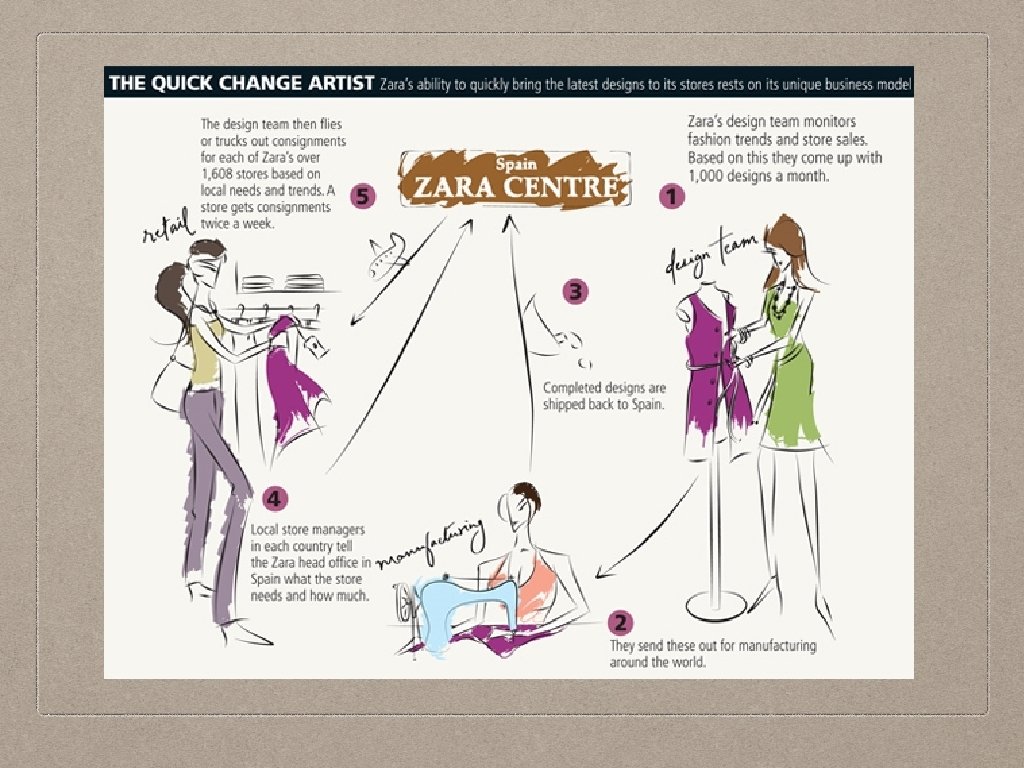

Zara’s Fast Track to Fashion The key to the Spanish clothing chain is efficiency – with a side order of fashion sense. • Spanish retailer Inditex, owner of cheap-chic clothing chain Zara, pioneered the concept of fast fashion. • While most of the retail industry takes months to bring new merchandise to market, Zara is able to move from designer’s drawing board to shop floor in as little as two weeks thanks to its tight control over every step of the process.

Vertically Integrated Supply Chain Total control of the production process Tag Team • In Arteixo, Spain, Zara’s 200 in-house designers work in teams for the company’s women’s, and children’s clothing lines.

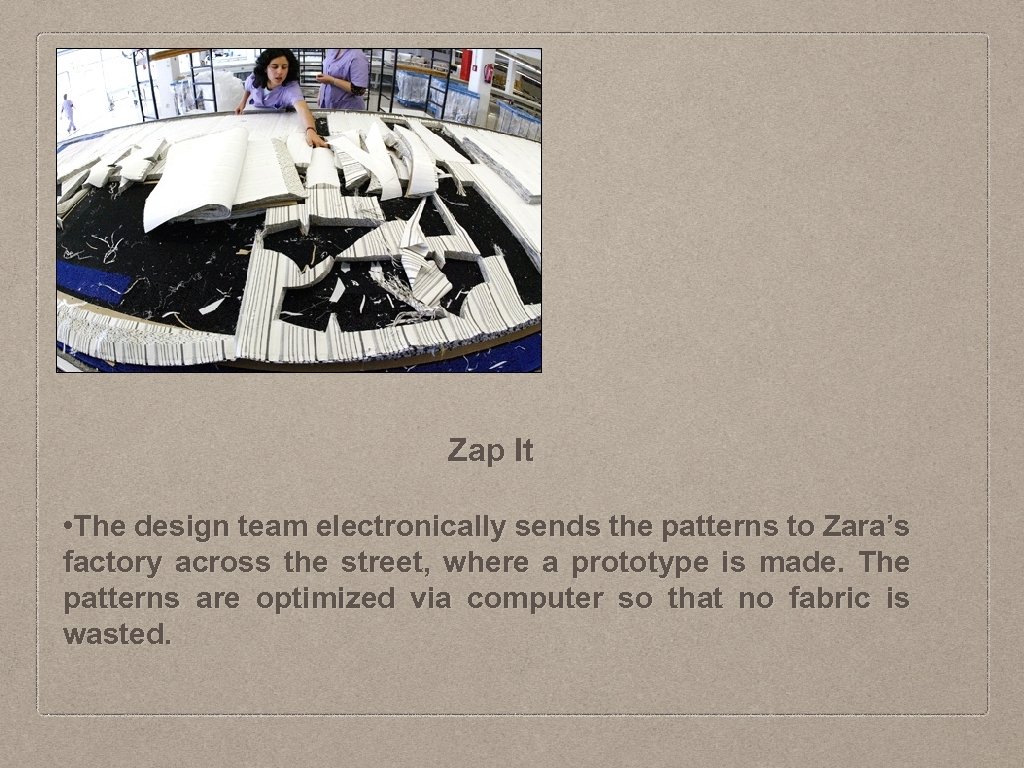

Zap It • The design team electronically sends the patterns to Zara’s factory across the street, where a prototype is made. The patterns are optimized via computer so that no fabric is wasted.

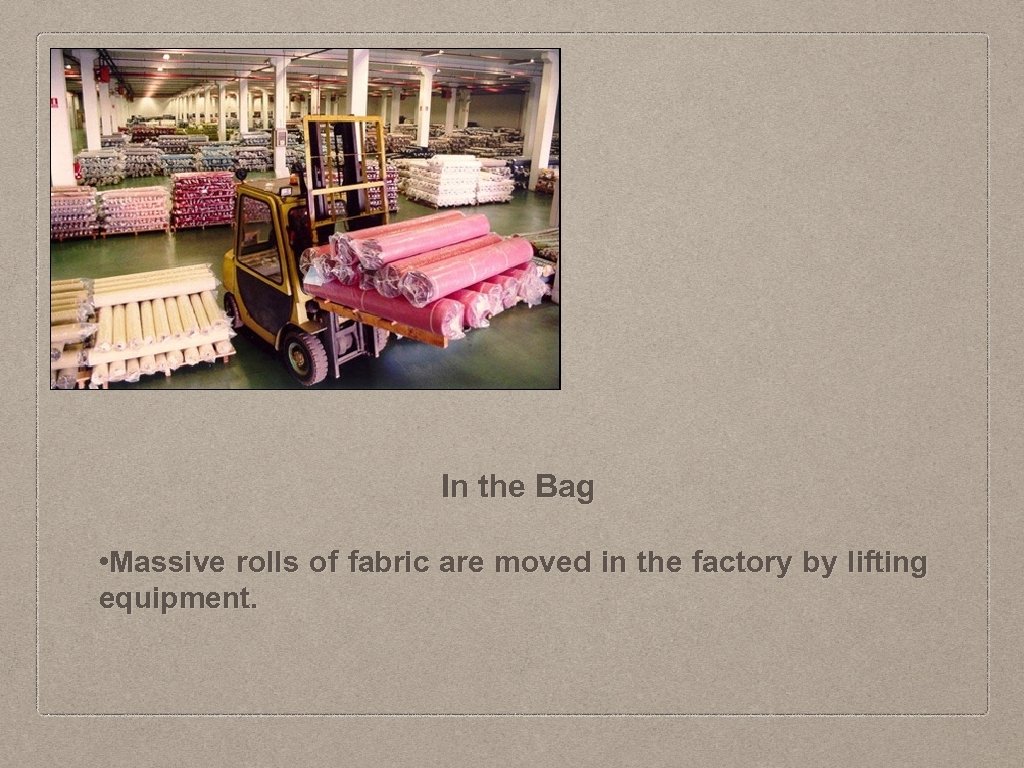

In the Bag • Massive rolls of fabric are moved in the factory by lifting equipment.

Press and Go • Once the finished clothing is back at the Arteixo factory, workers handle finishing touches, such as adding buttons and detailing.

“Stores managers feel like the owners of the store” Alarming Efficiency • Next, labels for each country are attached. Zara on store managers to do this once the product store. used to rely reached the

Lonely Job • Once tagged, the garments are sent to Zara’s nearby distribution center via tunnel.

Short lead times “Catching fashion while it is hot” Focus on short time response Quick Turnaround • More than 2. 6 million items move through the distribution center each week, and most spend little more than a few hours at the center. Meet the customer expectation on time Produce a new style in 2– 4 weeks

Show Time • Just two days after leaving Zara’s distribution center in Spain, merchandise arrives in U. S. stores. • Zara transports its merchandise to the U. S. and Asia by plane, enabling it to arrive in 48 hours. • Delivery time in Europe is even faster.

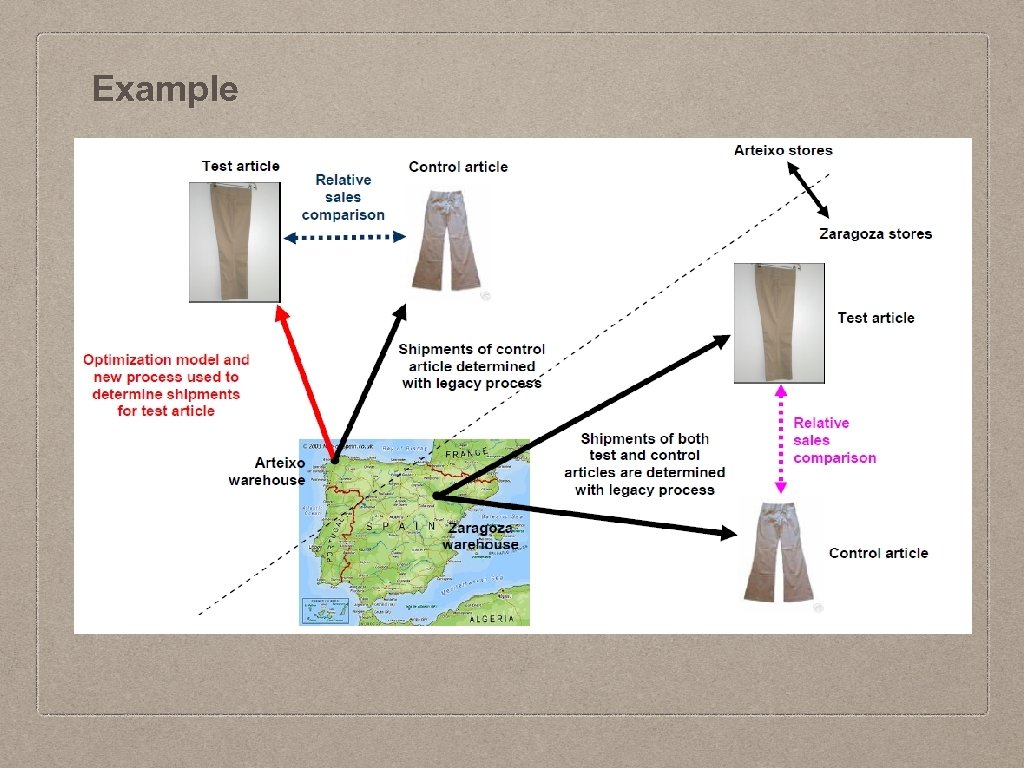

Example

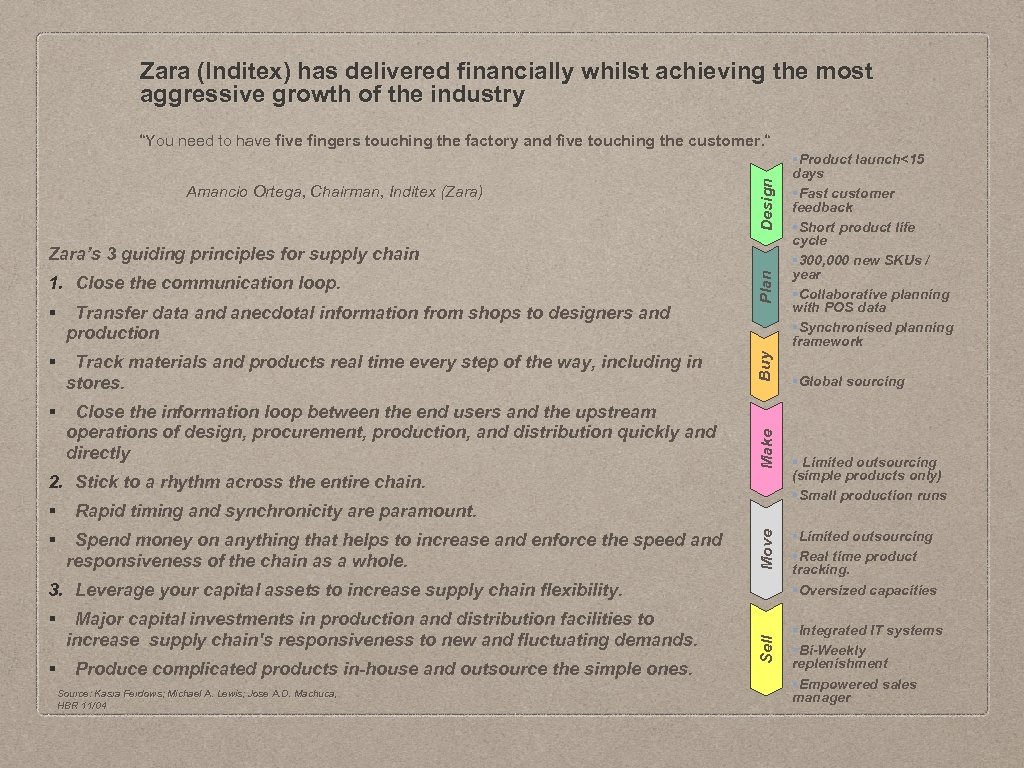

Zara (Inditex) has delivered financially whilst achieving the most aggressive growth of the industry Amancio Ortega, Chairman, Inditex (Zara) Design “You need to have fingers touching the factory and five touching the customer. “ Transfer data and anecdotal information from shops to designers and production § Track materials and products real time every step of the way, including in stores. § Close the information loop between the end users and the upstream operations of design, procurement, production, and distribution quickly and directly Buy § Make 1. Close the communication loop. Plan Zara’s 3 guiding principles for supply chain 2. Stick to a rhythm across the entire chain. § Rapid timing and synchronicity are paramount. Spend money on anything that helps to increase and enforce the speed and responsiveness of the chain as a whole. Move § § Major capital investments in production and distribution facilities to increase supply chain's responsiveness to new and fluctuating demands. § Produce complicated products in-house and outsource the simple ones. Source: Kasra Ferdows; Michael A. Lewis; Jose A. D. Machuca, HBR 11/04 Sell 3. Leverage your capital assets to increase supply chain flexibility. §Product launch<15 days §Fast customer feedback §Short product life cycle § 300, 000 new SKUs / year §Collaborative planning with POS data §Synchronised planning framework §Global sourcing § Limited outsourcing (simple products only) §Small production runs §Limited outsourcing §Real time product tracking. §Oversized capacities §Integrated IT systems §Bi-Weekly replenishment §Empowered sales manager

Main Brands

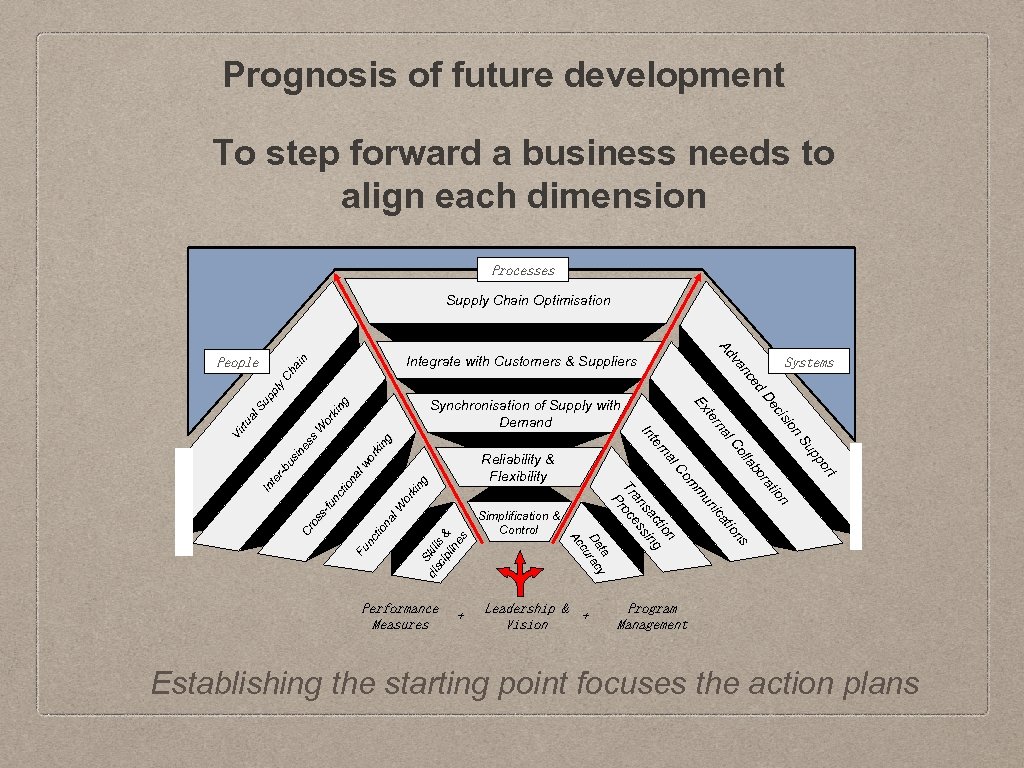

Prognosis of future development To step forward a business needs to align each dimension Processes Supply Chain Optimisation n io ns tio ica n Ch ai Cr s os W sor fu kin nc tio g na Fu lw nc or tio kin na g l. W or kin g Sk dis ill cip s & lin es t or pp us in es Su at or r-b n b la un m Leadership & + Vision io ol te cis l. C m Co In De up pl y ed na al rn Simplification & Control n io ct g sa sin an es Tr roc P + Reliability & Flexibility ta y Da rac cu Ac Performance Measures r te al S nc Synchronisation of Supply with Demand Ex rtu Systems va Integrate with Customers & Suppliers te In Vi Ad People Program Management Establishing the starting point focuses the action plans

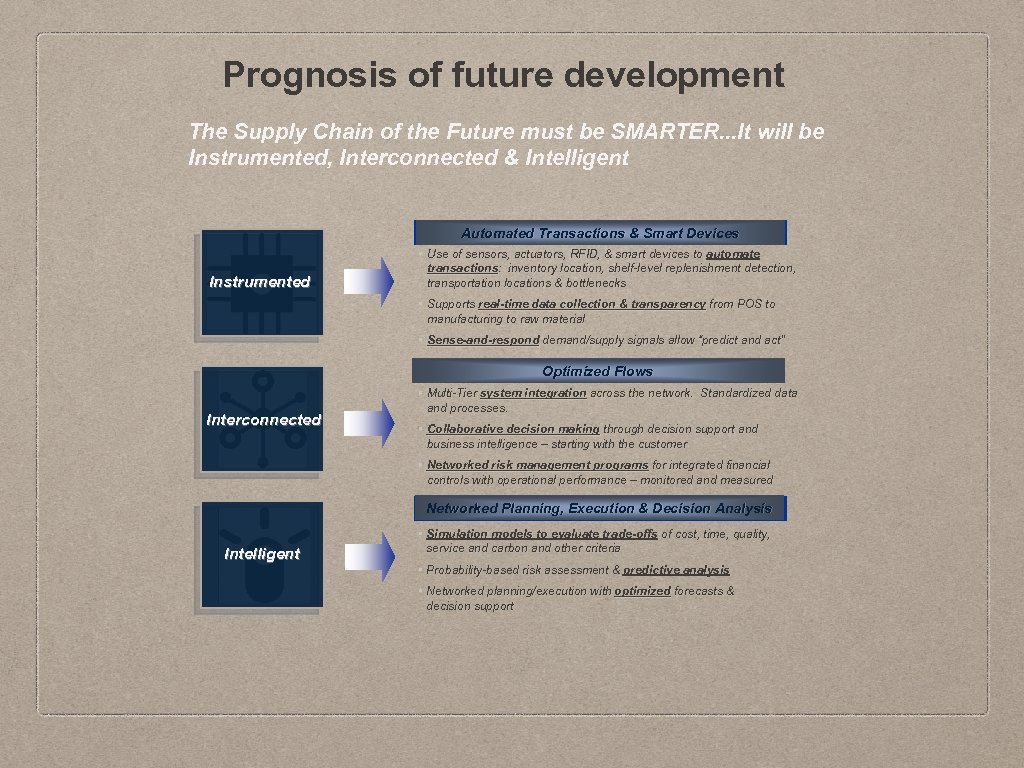

Prognosis of future development The Supply Chain of the Future must be SMARTER. . . It will be Instrumented, Interconnected & Intelligent Automated Transactions & Smart Devices Instrumented • Use of sensors, actuators, RFID, & smart devices to automate transactions: inventory location, shelf-level replenishment detection, transactions: transportation locations & bottlenecks • Supports real-time data collection & transparency from POS to manufacturing to raw material • Sense-and-respond demand/supply signals allow “predict and act” Optimized Flows Interconnected • Multi-Tier system integration across the network. Standardized data and processes. • Collaborative decision making through decision support and business intelligence – starting with the customer • Networked risk management programs for integrated financial controls with operational performance – monitored and measured Networked Planning, Execution & Decision Analysis Intelligent • Simulation models to evaluate trade-offs of cost, time, quality, service and carbon and other criteria • Probability-based risk assessment & predictive analysis • Networked planning/execution with optimized forecasts & decision support

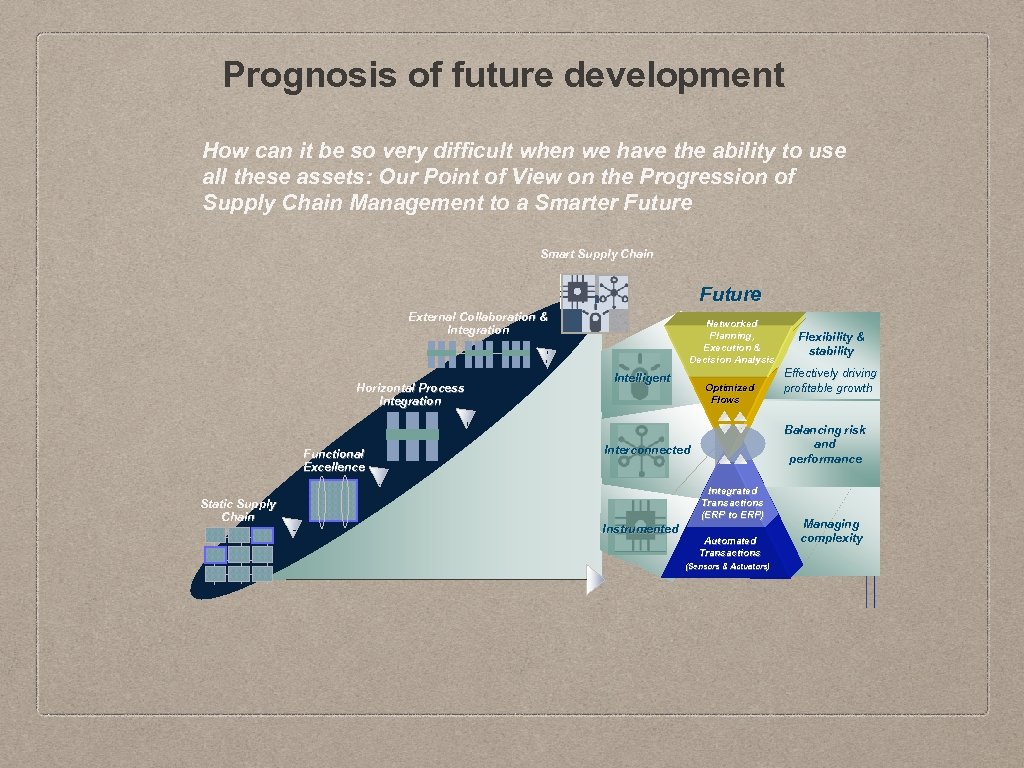

Prognosis of future development How can it be so very difficult when we have the ability to use all these assets: Our Point of View on the Progression of Supply Chain Management to a Smarter Future Smart Supply Chain Future External Collaboration & Integration Horizontal Process Integration Functional Excellence Static Supply Chain Networked Planning, Execution & Decision Analysis Intelligent Optimized Flows Effectively driving profitable growth Balancing risk and performance Interconnected Integrated Transactions (ERP to ERP) Instrumented Flexibility & stability Automated Transactions (Sensors & Actuators) Managing complexity

Conclusion • • Zara’s production system is pulled by demand which allows a better alignment to customers’ expectations. Zara’s vertically integrated supply chain process is the keystone of its success since its ensure the needed flexibility to be able to react quickly to the market trends.

519afef2300bb049e4f6f01a58c13308.ppt