63e44a0604f7b66c9105928b54b8fd7a.ppt

- Количество слайдов: 32

“Best Practices” - Branch Ops

Sx. e AIM Grant Howard Grant W. Howard Company 2*

Grant Howard: • Expert on Inventory Management, System Utilization and “Getting Results” • Works with Multiple Distributors, Associations and Software Houses • Conceptual Designer Behind Sx. e’s AIM • Sits on Multiple Board of Directors • Founder of Grant W. Howard Company 3*

Our Discussion Today • • • Company Objectives Inventory Management Model Branch/Ops Involvement Branch/Ops Tools 4*

Company Objectives Profitability Growth Bottom Line Profits (P&L) GM and Oper. Efficiency Asset Management Longevity Customer Service & Retention Maintain the base Employee Happiness 5*

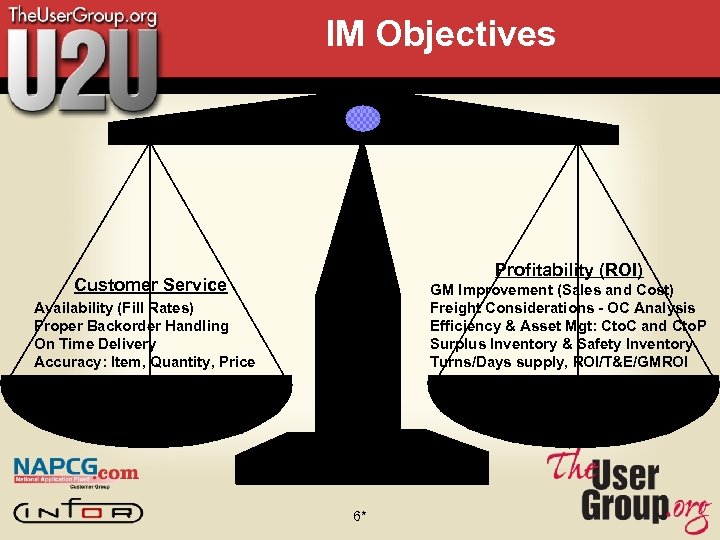

IM Objectives Profitability (ROI) Customer Service GM Improvement (Sales and Cost) Freight Considerations - OC Analysis Efficiency & Asset Mgt: Cto. C and Cto. P Surplus Inventory & Safety Inventory Turns/Days supply, ROI/T&E/GMROI Availability (Fill Rates) Proper Backorder Handling On Time Delivery Accuracy: Item, Quantity, Price Watch the C to C Watch the C to P (Warehousing, Handling, Obsol. & Shrink, (Purchasing/Replenishment, Receiving & Put-away, Taxes, Interest) A/P) 6*

Service - Fill Rates • • How well a business meets its customer’s needs - pulse of customer’s happiness/loyalty. What to Measure: Fill Rates = Shipped/Ordered Quantity: 9 out of 10 = 90% Line Item SC: 9 out of 10 = 0% Order Ship Complete? • • • What Should Fill Rates Be? The Report is Broken - Look at “First Pass” Orders - EDI, Fax, Internet, etc for true fill rates and backorder retention Only one way to better Fill Rates - The Right Inventory. Two ways to the Right Inventory. . . 7

Service Level • High Service Level: – Maintain/gain customers – Less B/O’s paper float - Save $ • Low Service Level: – Lost $ – Lost customers 8*

Inventory Profits • Low Turns/GMROI/T&E – Kills the bottom line -Cost to carry – Some inventory $ not working - steals from products really needed- Service Level Suffering • High Turns/GMROI/T&E – Cost of Purchasing – Service level may be suffering 9*

The Replenishment Model A Good Replenishment Model addresses the two objectives of Customer Service and Profitability When to Replenish? What to Replenish and How much? What is not needed? 10*

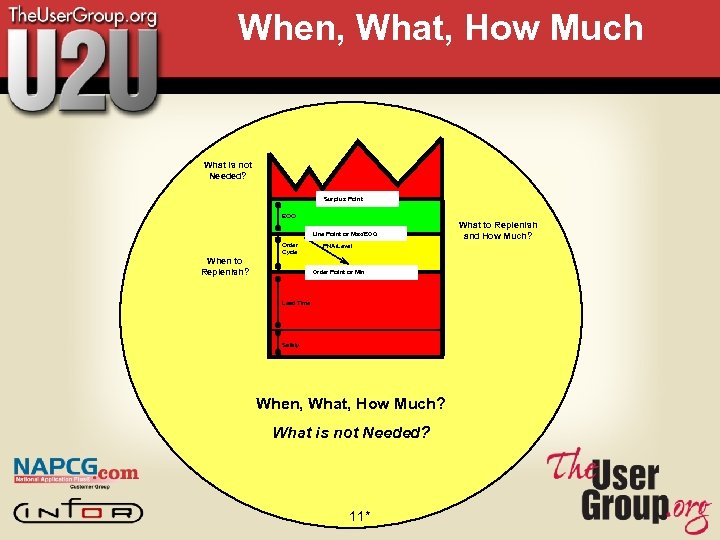

When, What, How Much What is not Needed? Surplus Point EOQ Line Point or Max/EOQ Order Cycle When to Replenish? PNA/Level Order Point or Min Lead Time Safety When, What, How Much? What is not Needed? 11* What to Replenish and How Much?

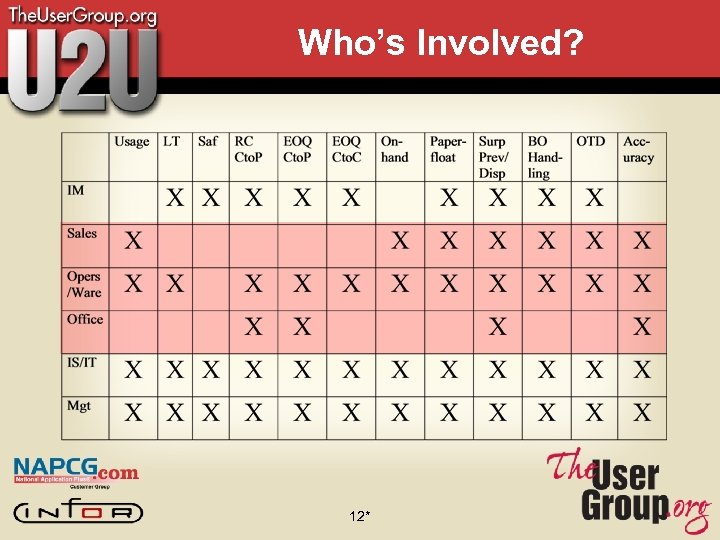

Who’s Involved? 12*

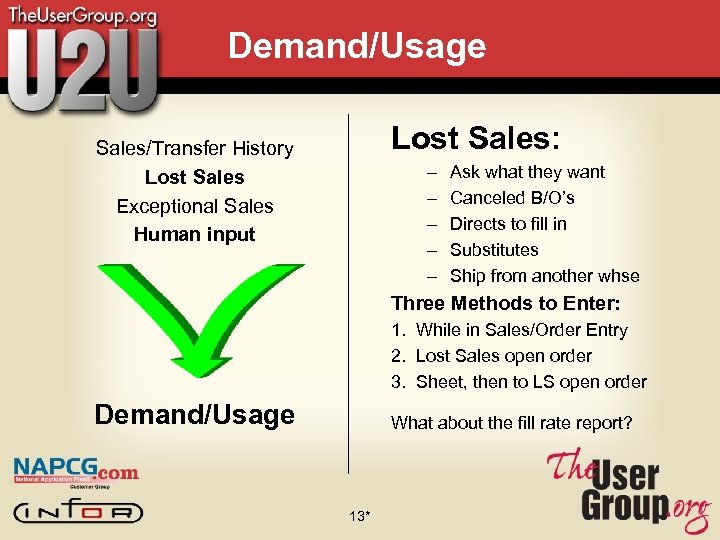

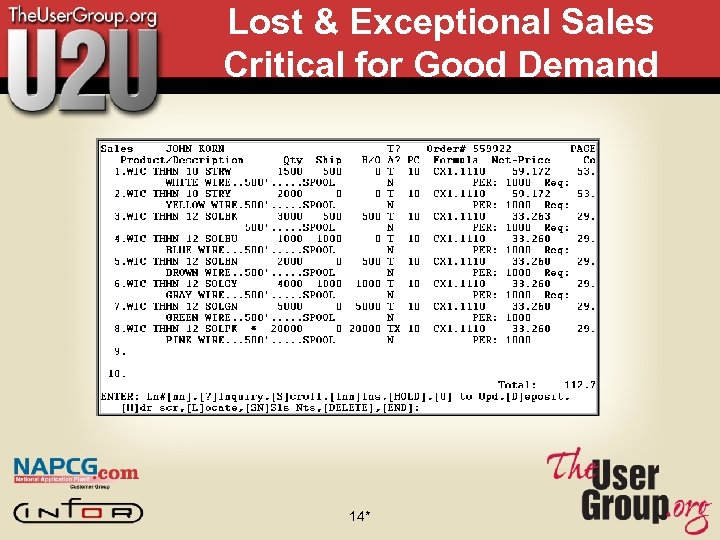

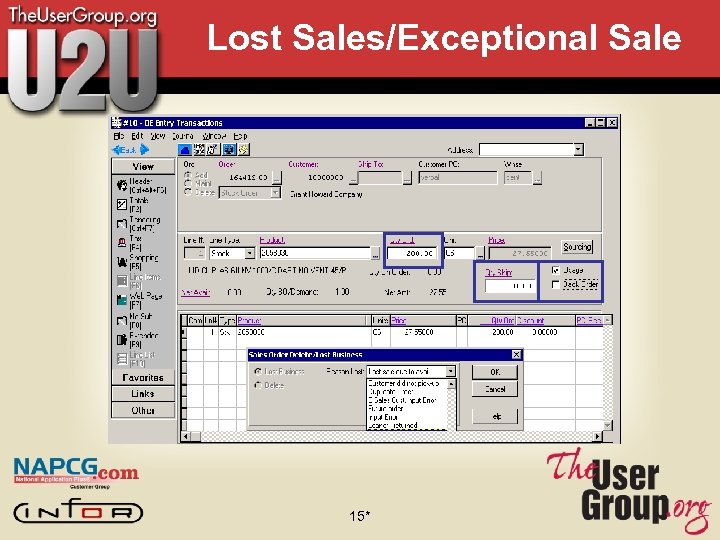

Demand/Usage Lost Sales: Sales/Transfer History Lost Sales Exceptional Sales Human input – – – Ask what they want Canceled B/O’s Directs to fill in Substitutes Ship from another whse Three Methods to Enter: 1. While in Sales/Order Entry 2. Lost Sales open order 3. Sheet, then to LS open order Demand/Usage What about the fill rate report? 13*

Lost & Exceptional Sales Critical for Good Demand 14*

Lost Sales/Exceptional Sale 15*

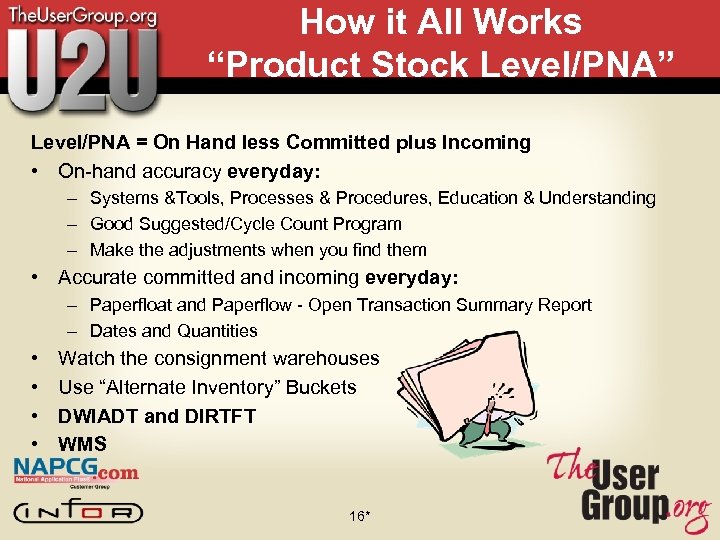

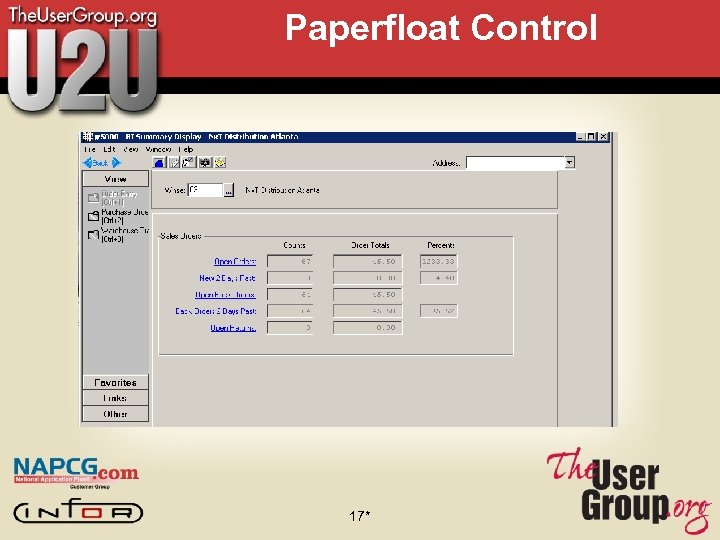

How it All Works “Product Stock Level/PNA” Level/PNA = On Hand less Committed plus Incoming • On-hand accuracy everyday: – Systems &Tools, Processes & Procedures, Education & Understanding – Good Suggested/Cycle Count Program – Make the adjustments when you find them • Accurate committed and incoming everyday: – Paperfloat and Paperflow - Open Transaction Summary Report – Dates and Quantities • • Watch the consignment warehouses Use “Alternate Inventory” Buckets DWIADT and DIRTFT WMS 16*

Paperfloat Control 17*

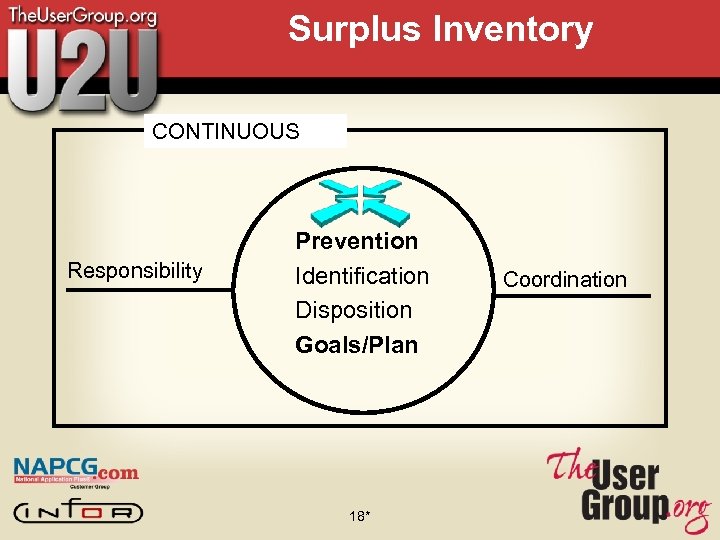

Surplus Inventory CONTINUOUS Responsibility Prevention Identification Disposition Goals/Plan 18* Coordination

Surplus Inventory Disposition BOP/GAP - Put of the fire: Short or Long Term BLP/Sugg Xfers - Use it where you can: Long Term Teach branches to use LT first. Don’t borrow stock and put branch in “need”. 1. 2. 3. 4. 5. Stock Balance: (“X” Months Supply) - With “To” branch approval/Before Buy Sell Above Cost: Customer, Other Distributor At Cost: Sell at cost, Return at cost with no charges (freight, restock) Below Cost: Sell below cost, Return below cost and/or with charges Sell Above “Write-off” Cost: Garage/Fire Sale, Flea Market, Auction House, Liquidation House 6. Dump at “Write-off” Cost: Donate, Scrap, Dump 19*

We have to have Branch, Operations and Sales Understanding, Buy-in and Help - TEAM: • Usage/Demand: Sales, Transfers, Lost Sales, Exceptional Sales, Manual/Automated overrides • Lead Time: P/Os, Transfers, Manual overrides • Purchasing Net Available: On-hand open docs – Orders, Transfers, P/Os, Workorders • Stock List and Excess Prevention/Disposition 20*

Getting Results 21*

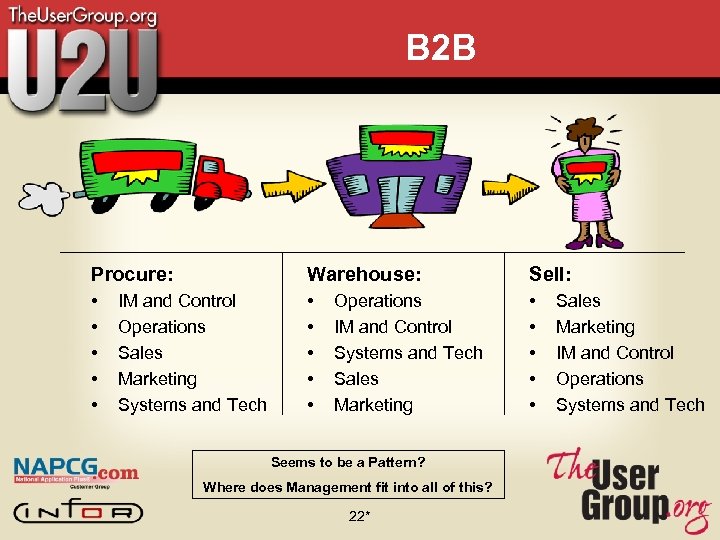

B 2 B Procure: Warehouse: Sell: • • • • IM and Control Operations Sales Marketing Systems and Tech Operations IM and Control Systems and Tech Sales Marketing Seems to be a Pattern? Where does Management fit into all of this? 22* Sales Marketing IM and Control Operations Systems and Tech

Back to Basics Many distributors DON’T: • Set the system up properly • Feed the system good data • Understand or Use the system properly • Clean up bad processes and procedures • Educate their people on the system or processes • Help departments work together • Help work towards common goals Yet they think it will all just magically work 23*

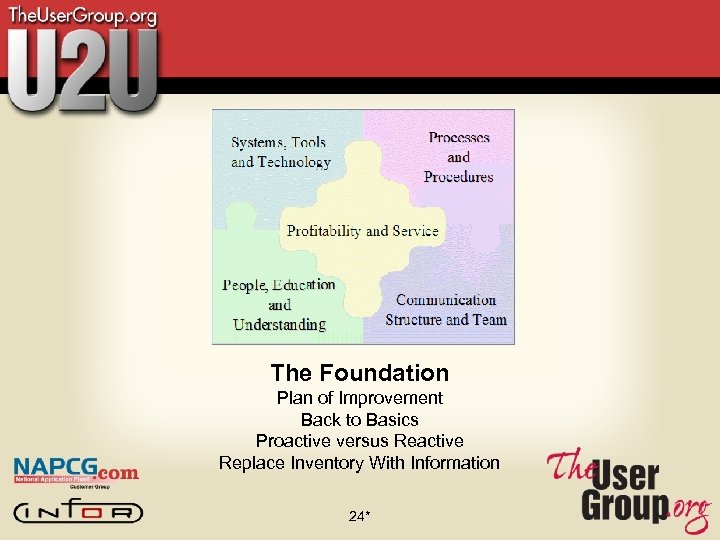

The Foundation Plan of Improvement Back to Basics Proactive versus Reactive Replace Inventory With Information 24*

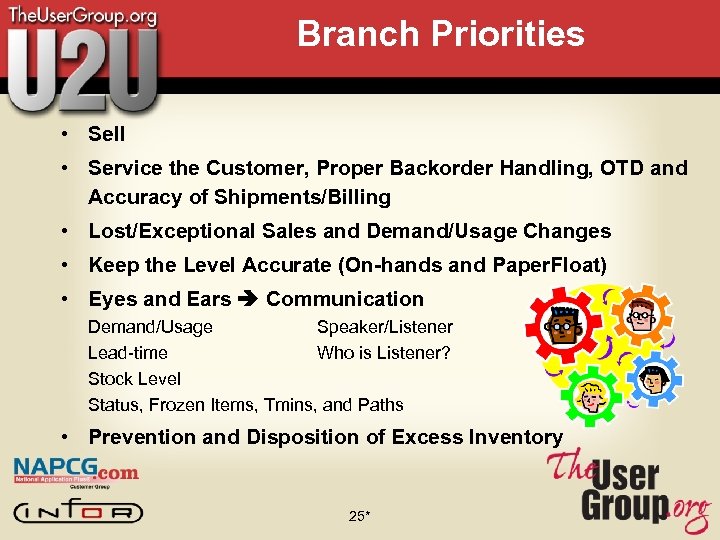

Branch Priorities • Sell • Service the Customer, Proper Backorder Handling, OTD and Accuracy of Shipments/Billing • Lost/Exceptional Sales and Demand/Usage Changes • Keep the Level Accurate (On-hands and Paper. Float) • Eyes and Ears Communication Demand/Usage Speaker/Listener Lead-time Who is Listener? Stock Level Status, Frozen Items, Tmins, and Paths • Prevention and Disposition of Excess Inventory 25*

The Tools Branch Management Tools - Toolkit: – Open Transaction Summary and CC Monitor (daily) - Keeping the stock level accurate – Lost Sales/Exceptional Sales (Daily and Monthly) Keeping demand accurate – Customer Service Action (daily) - Providing outstanding service, getting backorders in and out to the customer - Closed Loop Thinking – Suppressed with Activity, (Monthly and Daily) Stocking the right inventory – Top 25 Surplus (weekly) - Reducing surplus and improving profitability AND SERVICE 26*

JDI It’s too hard to log lost and exceptional sales It’s too hard to keep the paper work clean It’s too hard to keep the on-hand correct It’s too hard to work excess inventory It’s too hard. . . If…, It’s too hard. . . , The system is broken or doesn’t have it…, We will never get them to do that…, We don’t know how to do that… J D I ! 27*

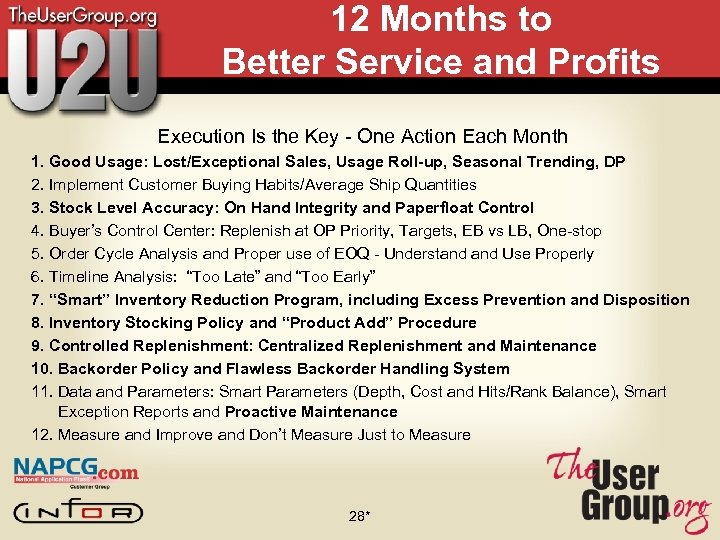

12 Months to Better Service and Profits Execution Is the Key - One Action Each Month 1. Good Usage: Lost/Exceptional Sales, Usage Roll-up, Seasonal Trending, DP 2. Implement Customer Buying Habits/Average Ship Quantities 3. Stock Level Accuracy: On Hand Integrity and Paperfloat Control 4. Buyer’s Control Center: Replenish at OP Priority, Targets, EB vs LB, One-stop 5. Order Cycle Analysis and Proper use of EOQ - Understand Use Properly 6. Timeline Analysis: “Too Late” and “Too Early” 7. “Smart” Inventory Reduction Program, including Excess Prevention and Disposition 8. Inventory Stocking Policy and “Product Add” Procedure 9. Controlled Replenishment: Centralized Replenishment and Maintenance 10. Backorder Policy and Flawless Backorder Handling System 11. Data and Parameters: Smart Parameters (Depth, Cost and Hits/Rank Balance), Smart Exception Reports and Proactive Maintenance 12. Measure and Improve and Don’t Measure Just to Measure 28*

Spend your days reacting to the fires. . . you may be efficient, but will you be effective? Fire Prevention. . . 29*

GWHCO Our approach involves tailoring the best practices in distribution to the specific needs of our clients. Our working philosophy revolves around building a strong and selfmaintaining infrastructure by developing a working plan based on processes and procedures, education and understanding, implementation of tools and technology; and through communication, organizational structure and team environments. www. gwhco. org Grant Howard: ghoward@gwhco. org 734 -428 -0529 Phone 734 -428 -0593 Fax John Cason: jcason@gwhco. org 256 -830 -0676 Phone 256 -830 -0481 Fax 30*

Q&A

Thank You!

63e44a0604f7b66c9105928b54b8fd7a.ppt