0a079b88429a487d266386f83722ce08.ppt

- Количество слайдов: 44

Benchmarking the Engineering & Construction Industry 32 nd National Energy & Environmental Conference September 19, 2005

Benchmarking Defined Benchmarking is the systematic process of measuring one’s performance against recognized leaders for the purpose of determining best practices that lead to superior performance when adapted and utilized. - CII, 1995

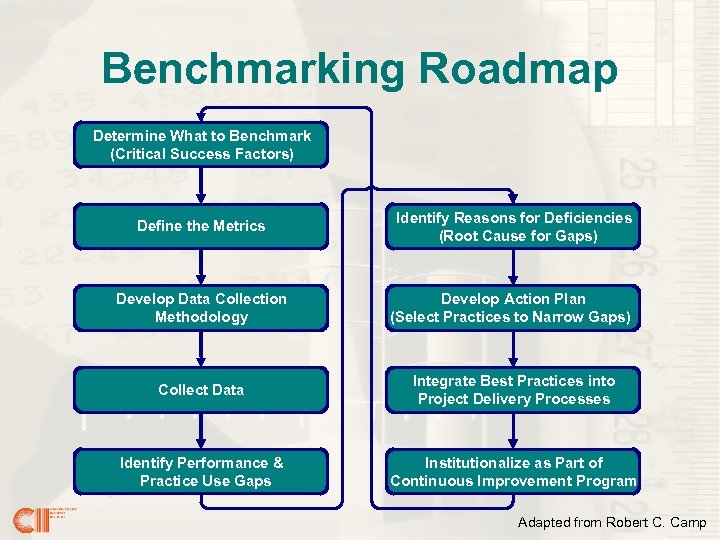

Benchmarking Roadmap Determine What to Benchmark (Critical Success Factors) Define the Metrics Identify Reasons for Deficiencies (Root Cause for Gaps) Develop Data Collection Methodology Develop Action Plan (Select Practices to Narrow Gaps) Collect Data Integrate Best Practices into Project Delivery Processes Identify Performance & Practice Use Gaps Institutionalize as Part of Continuous Improvement Program Adapted from Robert C. Camp

Essential Elements of Benchmarking • • Process (structured/systematic) Best practice oriented Part of a continuous improvement process Understanding what is important to your organization (critical success factors) • Measurement, comparison, gap analysis against leaders • Adapting practices to your organization

Metric A quantifiable, simple, and understandable measure that can be used to compare and improve performance.

Attributes of a Good Metric • • Quantifiable – objectively or subjectively Simple, unambiguous, and understandable Reliable and consistent Verifiable Timely Cost-effective Meaningful to users Drives the appropriate action NYSOT 2003 and AFSC 1990

Principles of Metrics • • Provides value to stakeholders Focused on continuous improvement Establishes objective targets Are ones we have the ability to influence • Should be kept to the critical few

What Metrics are NOT 1. Charts – Charts graphically display metrics, but the chart itself is not a metric. 2. Schedules – Schedules can be used to produce metrics, but the schedule itself is not a metric. 3. Goals, Objectives, Strategies, Plans, etc. , although these can be measured, they are not metrics, but rather they can be stated in terms of metrics. 4. Snapshots or one-time status measures as displayed in pie charts. Comparisons of status over time can be a metric. 1 Adapted from AFSC - 1990

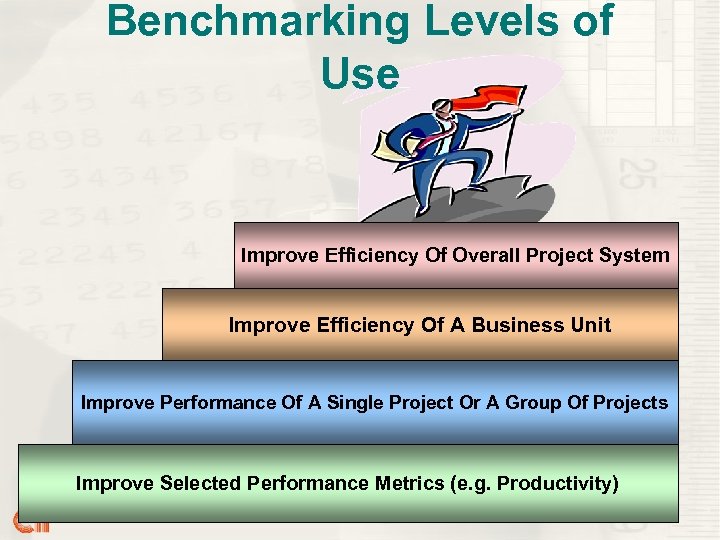

Benchmarking Levels of Use Improve Efficiency Of Overall Project System Improve Efficiency Of A Business Unit Improve Performance Of A Single Project Or A Group Of Projects Improve Selected Performance Metrics (e. g. Productivity)

Measuring Performance

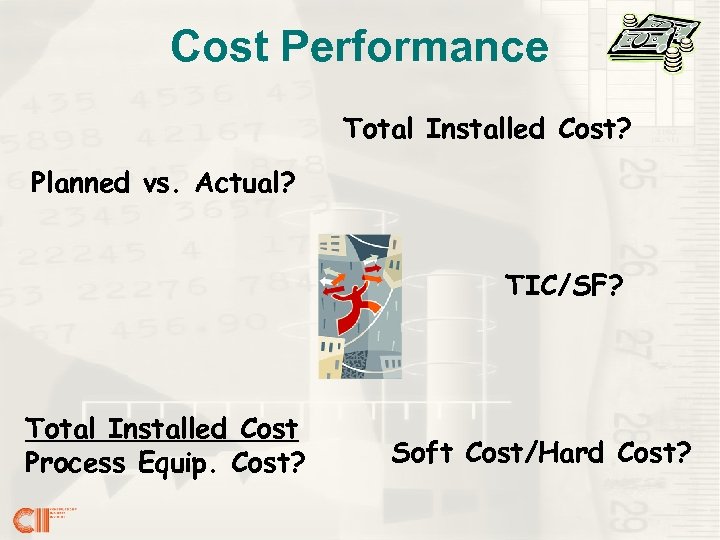

Cost Performance Total Installed Cost? Planned vs. Actual? TIC/SF? Total Installed Cost Process Equip. Cost? Soft Cost/Hard Cost?

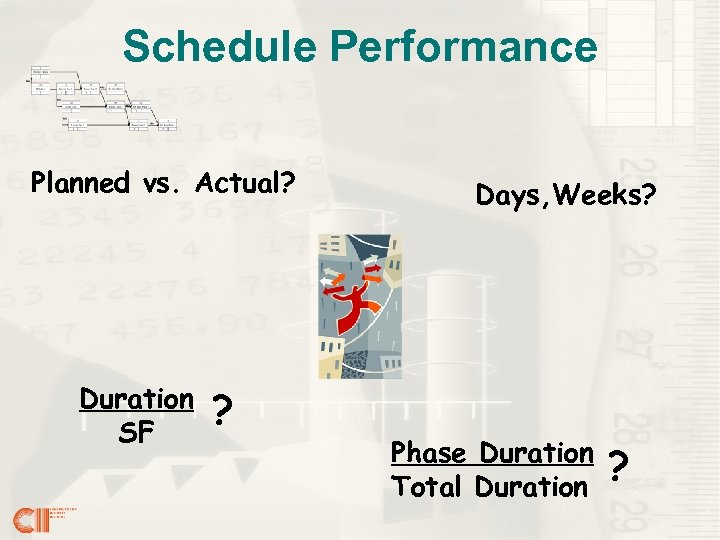

Schedule Performance Planned vs. Actual? Duration SF ? Days, Weeks? Phase Duration Total Duration ?

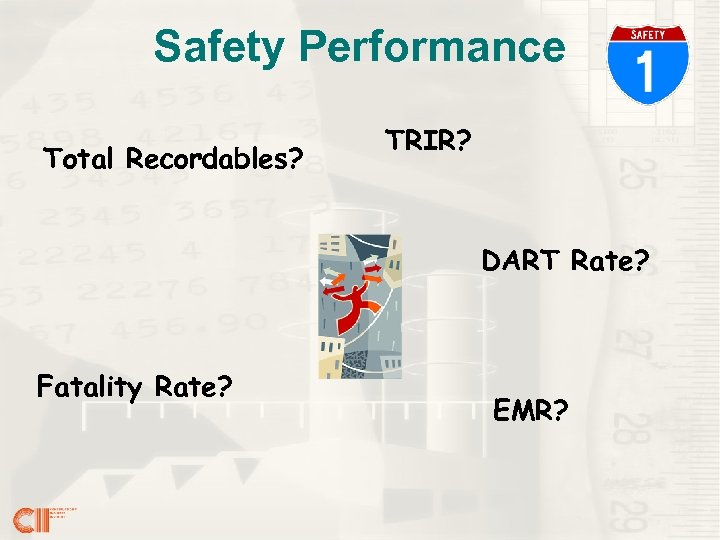

Safety Performance Total Recordables? TRIR? DART Rate? Fatality Rate? EMR?

Change Performance Development Changes? Scope Changes? Cost Impacts? Cost of Changes Total Installed Cost ? Schedule Impacts?

Rework Performance Dollar Cost? Rework Cost ? Construction Cost Schedule Impact? Productivity Impact?

Productivity Performance Directs vs. Indirects? Engineering or Construction? Cy/Hr? Tons/Hr?

Measuring Practice Use

Best Practice Use • Pre-Project Planning • Constructability • Change Management • Team Building • Zero Accident Techniques • Planning for Startup • Materials Management • Automation/Integration Tech • Quality Management • Alignment • Risk Assessment • Design for Maintainability Quantitative or Qualitative?

Formats for Comparison

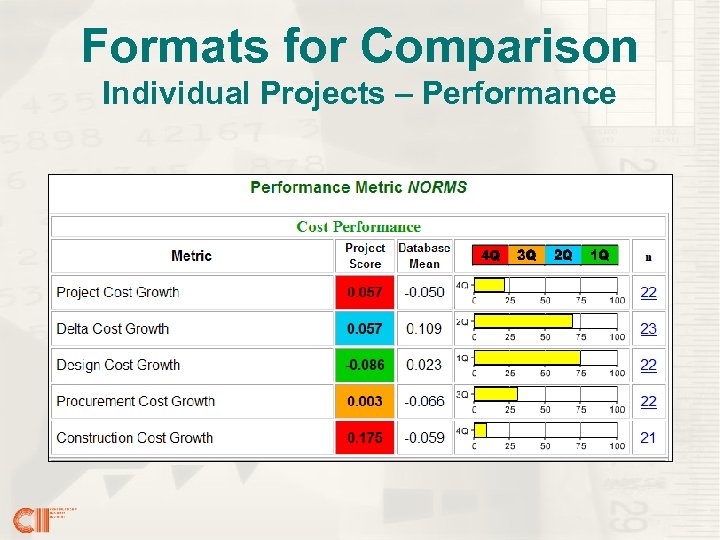

Formats for Comparison Individual Projects – Performance

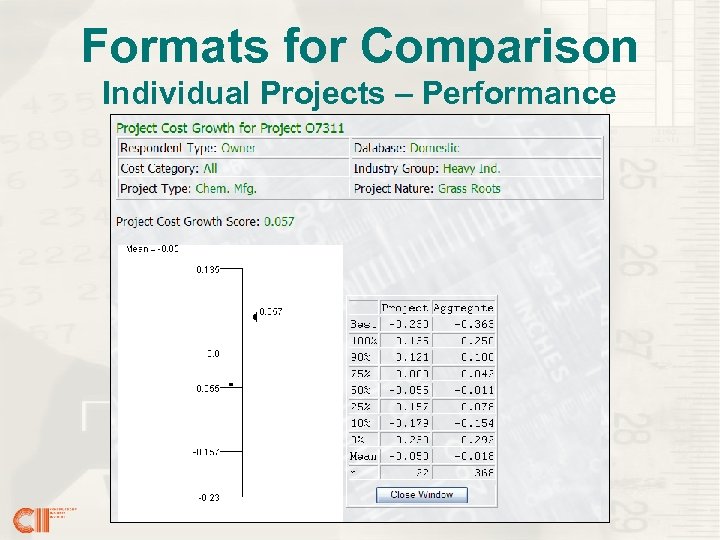

Formats for Comparison Individual Projects – Performance

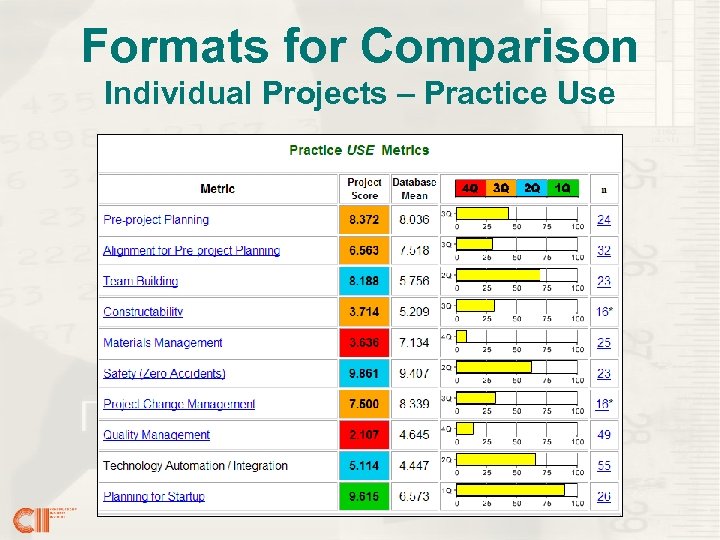

Formats for Comparison Individual Projects – Practice Use

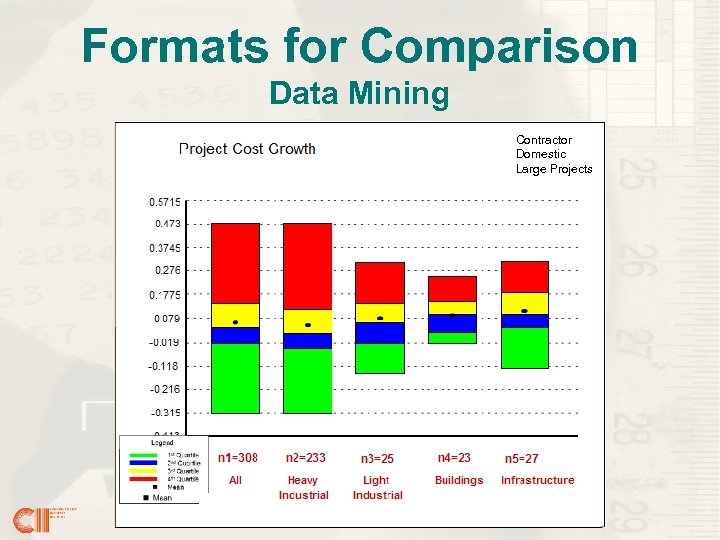

Formats for Comparison Data Mining Contractor Domestic Large Projects

Quantifying Value of Best Practices

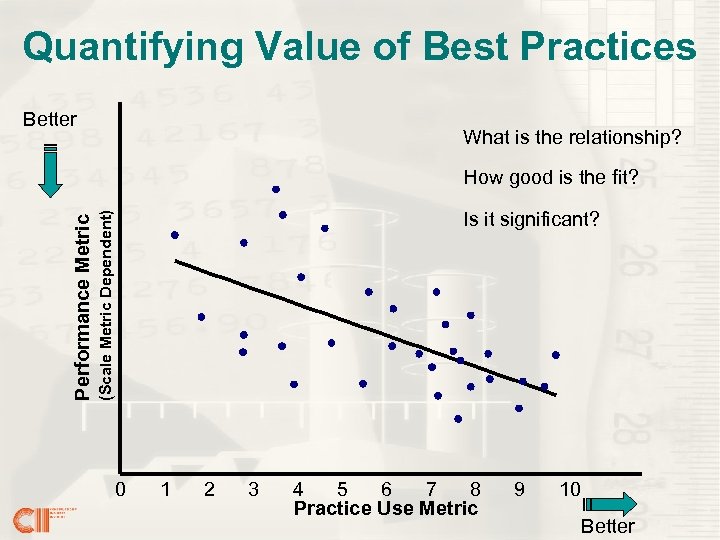

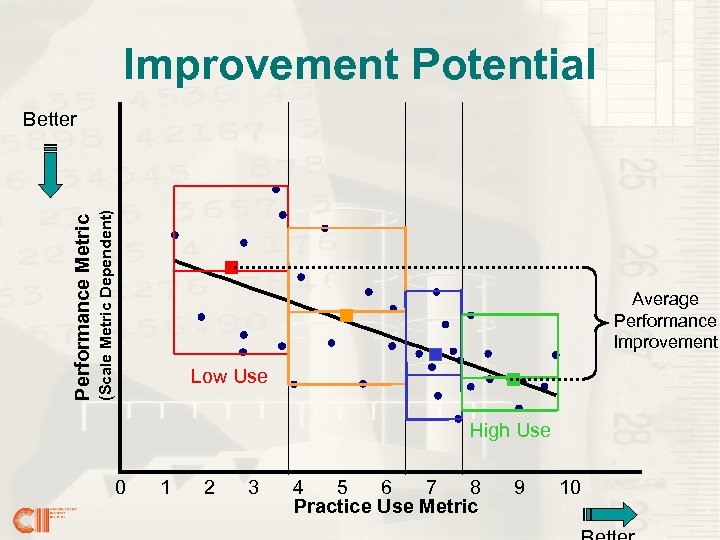

Quantifying Value of Best Practices Better What is the relationship? Is it significant? (Scale Metric Dependent) Performance Metric How good is the fit? 0 1 2 3 4 5 6 7 8 Practice Use Metric 9 10 Better

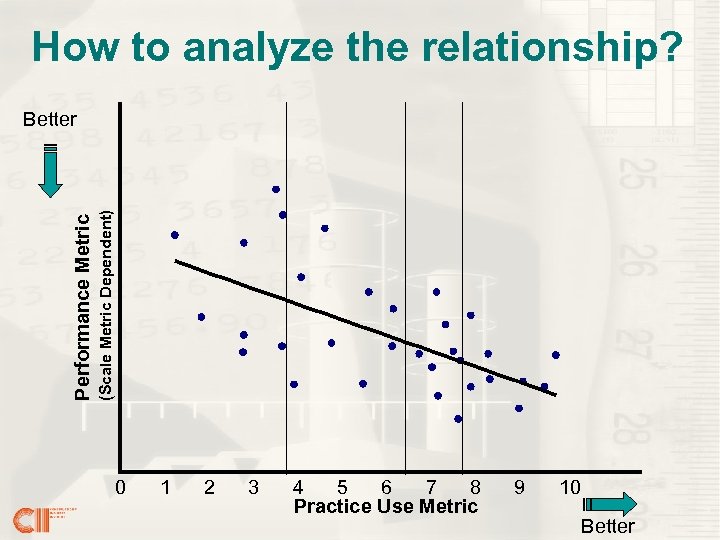

How to analyze the relationship? (Scale Metric Dependent) Performance Metric Better 0 1 2 3 4 5 6 7 8 Practice Use Metric 9 10 Better

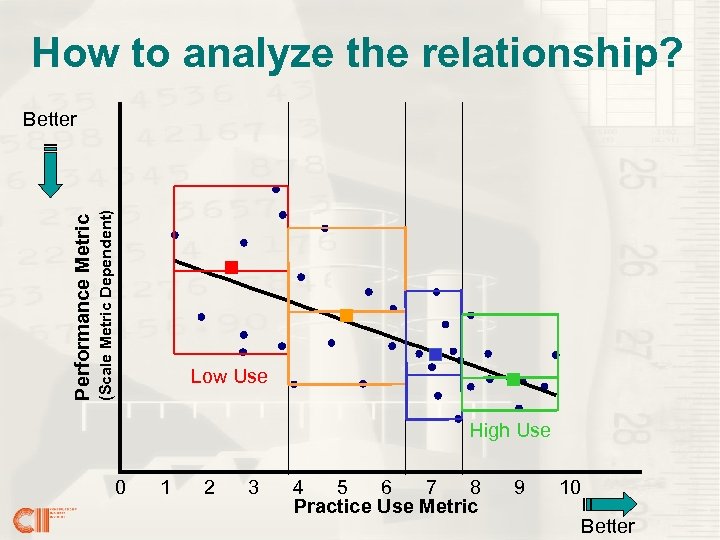

How to analyze the relationship? (Scale Metric Dependent) Performance Metric Better Low Use High Use 0 1 2 3 4 5 6 7 8 Practice Use Metric 9 10 Better

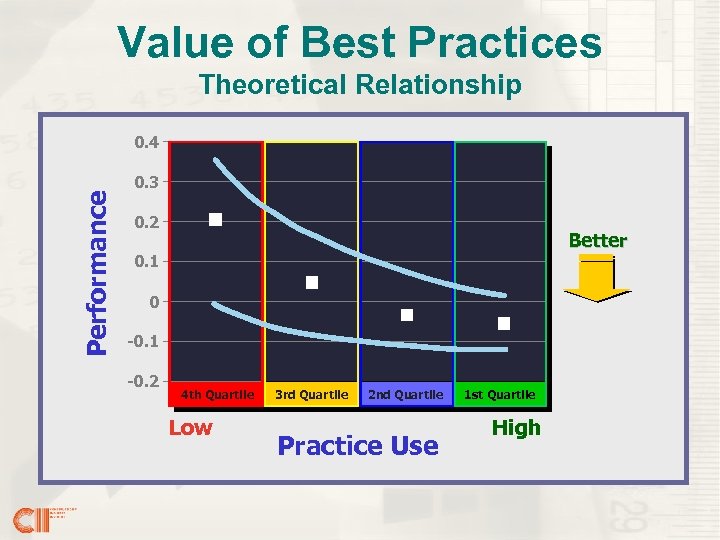

Value of Best Practices Theoretical Relationship Performance 0. 4 0. 3 0. 2 Better 0. 1 0 -0. 1 -0. 2 4 th Quartile Low 3 rd Quartile 2 nd Quartile Practice Use 1 st Quartile High

Improvement Potential (Scale Metric Dependent) Performance Metric Better Average Performance Improvement Low Use High Use 0 1 2 3 4 5 6 7 8 Practice Use Metric 9 10

Accessing the Online System

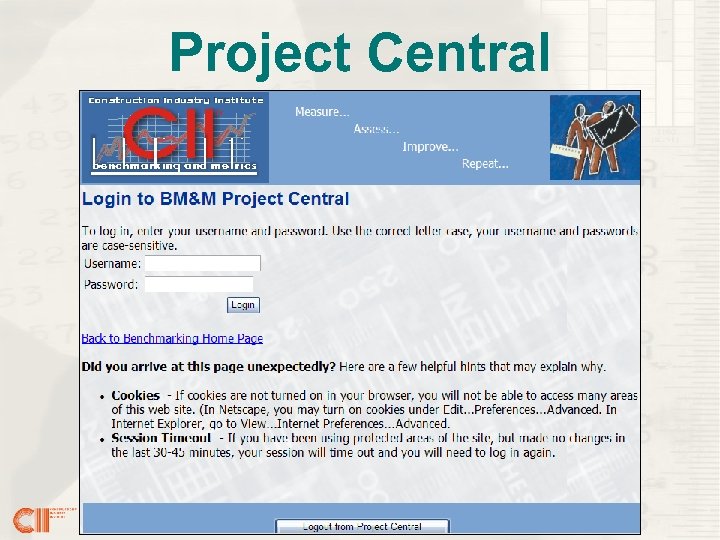

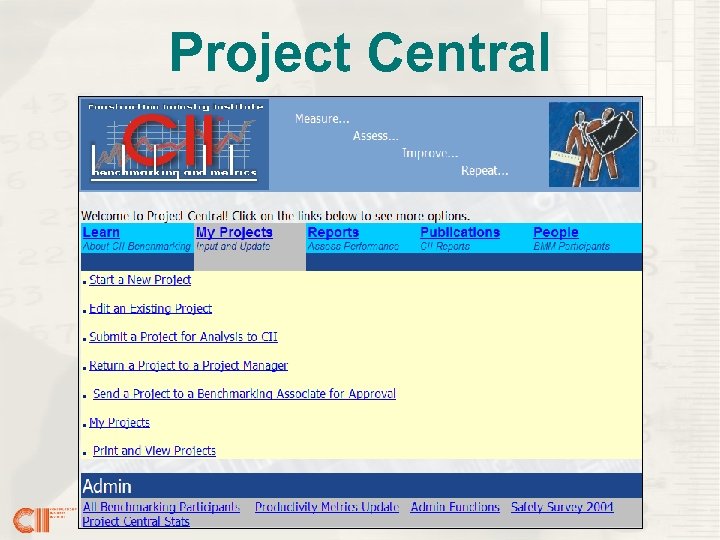

Project Central

Project Central

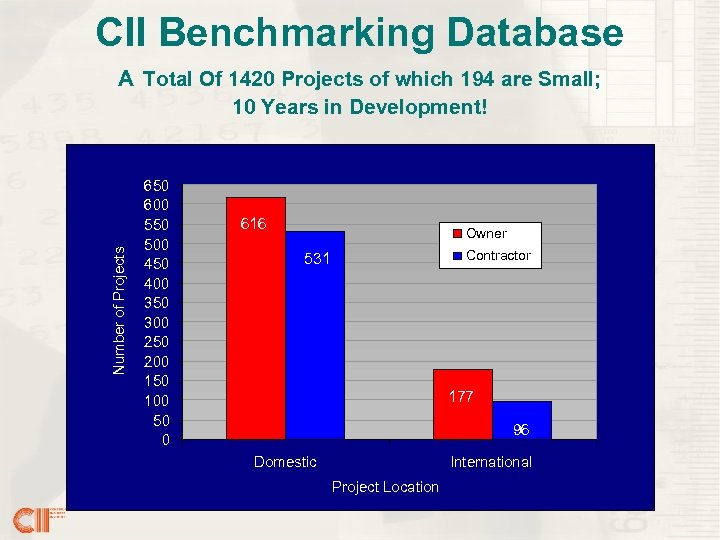

CII Benchmarking Database Number of Projects A Total Of 1420 Projects of which 194 are Small; 10 Years in Development! 650 600 550 500 450 400 350 300 250 200 150 100 50 0 616 Owner Contractor 531 177 96 Domestic International Project Location

Current CII Benchmarking Systems Available • • Large Project Small Project Pharmaceutical Productivity

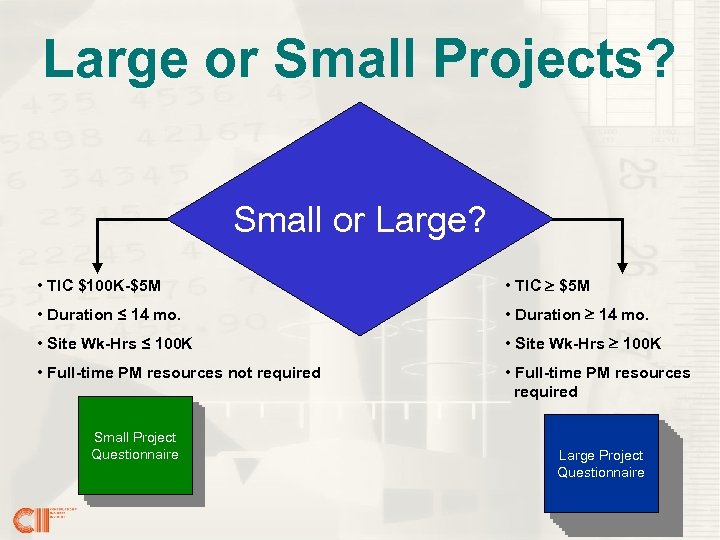

Large or Small Projects? Small or Large? • TIC $100 K-$5 M • TIC $5 M • Duration ≤ 14 mo. • Duration 14 mo. • Site Wk-Hrs ≤ 100 K • Site Wk-Hrs 100 K • Full-time PM resources not required • Full-time PM resources required Small Project Questionnaire Large Project Questionnaire

Summary • Best Practices can improve performance. • Benchmarking helps you to: – quantify performance and practice use. – establish improvement goals. – achieve “best in class performance. ”

Availability • Free to member companies. • $7500 for non-member access* *Limit of 10 projects per year

Questions?

Backups

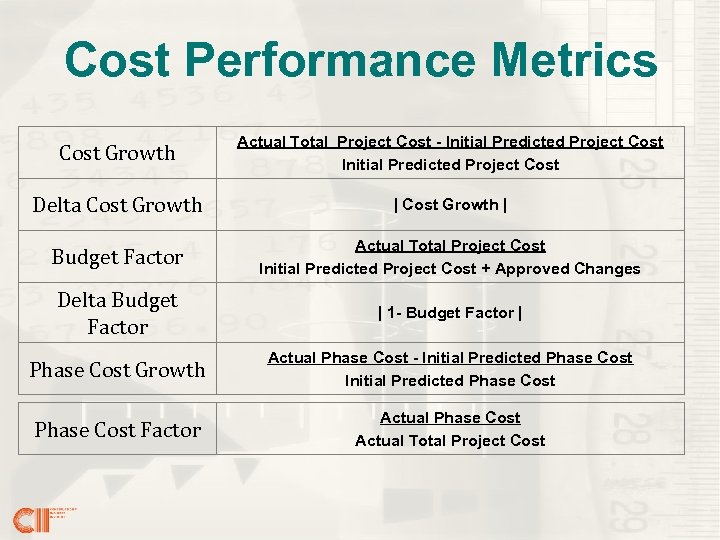

Cost Performance Metrics Cost Growth Actual Total Project Cost - Initial Predicted Project Cost Delta Cost Growth | Budget Factor Actual Total Project Cost Initial Predicted Project Cost + Approved Changes Delta Budget Factor | 1 - Budget Factor | Phase Cost Growth Actual Phase Cost - Initial Predicted Phase Cost Factor Actual Phase Cost Actual Total Project Cost

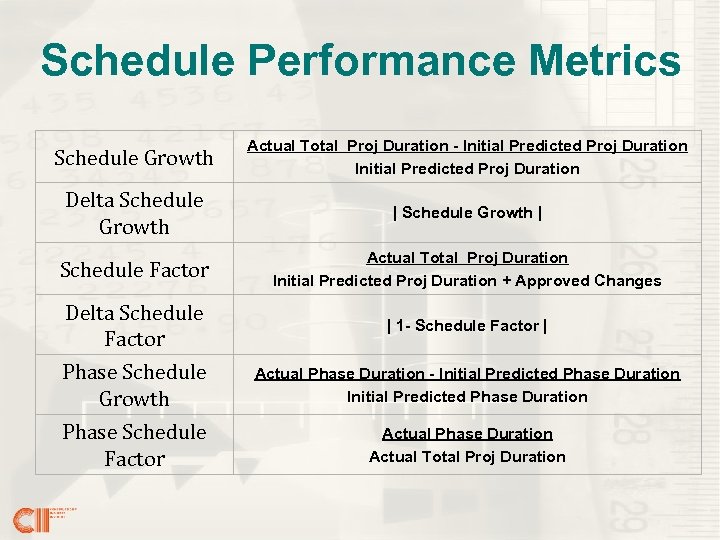

Schedule Performance Metrics Schedule Growth Actual Total Proj Duration - Initial Predicted Proj Duration Delta Schedule Growth | Schedule Factor Actual Total Proj Duration Initial Predicted Proj Duration + Approved Changes Delta Schedule Factor | 1 - Schedule Factor | Phase Schedule Growth Actual Phase Duration - Initial Predicted Phase Duration Phase Schedule Factor Actual Phase Duration Actual Total Proj Duration

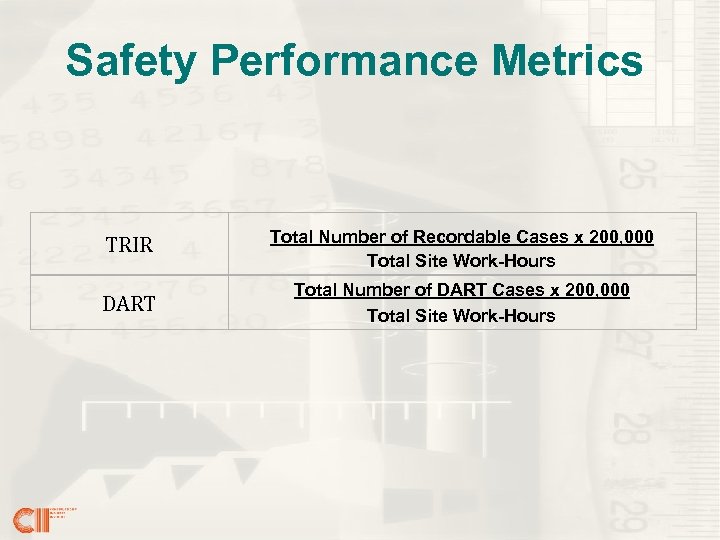

Safety Performance Metrics TRIR Total Number of Recordable Cases x 200, 000 Total Site Work-Hours DART Total Number of DART Cases x 200, 000 Total Site Work-Hours

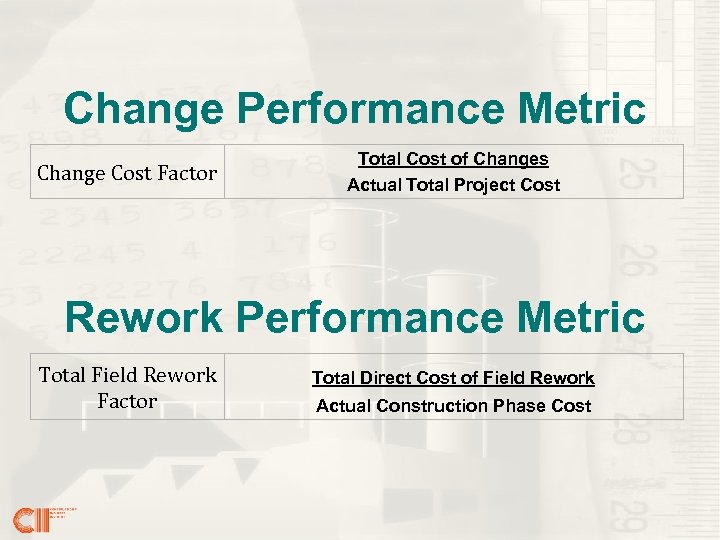

Change Performance Metric Change Cost Factor Total Cost of Changes Actual Total Project Cost Rework Performance Metric Total Field Rework Factor Total Direct Cost of Field Rework Actual Construction Phase Cost

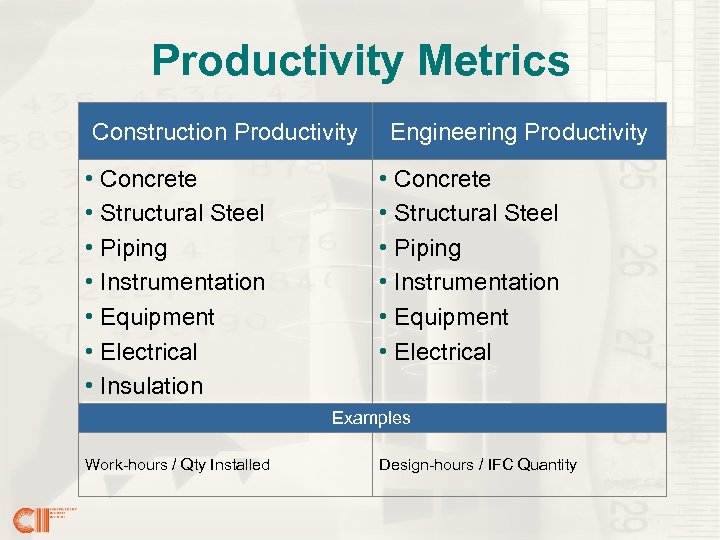

Productivity Metrics Construction Productivity • Concrete • Structural Steel • Piping • Instrumentation • Equipment • Electrical • Insulation Engineering Productivity • Concrete • Structural Steel • Piping • Instrumentation • Equipment • Electrical Examples Work-hours / Qty Installed Design-hours / IFC Quantity

0a079b88429a487d266386f83722ce08.ppt