6cb6d9c0413b9b485bed8ae82fabef69.ppt

- Количество слайдов: 19

Belenos Clean Power Holding Ltd. Belenos activities in the field of green energy and its storage E. Varkaraki, U. Hannesen, A. Closset 7 th International Scientific Conference on Energy and Climate Change – Green Economy 8 -10 October 2014, KEPA, UOA, Athens, Greece

Introduction 2007: Belenos Clean Power Holding was founded by N. G. Hayek to develop a sustainable energy chain starting from solar energy Prestigious partners were associated to the project: Swatch Group Ltd, Hayek Engineering, Deutsche Bank, Swiss Federal Institute of Technology Zurich, Paul Scherrer Institut, Ammann-Group, Group E and actor George Clooney Since 2008: Development of a unique FC system running on Hydrogen and pure Oxygen in partnership with the Paul-Scherrer-Institute (PSI) Since 2011: Development of Hydrogen/Air FC system for mobile applications. Redesign of H 2/O 2 FC system for stationary applications Since 2012: Development of a PEM electrolyser for the production of hydrogen fuel from water and renewable energy

The Belenos Clean Energy Chain PV Panels PV Surface: Annual Mobility: DC/AC H 2 O 70 m 2 15’ 000 km Electrolysis c Grid M FC H 2 O 2 Battery

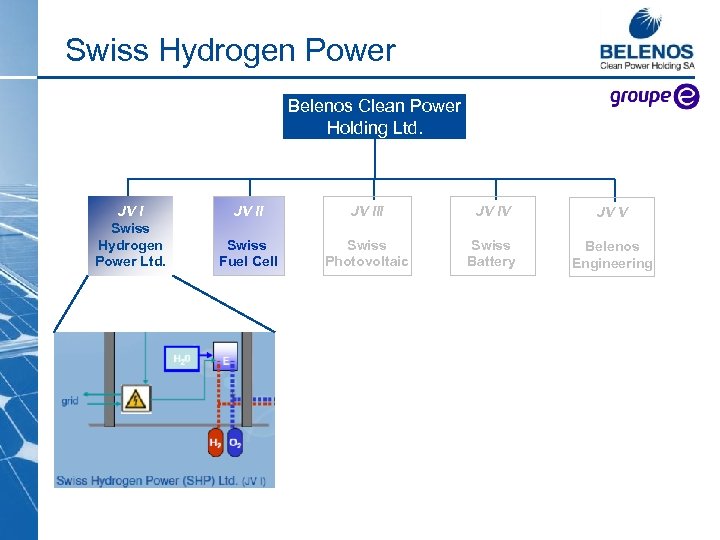

Swiss Hydrogen Power Belenos Clean Power Holding Ltd. JV I Swiss Hydrogen Power Ltd. JV III JV IV JV V Swiss Fuel Cell Swiss Photovoltaic Swiss Battery Belenos Engineering

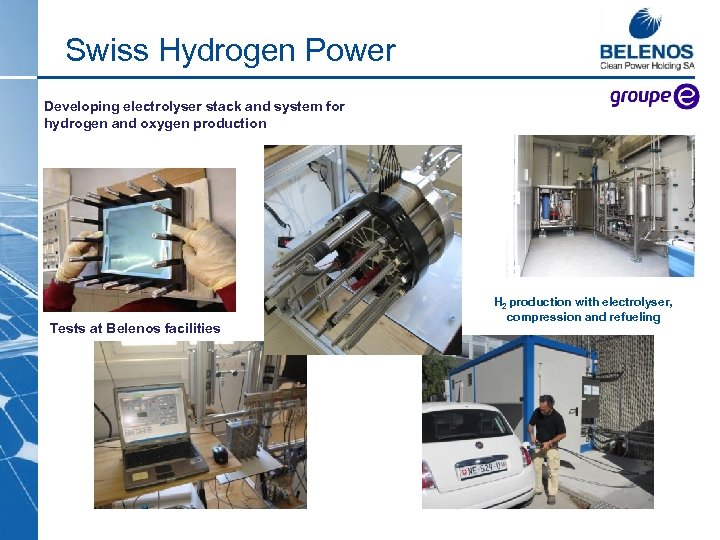

Swiss Hydrogen Power Developing electrolyser stack and system for hydrogen and oxygen production Tests at Belenos facilities H 2 production with electrolyser, compression and refueling

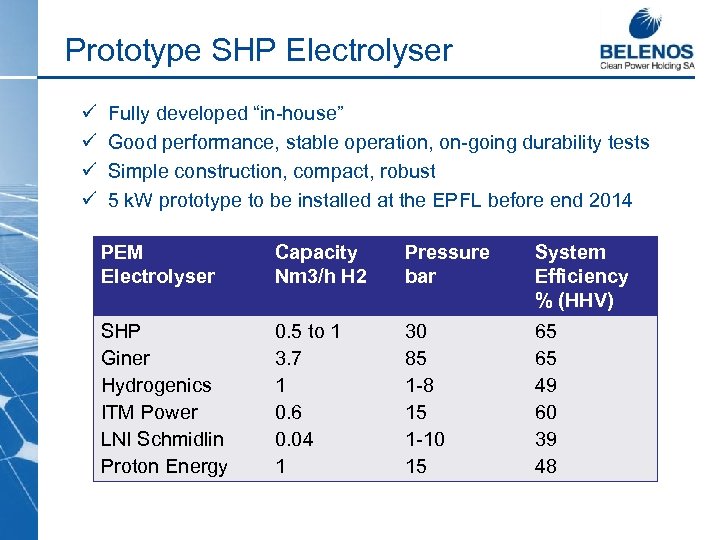

Prototype SHP Electrolyser ü ü Fully developed “in-house” Good performance, stable operation, on-going durability tests Simple construction, compact, robust 5 k. W prototype to be installed at the EPFL before end 2014 PEM Electrolyser Capacity Nm 3/h H 2 Pressure bar System Efficiency % (HHV) SHP Giner Hydrogenics ITM Power LNI Schmidlin Proton Energy 0. 5 to 1 3. 7 1 0. 6 0. 04 1 30 85 1 -8 15 1 -10 15 65 65 49 60 39 48

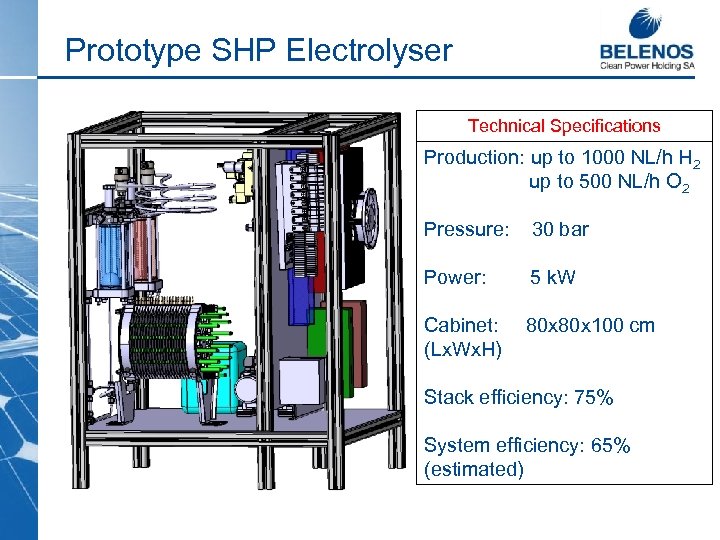

Prototype SHP Electrolyser Technical Specifications Production: up to 1000 NL/h H 2 up to 500 NL/h O 2 Pressure: 30 bar Power: 5 k. W Cabinet: (Lx. Wx. H) 80 x 100 cm Stack efficiency: 75% System efficiency: 65% (estimated)

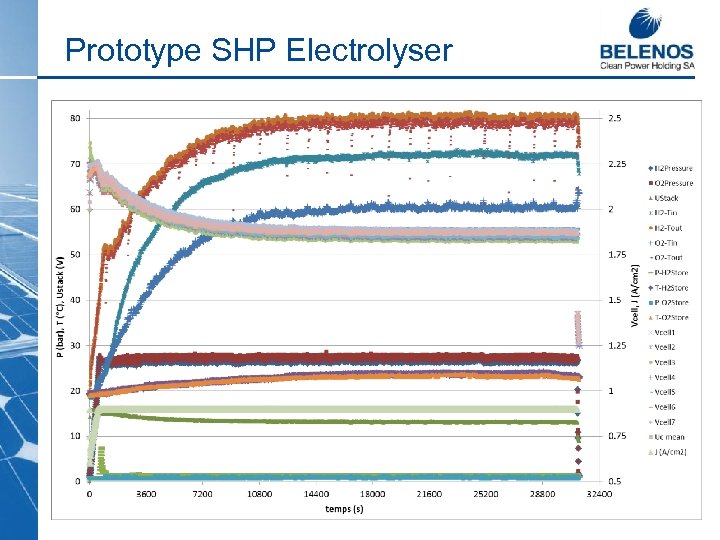

Prototype SHP Electrolyser

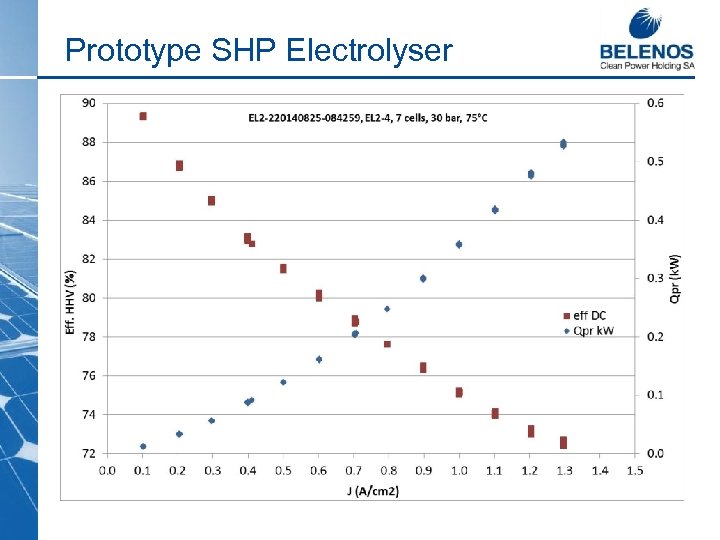

Prototype SHP Electrolyser

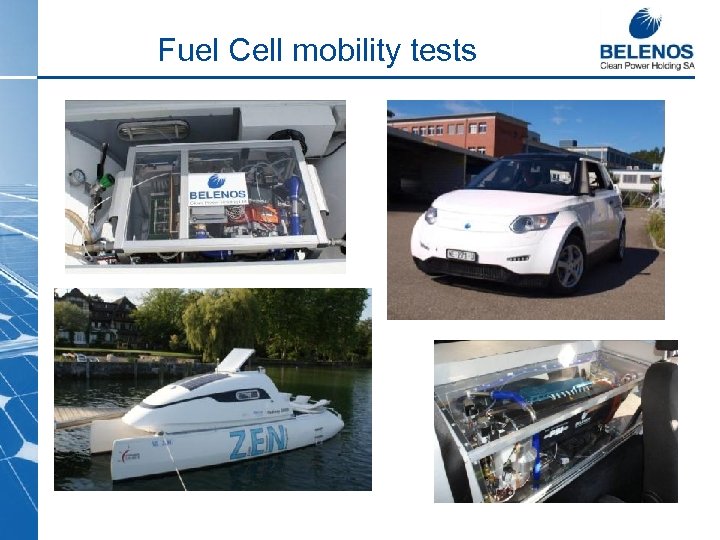

Fuel Cell mobility tests

Belenos Fuel Cell System ü Proprietary design of fuel cell stack and FC system ü Development of low cost PEM membrane with excellent durability in collaboration with PSI ü Bipolar plate development with leading supplier for stationary FC systems ü Integrated system components for improved performance and reduced cost ü Production capacity for 1 MW/month available

Advantages H 2/O 2 FC over H 2/Air FC Higher system efficiency v 60. . 70% with H 2/O 2 vs. 45. . 55% with H 2/Air Significantly lower cost v Power density (W/cm 2 active area) is twice as high at same efficiency v 80% of FC cost is active area cost (bipolar plates and MEA) Better reliability v Very simple system v Very few moving parts Fast start-up v Full power achievable within a few seconds v No startup-time and -energy for air compressor required Independent from ambient air conditions v Operation at high altitudes possible v Operation at any ambient temperature and humidity possible v No degradation due to air pollution

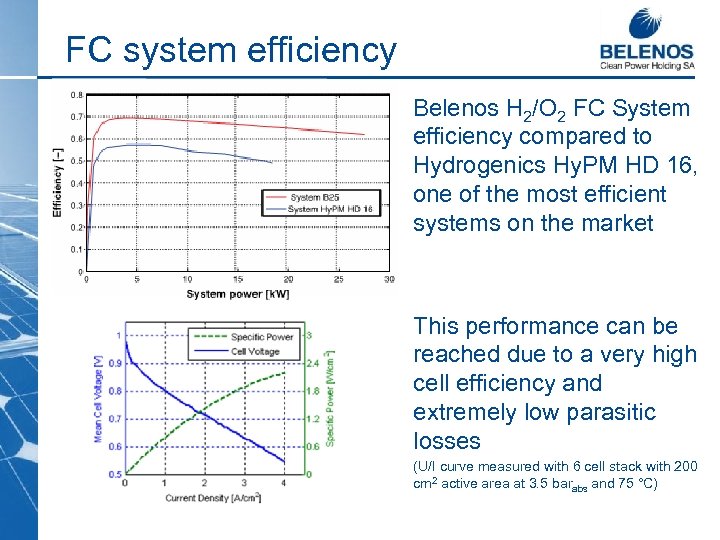

FC system efficiency Belenos H 2/O 2 FC System efficiency compared to Hydrogenics Hy. PM HD 16, one of the most efficient systems on the market This performance can be reached due to a very high cell efficiency and extremely low parasitic losses (U/I curve measured with 6 cell stack with 200 cm 2 active area at 3. 5 barabs and 75 °C)

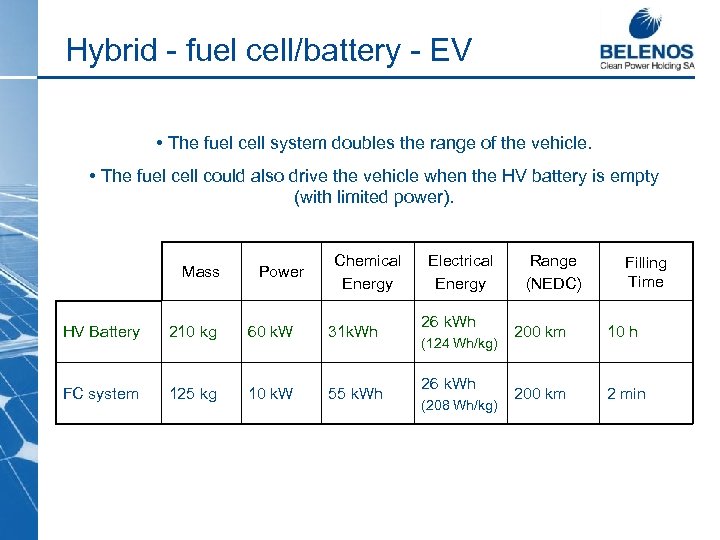

Hybrid - fuel cell/battery - EV • The fuel cell system doubles the range of the vehicle. • The fuel cell could also drive the vehicle when the HV battery is empty (with limited power). Mass Power Chemical Energy HV Battery 210 kg 60 k. W 31 k. Wh FC system 125 kg 10 k. W 55 k. Wh Electrical Energy 26 k. Wh (124 Wh/kg) 26 k. Wh (208 Wh/kg) Range (NEDC) Filling Time 200 km 10 h 200 km 2 min

Electric FIAT 500 with FC range extender Fuel Cell (FC) system information: Batteries • Emissions • Electric power/peak =0 = 20/60 k. W • Battery capacity = 26 k. Wh • Battery weight = 210 kg • Hydrogen capacity = 1. 7 kg • Fuel Cell power = 10 k. W • Battery driving range = 200 km • H 2 driving range • Total Range Drive train, power electronics and Fuel Cell H 2 tank & security system control = 200 km = 400 km • Curb Weight = 1300 kg • Number of seats =4

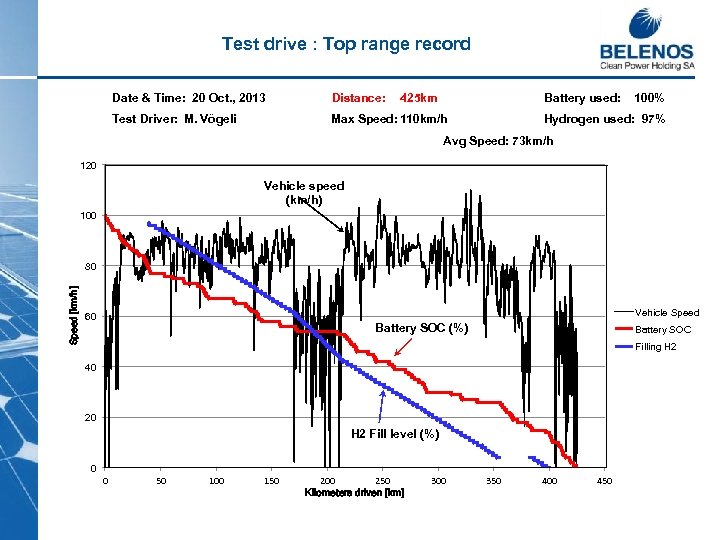

Test drive : Top range record Date & Time: 20 Oct. , 2013 Distance: 425 km Battery used: Test Driver: M. Vögeli Max Speed: 110 km/h 100% Hydrogen used: 97% Avg Speed: 73 km/h 120 Vehicle speed (km/h) 100 Speed [km/h] 80 Vehicle Speed 60 Battery SOC (%) Battery SOC Filling H 2 40 20 H 2 Fill level (%) 0 0 50 100 150 200 250 Kilometers driven [km] 300 350 400 450

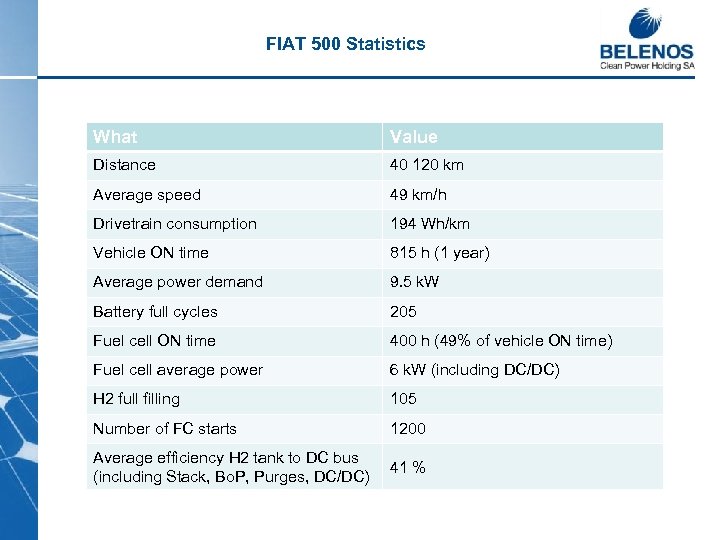

FIAT 500 Statistics What Value Distance 40 120 km Average speed 49 km/h Drivetrain consumption 194 Wh/km Vehicle ON time 815 h (1 year) Average power demand 9. 5 k. W Battery full cycles 205 Fuel cell ON time 400 h (49% of vehicle ON time) Fuel cell average power 6 k. W (including DC/DC) H 2 full filling 105 Number of FC starts 1200 Average efficiency H 2 tank to DC bus (including Stack, Bo. P, Purges, DC/DC) 41 %

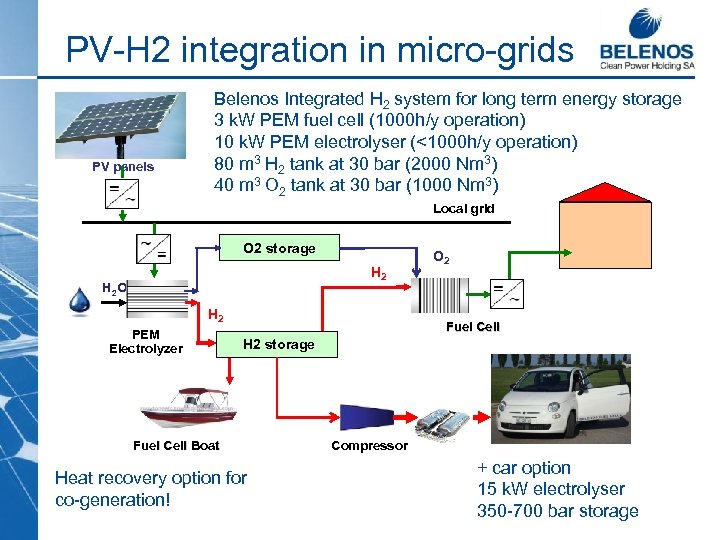

PV-H 2 integration in micro-grids PV panels Belenos Integrated H 2 system for long term energy storage 3 k. W PEM fuel cell (1000 h/y operation) 10 k. W PEM electrolyser (<1000 h/y operation) 80 m 3 H 2 tank at 30 bar (2000 Nm 3) 40 m 3 O 2 tank at 30 bar (1000 Nm 3) Local grid O 2 storage H 2 O H 2 PEM Electrolyzer O 2 Fuel Cell H 2 storage Fuel Cell Boat Heat recovery option for co-generation! Compressor + car option 15 k. W electrolyser 350 -700 bar storage

Thank you for your attention!

6cb6d9c0413b9b485bed8ae82fabef69.ppt