bdd7be050a081a78aed0310cb08fd6cc.ppt

- Количество слайдов: 27

Behavioural Safety – Journey towards Excellence in Safety Presented by Sunil Kumar C S Senior Specialist Corporate Environment, Health & Safety ITC Limited

ITC’s Journey towards zero accidents Corporate EHS department set up in 1990 85 % of EHS Management is nothing but good engineering practices State-of-art fire detection & protection systems - NFPA codes Best-in-classs electricals – National/International Standards Civil structures conforming to Indian Standards/NBC Management Systems – OHSAS 18001 certified Design for Safety Progressing towards reducing accidents,

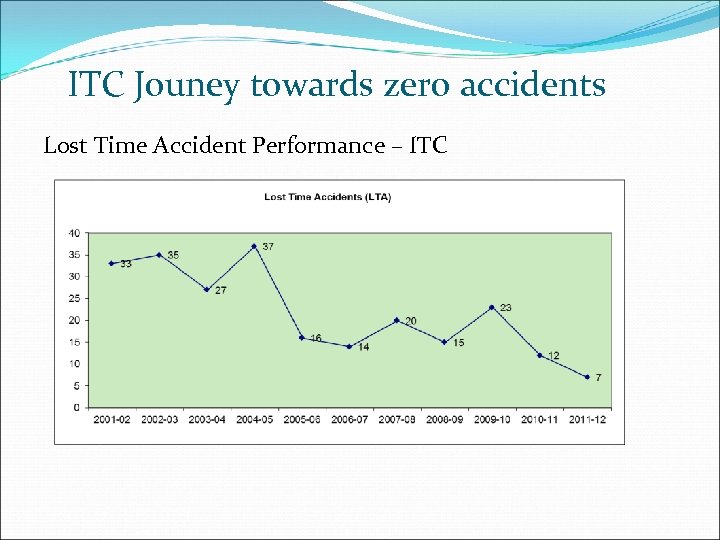

ITC Jouney towards zero accidents Lost Time Accident Performance – ITC

ITC’s Journey towards zero accidents UNITS – ACHIEVED ZERO ACCIDENTS MILESTONE IN 2011 -12 Cigarette factories at Kidderpore, Pune and Saharanpur Leaf Threshing Units at Anaparti & Chirala Packaging & Printing Units at Haridwar, Tiruvottiyur & Munger Paperboards and Specialty Papers Units at Bollarum & Kovai Foods Unit at Haridwar Personal Care Products Units at Haridwar & Manpura Research Centres at Bengaluru & Rajahmundry ITC Infotech’s Bengaluru Office Complex ITC Green Centre, Gurgaon ITC Head Quarters, Kolkata ITC Grand Central, ITC Kakatiya, ITC Rajputana, ITC Maratha, , ITC Mughal, ITC Sonar & ITC Windsor My Fortune & Welcom. Hotel Sheraton New Delhi Fortune Resort Bay Island Hotel, Port Blair Surya Nepal’s Unit at Simra

Even with Best Management systems/ technologies, Accidents do happen Why ? ? ?

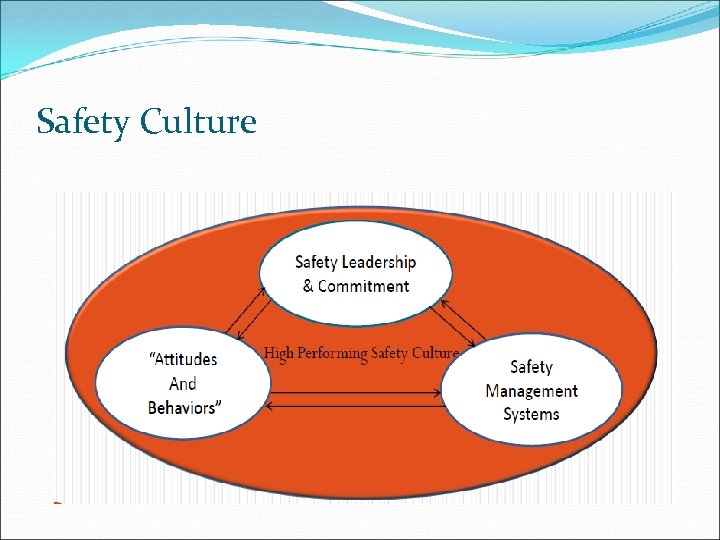

Safety Culture

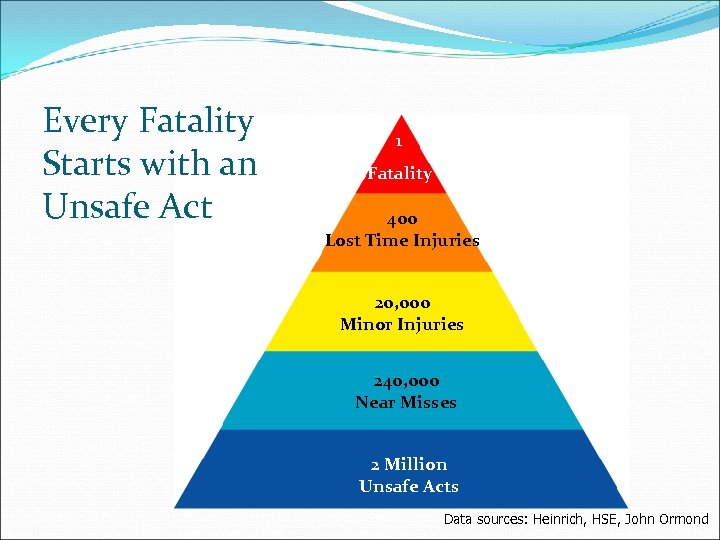

Every Fatality Starts with an Unsafe Act 1 1 Fatality 400 Lost Time Injuries 20, 000 Minor Injuries 240, 000 Near Misses 2 Million Unsafe Acts Data sources: Heinrich, HSE, John Ormond

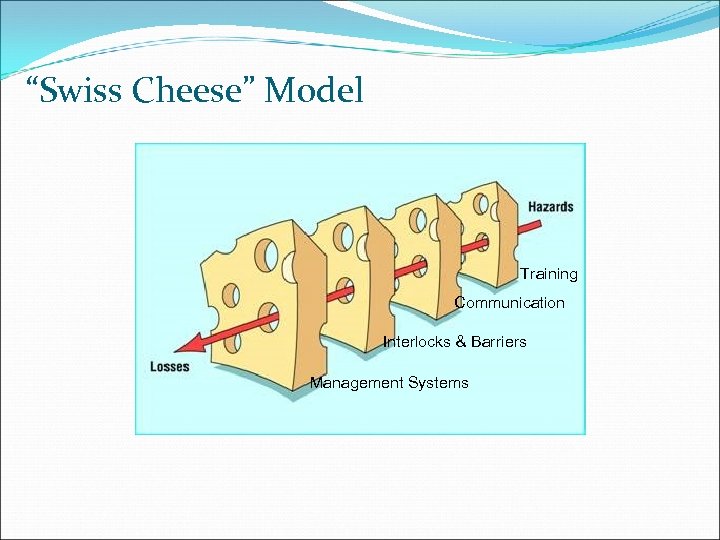

“Swiss Cheese” Model Training Communication Interlocks & Barriers Management Systems

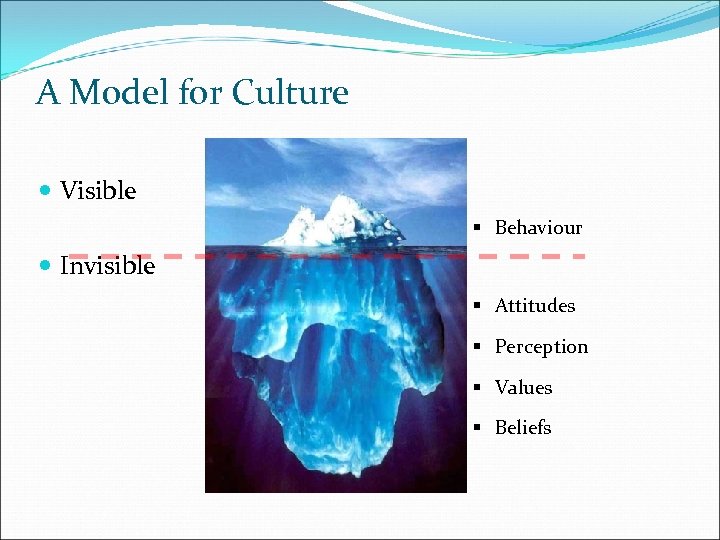

A Model for Culture Visible § Behaviour Invisible § Attitudes § Perception § Values § Beliefs

Need to shift focus ? ? Shifting the focus to the human factor – attitudes, behaviours, values and beliefs Aligning with Values of Organisation – at all levels of employees Common Belief – Everyone understands the importance of safety Build a culture of “Safety by Choice” Foster trust between employees and management

Background Behavioral safety approaches were first developed and applied in the US in the 1970’s in food manufacturing industry. From the 1980’s onwards, safety initiatives based on the observation of safe and unsafe acts/ behaviors were implemented in Europe in construction, manufacturing, nuclear and research. 11

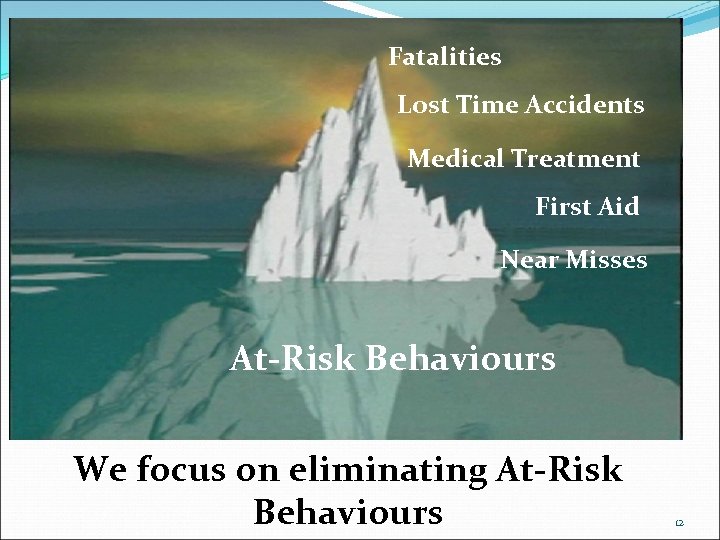

Fatalities Lost Time Accidents Medical Treatment First Aid Near Misses At-Risk Behaviours We focus on eliminating At-Risk Behaviours 12

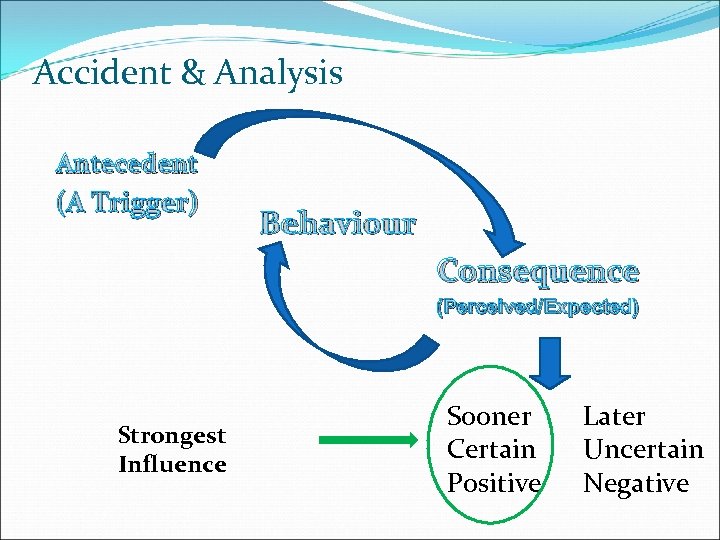

Accident & Analysis Antecedent (A Trigger) Behaviour Consequence (Perceived/Expected) Strongest Influence Sooner Certain Positive Later Uncertain Negative

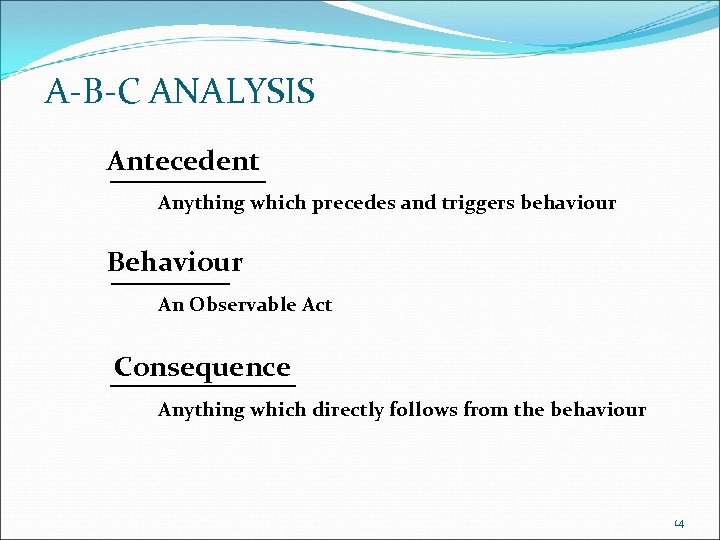

A-B-C ANALYSIS Antecedent Anything which precedes and triggers behaviour Behaviour An Observable Act Consequence Anything which directly follows from the behaviour 14

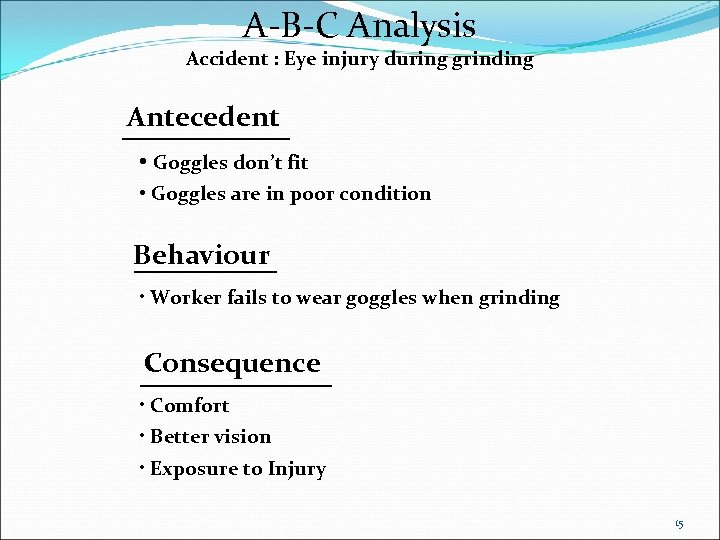

A-B-C Analysis Accident : Eye injury during grinding Antecedent • Goggles don’t fit • Goggles are in poor condition Behaviour • Worker fails to wear goggles when grinding Consequence • Comfort • Better vision • Exposure to Injury 15

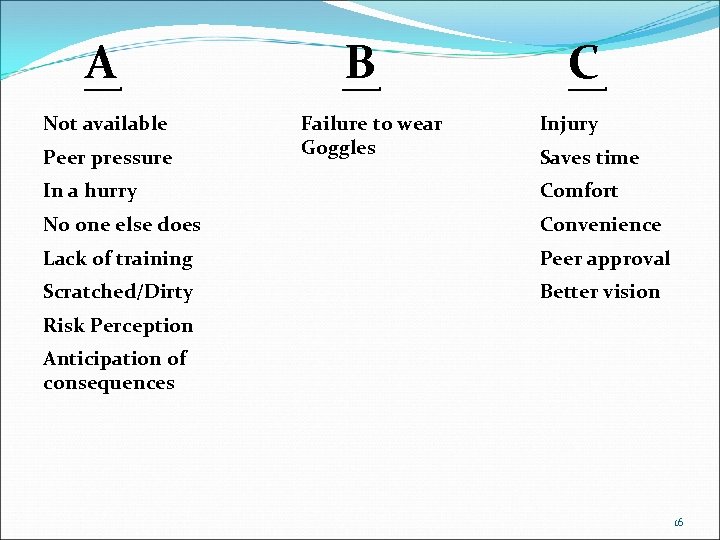

A Not available Peer pressure B Failure to wear Goggles C Injury Saves time In a hurry Comfort No one else does Convenience Lack of training Peer approval Scratched/Dirty Better vision Risk Perception Anticipation of consequences 16

The Process: Diagnose: Assess the present safety culture of the Unit Structured cultural assessment of the Unit • Well designed set of questions • Responses from selected employees at all employees levels including the service providers • Collate the responses to arrive at the overall picture 17

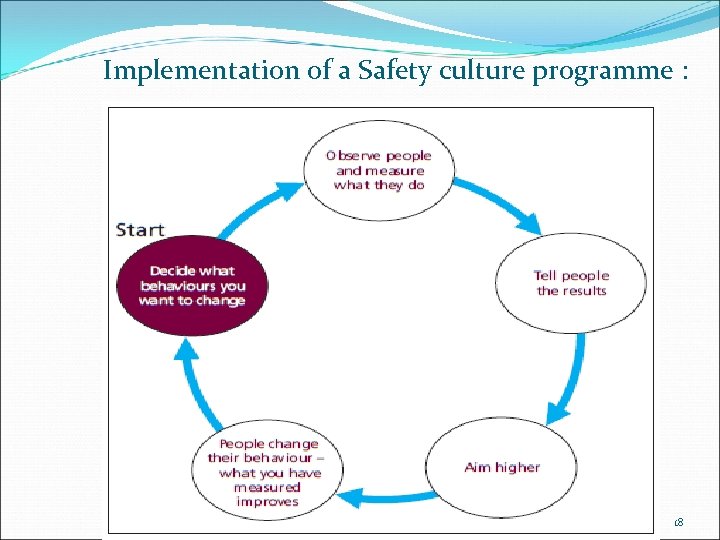

Implementation of a Safety culture programme : 18

The Process: Design: Building Teams & Workshops Integrate with Management Structure For example TPM structure Engagement through SUSA ( Safe Unsafe Act) Workshops 19

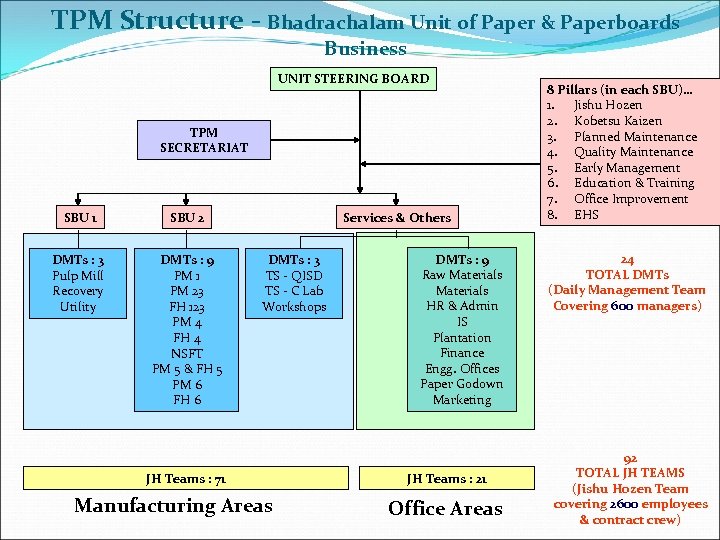

TPM Structure - Bhadrachalam Unit of Paper & Paperboards Business UNIT STEERING BOARD TPM SECRETARIAT SBU 1 SBU 2 DMTs : 3 Pulp Mill Recovery Utility DMTs : 9 PM 1 PM 23 FH 123 PM 4 FH 4 NSFT PM 5 & FH 5 PM 6 FH 6 Services & Others DMTs : 3 TS - QISD TS - C Lab Workshops JH Teams : 71 Manufacturing Areas DMTs : 9 Raw Materials HR & Admin IS Plantation Finance Engg. Offices Paper Godown Marketing JH Teams : 21 Office Areas 8 Pillars (in each SBU)… 1. Jishu Hozen 2. Kobetsu Kaizen 3. Planned Maintenance 4. Quality Maintenance 5. Early Management 6. Education & Training 7. Office Improvement 8. EHS 24 TOTAL DMTs (Daily Management Team Covering 600 managers) 92 TOTAL JH TEAMS (Jishu Hozen Team covering 2600 employees & contract crew)

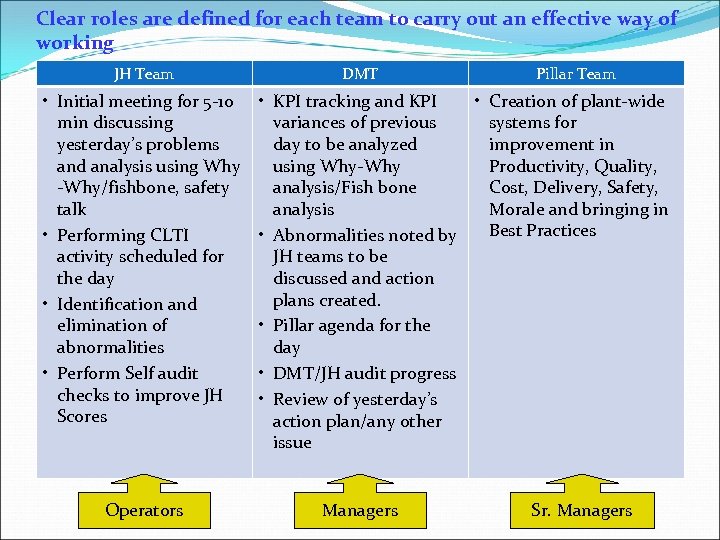

Clear roles are defined for each team to carry out an effective way of working JH Team • Initial meeting for 5 -10 min discussing yesterday’s problems and analysis using Why -Why/fishbone, safety talk • Performing CLTI activity scheduled for the day • Identification and elimination of abnormalities • Perform Self audit checks to improve JH Scores Operators DMT Pillar Team • KPI tracking and KPI • Creation of plant-wide variances of previous systems for day to be analyzed improvement in using Why-Why Productivity, Quality, analysis/Fish bone Cost, Delivery, Safety, analysis Morale and bringing in Best Practices • Abnormalities noted by JH teams to be discussed and action plans created. • Pillar agenda for the day • DMT/JH audit progress • Review of yesterday’s action plan/any other issue Managers Sr. Managers

SUSA - A conversation about safety Asking about job Praising what is being done safely Asking about the injuries that could occur Asking about any unsafe acts Asking how the job could be done more safely Convincing the people to change their behaviour if necessary

Ask them all about the job they have done: Ø Find out as much as possible: what they did, how, when etc. Recognise and praise any safe behaviour they have described (do not patronise!) Ask them how they think someone could have been injured: Ø How might this have happened, what injuries could have resulted? What did they do to make sure the injury did not occur. Is there anything more, on reflection that they could or should have done? If there was any unsafe behaviour, find out why they did not do everything safely. Ask about how they will he do job next time – try to get a commitment from them to do this job safely next time

When People carry out SUSA: Awareness increases People feel cared for Unsafe behaviours are challenged Problems are discussed Behaviour changes Safe behaviours increase Injuries decrease

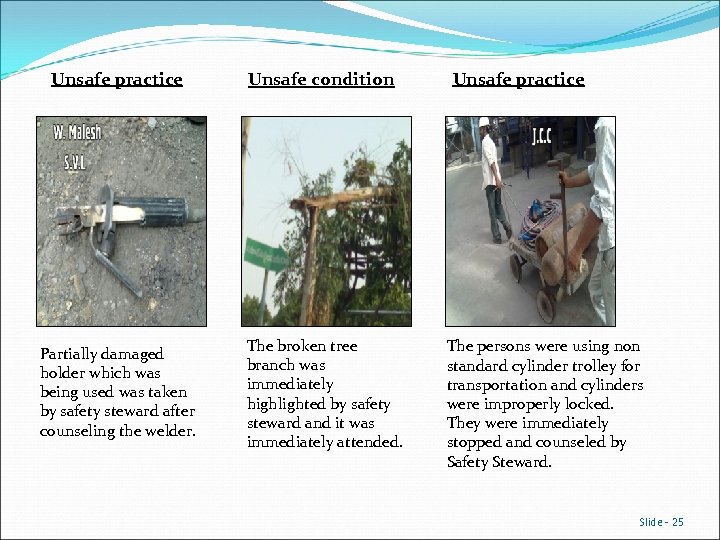

Unsafe practice Unsafe condition Partially damaged holder which was being used was taken by safety steward after counseling the welder. The broken tree branch was immediately highlighted by safety steward and it was immediately attended. Unsafe practice The persons were using non standard cylinder trolley for transportation and cylinders were improperly locked. They were immediately stopped and counseled by Safety Steward. Slide - 25

Conclusion: An organization that successfully develops a safety culture can expect • Immediate and tangible results in reducing workplace accidents • Bring down associated costs, • Increase productivity, • Improve employee morale, • Better work environment The Journey just started ……. Safety Culture Change 26

THANK YOU 27

bdd7be050a081a78aed0310cb08fd6cc.ppt