7c0ec767564f79395b28fdc4d0d1018e.ppt

- Количество слайдов: 82

Becoming Lean: The “Adkins Diet” for Companies Presented By: Patrick Shannon, Professor Department of Networking, Operations and Information Systems College of Business and Economics Shannon, Fall 2005

Today’s Outline n n Competitive Challenges Putting Companies on a Lean Diet n n n Shannon, Fall 2005 The Lean Tools Get on the Scale! – the Need to Measure Some Examples and Results

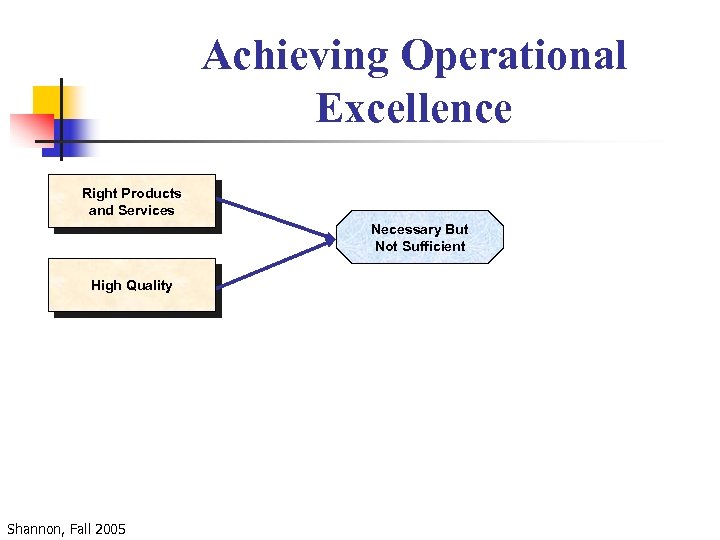

Achieving Operational Excellence Right Products and Services • Customer Focus • “Make what we sell” not “Sell what we make” • Innovation Shannon, Fall 2005

Achieving Operational Excellence Right Products and Services High Quality • Customer Satisfaction • Centered on the Target • Reduced Variability • Both Products and Services • Relentless Pursuit of Improvement Shannon, Fall 2005

Achieving Operational Excellence Right Products and Services Necessary But Not Sufficient High Quality Shannon, Fall 2005

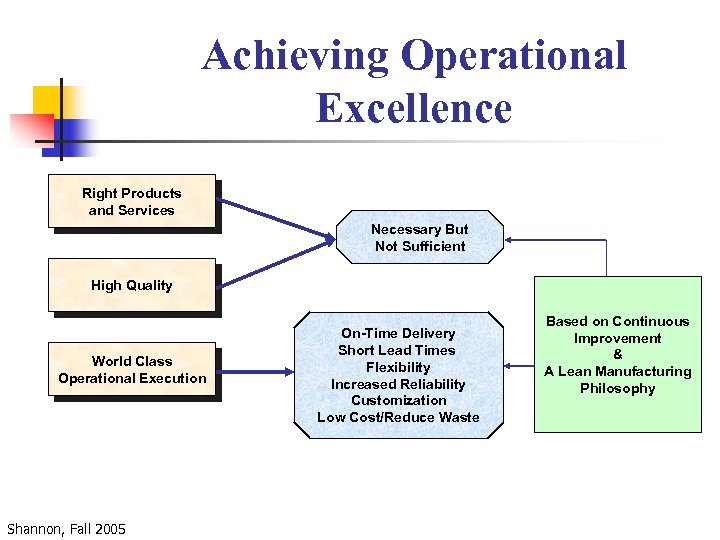

Achieving Operational Excellence Right Products and Services Necessary But Not Sufficient High Quality World Class Operational Execution Shannon, Fall 2005 On-Time Delivery Short Lead Times Flexibility Increased Reliability Customization Low Cost/Reduce Waste Based on Continuous Improvement & A Lean Manufacturing Philosophy

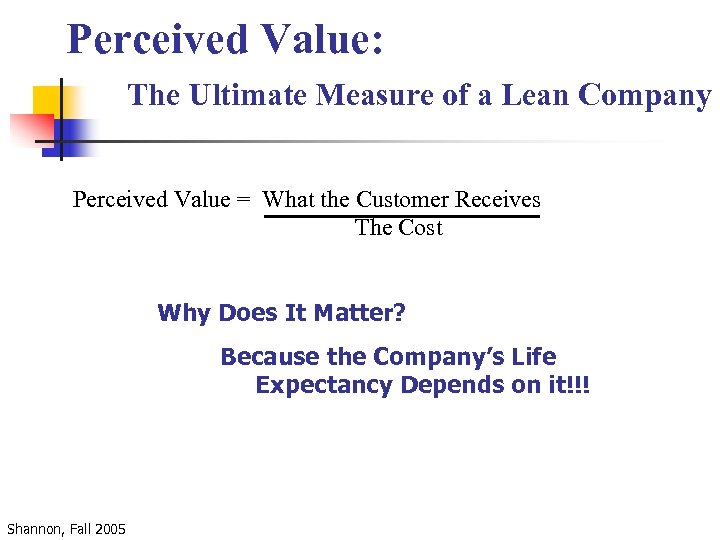

Perceived Value: The Ultimate Measure of a Lean Company Perceived Value = What the Customer Receives The Cost Why Does It Matter? Because the Company’s Life Expectancy Depends on it!!! Shannon, Fall 2005

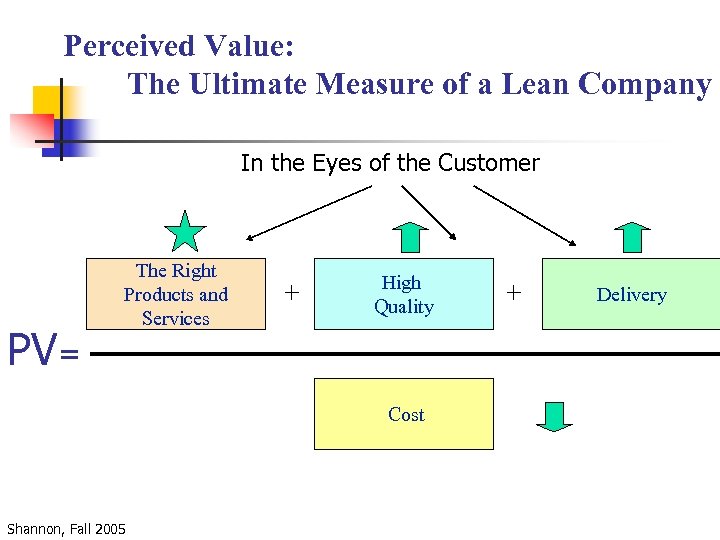

Perceived Value: The Ultimate Measure of a Lean Company In the Eyes of the Customer PV= The Right Products and Services + High Quality Cost Shannon, Fall 2005 + Delivery

The Motivation for Becoming Lean The New Economics: Old Way : Price = Cost + Profit Margin We set the price to assure the desired profit Now: Price - Cost = Profit Price is fixed (or falling) – customers have many options. How do we make a profit? Shannon, Fall 2005

Most Companies Are Too Fat Need to Reduce Costs How? • without decimating our team members • without skimping on maintenance and quality • without weakening the company in the long run. Must eliminate/reduce waste – increase yield Shannon, Fall 2005

The 8 Sources of Waste “The Bad Carbs” 1. 2. 3. 4. 5. 6. 7. 8. Overproduction Excess Inventory Defects/Re-Work Non Value Added Processing Idle (Waiting) Time Non Value Added Motions (people and machines) Non Value Added Conveyance of Materials Waste of People’s Talents and Time Shannon, Fall 2005

Putting Companies on a Lean Diet n n Lean focuses on eliminating waste in processes Lean is about expanding capacity by reducing costs and shortening cycle times between order and delivery Lean is about understanding what is important to the customer Lean is not about eliminating people Shannon, Fall 2005

Toyota Production System – TPS The Beginning of Lean Manufacturing Tiachi Ohno – Toyota U. S. Beginning – New United Motor Manufacturing, Inc. NUMMI – Freemont California http: //www. nummi. com/web_tour. html Shannon, Fall 2005

Shannon, Fall 2005

e Shannon, Fall 2005

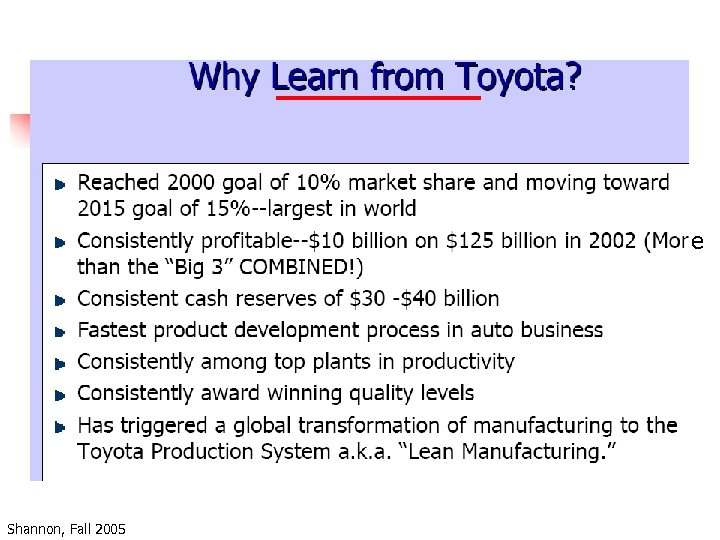

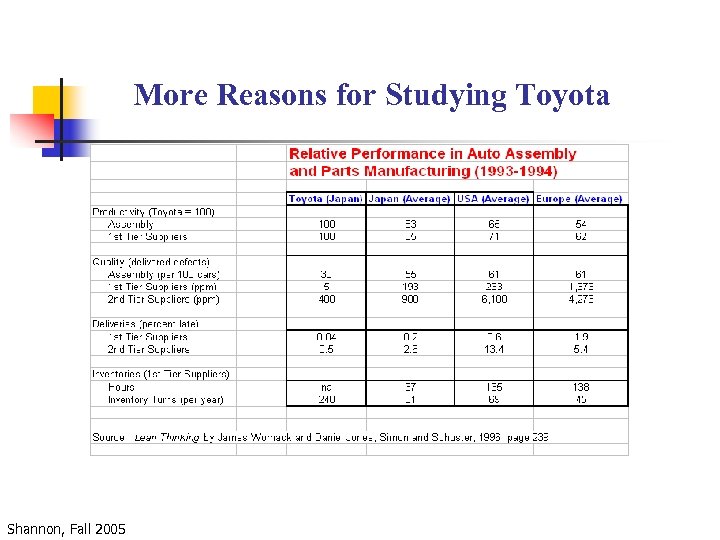

More Reasons for Studying Toyota Shannon, Fall 2005

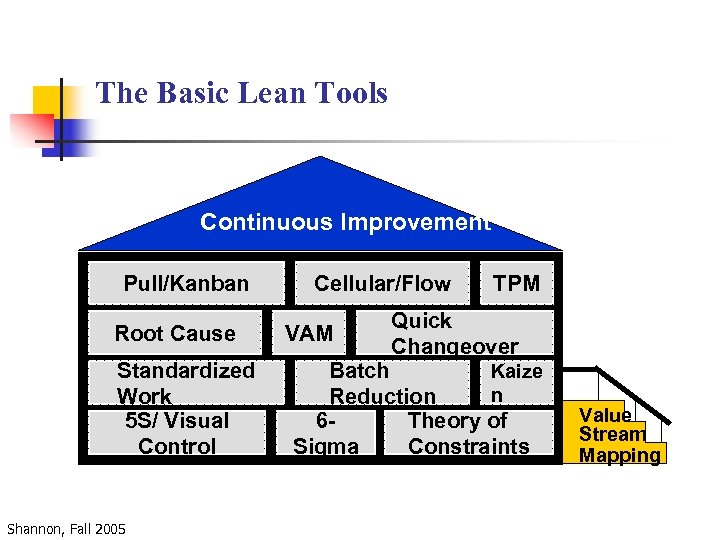

The Basic Lean Tools Continuous Improvement Pull/Kanban Root Cause Standardized Work 5 S/ Visual Control Shannon, Fall 2005 Cellular/Flow VAM TPM Quick Changeover Batch Kaize n Reduction 6 Theory of Sigma Constraints Value Stream Mapping

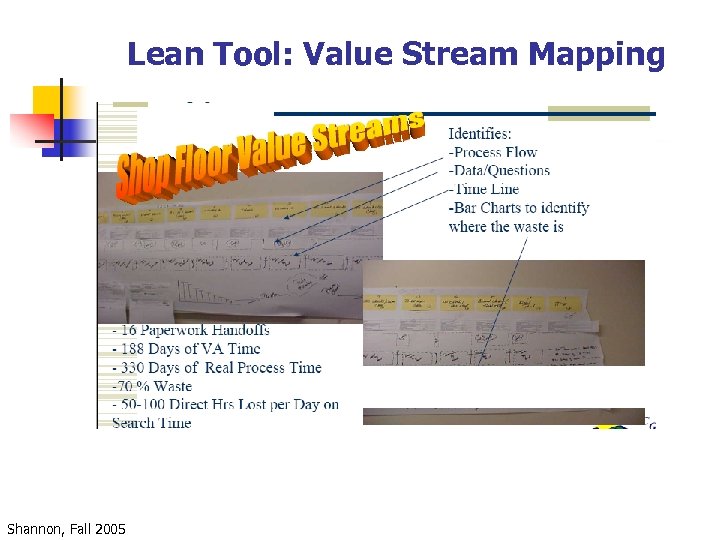

Lean Tool: Value Stream Mapping Shannon, Fall 2005

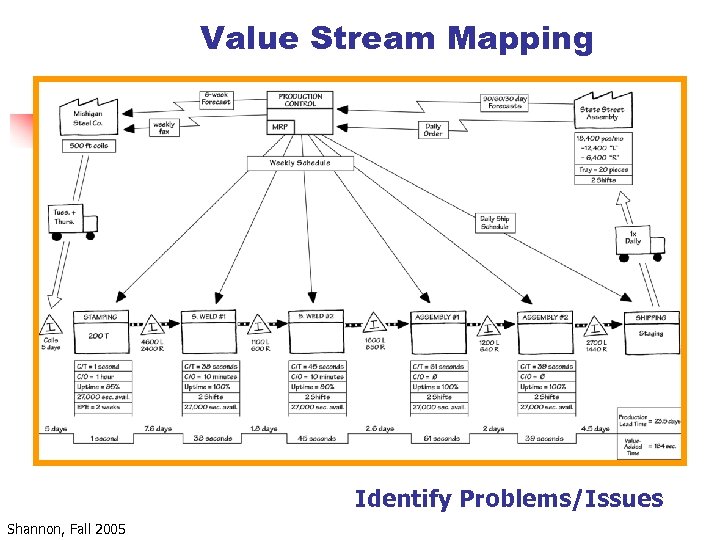

Value Stream Mapping Identify Problems/Issues Shannon, Fall 2005

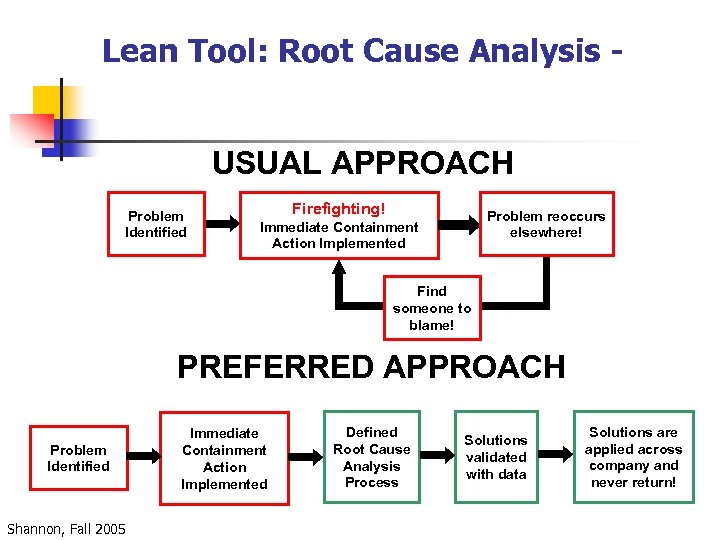

Lean Tool: Root Cause Analysis USUAL APPROACH Problem Identified Firefighting! Problem reoccurs elsewhere! Immediate Containment Action Implemented Find someone to blame! PREFERRED APPROACH Problem Identified Shannon, Fall 2005 Immediate Containment Action Implemented Defined Root Cause Analysis Process Solutions validated with data Solutions are applied across company and never return!

Root Cause Example Identify Problem Project Is behind Schedule – Won’t Finish on Time Shannon, Fall 2005

Immediate Action n n Shannon, Fall 2005 Additional resources applied to help get the project team back on schedule No new projects started until Root Cause Analysis completed

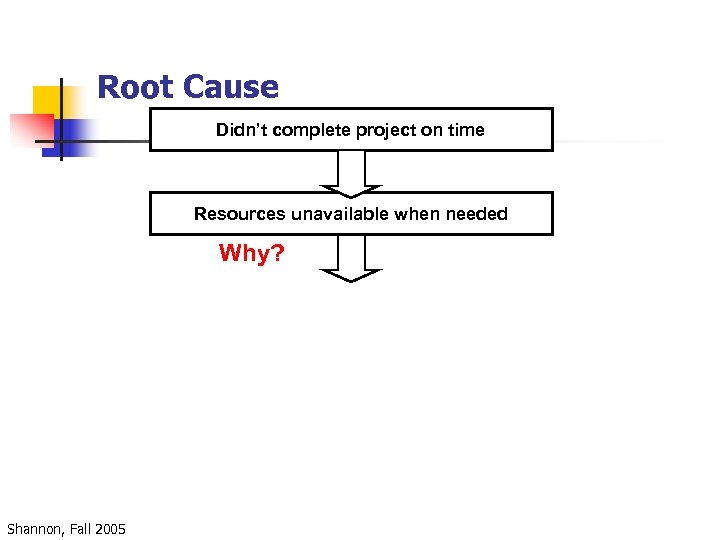

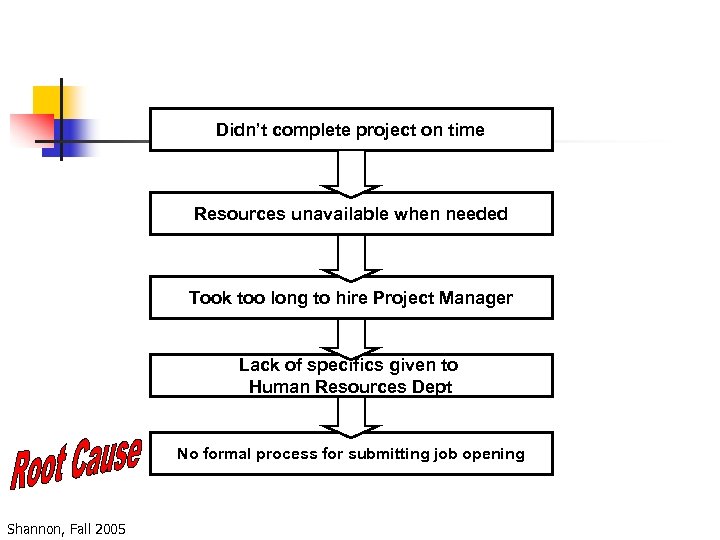

Root Cause Didn’t complete project on time Why? Shannon, Fall 2005

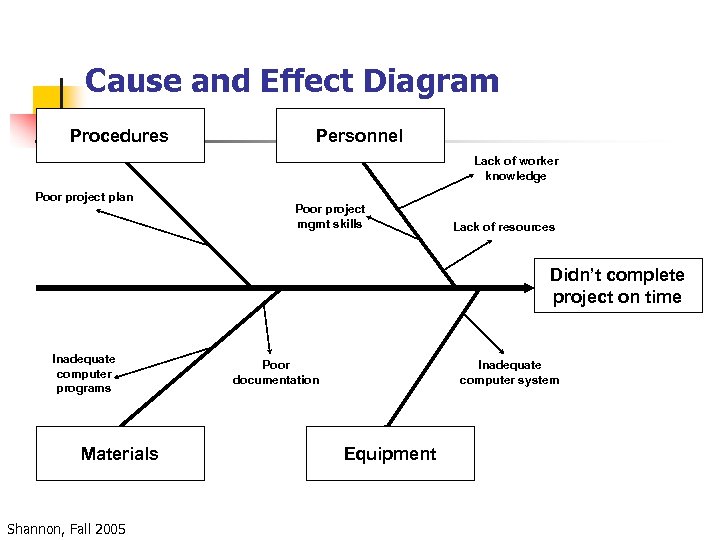

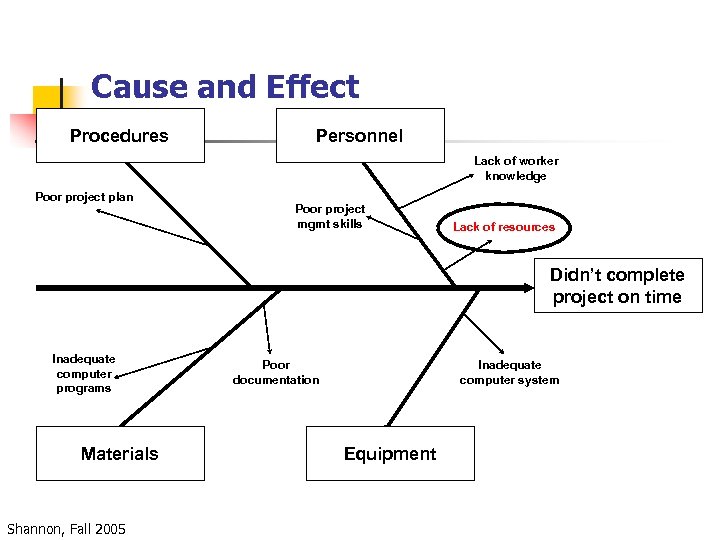

Cause and Effect Diagram Procedures Personnel Lack of worker knowledge Poor project plan Poor project mgmt skills Lack of resources Didn’t complete project on time Inadequate computer programs Materials Shannon, Fall 2005 Poor documentation Inadequate computer system Equipment

Cause and Effect Procedures Personnel Lack of worker knowledge Poor project plan Poor project mgmt skills Lack of resources Didn’t complete project on time Inadequate computer programs Materials Shannon, Fall 2005 Poor documentation Inadequate computer system Equipment

Root Cause Didn’t complete project on time Resources unavailable when needed Why? Shannon, Fall 2005

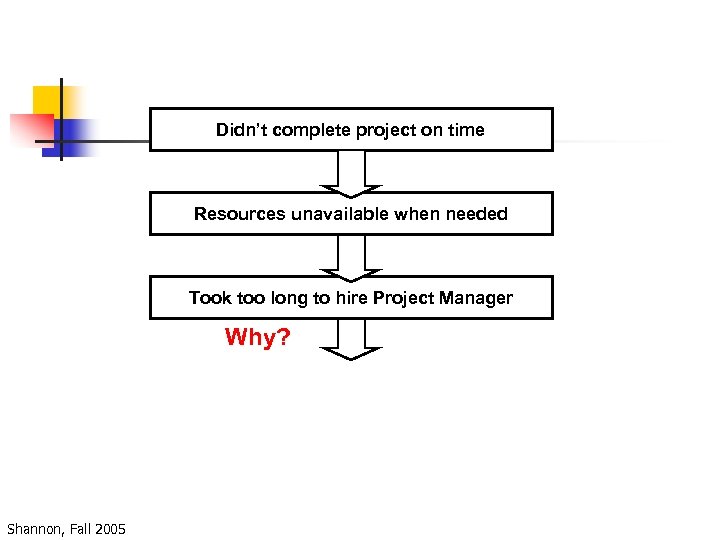

Didn’t complete project on time Resources unavailable when needed Took too long to hire Project Manager Why? Shannon, Fall 2005

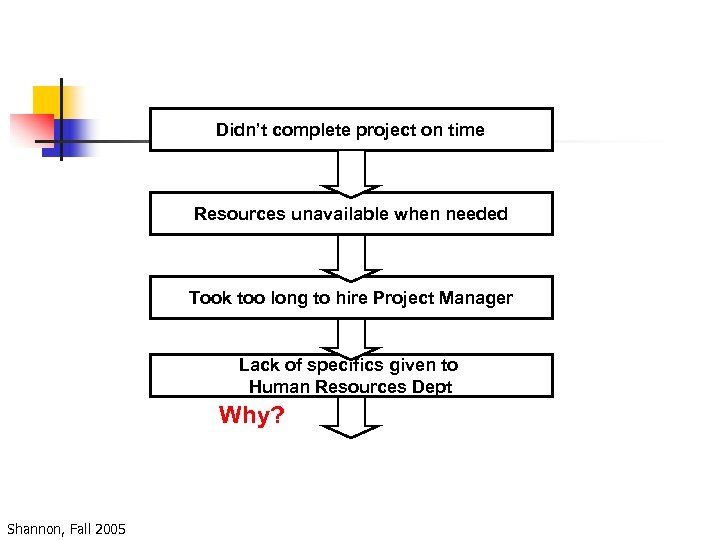

Didn’t complete project on time Resources unavailable when needed Took too long to hire Project Manager Lack of specifics given to Human Resources Dept Why? Shannon, Fall 2005

Didn’t complete project on time Resources unavailable when needed Took too long to hire Project Manager Lack of specifics given to Human Resources Dept No formal process for submitting job opening Shannon, Fall 2005

Corrective Action n n Shannon, Fall 2005 Permanent – Hired another project manager to meet needs of next project team Preventive - Developed checklist form with HR for submitting job openings in the future

Lean Tool: 5 S n n n Sort Straighten Shine Standardize Sustain Shannon, Fall 2005

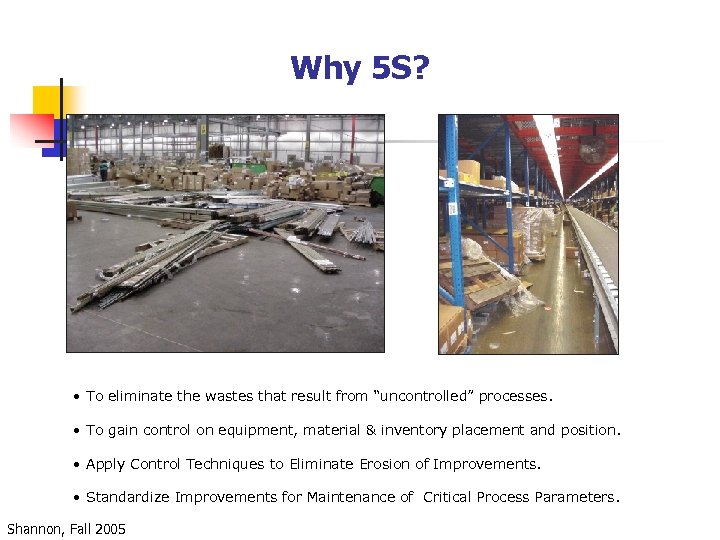

Why 5 S? • To eliminate the wastes that result from “uncontrolled” processes. • To gain control on equipment, material & inventory placement and position. • Apply Control Techniques to Eliminate Erosion of Improvements. • Standardize Improvements for Maintenance of Critical Process Parameters. Shannon, Fall 2005

After 5 S n n Clear, shiny aisles Color-coded areas Slogans & banners No work in process Shannon, Fall 2005

Lean Tool: Poka yoke Mistake-proofing systems Does not rely on operators catching mistakes Inexpensive Point of Origin inspection Quick feedback 100% of the time “Be more careful” is not effective Shannon, Fall 2005

Everyday Poke yoke Examples 3. 5 inch diskettes cannot be inserted unless diskette is oriented correctly. Fueling area of car has three error-proofing devices: 1. insert keeps leaded-fuel nozzle from being inserted 2. tether does not allow loss of gas cap 3. gas cap has ratchet to signal proper tightness and prevent overtightening. New lawn mowers are required to have a safety bar on the handle that must be pulled back in order to start the engine. If you let go of the safety bar, the mower blade stops in 3 seconds or less. Shannon, Fall 2005

3 Rules of POKA YOKE n n n Shannon, Fall 2005 Don’t wait for the perfect POKA YOKE. Do it now! If your POKA YOKE idea has better than 50% chance to succeed…Do it! Do it now…. improve later!

Lean Tool: Kaizen Events and the Kaizen Blitz n n Identify the customer Deming Cycle n Plan – identify what to change and how to do it n Current state n Future state n Implementation plan n Do – execute the improvement n Check – ensure the improvement works n Act – future and ongoing improvements n Repeat Shannon, Fall 2005

Kaizen Blitz - Agenda n n n Day 1: Setting the scene n Meet the team, training Day 2: Observe the current process n Flowchart, identify waste, identify root causes Day 3: Develop the future state process n Brainstorm and flowchart (typically the longest day!) Day 4: Implement the new process n Plan, communicate, implement, modify Day 5: Report and analyze n Performance vs expectations Shannon, Fall 2005

Use Visual Story Boards Shannon, Fall 2005

Identify the Current State Shannon, Fall 2005

Identify VA, NVA-R, and NVA Shannon, Fall 2005

Brainstorm and Analyze n n n Kaizen team brainstorming to develop new process Post improvement ideas on map or by category n Workflow n Technology n People / Organization n Procedures Develop detailed future state map n New workflow n Value Add and Non-Value Add n Cycle times n Identify Kaizen “bursts” (immediate radical change) Shannon, Fall 2005

Develop the Future State Shannon, Fall 2005

Lean Implementation Examples at Welco Lumber Company Shannon, Fall 2005

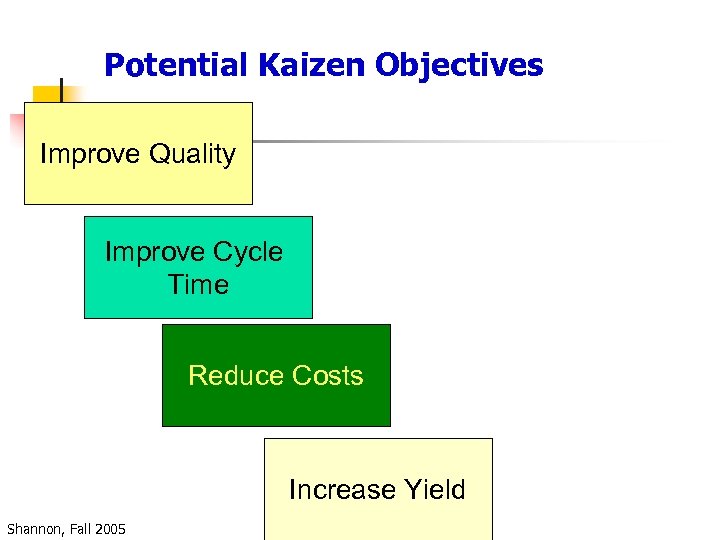

Potential Kaizen Objectives Improve Quality Improve Cycle Time Reduce Costs Increase Yield Shannon, Fall 2005

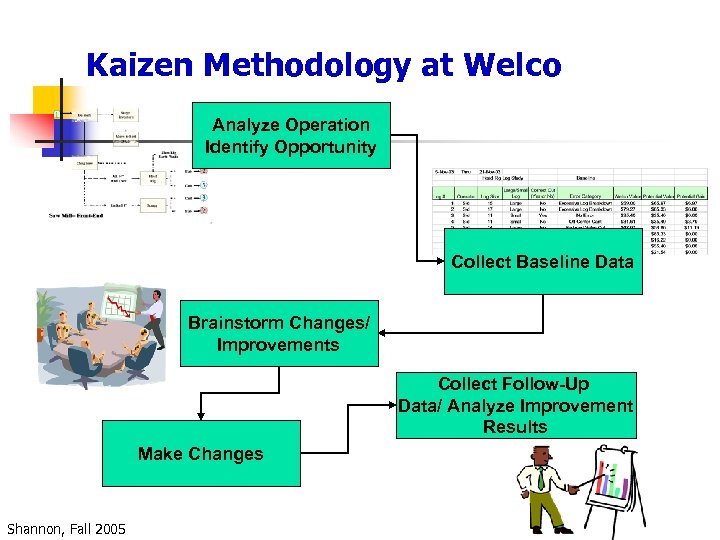

Kaizen Methodology at Welco Analyze Operation Identify Opportunity Collect Baseline Data Brainstorm Changes/ Improvements Collect Follow-Up Data/ Analyze Improvement Results Make Changes Shannon, Fall 2005

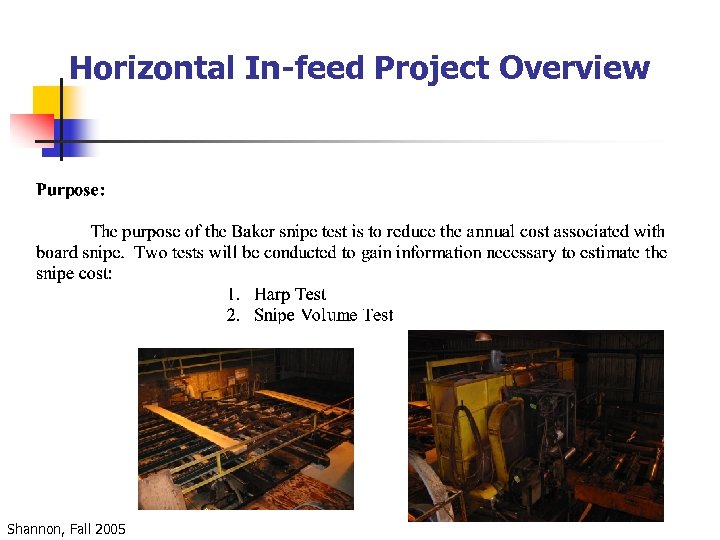

Horizontal In-feed Project Overview Shannon, Fall 2005

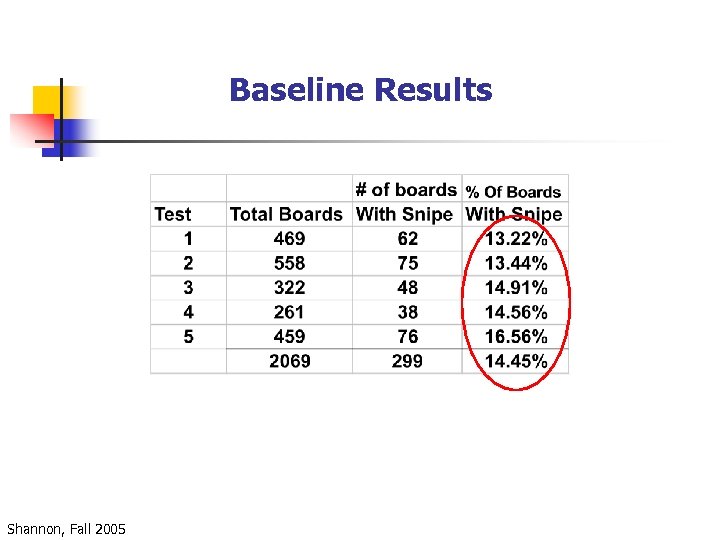

Baseline Results Shannon, Fall 2005

Proposed Change to Horizontal In-feed Process Run Slabs 1 at a time rather than side-by-side Process Change Only No New Equipment Shannon, Fall 2005

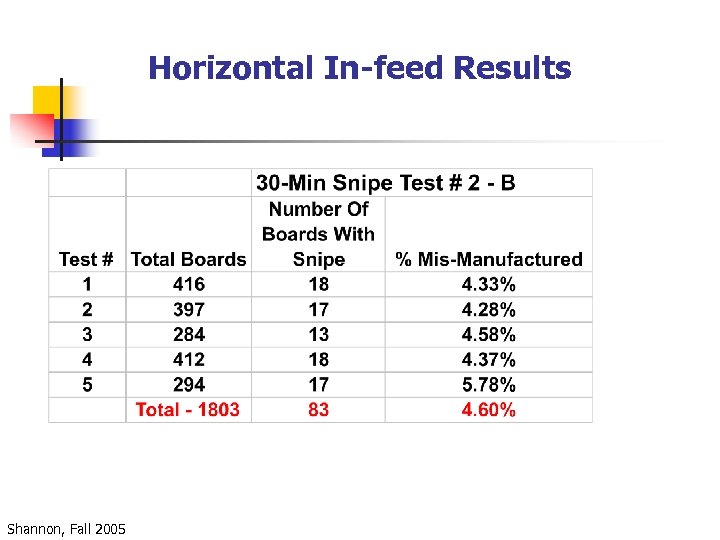

Horizontal In-feed Results Shannon, Fall 2005

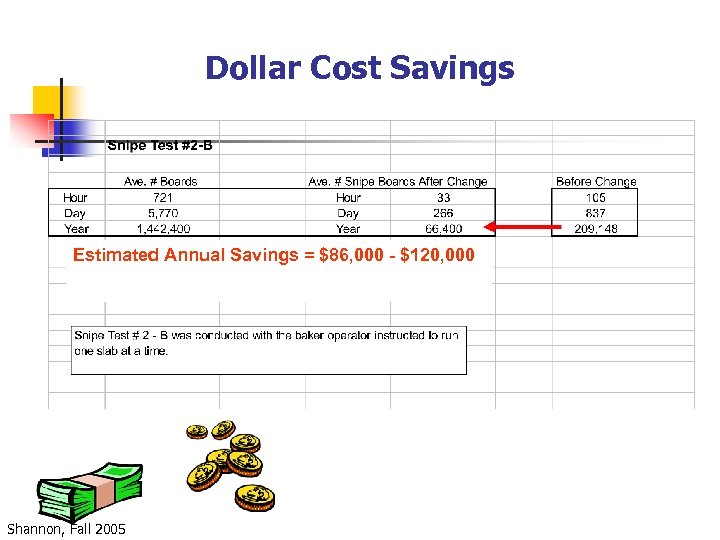

Dollar Cost Savings Estimated Annual Savings = $86, 000 - $120, 000 Shannon, Fall 2005

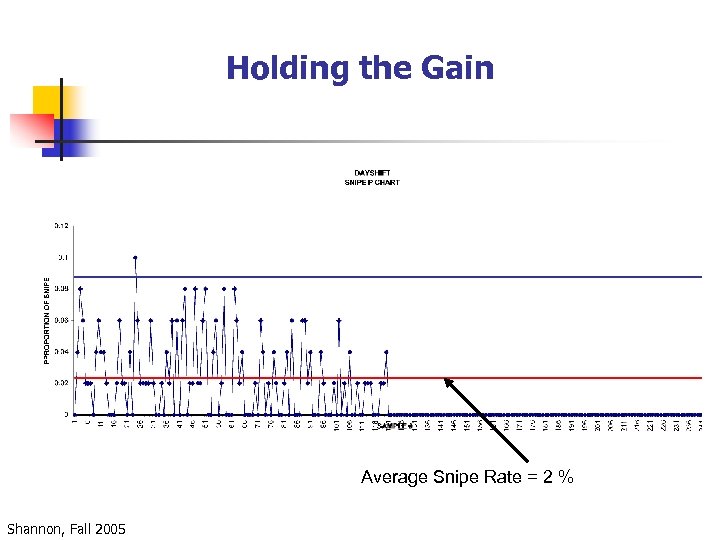

Holding the Gain Average Snipe Rate = 2 % Shannon, Fall 2005

Head Rig Project Objective: Increasing Recovery/Value Shannon, Fall 2005

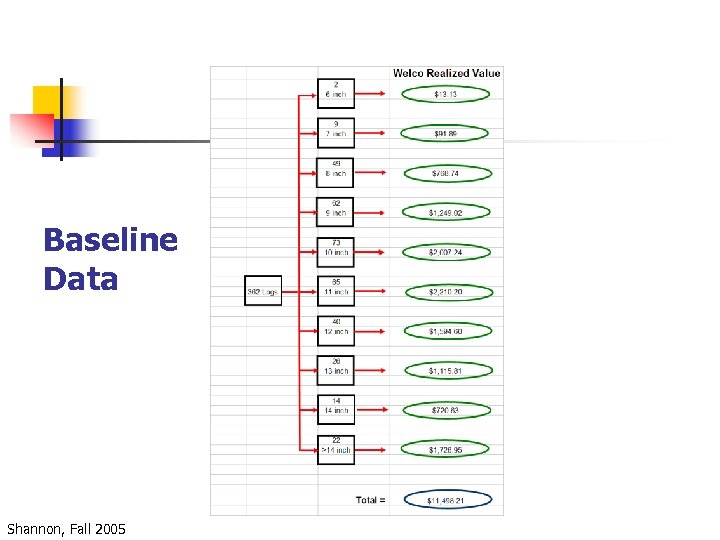

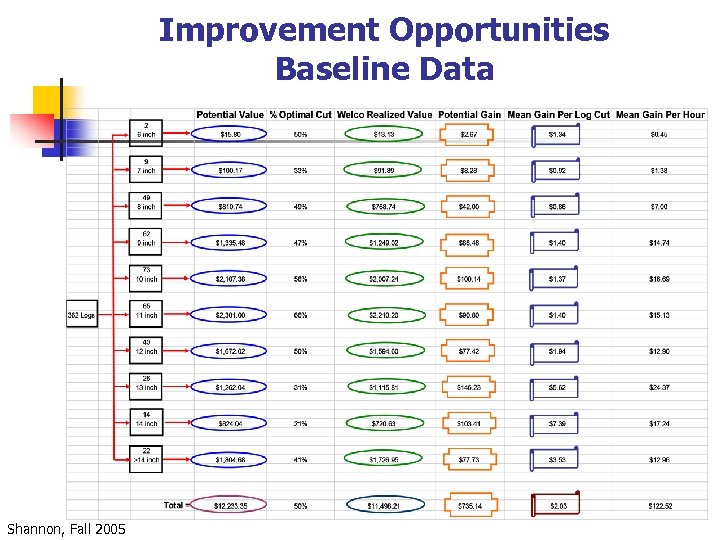

Baseline Data Collection n 3 Operators 6 Hours Video 362 logs (all diameters) View the Head Rig Saw Shannon, Fall 2005

Baseline Data Shannon, Fall 2005

Beck Group Log Breakdown Rules Based on Optimizing Log Recovery and Value of Finished Product Shannon, Fall 2005

Potential For Improvement Welco Log Breakdown Decisions Based on Past Training Versus The Beck Group Optimal Breakdown Rules Shannon, Fall 2005

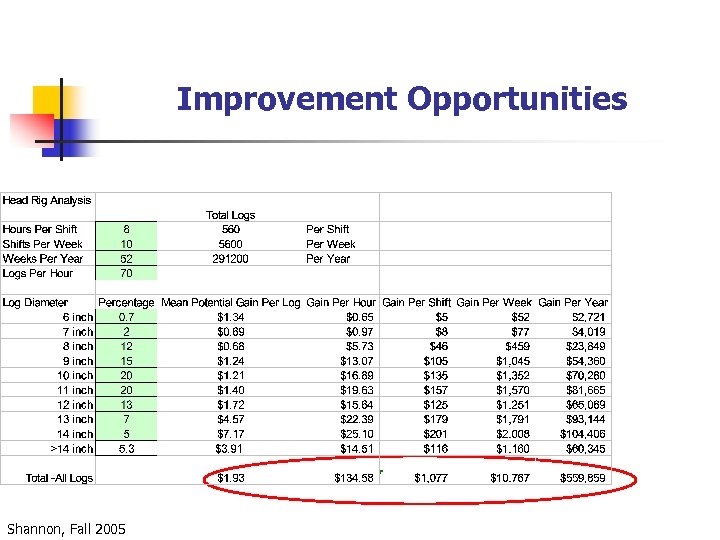

Improvement Opportunities Baseline Data Shannon, Fall 2005

Improvement Opportunities Shannon, Fall 2005

How to Achieve The Gains? n n n Shannon, Fall 2005 Know the Beck Group Rules Operator Training Use the Beck Group Rules Laser Lights Other ? ? ?

Analyze Changes n n Shannon, Fall 2005 Video Data Collection and Analysis Assess Progress Hold the Gains

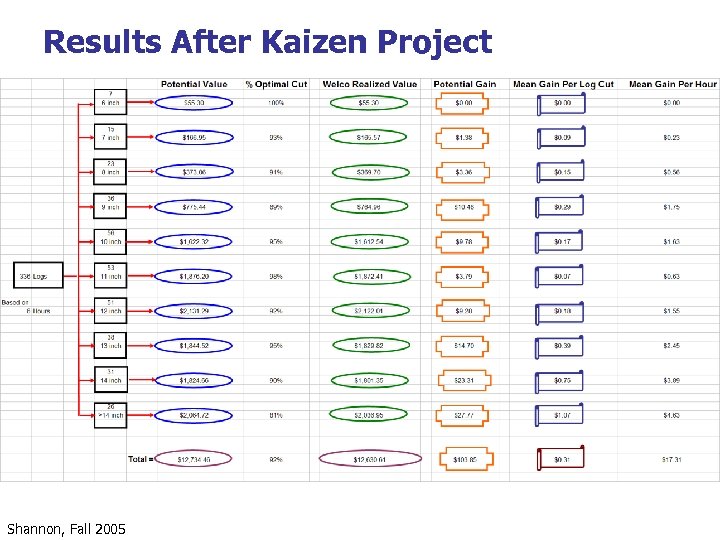

Results After Kaizen Project Shannon, Fall 2005

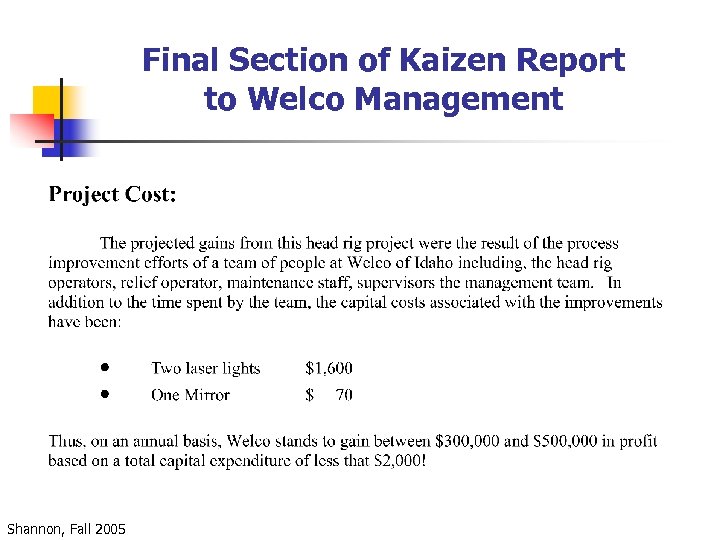

Final Section of Kaizen Report to Welco Management Shannon, Fall 2005

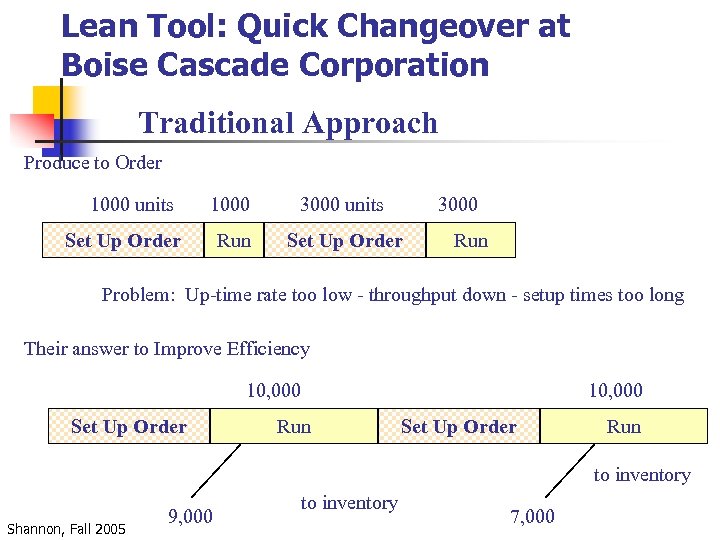

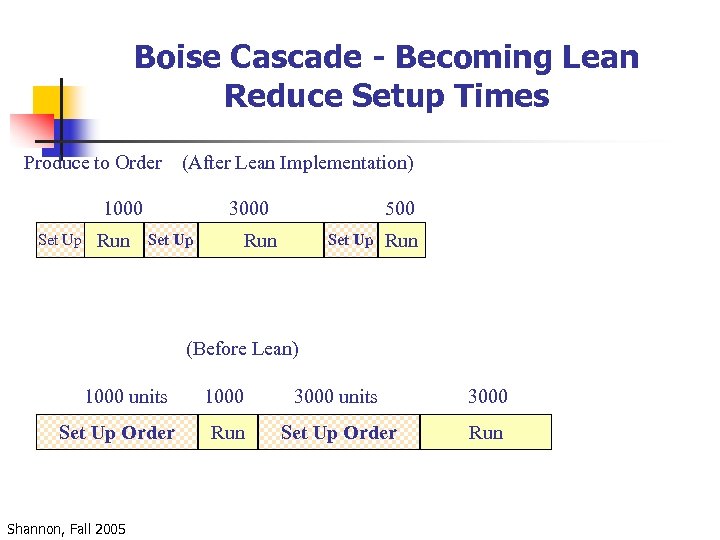

Lean Tool: Quick Changeover at Boise Cascade Corporation Traditional Approach Produce to Order 1000 units 1000 3000 units Run Set Up Order 3000 Run Problem: Up-time rate too low - throughput down - setup times too long Their answer to Improve Efficiency 10, 000 Set Up Order 10, 000 Run Set Up Order Run to inventory Shannon, Fall 2005 9, 000 to inventory 7, 000

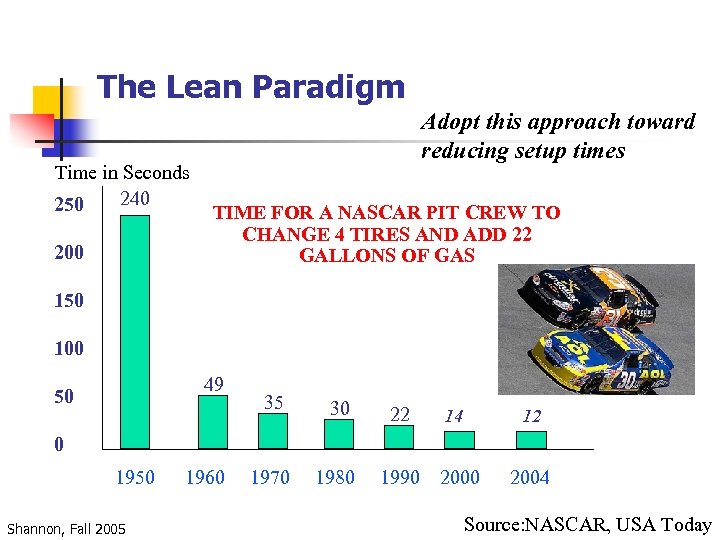

The Lean Paradigm Time in Seconds 240 250 200 Adopt this approach toward reducing setup times TIME FOR A NASCAR PIT CREW TO CHANGE 4 TIRES AND ADD 22 GALLONS OF GAS 150 100 49 50 35 30 22 1970 1980 1990 14 12 0 1950 Shannon, Fall 2005 1960 2004 Source: NASCAR, USA Today

Lean Tool: Quick Changeover Methodology n n Identify internal and external steps Convert internal steps to external Improve all aspects of the setup operation Abolish setup Shannon, Fall 2005

Boise Cascade - Becoming Lean Reduce Setup Times Produce to Order (After Lean Implementation) 1000 Set Up Run 3000 Set Up 500 Run Set Up Run (Before Lean) 1000 units Set Up Order Shannon, Fall 2005 1000 3000 units 3000 Run Set Up Order Run

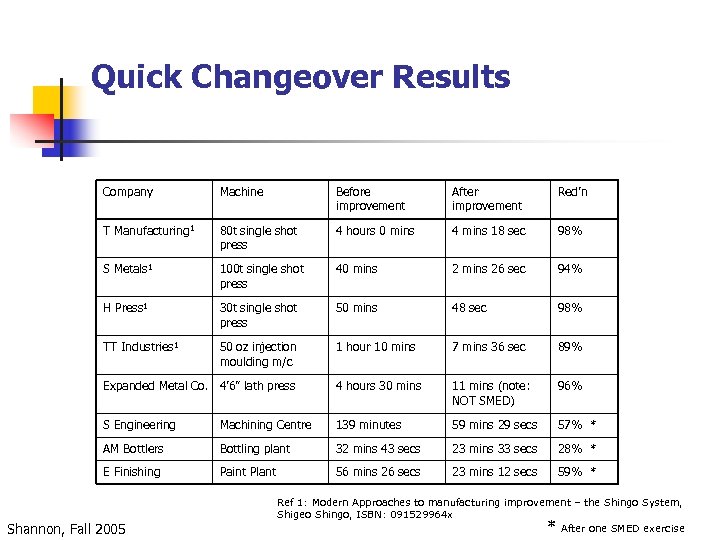

Quick Changeover Results Company Machine Before improvement After improvement Red’n T Manufacturing 1 80 t single shot press 4 hours 0 mins 4 mins 18 sec 98% S Metals 1 100 t single shot press 40 mins 26 sec 94% H Press 1 30 t single shot press 50 mins 48 sec 98% TT Industries 1 50 oz injection moulding m/c 1 hour 10 mins 7 mins 36 sec 89% Expanded Metal Co. 4’ 6” lath press 4 hours 30 mins 11 mins (note: NOT SMED) 96% S Engineering Machining Centre 139 minutes 59 mins 29 secs 57% * AM Bottlers Bottling plant 32 mins 43 secs 23 mins 33 secs 28% * E Finishing Paint Plant 56 mins 26 secs 23 mins 12 secs 59% * Shannon, Fall 2005 Ref 1: Modern Approaches to manufacturing improvement – the Shingo System, Shigeo Shingo, ISBN: 091529964 x After one SMED exercise *

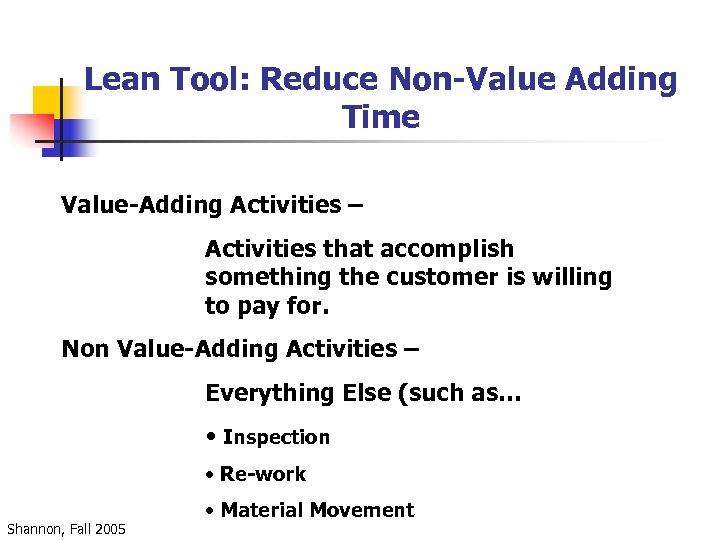

Lean Tool: Reduce Non-Value Adding Time Value-Adding Activities – Activities that accomplish something the customer is willing to pay for. Non Value-Adding Activities – Everything Else (such as… • Inspection • Re-work Shannon, Fall 2005 • Material Movement

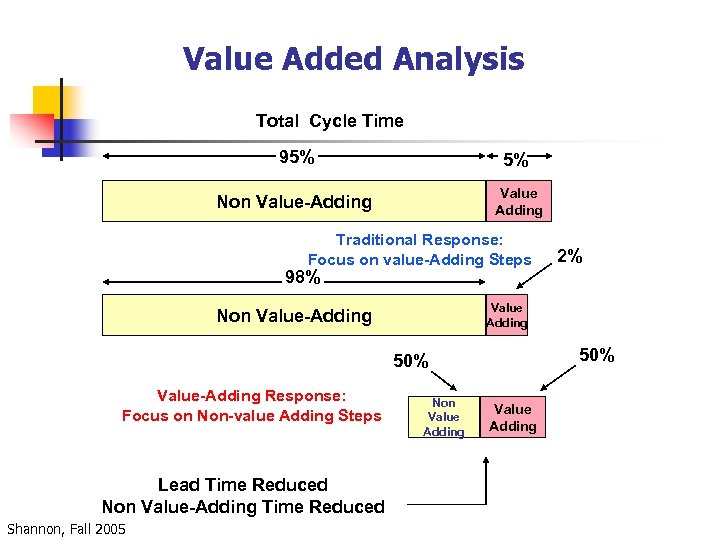

Value Added Analysis Total Cycle Time 95% 5% Non Value-Adding Value Adding Traditional Response: Focus on value-Adding Steps 2% 98% Value Adding Non Value-Adding 50% Value-Adding Response: Focus on Non-value Adding Steps Lead Time Reduced Non Value-Adding Time Reduced Shannon, Fall 2005 Non Value Adding

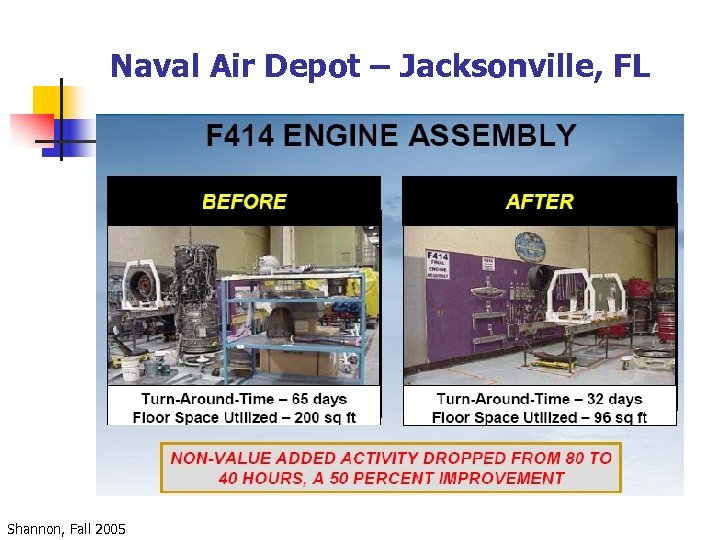

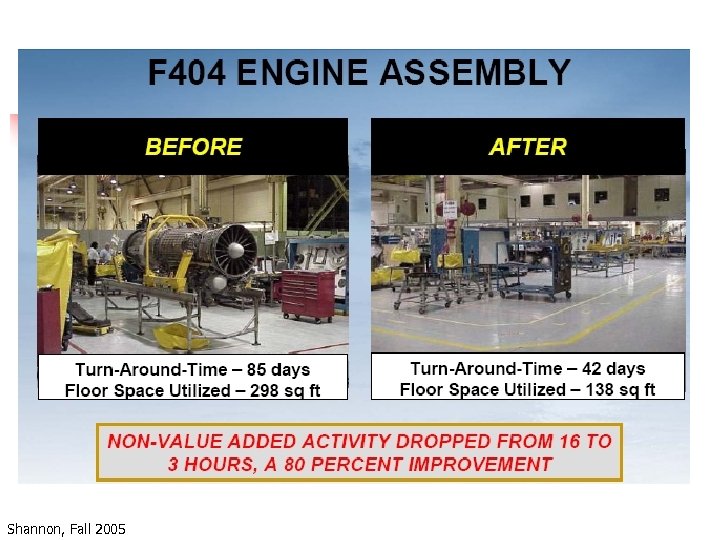

Naval Air Depot – Jacksonville, FL Shannon, Fall 2005

Shannon, Fall 2005

Right Get the Company On the Scale Impediment to Success; Measuring the Wrong Things “People do how they are measured. ” Dave Packard -- HP Shannon, Fall 2005

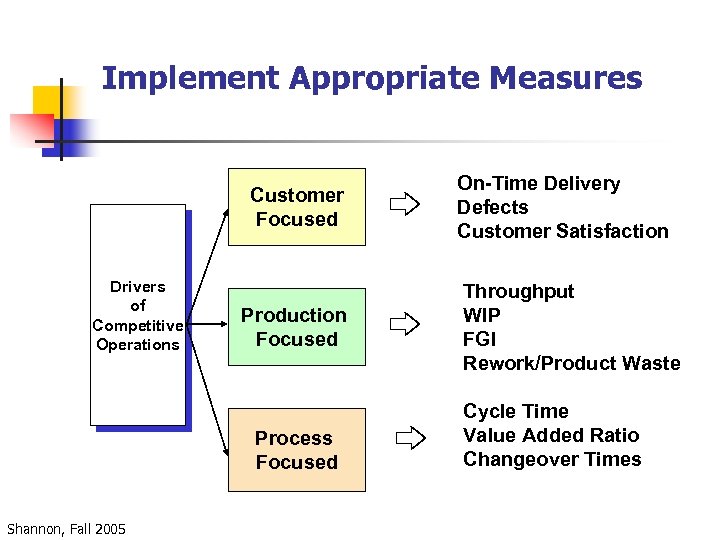

Implement Appropriate Measures Customer Focused Drivers of Competitive Operations Production Focused Process Focused Shannon, Fall 2005 On-Time Delivery Defects Customer Satisfaction Throughput WIP FGI Rework/Product Waste Cycle Time Value Added Ratio Changeover Times

Implementing Lean n n Gain Top Management “Buy In” and Support Perform overall company assessment tied to company strategic, operational, and marketing plans Develop strategic lean deployment plan Integrate customized training with lean to improve specific skill sets, leverage training resources Shannon, Fall 2005

More Implementation Steps Team Building, Communications, Problem Solving, Change Management, Lean Manufacturing Tools n n Conduct “Kaizen blitz” high impact events 5 S, Manufacturing Cell, Set-Up Reductions, Inventory Reductions, Work Standardization n Use an enterprise wide approach to help “Transform” a Company’s culture and the way they do business. n Shannon, Fall 2005

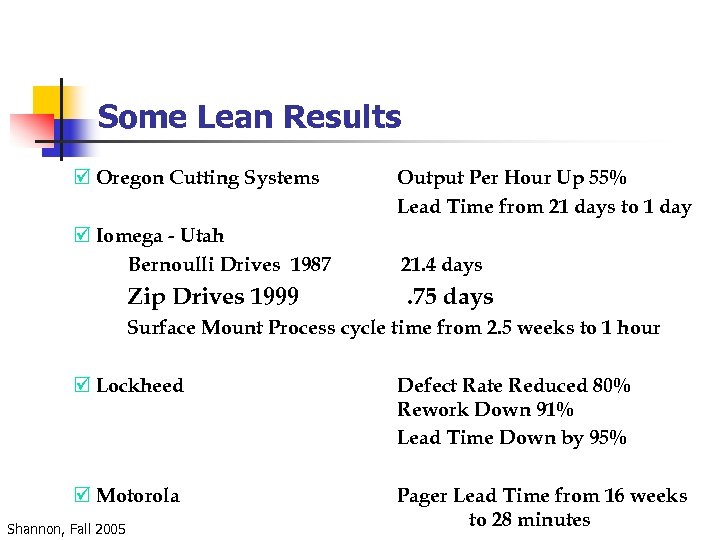

Some Lean Results þ Oregon Cutting Systems þ Iomega - Utah Bernoulli Drives 1987 Zip Drives 1999 Output Per Hour Up 55% Lead Time from 21 days to 1 day 21. 4 days . 75 days Surface Mount Process cycle time from 2. 5 weeks to 1 hour þ Lockheed Defect Rate Reduced 80% Rework Down 91% Lead Time Down by 95% þ Motorola Pager Lead Time from 16 weeks to 28 minutes Shannon, Fall 2005

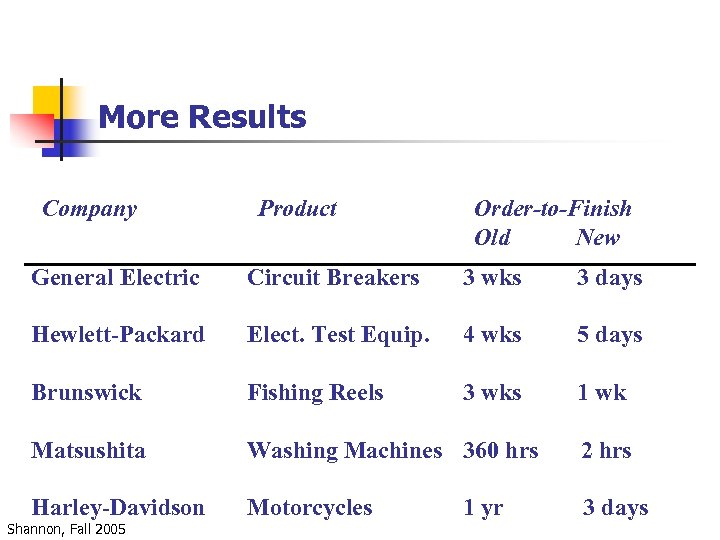

More Results Company Product Order-to-Finish Old New General Electric Circuit Breakers 3 wks 3 days Hewlett-Packard Elect. Test Equip. 4 wks 5 days Brunswick Fishing Reels 3 wks 1 wk Matsushita Washing Machines 360 hrs 2 hrs Harley-Davidson Motorcycles 3 days Shannon, Fall 2005 1 yr

Lean vs. Traditional Manufacturing n n n n Half the hours of engineering effort Half the product development time Half the investment in machinery, tools and equipment Half the hours of human effort in the factory Half the defects in the finished product Half the factory space for the same output A tenth or less of in-process inventories Source: The Machine that Changed the World, Womack, Jones, and Roos, 1990. Shannon, Fall 2005

Barriers to Lean n Implementing Lean Can Be Difficult Because it is Counterintuitive from a Traditional Paradigm: n n There is no step-by-step cook book n n n Buying multiple small machines rather than one big machine that offers economies of scale. Shutting down equipment when maximum inventory levels are reached rather than running flat out. Using standards to continuously improve. There are some basic steps but the how-to varies from organization to organization Requires an assessment of the company in order to map out the strategy Company culture plays a big part in the how-to Shannon, Fall 2005

Lean Is A Journey n n The Journey never ends Toyota estimates it is only 50% waste-free There is much room for Improvement It is time to begin. Shannon, Fall 2005

A Few References Lean Thinking By James Womack and Daniel Jones, Simon and Schuster, 1996 The Toyota Way, Jeffrey Liker, Mc. Graw-Hill, 2004 Fast Track To Waste-Free Manufacturing by John Davis, Productivity Press, 1999 Toyota Production System, by Taiichi Ohno, Productivity Press, 1988 Lean Production Simplified, By Pascal Dennis, Productivity Press, 2002 The Lean Enterprise Memory Jogger, Goal/QPC, 2002 Becoming Lean, By Jeffery Liker, Productivity Press, 1998 The Goal, By Eliyahu Goldratt and Jeff Cox, North River Press, 1986 It’s Not Luck, By Eliyahu Goldratt, North River Press, 1994 The Machine That Changed The World, By James Womack, Daniel Jones, and Daniel Roos Goldratt’s Theory of Constraints, By H. William Detmer Shannon, Fall 2005

7c0ec767564f79395b28fdc4d0d1018e.ppt