0c67b635c7621844b670822191abd60a.ppt

- Количество слайдов: 30

Beating The Heat Reduction Solution Made in Australia Since 1986

Insulpaint Index ® One Paint • Introducing • Summary • Properties One Solution INSULPAINT Reduction • Recapture • Savings • FAQ • Distributor ® Heat Reduction • Heat Save $$ Energy

What is Insulpaint ? ® Internal temperature reduction of 6 to 14 OC ® Insulpaint is a water based, high quality paint, that is impregnated with a special proprietary insulating ingredient called Acrad 8. The Acrad 8 gives the coating an unusual ability, to block and reflect heat transfer, from the outside of the surface to the inside of the building

® Insulpaint Summary ® Main characteristics that make Insulpaint so good: üHeat Reduction üSound Insulator üMade in WA. since 1986. üDrinking Water Safe üReduces Maintenance üGreen. Mark Product üSustainable Energy üEco Specifier ü 10 Years Guarantee üGovernment Passed

Why Insulpaint Is So Good? ® ® üInsulpaint is a preventative coating, that has thermal and acoustic properties, keeping buildings cool in summer, and warm in winter. Insulpaint has been independently tested, and conclusively proven, to be very effective in reducing internal temperatures, on all types of surfaces and building structures

Why Insulpaint Is So Good? ® ® ØInsulpaint clients in extreme and normal conditions, are still reporting substantial reductions in energy costs, after coating their roofs and walls, up to 10 years ago! ØIndependent testing by engineering firms, and energy saving consultants, from 1986 onwards, has confirmed what these clients had found, through experience. ® ØIn practical tests, Insulpaint consistently recorded a 30% to 60% saving in air-con costs. ØCost reductions such as these often ® mean Insulpaint has paid for itself in ENERGY savings, within the first year or two! Remember!! ØTHE HOTTER IT GETS THE BETTER IT WORKS!!

Why Insulpaint Is So Good? ® ØTraditional heat reflecting paints use ceramic bead fillers, which within several years lose part of thermal performance. ØThe reason this occurs is because thousands of ceramic beads in the surface coating create an abrasive surface that collects dust and dirt through acid rain and pollution. ® ØInsulpaint on the other hand contains ACRAD 8, a plant fibre based insulating ingredient, made in Australia, that helps Insulpaint® retain a completely smooth surface. ® ü Insulpaint will keep on Looking Good.

Why Insulpaint Is So Good? ® ® ØInsulpaint is available in 18 standard colours and custom tints, allowing you colour of choice, to suit your roof and walls at home, or commercial building. ØIf you really want that high gloss finish, and even longer life, your roof and walls, can be finished with our A 800 ® Insulglaze , this is a clear and robust coating, that stands up very well, to abrasion, and the elements, making it an ideal top coat over Insulpaint, if required. ® ü Insulpaint brightens up your life.

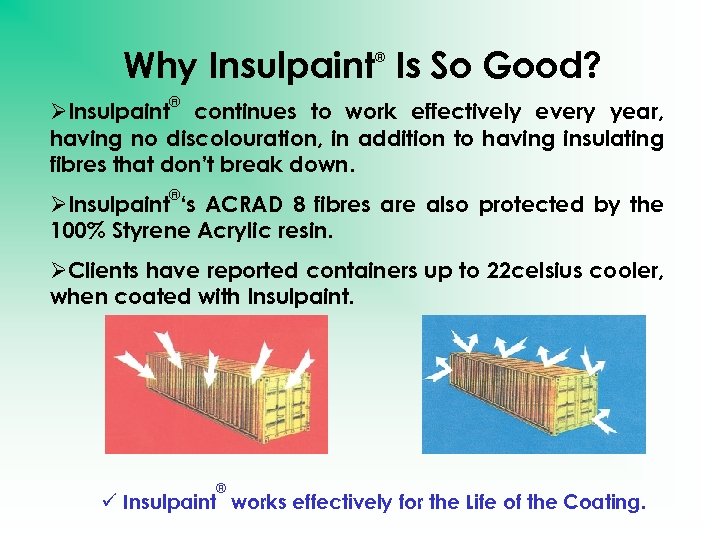

Why Insulpaint Is So Good? ® ® ØInsulpaint continues to work effectively every year, having no discolouration, in addition to having insulating fibres that don’t break down. ® ØInsulpaint ‘s ACRAD 8 fibres are also protected by the 100% Styrene Acrylic resin. ØClients have reported containers up to 22 celsius cooler, when coated with Insulpaint. ® ü Insulpaint works effectively for the Life of the Coating.

Why Insulpaint Is So Good? ® ® ØInsulpaint ‘s resin is completely impervious to airborne pollution & extreme weather conditions, and is also non flammable, non toxic and contains no hazardous fibres. ® Ø Insulpaint is waterproof, but at the same time is microporous, allowing the substrate to breathe, avoiding cracking in ceiling masonry, or render, and saving money, on long term maintenance costs. ® ü Insulpaint keeps you clean and breathing.

Why Insulpaint Is So Good? ® ® ØAfter 23 years of commercial success, Insulpaint has stood the test of time, and continues to delight private clients, and commercial building owners, worldwide. ØThis high performance surface coating, has now been applied to buildings throughout the globe, including, the Middle East, Singapore, Malaysia, China, India, and Japan. ØTest 1/01/06 ASTM C 1549 Chinese Goverment ØTest 1/01/06 ASTM C 1371 Chinese Goverment Ø 30/05/05 Approved for Australian Goverment ØThousands of very happy, client testimonials. ® ü Insulpaint is time tested and proven to work.

Insulpaint Reducing Heat Loads ® ® ØKey ingredient of Insulpaint is Acrad 8, and the 100% Styrene Acrylic Resin (SAR). ØAcrad 8 acts as an insulator and functions as a thermal barrier to prevent heat transfer. o Thus Arcad 8 prevents the conduction of heat through the coating. o This causes the inside of the painted surface, to be much cooler than the outside.

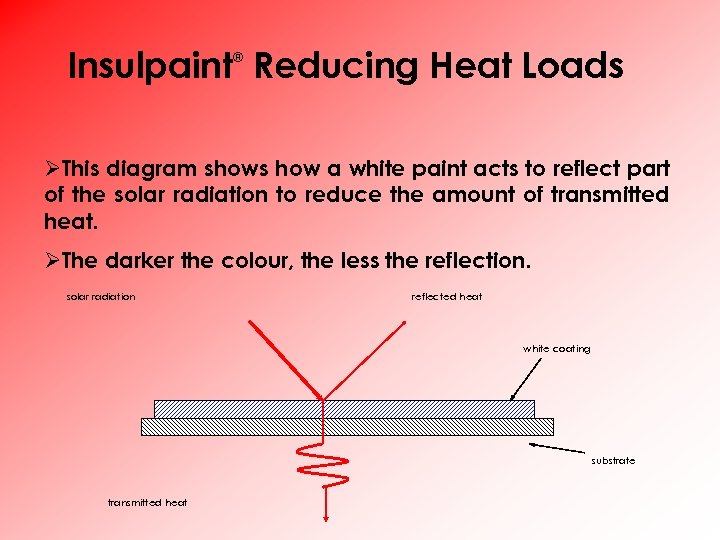

Insulpaint Reducing Heat Loads ® ØThis diagram shows how a white paint acts to reflect part of the solar radiation to reduce the amount of transmitted heat. ØThe darker the colour, the less the reflection. solar radiation reflected heat white coating substrate transmitted heat

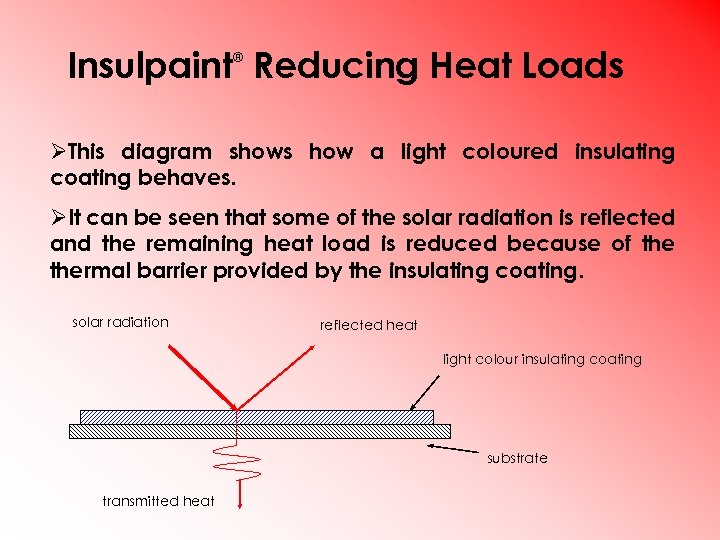

Insulpaint Reducing Heat Loads ® ØThis diagram shows how a light coloured insulating coating behaves. ØIt can be seen that some of the solar radiation is reflected and the remaining heat load is reduced because of thermal barrier provided by the insulating coating. solar radiation reflected heat light colour insulating coating substrate transmitted heat

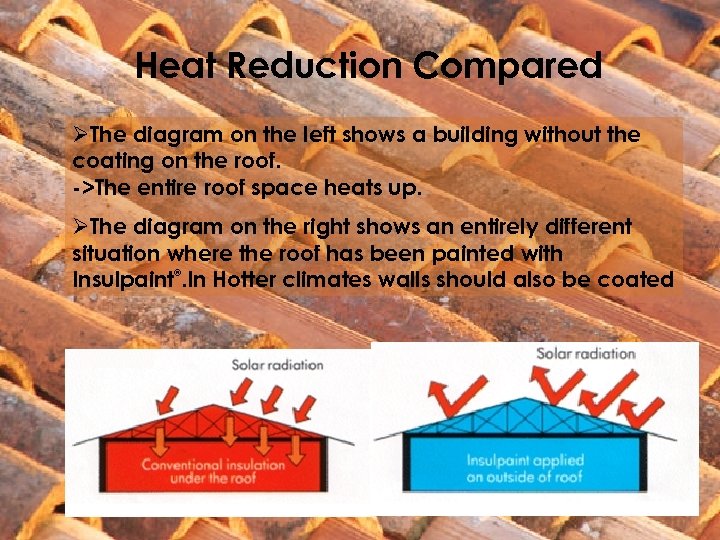

Heat Reduction Compared ØThe diagram on the left shows a building without the coating on the roof. ->The entire roof space heats up. ØThe diagram on the right shows an entirely different situation where the roof has been painted with ® Insulpaint. In Hotter climates walls should also be coated

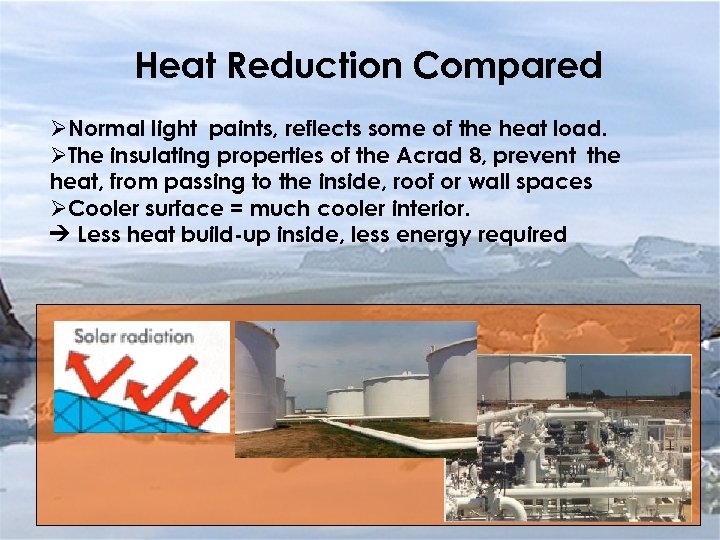

Heat Reduction Compared ØNormal light paints, reflects some of the heat load. ØThe insulating properties of the Acrad 8, prevent the heat, from passing to the inside, roof or wall spaces ØCooler surface = much cooler interior. Less heat build-up inside, less energy required

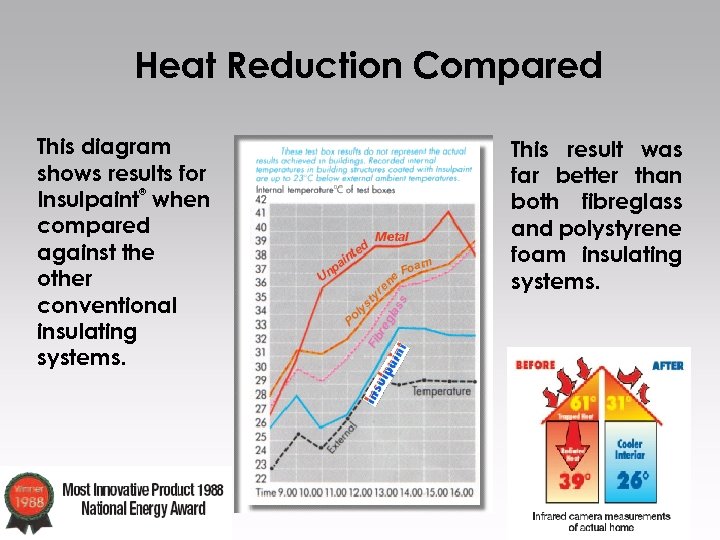

Heat Reduction Compared This diagram shows results for ® Insulpaint when compared against the other conventional insulating systems. This result was far better than both fibreglass and polystyrene foam insulating systems.

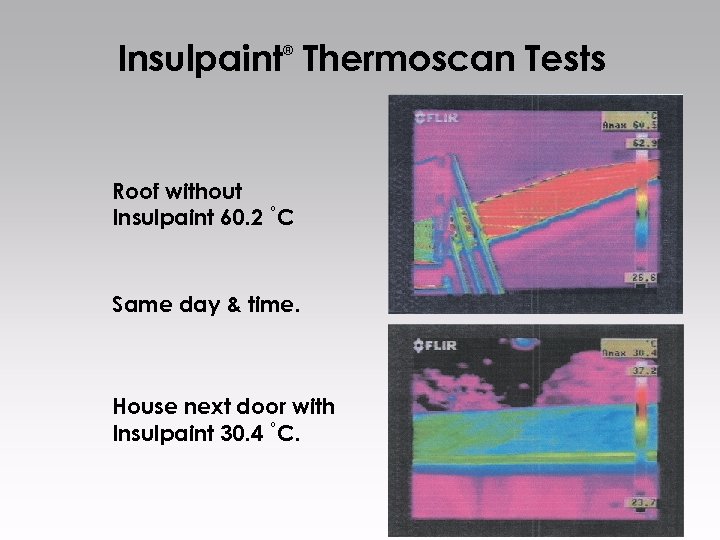

Insulpaint Thermoscan Tests ® Roof without Insulpaint 60. 2 ˚C Same day & time. House next door with Insulpaint 30. 4 ˚C.

Recapture: Insulpaint ® ü Insulpaint has great strength coupled with flexibility ® ü Insulpaint is completely impervious to airborne pollution & extreme weather conditions ® ü Insulpaint is non-flammable, non-toxic & contains no hazardous materials (for example asbestos, glass or mineral fibres)

Recapture: Insulpaint ü Insulpaints has 18 standard colours, and can be tinted, to Client requirements, for the roof and walls within reason. ® ü Insulpaint is completely waterproof and yet is microporous, allowing the substrate to breathe, and giving remarkable stability, particularly on concrete.

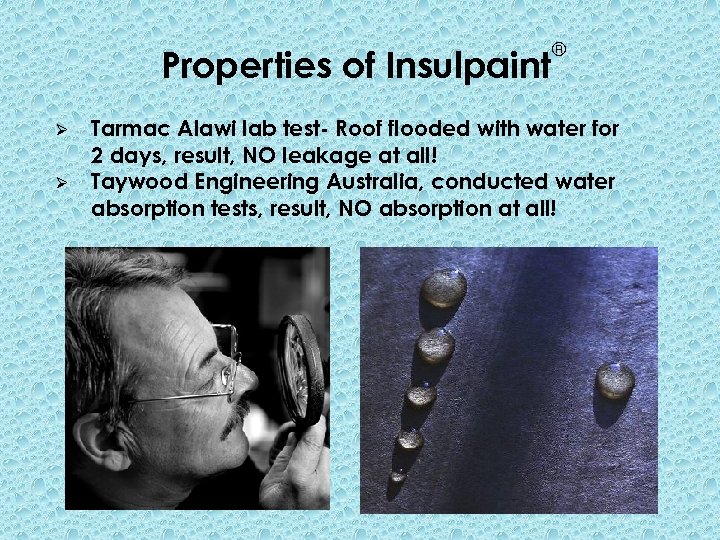

Properties of Insulpaint Ø Ø ® Tarmac Alawi lab test- Roof flooded with water for 2 days, result, NO leakage at all! Taywood Engineering Australia, conducted water absorption tests, result, NO absorption at all!

The Importance of the Paint Base The base resin used in the manufacturing of the paint determines the quality of the coating. If a cheap base is used, then the coating will break down prematurely. ® ü Insulpaint resin is 100% Styrene Acrylic Resin (SAR). ü SAR is far superior to any other acrylic resin, combining: Ø Superior hardness Ø Superior flexibility Ø Superior durability ü SAR properties ideally suit for roof/wall coatings. ü Water based allowing easy cleanup.

Savings with Insulpaint ® A. E. Smith Westair engineers, recorded temperatures and air conditioner usage, over a seven day period, inside 2 identical tiled roof houses at Karratha WA. in 1990. The house with Insulpaint used 51 units of air conditioner power, the house without Insulpaint, used 130 units a/c power. In this example the savings were $ 89 per month. The company who owned the houses conducted an Energy Audit in 2002, and found that Insulpaint was still performing at the same rate of savings, after 12 years.

Testimonials “Initially we had a problem that vegetable oil stored in steel tanks, was being constantly heated by the sun, and losing its intrinsic qualities. We were so impressed by the reduction in the temperature of the oil, after Insulpaint was applied to the tanks, we decided to coat our office porta-cabins. Since doing this, we have noticed a consistent 15% energy saving on air- con usage. We’re very satisfied with Insulpaint, and would not hesitate, to recommend it to anybody, to save money. Prem Maker Director

Testimonials “I was involved in a project where we converted sea containers, into on site medical units, for remote desert locations. After coating the roof and walls of the containers, the interior temperature would always remain 10 C - 15 C below the ambient temperature. This allowed a much cooler working environment, for doctors and patients, and what’s more, Insulpaint required NO maintenance at all. Ray Mc. Nally Managing Director Ray Mc. Nally Builders

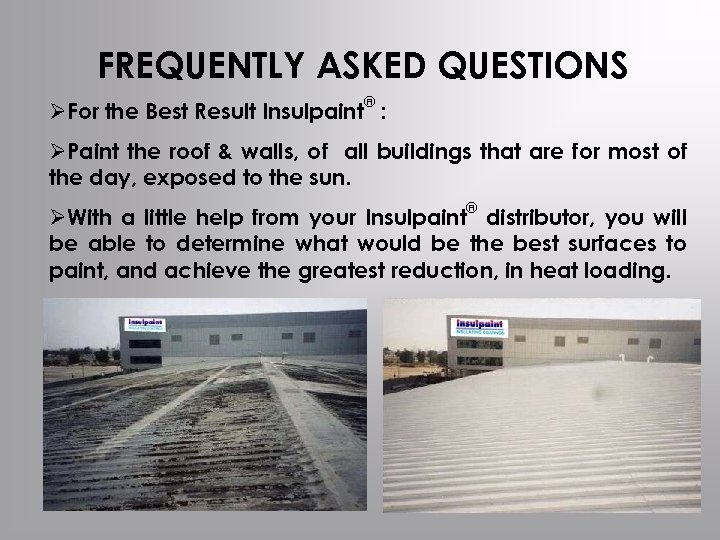

FREQUENTLY ASKED QUESTIONS ® ØFor the Best Result Insulpaint : ØPaint the roof & walls, of all buildings that are for most of the day, exposed to the sun. ® ØWith a little help from your Insulpaint distributor, you will be able to determine what would be the best surfaces to paint, and achieve the greatest reduction, in heat loading.

FREQUENTLY ASKED QUESTIONS Application Thickness Insulpaint® : ® ØGenerally the Insulpaint is applied to a wet film thickness of 0. 45 mm or 450 microns, resulting in 250 microns dry. ØThis Equates To Half a Litre Per Square Metre, all up, so a 200 M 2 surface, requires 100 Ltrs of Insulpaint.

FREQUENTLY ASKED QUESTIONS ® What Surfaces can be Painted with Insulpaint ? Insulpaint reduces the internal temperature when applied to the external surfaces of the following substrates: Ø All Metals Ø Tiles Ø Brick Ø Fibreglass Ø Render Ø Concrete Ø Timber Ø Asbestos

FREQUENTLY ASKED QUESTIONS What are some Ideal Insulpaint Applications? Insulpaint dramatically reduces the solar radiation heat loading, when applied to all surfaces such as, Ø Ø Ø Roofs and Walls on all Factories/Houses ANY HOT SURFACE! Concrete Tilt. Panels. Concrete Foundation Slabs. All Metals/Asbestos/Wood/ Fiberglass/Concrete Block/Render/Colorbond/All Roof Tile&Wall Types Portable Structures/Boats/ Any surface material. Water Storage Tanks/HOT Pipes / Railings / Gates / Driveways / Decking / Pools / Steps / Garage Doors / Trailers/Sea Containers/Trucks/Bridges.

The ULTIMATE in Insulating Coatings Please contact the International Container and Road Transport Exclusive Distributor Mr Alastair Elliott. Managing Director. Elliott Containers Pty. Ltd.

0c67b635c7621844b670822191abd60a.ppt