Bearingless_electrical_motor.ppt

- Количество слайдов: 6

BEARINGLESS ELECTRICAL MOTOR Pskov State University Loginov Sergei

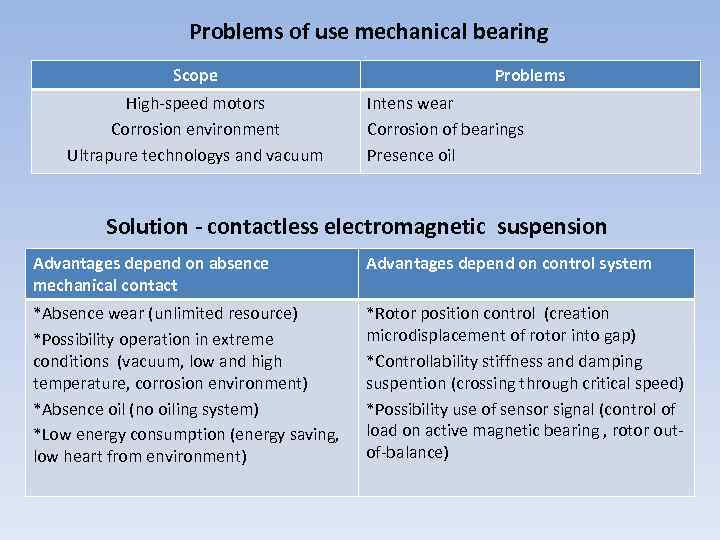

Problems of use mechanical bearing Scope High-speed motors Corrosion environment Ultrapure technologys and vacuum Problems Intens wear Corrosion of bearings Presence oil Solution - contactless electromagnetic suspension Advantages depend on absence mechanical contact Advantages depend on control system *Absence wear (unlimited resource) *Possibility operation in extreme conditions (vacuum, low and high temperature, corrosion environment) *Absence oil (no oiling system) *Low energy consumption (energy saving, low heart from environment) *Rotor position control (creation microdisplacement of rotor into gap) *Controllability stiffness and damping suspention (crossing through critical speed) *Possibility use of sensor signal (control of load on active magnetic bearing , rotor outof-balance)

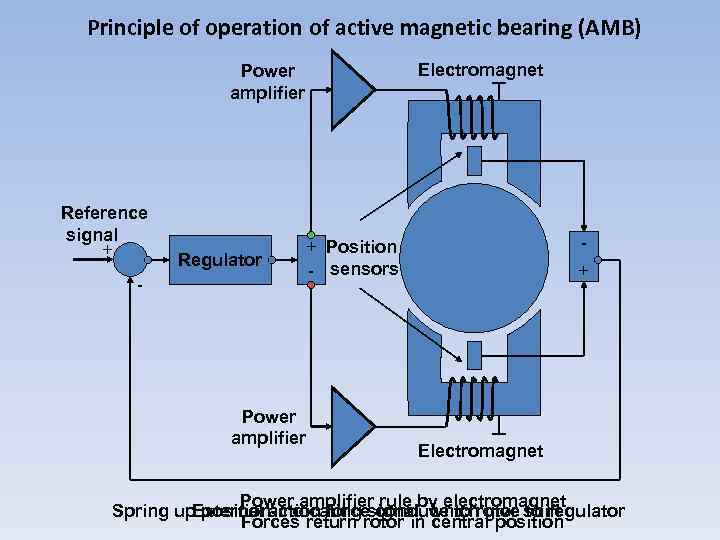

Principle of operation of active magnetic bearing (AMB) Electromagnet Reference signal + - Regulator + - Power amplifier + Position - sensors Power amplifier Electromagnet Power amplifier rule by electromagnet Spring up. External action force conduce to rotor shift position-indicating signal, which give to regulator Forces return rotor in central position

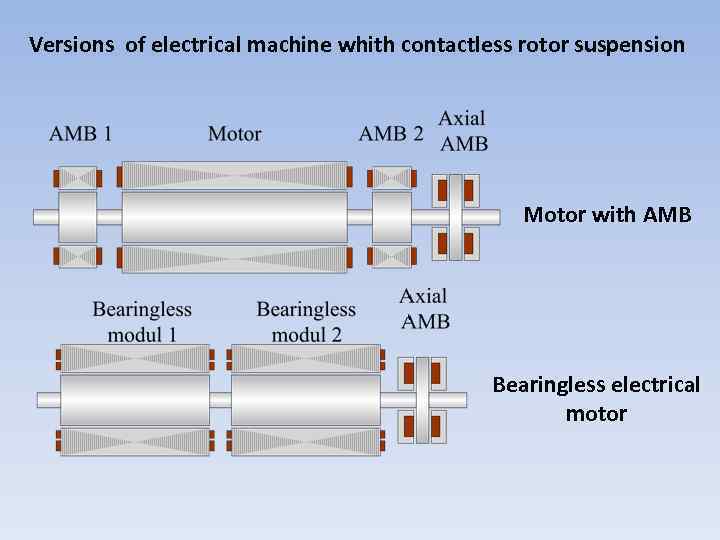

Versions of electrical machine whith contactless rotor suspension Motor with AMB Bearingless electrical motor

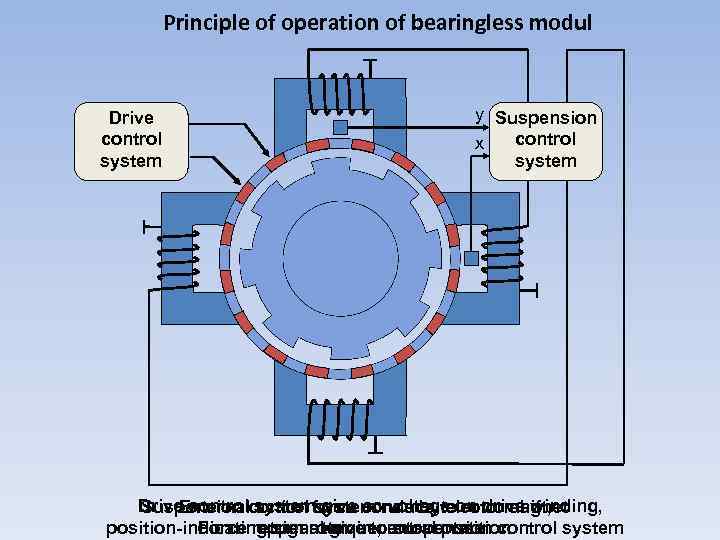

Principle of operation of bearingless modul Drive control system у Suspension control х system Drive control force conduce toon drive winding, Suspension system rule by electromagnet External action give ac voltage rotor shift, appear give central position-indicating signaltorque, rotor rotate control system Force return rotor into suspension

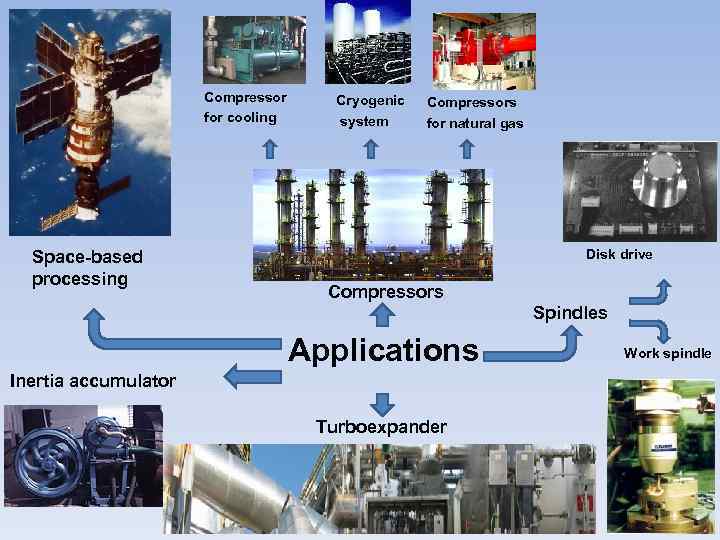

Compressor for cooling Space-based processing Cryogenic system Compressors for natural gas Disk drive Compressors Spindles Applications Inertia accumulator Turboexpander Work spindle

Bearingless_electrical_motor.ppt