6b84b6e1a1f0cc2659d495feec04d805.ppt

- Количество слайдов: 16

Batteries and Corrosion 1

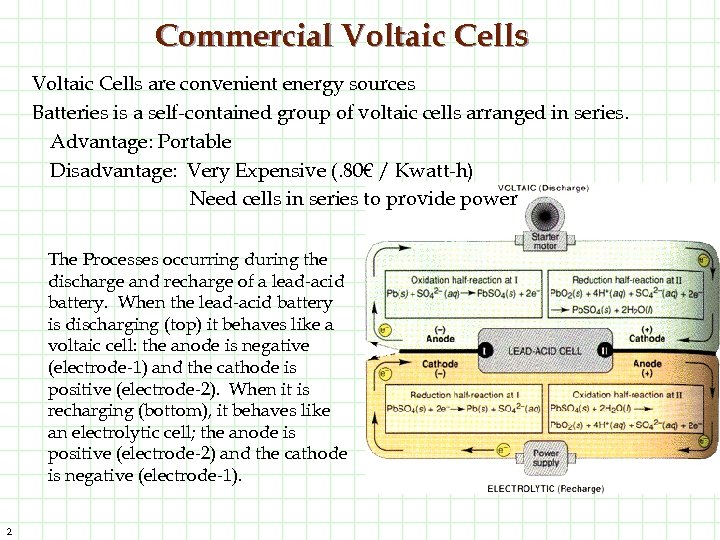

Commercial Voltaic Cells are convenient energy sources Batteries is a self-contained group of voltaic cells arranged in series. Advantage: Portable Disadvantage: Very Expensive (. 80€ / Kwatt-h) Need cells in series to provide power The Processes occurring during the discharge and recharge of a lead-acid battery. When the lead-acid battery is discharging (top) it behaves like a voltaic cell: the anode is negative (electrode-1) and the cathode is positive (electrode-2). When it is recharging (bottom), it behaves like an electrolytic cell; the anode is positive (electrode-2) and the cathode is negative (electrode-1). 2

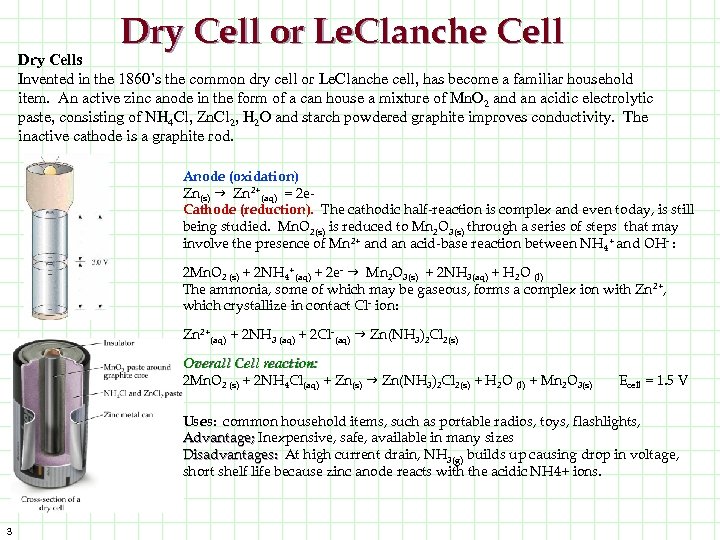

Dry Cell or Le. Clanche Cell Dry Cells Invented in the 1860’s the common dry cell or Le. Clanche cell, has become a familiar household item. An active zinc anode in the form of a can house a mixture of Mn. O 2 and an acidic electrolytic paste, consisting of NH 4 Cl, Zn. Cl 2, H 2 O and starch powdered graphite improves conductivity. The inactive cathode is a graphite rod. Anode (oxidation) Zn(s) g Zn 2+(aq) = 2 e. Cathode (reduction). The cathodic half-reaction is complex and even today, is still being studied. Mn. O 2(s) is reduced to Mn 2 O 3(s) through a series of steps that may involve the presence of Mn 2+ and an acid-base reaction between NH 4+ and OH- : 2 Mn. O 2 (s) + 2 NH 4+(aq) + 2 e- g Mn 2 O 3(s) + 2 NH 3(aq) + H 2 O (l) The ammonia, some of which may be gaseous, forms a complex ion with Zn 2+, which crystallize in contact Cl- ion: Zn 2+(aq) + 2 NH 3 (aq) + 2 Cl-(aq) g Zn(NH 3)2 Cl 2(s) Overall Cell reaction: 2 Mn. O 2 (s) + 2 NH 4 Cl(aq) + Zn(s) g Zn(NH 3)2 Cl 2(s) + H 2 O (l) + Mn 2 O 3(s) Ecell = 1. 5 V Uses: common household items, such as portable radios, toys, flashlights, Advantage; Inexpensive, safe, available in many sizes Disadvantages: At high current drain, NH 3(g) builds up causing drop in voltage, short shelf life because zinc anode reacts with the acidic NH 4+ ions. 3

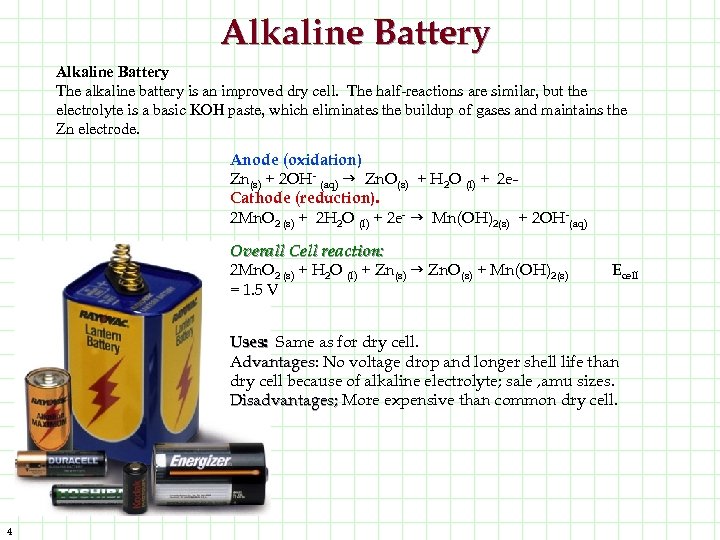

Alkaline Battery The alkaline battery is an improved dry cell. The half-reactions are similar, but the electrolyte is a basic KOH paste, which eliminates the buildup of gases and maintains the Zn electrode. Anode (oxidation) Zn(s) + 2 OH- (aq) g Zn. O(s) + H 2 O (l) + 2 e. Cathode (reduction). 2 Mn. O 2 (s) + 2 H 2 O (l) + 2 e- g Mn(OH)2(s) + 2 OH-(aq) Overall Cell reaction: 2 Mn. O 2 (s) + H 2 O (l) + Zn(s) g Zn. O(s) + Mn(OH)2(s) = 1. 5 V Ecell Uses: Same as for dry cell. Advantages: No voltage drop and longer shell life than dry cell because of alkaline electrolyte; sale , amu sizes. Disadvantages; More expensive than common dry cell. 4

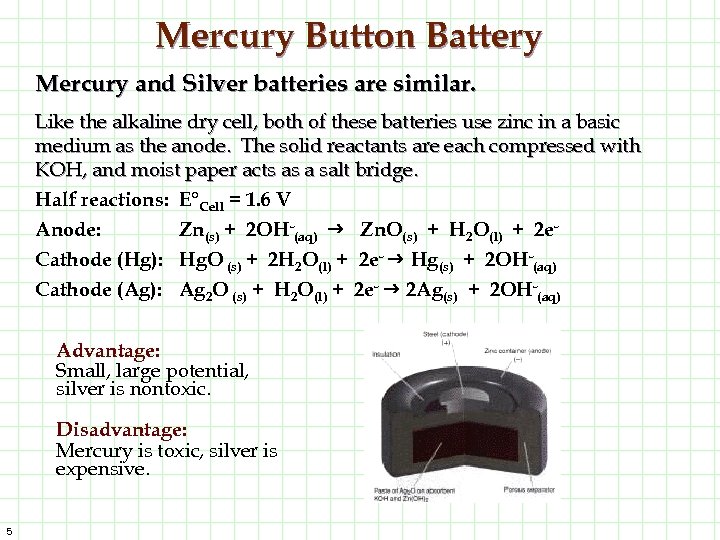

Mercury Button Battery Mercury and Silver batteries are similar. Like the alkaline dry cell, both of these batteries use zinc in a basic medium as the anode. The solid reactants are each compressed with KOH, and moist paper acts as a salt bridge. Half reactions: E°Cell = 1. 6 V Anode: Zn(s) + 2 OH-(aq) Zn. O(s) + H 2 O(l) + 2 e. Cathode (Hg): Hg. O (s) + 2 H 2 O(l) + 2 e- Hg(s) + 2 OH-(aq) Cathode (Ag): Ag 2 O (s) + H 2 O(l) + 2 e- 2 Ag(s) + 2 OH-(aq) Advantage: Small, large potential, silver is nontoxic. Disadvantage: Mercury is toxic, silver is expensive. 5

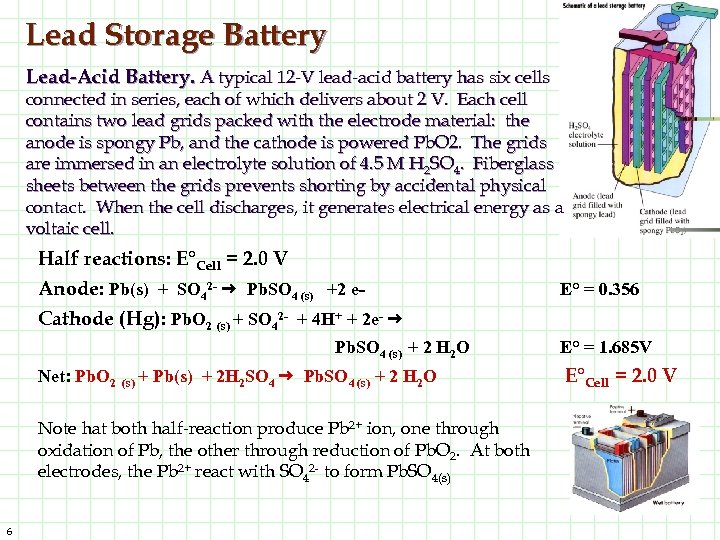

Lead Storage Battery Lead-Acid Battery. A typical 12 -V lead-acid battery has six cells connected in series, each of which delivers about 2 V. Each cell contains two lead grids packed with the electrode material: the anode is spongy Pb, and the cathode is powered Pb. O 2. The grids are immersed in an electrolyte solution of 4. 5 M H 2 SO 4. Fiberglass sheets between the grids prevents shorting by accidental physical contact. When the cell discharges, it generates electrical energy as a voltaic cell. Half reactions: E°Cell = 2. 0 V Anode: Pb(s) + SO 42 - Pb. SO 4 (s) +2 e. Cathode (Hg): Pb. O 2 (s) + SO 42 - + 4 H+ + 2 e- Pb. SO 4 (s) + 2 H 2 O Net: Pb. O 2 (s) + Pb(s) + 2 H 2 SO 4 Pb. SO 4 (s) + 2 H 2 O Note hat both half-reaction produce Pb 2+ ion, one through oxidation of Pb, the other through reduction of Pb. O 2. At both electrodes, the Pb 2+ react with SO 42 - to form Pb. SO 4(s) 6 E° = 0. 356 E° = 1. 685 V E°Cell = 2. 0 V

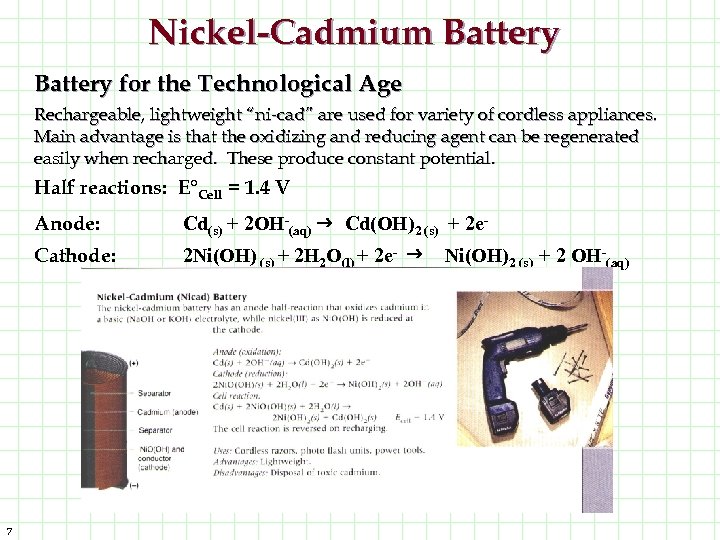

Nickel-Cadmium Battery for the Technological Age Rechargeable, lightweight “ni-cad” are used for variety of cordless appliances. Main advantage is that the oxidizing and reducing agent can be regenerated easily when recharged. These produce constant potential. Half reactions: E°Cell = 1. 4 V Anode: Cathode: 7 Cd(s) + 2 OH-(aq) Cd(OH)2 (s) + 2 e 2 Ni(OH) (s) + 2 H 2 O(l) + 2 e- Ni(OH)2 (s) + 2 OH-(aq)

Lithium Ion Batteries Chemistry Graphite (-), cobalt or manganese (+) Nonaqueous electrolyte Features + 40% more capacity than Ni. Cd + Flat discharge (like Ni. Cd) + Self-discharge 50% less than Ni. Cd Expensive 8

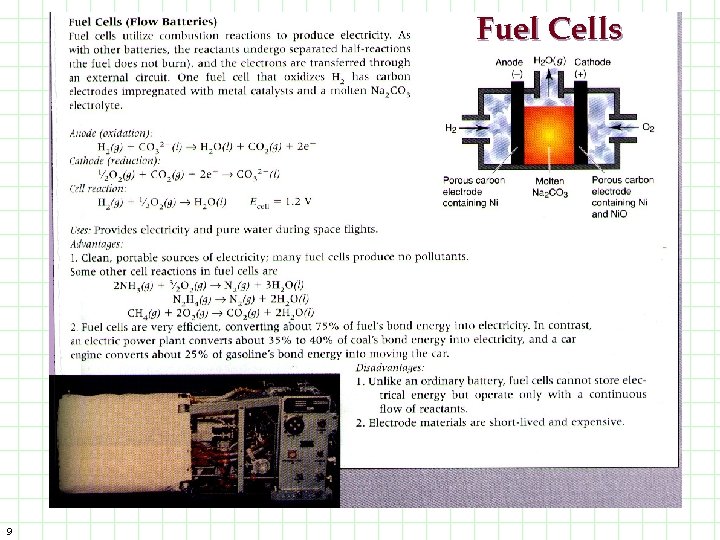

Fuel Cells 9

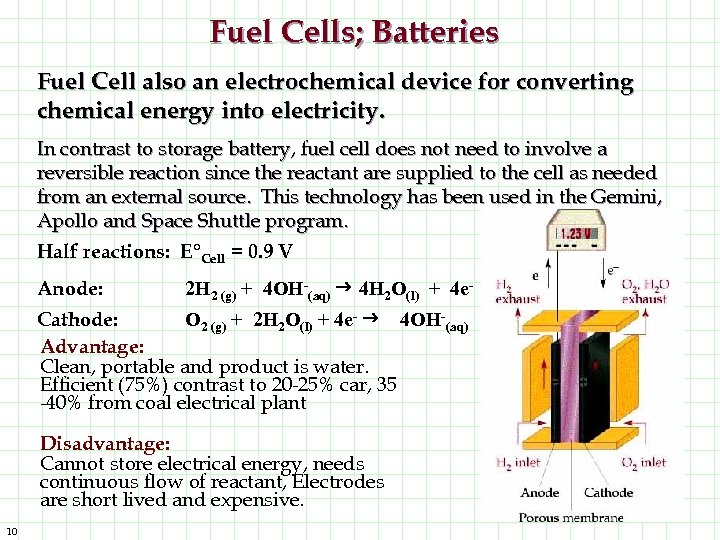

Fuel Cells; Batteries Fuel Cell also an electrochemical device for converting chemical energy into electricity. In contrast to storage battery, fuel cell does not need to involve a reversible reaction since the reactant are supplied to the cell as needed from an external source. This technology has been used in the Gemini, Apollo and Space Shuttle program. Half reactions: E°Cell = 0. 9 V Anode: 2 H 2 (g) + 4 OH-(aq) 4 H 2 O(l) + 4 e- Cathode: O 2 (g) + 2 H 2 O(l) + 4 e- 4 OH-(aq) Advantage: Clean, portable and product is water. Efficient (75%) contrast to 20 -25% car, 35 -40% from coal electrical plant Disadvantage: Cannot store electrical energy, needs continuous flow of reactant, Electrodes are short lived and expensive. 10

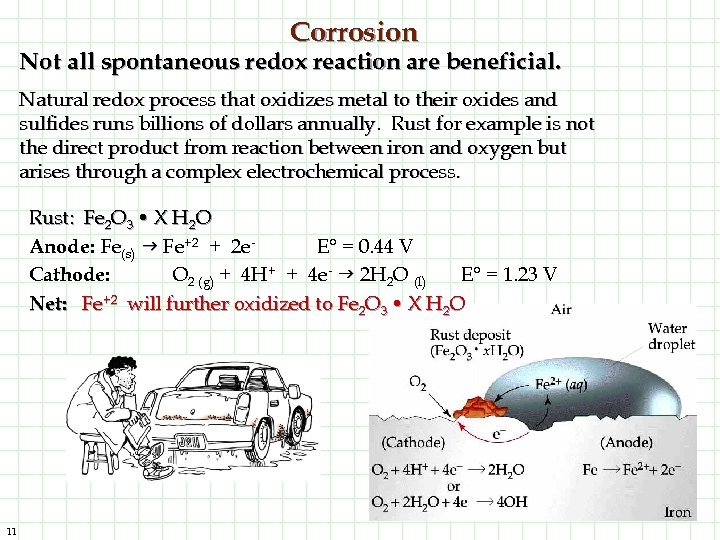

Corrosion Not all spontaneous redox reaction are beneficial. Natural redox process that oxidizes metal to their oxides and sulfides runs billions of dollars annually. Rust for example is not the direct product from reaction between iron and oxygen but arises through a complex electrochemical process. Rust: Fe 2 O 3 • X H 2 O Anode: Fe(s) g Fe+2 + 2 e. E° = 0. 44 V Cathode: O 2 (g) + 4 H+ + 4 e- g 2 H 2 O (l) E° = 1. 23 V Net: Fe+2 will further oxidized to Fe 2 O 3 • X H 2 O 11

Conditions for Corrosion Conditions for Iron Oxidation: Iron will oxidize in acidic medium SO 2 g H 2 SO 4 g H+ + HSO 4+ Anions improve conductivity for oxidation. Cl- from seawater or Na. Cl (snow melting) enhances rusting Conditions for Prevention: Iron will not rust in dry air; moisture must be present Iron will not rust in air-free water; oxygen must be present Iron rusts most rapidly in ionic solution and low p. H (high H+) The loss of iron and deposit of rust occur at different placm on object Iron rust faster in contact with a less active metal (Cu) Iron rust slower in contact with a more active metal (Zn) 12

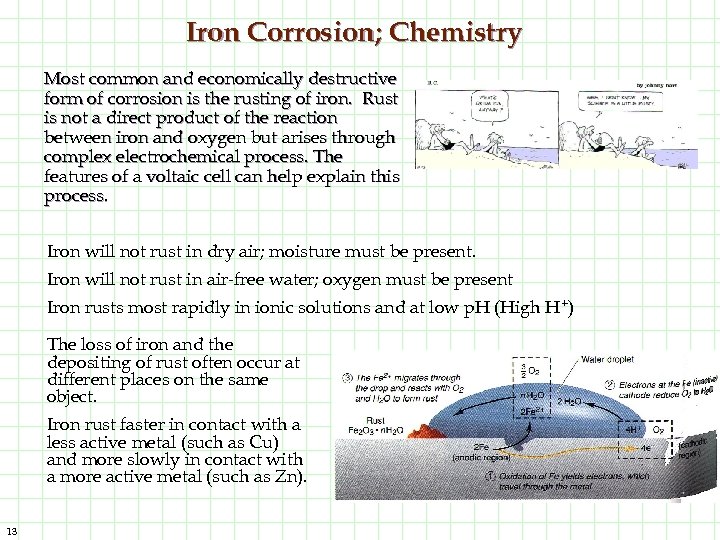

Iron Corrosion; Chemistry Most common and economically destructive form of corrosion is the rusting of iron. Rust is not a direct product of the reaction between iron and oxygen but arises through complex electrochemical process. The features of a voltaic cell can help explain this process. Iron will not rust in dry air; moisture must be present. Iron will not rust in air-free water; oxygen must be present Iron rusts most rapidly in ionic solutions and at low p. H (High H+) The loss of iron and the depositing of rust often occur at different places on the same object. Iron rust faster in contact with a less active metal (such as Cu) and more slowly in contact with a more active metal (such as Zn). 13

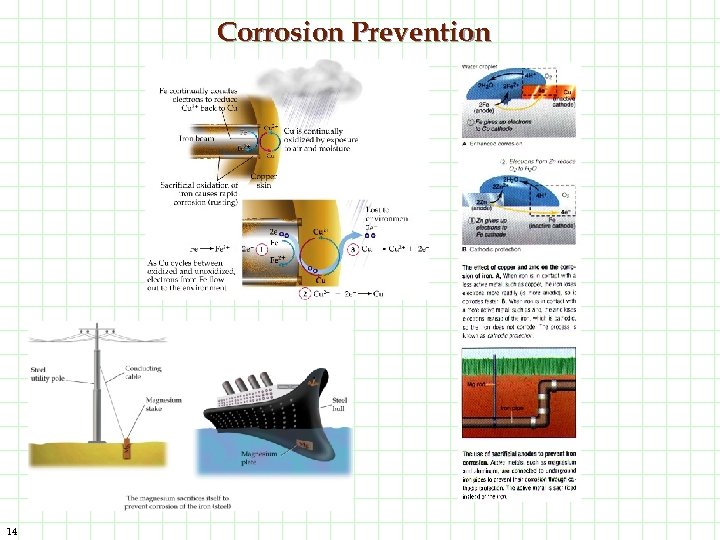

Corrosion Prevention 14

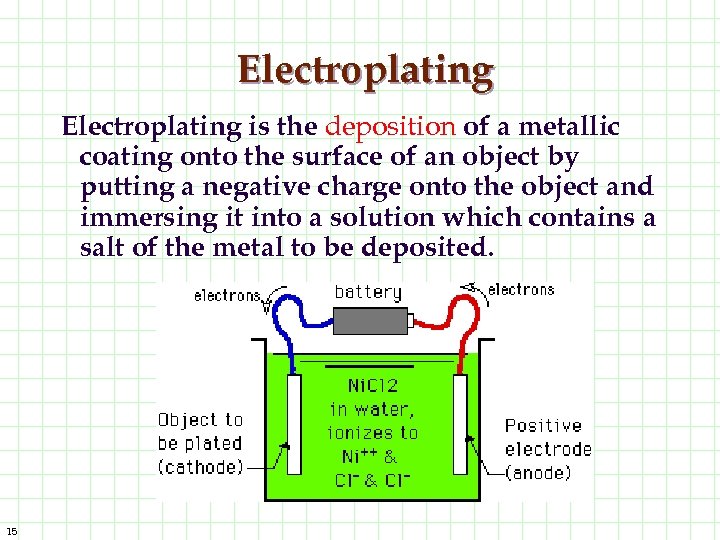

Electroplating is the deposition of a metallic coating onto the surface of an object by putting a negative charge onto the object and immersing it into a solution which contains a salt of the metal to be deposited. 15

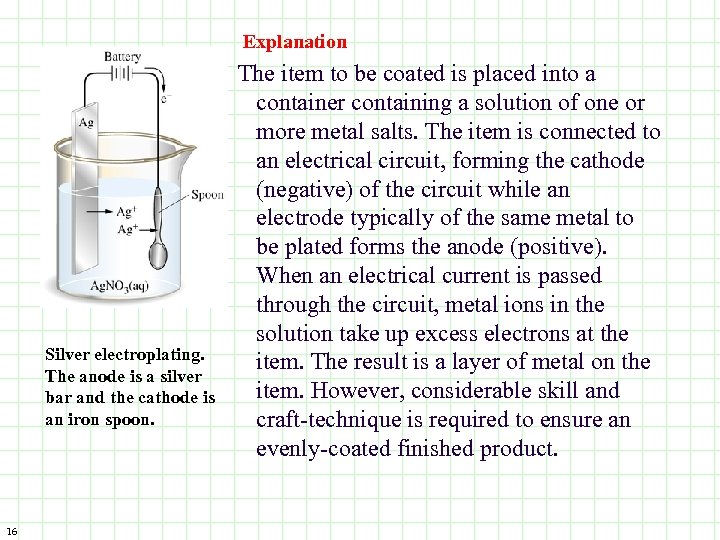

Explanation Silver electroplating. The anode is a silver bar and the cathode is an iron spoon. 16 The item to be coated is placed into a container containing a solution of one or more metal salts. The item is connected to an electrical circuit, forming the cathode (negative) of the circuit while an electrode typically of the same metal to be plated forms the anode (positive). When an electrical current is passed through the circuit, metal ions in the solution take up excess electrons at the item. The result is a layer of metal on the item. However, considerable skill and craft-technique is required to ensure an evenly-coated finished product.

6b84b6e1a1f0cc2659d495feec04d805.ppt