e0dee3b4581e803b9bfc19079b619a92.ppt

- Количество слайдов: 26

Batch Standardisation Module (BSM)

BSM Introduction When a work order is fully dispensed, quantities of innate ingredients, such as Minerals & Vitamins, need to be calculated, based on the micro & macro material weight and lot / innate profile table. If the innate quantity does not satisfy the pre-defined product standard, materials may need to be added or removed from the work order. Or a different Lotno may be used instead to change the innate material quantities, across the order. The intent of the BSM functionality is to guarantee the innate quantity across all Minerals & Vitamins of the finished product. BSM functionality is used at Wyeth Nutrition China (Suzhou).

BSM Work flow 1. BSM Preparation - setup of material & lot COA rules 2. ERP such as SAP sends COA results data to 3 WS 3. ERP such as SAP sends Work Order data to 3 WS 4. Dispensing is completed. BSM checking can be started 5. BSM Innate Quantity calculation, with Error notification 6. BSM Work Order adjustment, starts M&V recalculation

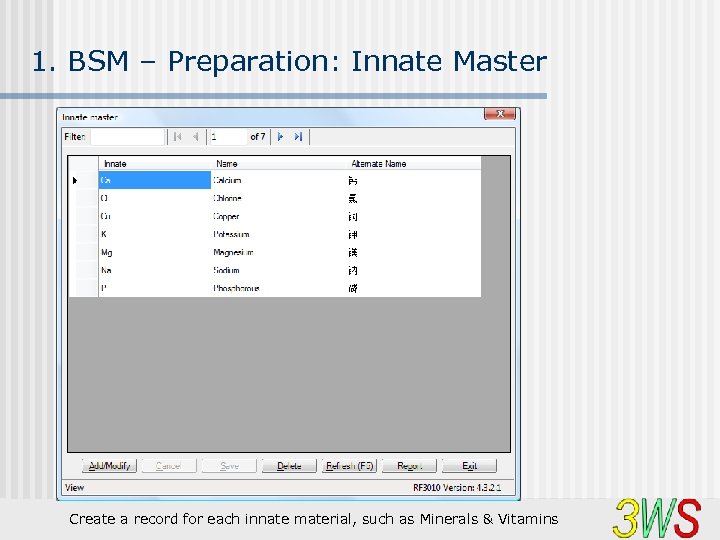

1. BSM – Preparation: Innate Master Create a record for each innate material, such as Minerals & Vitamins

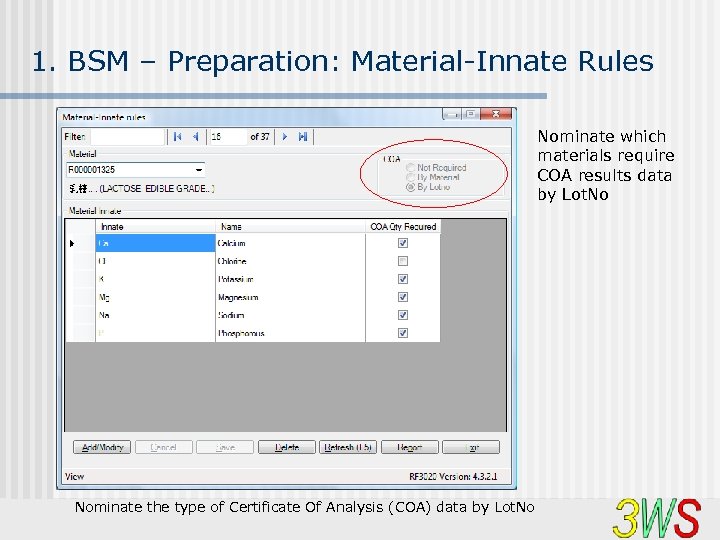

1. BSM – Preparation: Material-Innate Rules Nominate which materials require COA results data by Lot. No Nominate the type of Certificate Of Analysis (COA) data by Lot. No

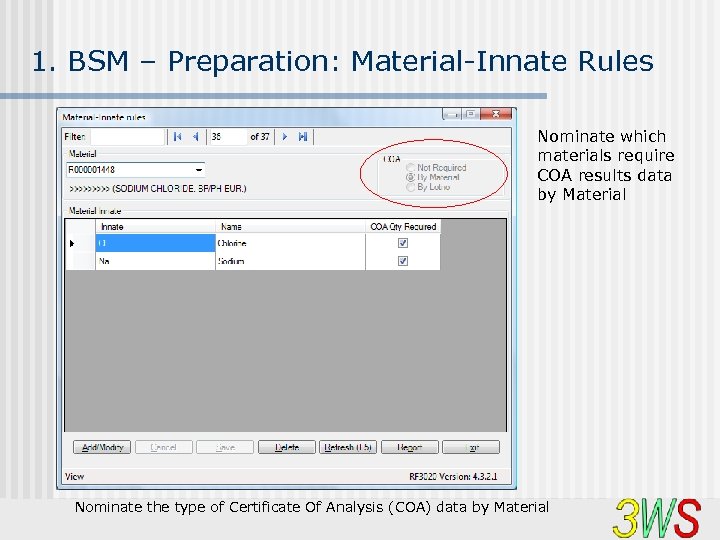

1. BSM – Preparation: Material-Innate Rules Nominate which materials require COA results data by Material Nominate the type of Certificate Of Analysis (COA) data by Material

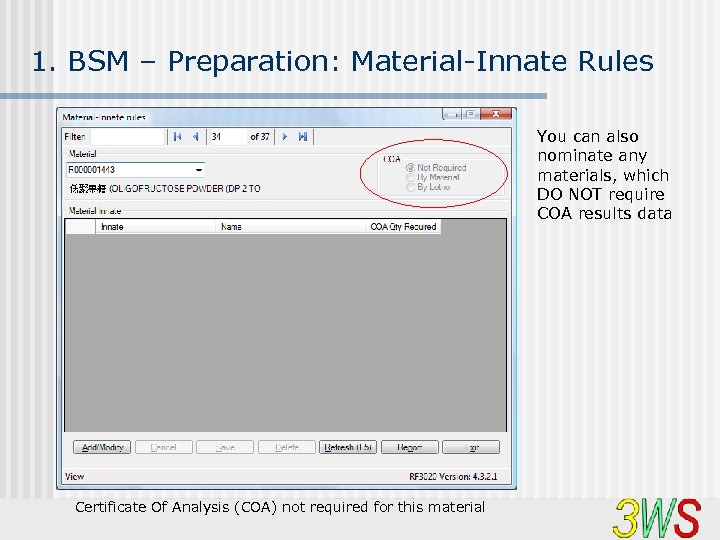

1. BSM – Preparation: Material-Innate Rules You can also nominate any materials, which DO NOT require COA results data Certificate Of Analysis (COA) not required for this material

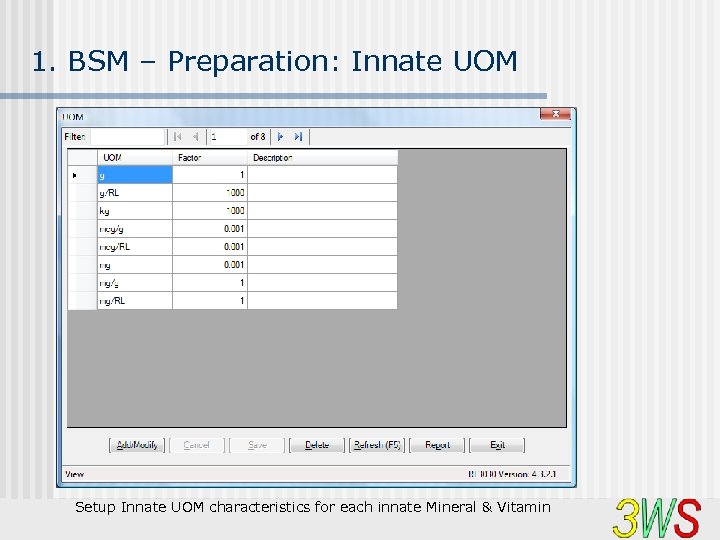

1. BSM – Preparation: Innate UOM Setup Innate UOM characteristics for each innate Mineral & Vitamin

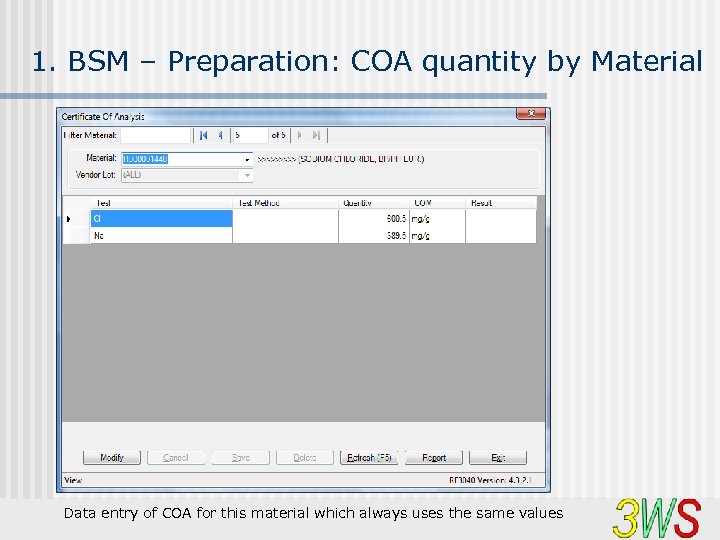

1. BSM – Preparation: COA quantity by Material Data entry of COA for this material which always uses the same values

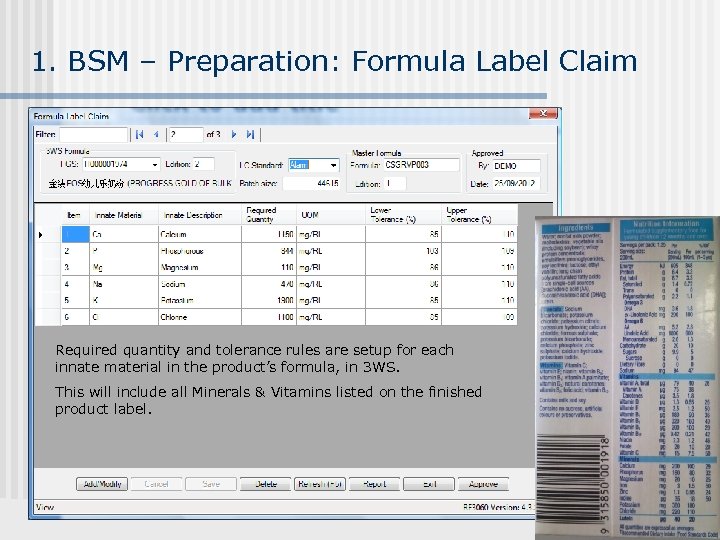

1. BSM – Preparation: Formula Label Claim Required quantity and tolerance rules are setup for each innate material in the product’s formula, in 3 WS. This will include all Minerals & Vitamins listed on the finished product label.

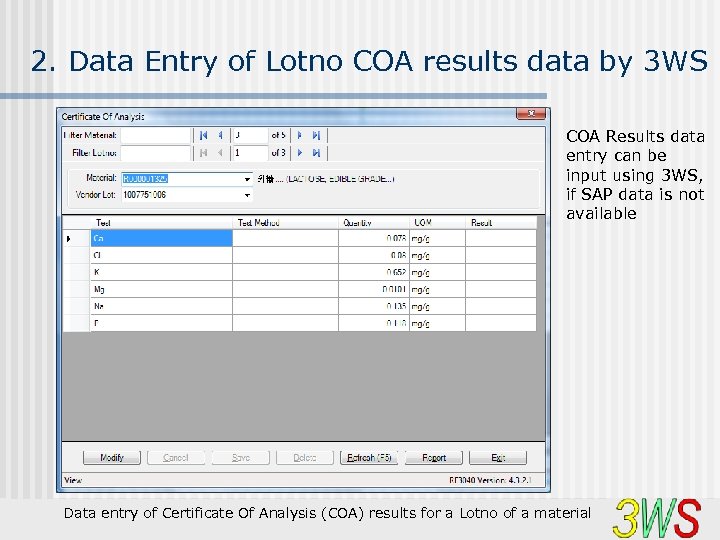

2. Data Entry of Lotno COA results data by 3 WS COA Results data entry can be input using 3 WS, if SAP data is not available Data entry of Certificate Of Analysis (COA) results for a Lotno of a material

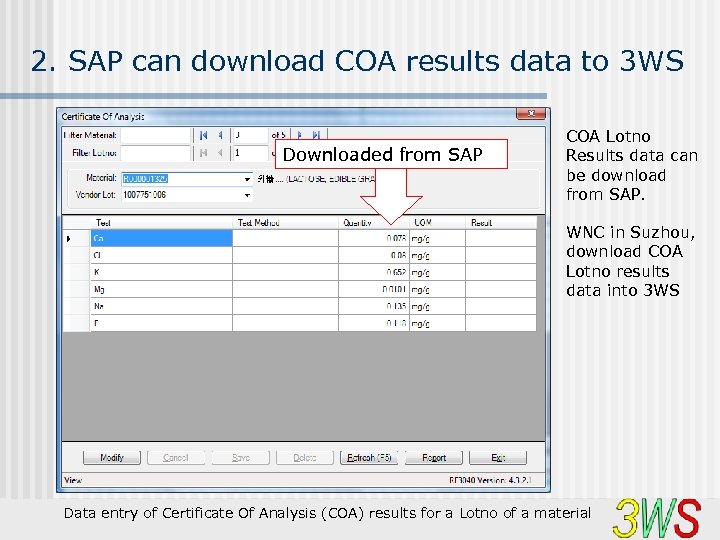

2. SAP can download COA results data to 3 WS Downloaded from SAP COA Lotno Results data can be download from SAP. WNC in Suzhou, download COA Lotno results data into 3 WS Data entry of Certificate Of Analysis (COA) results for a Lotno of a material

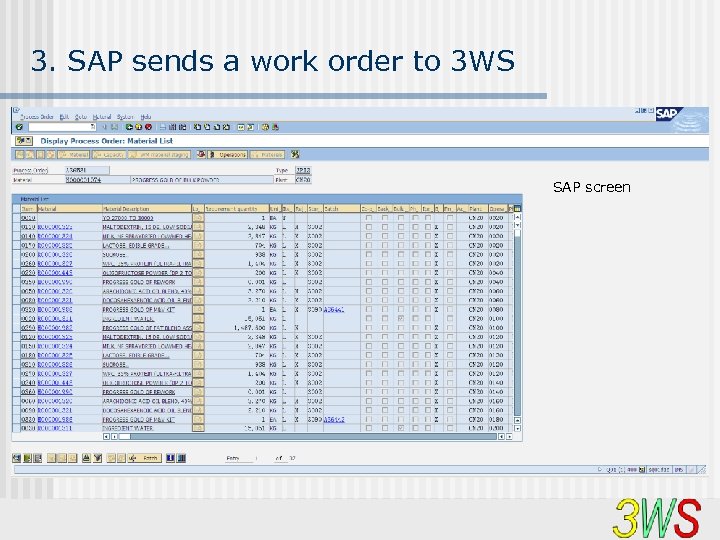

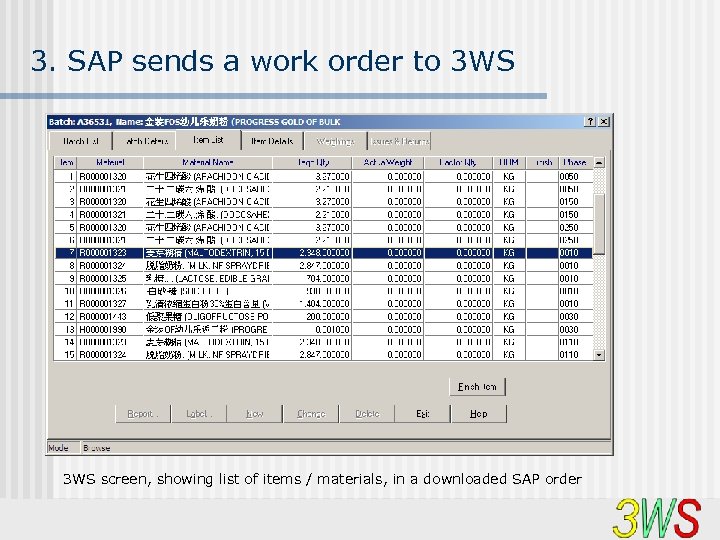

3. SAP sends a work order to 3 WS SAP screen

3. SAP sends a work order to 3 WS screen, showing list of items / materials, in a downloaded SAP order

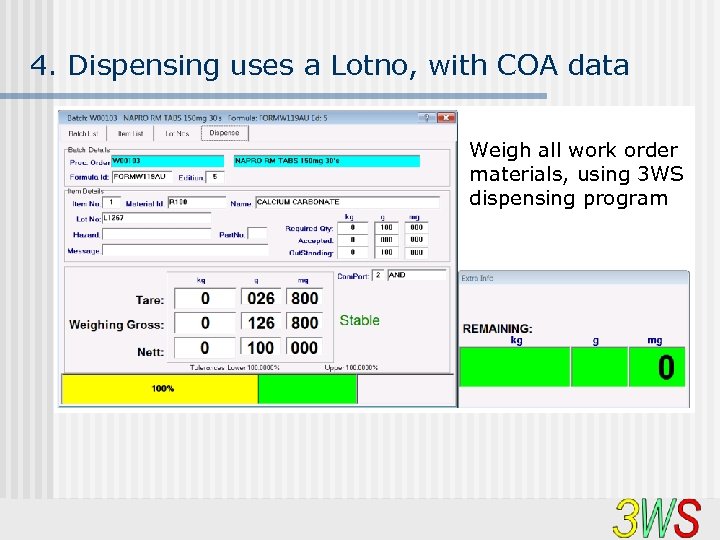

4. Dispensing uses a Lotno, with COA data Weigh all work order materials, using 3 WS dispensing program

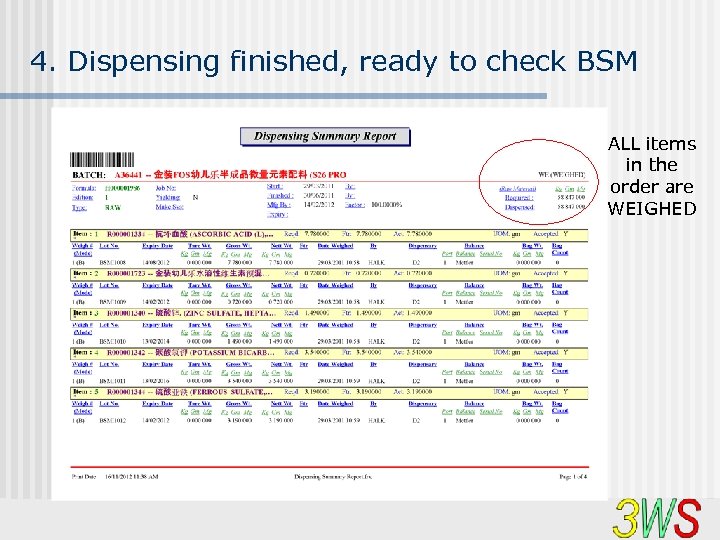

4. Dispensing finished, ready to check BSM ALL items in the order are WEIGHED

4. BSM Calculation All the data for BSM calculation is ready: COA quantity for each Lotno and material Innate quantity and tolerance rules for the product Weight for each material in the work order The BSM Calculation can now be actioned…. .

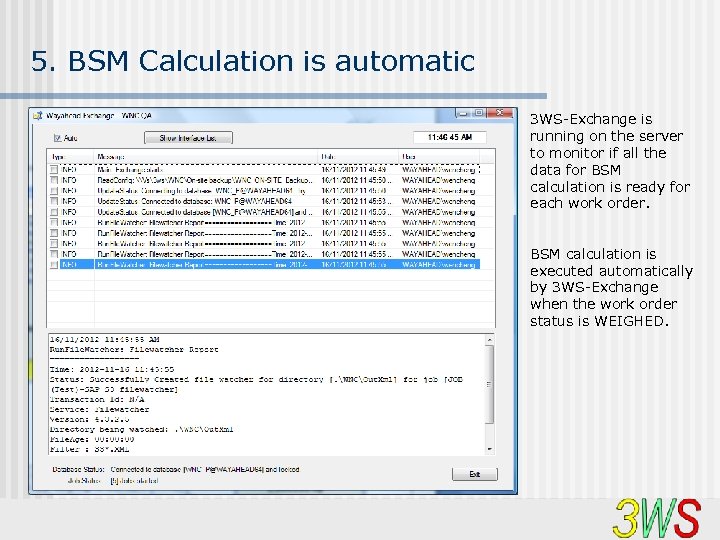

5. BSM Calculation is automatic 3 WS-Exchange is running on the server to monitor if all the data for BSM calculation is ready for each work order. BSM calculation is executed automatically by 3 WS-Exchange when the work order status is WEIGHED.

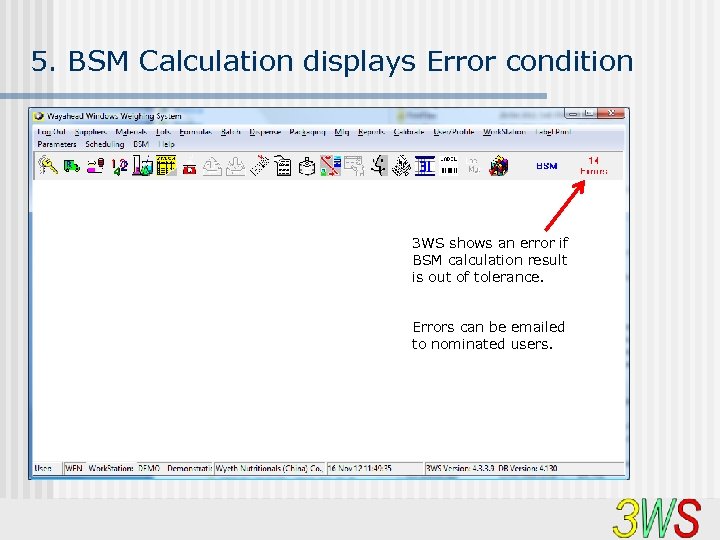

5. BSM Calculation displays Error condition 3 WS shows an error if BSM calculation result is out of tolerance. Errors can be emailed to nominated users.

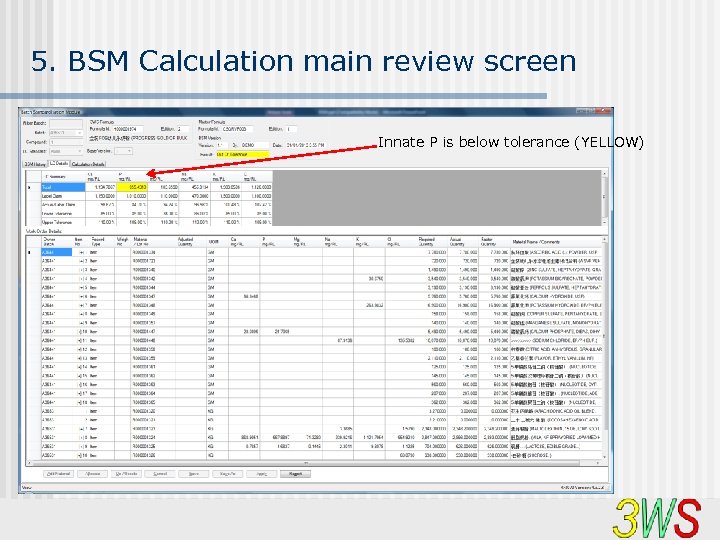

5. BSM Calculation main review screen Innate P is below tolerance (YELLOW)

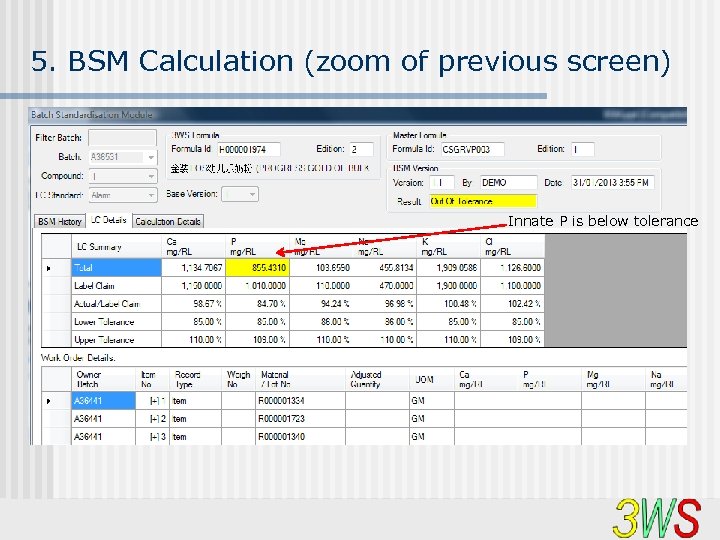

5. BSM Calculation (zoom of previous screen) Innate P is below tolerance

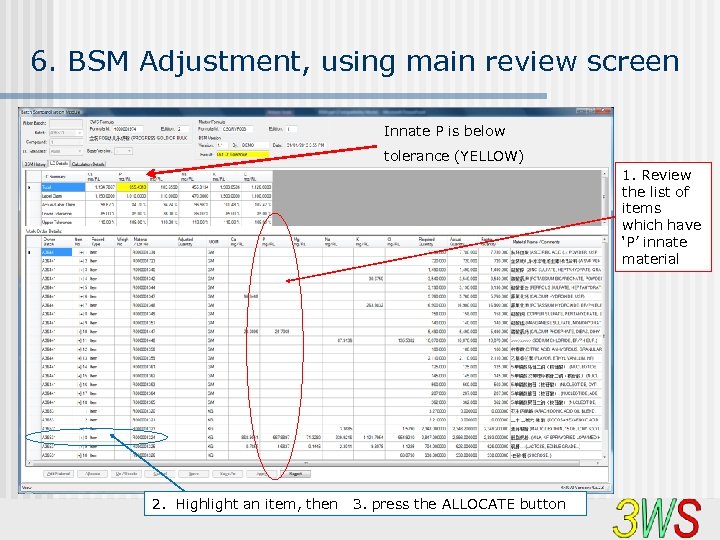

6. BSM Adjustment, using main review screen Innate P is below tolerance (YELLOW) 1. Review the list of items which have ‘P’ innate material 2. Highlight an item, then 3. press the ALLOCATE button

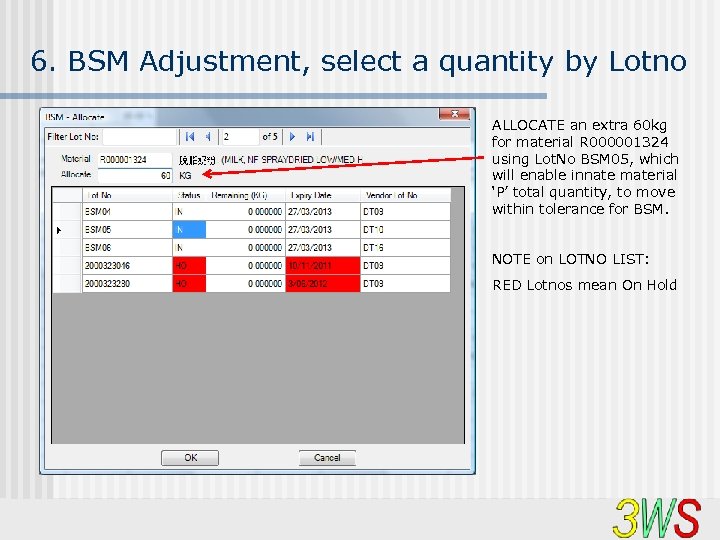

6. BSM Adjustment, select a quantity by Lotno ALLOCATE an extra 60 kg for material R 000001324 using Lot. No BSM 05, which will enable innate material ‘P’ total quantity, to move within tolerance for BSM. NOTE on LOTNO LIST: RED Lotnos mean On Hold

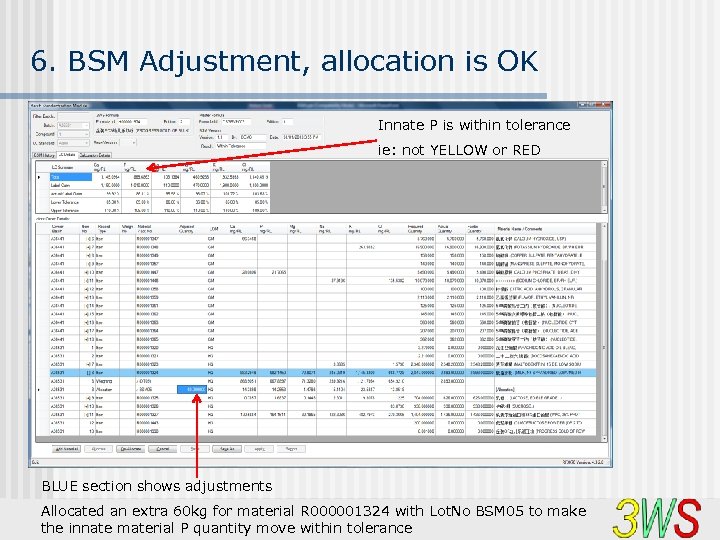

6. BSM Adjustment, allocation is OK Innate P is within tolerance ie: not YELLOW or RED BLUE section shows adjustments Allocated an extra 60 kg for material R 000001324 with Lot. No BSM 05 to make the innate material P quantity move within tolerance

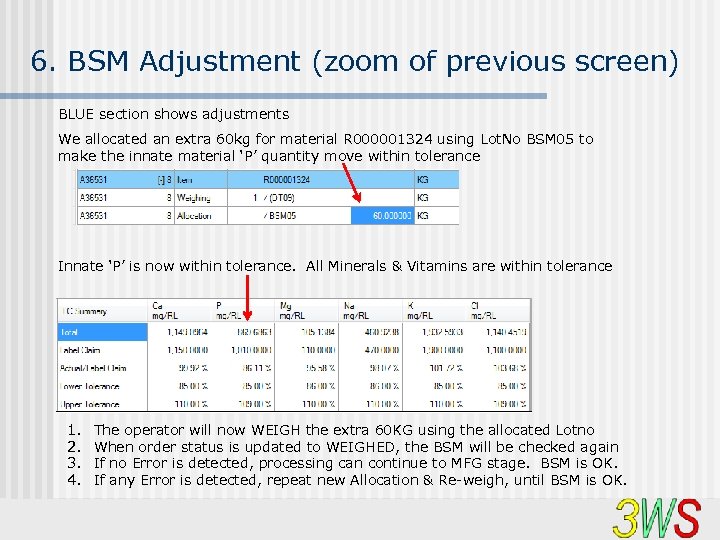

6. BSM Adjustment (zoom of previous screen) BLUE section shows adjustments We allocated an extra 60 kg for material R 000001324 using Lot. No BSM 05 to make the innate material ‘P’ quantity move within tolerance Innate ‘P’ is now within tolerance. All Minerals & Vitamins are within tolerance 1. 2. 3. 4. The operator will now WEIGH the extra 60 KG using the allocated Lotno When order status is updated to WEIGHED, the BSM will be checked again If no Error is detected, processing can continue to MFG stage. BSM is OK. If any Error is detected, repeat new Allocation & Re-weigh, until BSM is OK.

BSM considerations • Automatic calculation across all Minerals & Vitamins • Instantly show adjustment result • Multiple tolerance levels (Alarm, Release, Industry) • Reduces QA / QC role in checking innate quantities • Site can interface COA data from other system, ie SAP • Full audit trail of BSM calculation for validation results • Full audit trail of e. Signatures for all adjustments • Simulation of new product calculations • Simulation of alternate Lotno calculations • Finished product label claim M&V quantities guaranteed

e0dee3b4581e803b9bfc19079b619a92.ppt