Basic_Principle.ppt

- Количество слайдов: 42

Basic Principles of Ultrasonic Testing Theory and Practice

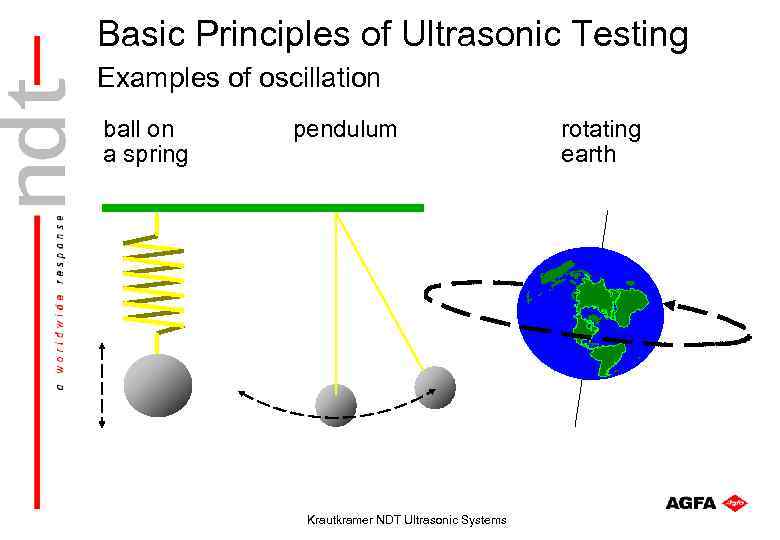

Basic Principles of Ultrasonic Testing Examples of oscillation ball on a spring pendulum Krautkramer NDT Ultrasonic Systems rotating earth

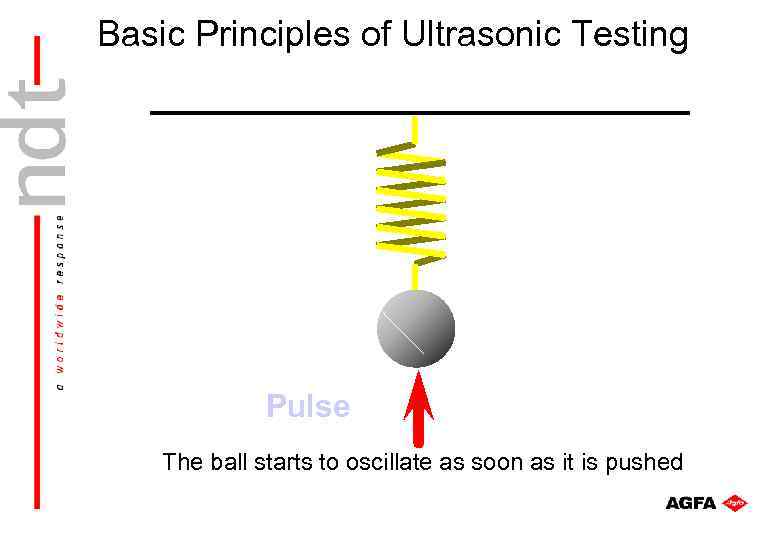

Basic Principles of Ultrasonic Testing Pulse The ball starts to oscillate as soon as it is pushed

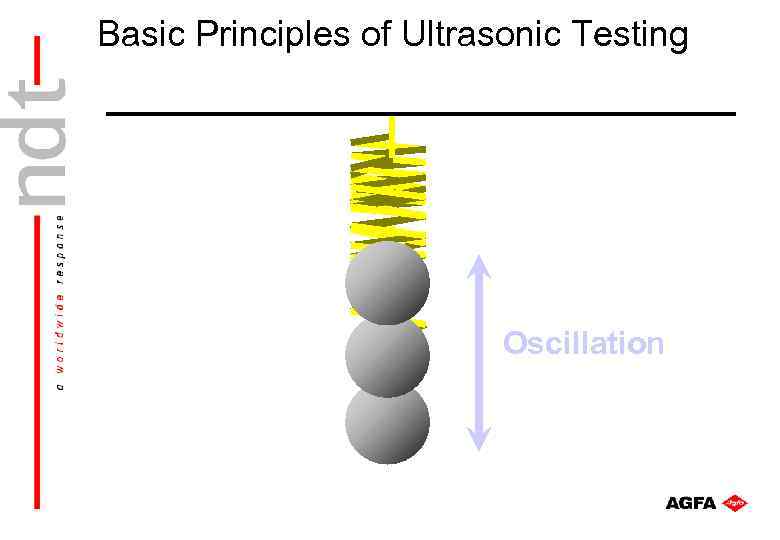

Basic Principles of Ultrasonic Testing Oscillation

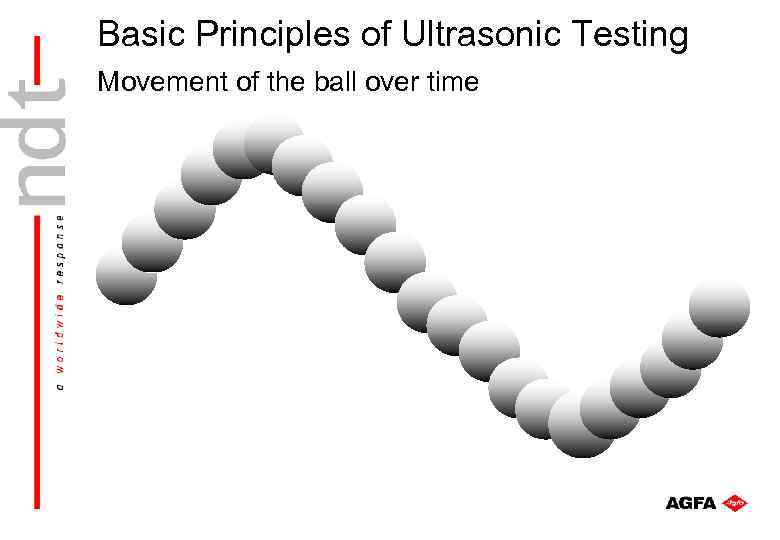

Basic Principles of Ultrasonic Testing Movement of the ball over time

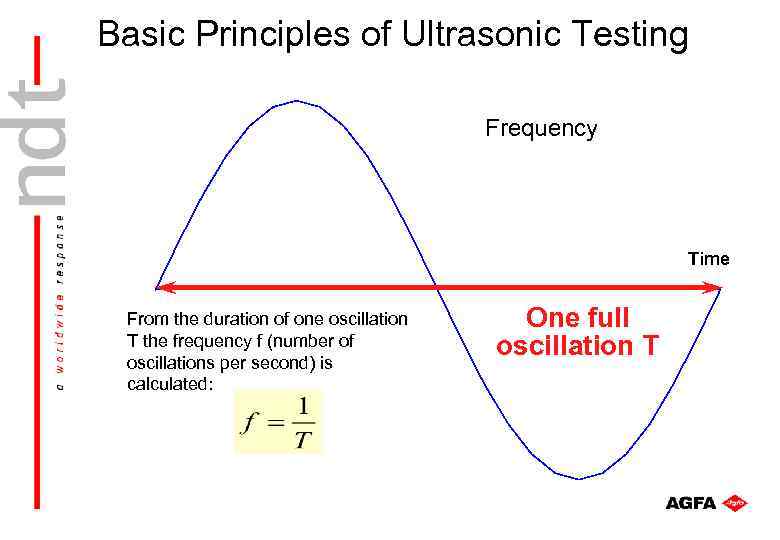

Basic Principles of Ultrasonic Testing Frequency Time From the duration of one oscillation T the frequency f (number of oscillations per second) is calculated: One full oscillation T

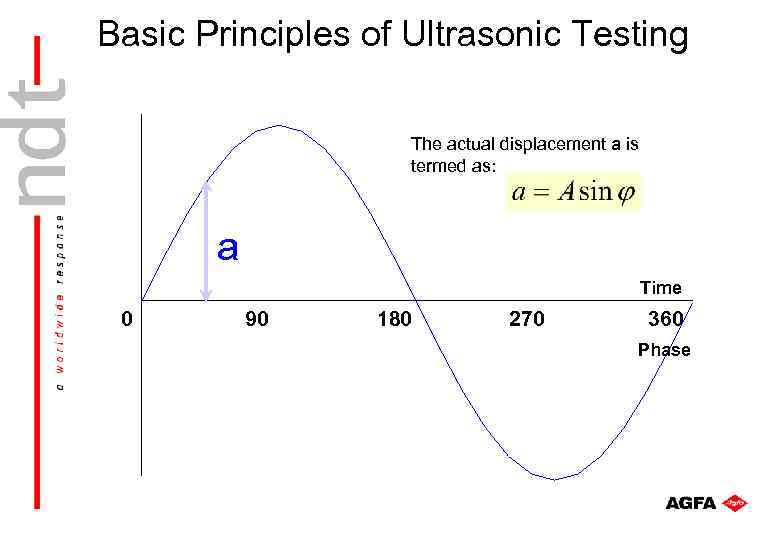

Basic Principles of Ultrasonic Testing The actual displacement a is termed as: a Time 0 90 180 270 360 Phase

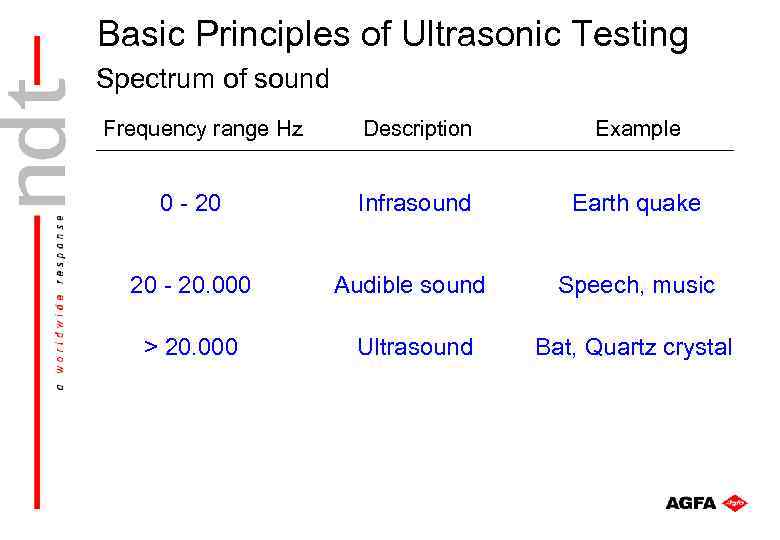

Basic Principles of Ultrasonic Testing Spectrum of sound Description Example 0 - 20 Infrasound Earth quake 20 - 20. 000 Audible sound Speech, music > 20. 000 Ultrasound Bat, Quartz crystal Frequency range Hz

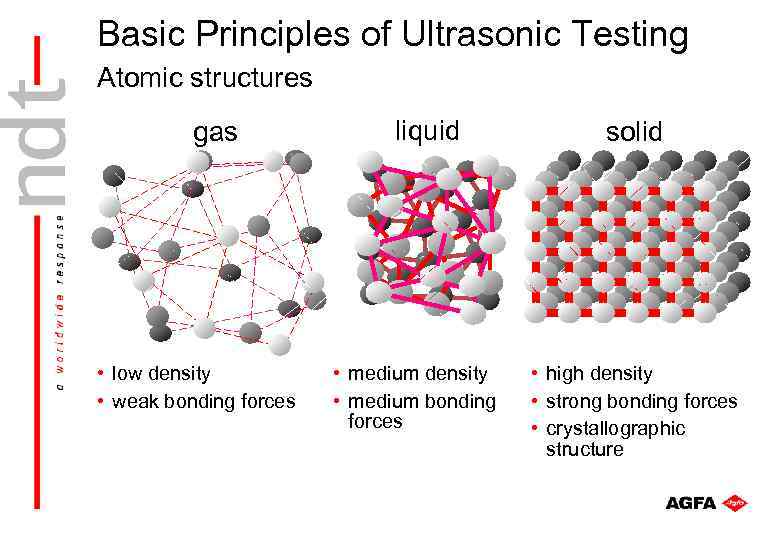

Basic Principles of Ultrasonic Testing Atomic structures gas • low density • weak bonding forces liquid • medium density • medium bonding forces solid • high density • strong bonding forces • crystallographic structure

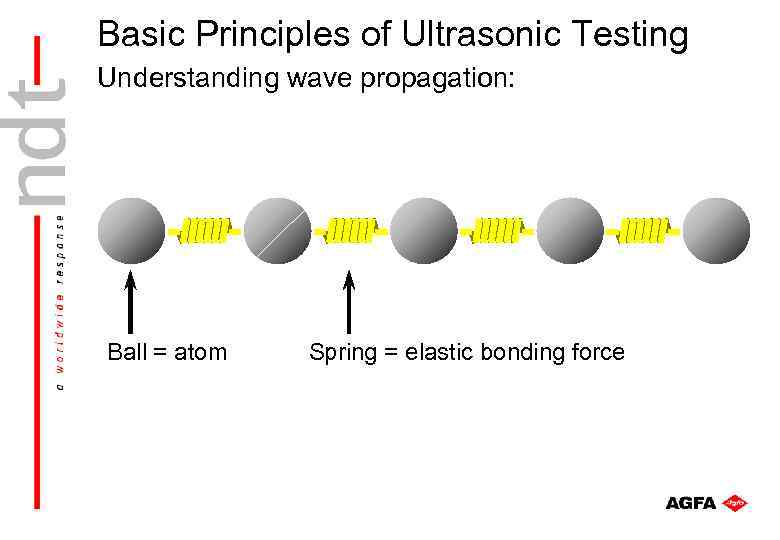

Basic Principles of Ultrasonic Testing Understanding wave propagation: Ball = atom Spring = elastic bonding force

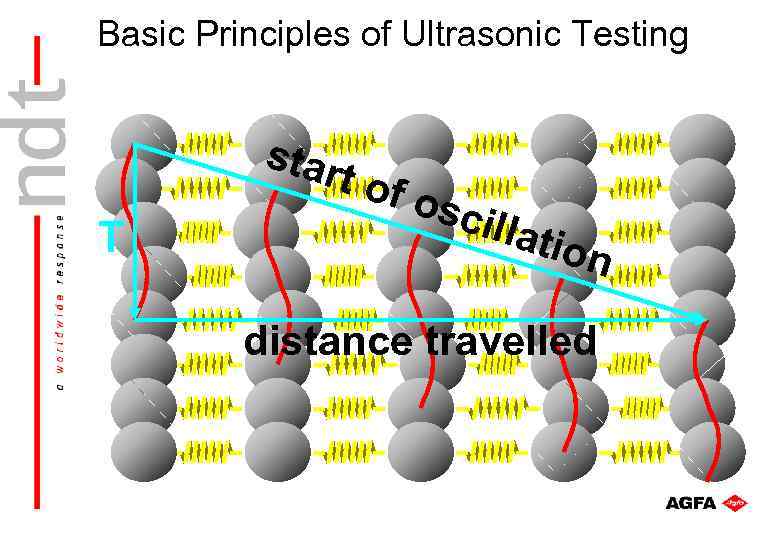

Basic Principles of Ultrasonic Testing star T t of osc illat ion distance travelled

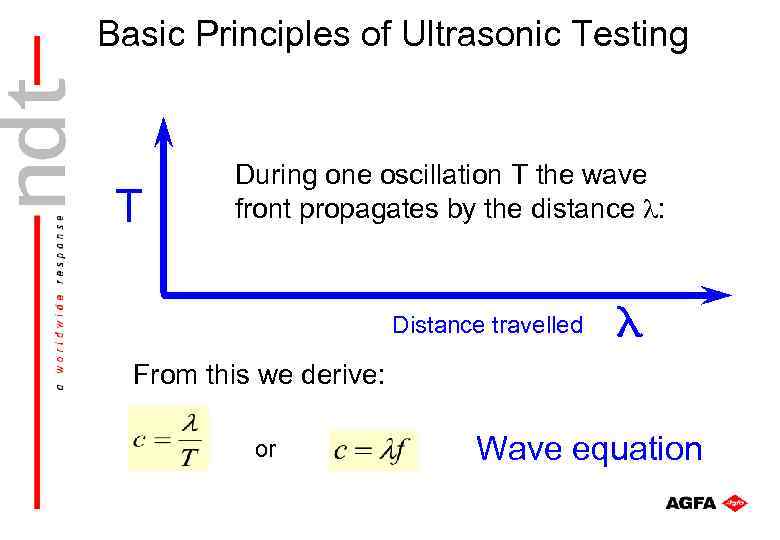

Basic Principles of Ultrasonic Testing T During one oscillation T the wave front propagates by the distance : Distance travelled From this we derive: or Wave equation

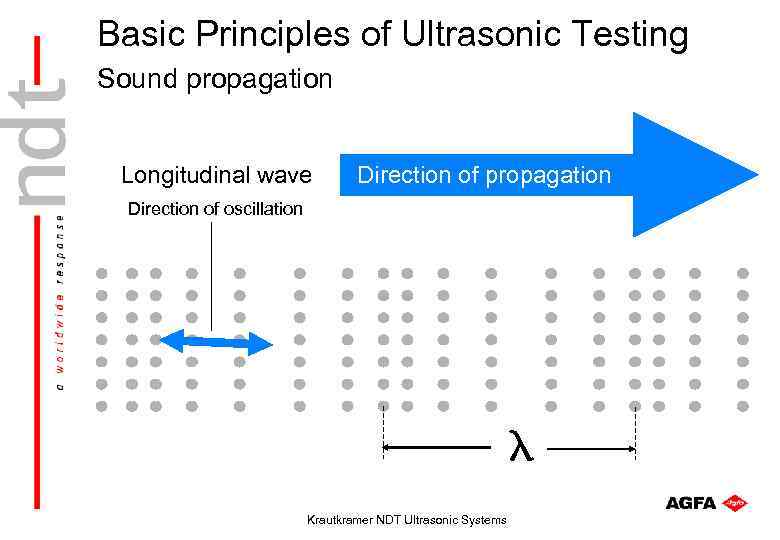

Basic Principles of Ultrasonic Testing Sound propagation Longitudinal wave Direction of propagation Direction of oscillation Krautkramer NDT Ultrasonic Systems

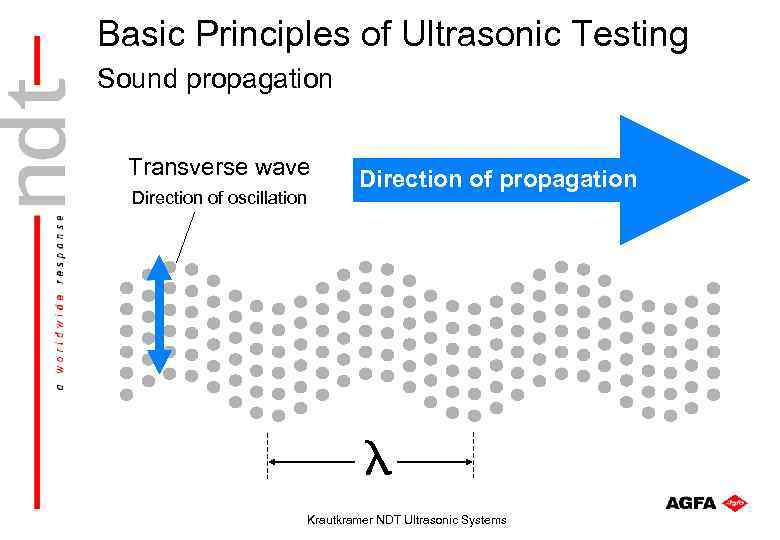

Basic Principles of Ultrasonic Testing Sound propagation Transverse wave Direction of oscillation Direction of propagation Krautkramer NDT Ultrasonic Systems

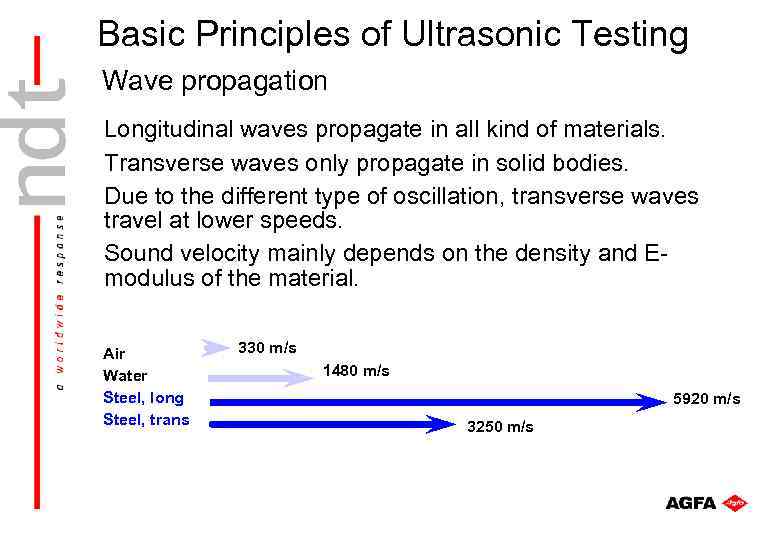

Basic Principles of Ultrasonic Testing Wave propagation Longitudinal waves propagate in all kind of materials. Transverse waves only propagate in solid bodies. Due to the different type of oscillation, transverse waves travel at lower speeds. Sound velocity mainly depends on the density and Emodulus of the material. Air Water Steel, long Steel, trans 330 m/s 1480 m/s 5920 m/s 3250 m/s

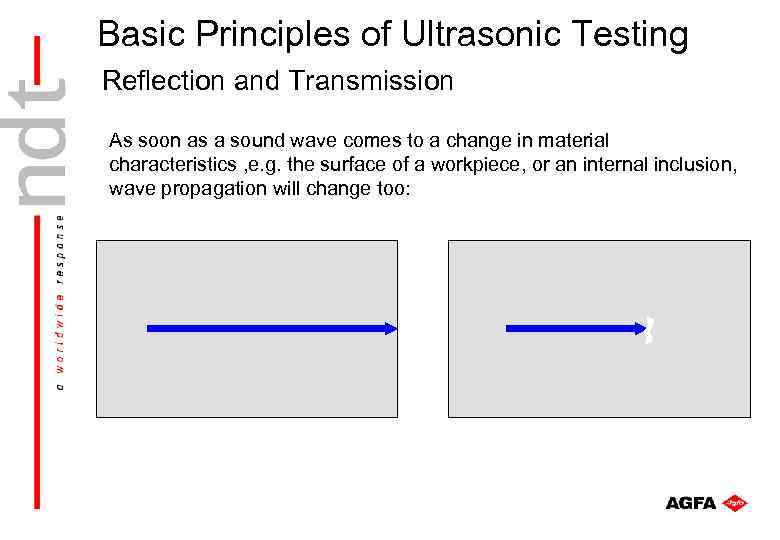

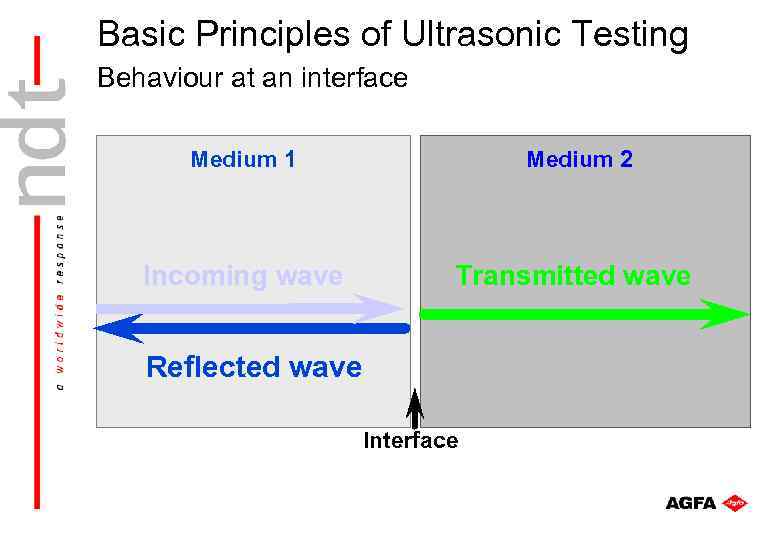

Basic Principles of Ultrasonic Testing Reflection and Transmission As soon as a sound wave comes to a change in material characteristics , e. g. the surface of a workpiece, or an internal inclusion, wave propagation will change too:

Basic Principles of Ultrasonic Testing Behaviour at an interface Medium 1 Medium 2 Incoming wave Transmitted wave Reflected wave Interface

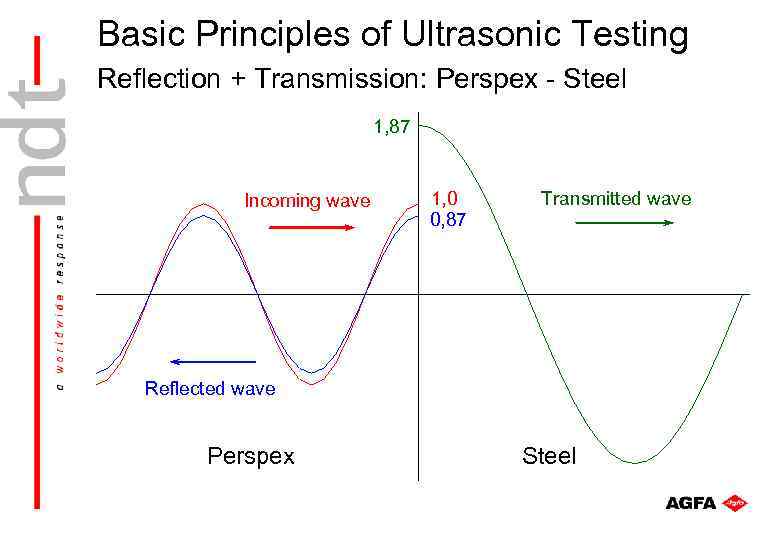

Basic Principles of Ultrasonic Testing Reflection + Transmission: Perspex - Steel 1, 87 Incoming wave 1, 0 0, 87 Transmitted wave Reflected wave Perspex Steel

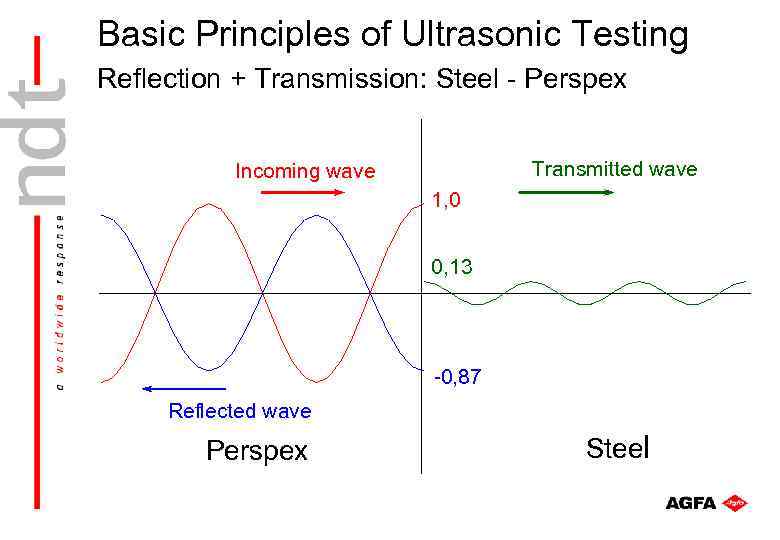

Basic Principles of Ultrasonic Testing Reflection + Transmission: Steel - Perspex Transmitted wave Incoming wave 1, 0 0, 13 -0, 87 Reflected wave Perspex Steel

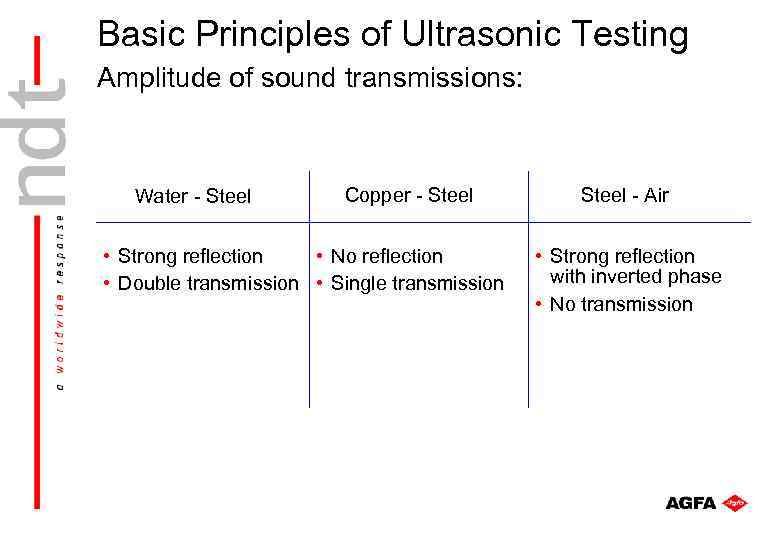

Basic Principles of Ultrasonic Testing Amplitude of sound transmissions: Water - Steel Copper - Steel • Strong reflection • No reflection • Double transmission • Single transmission Steel - Air • Strong reflection with inverted phase • No transmission

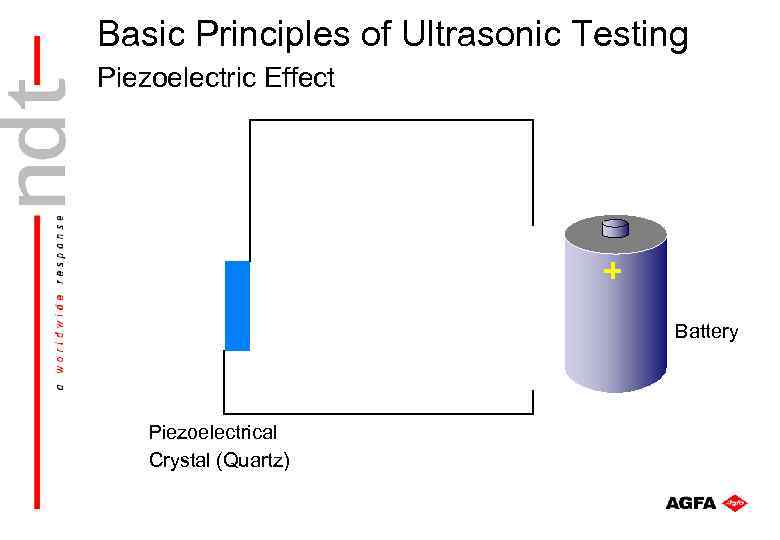

Basic Principles of Ultrasonic Testing Piezoelectric Effect + Battery Piezoelectrical Crystal (Quartz)

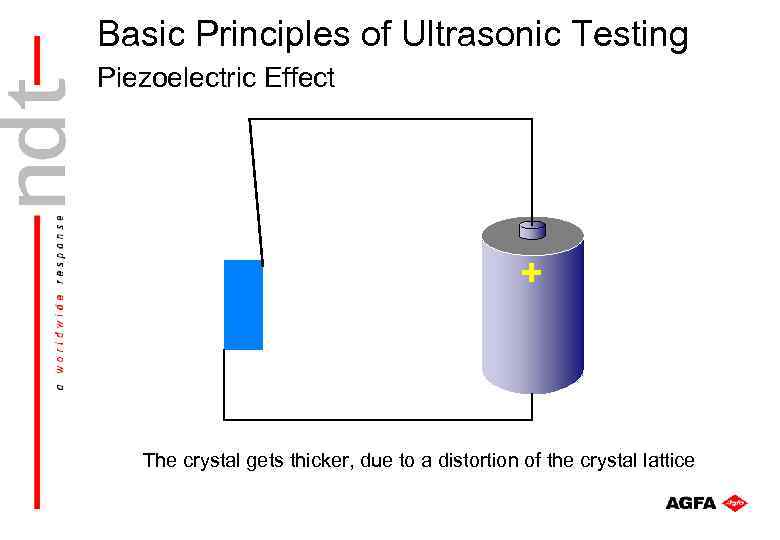

Basic Principles of Ultrasonic Testing Piezoelectric Effect + The crystal gets thicker, due to a distortion of the crystal lattice

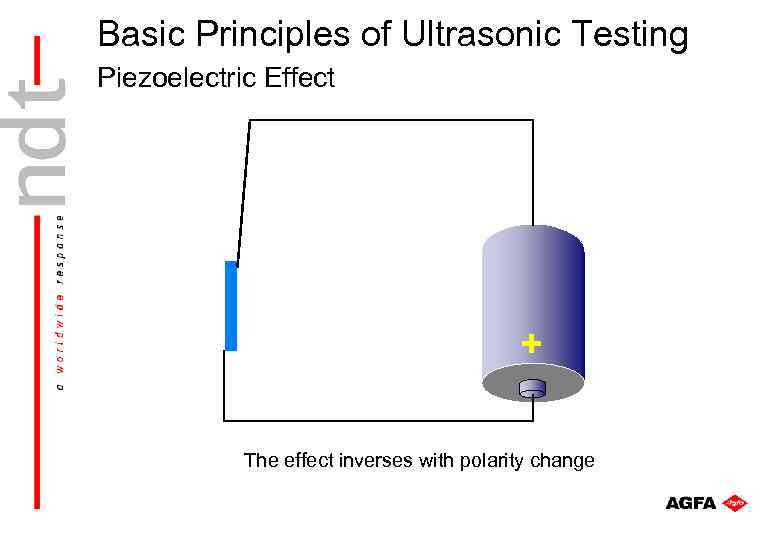

Basic Principles of Ultrasonic Testing Piezoelectric Effect + The effect inverses with polarity change

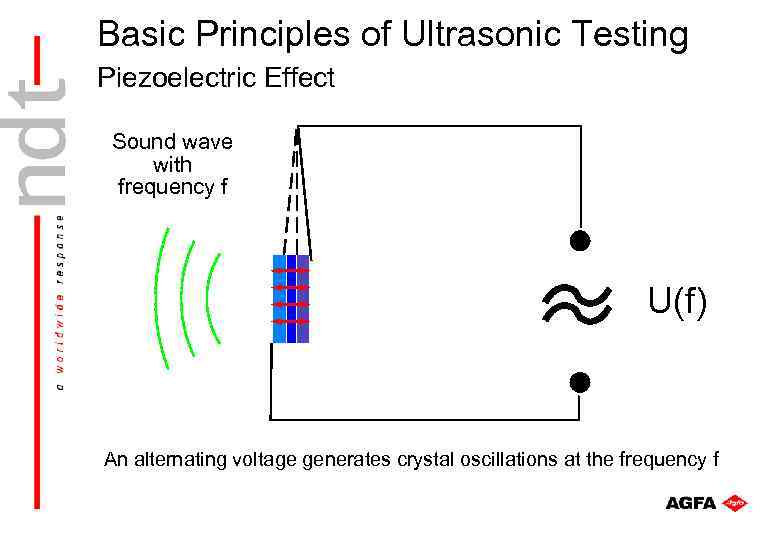

Basic Principles of Ultrasonic Testing Piezoelectric Effect Sound wave with frequency f U(f) An alternating voltage generates crystal oscillations at the frequency f

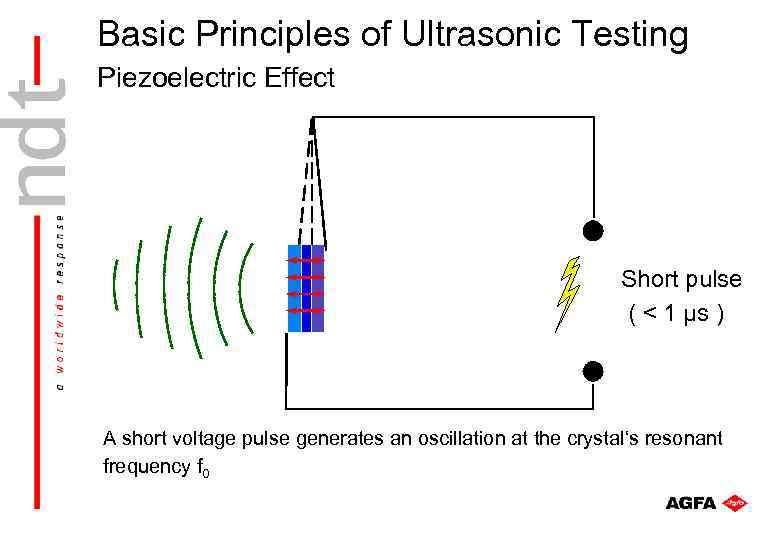

Basic Principles of Ultrasonic Testing Piezoelectric Effect Short pulse ( < 1 µs ) A short voltage pulse generates an oscillation at the crystal‘s resonant frequency f 0

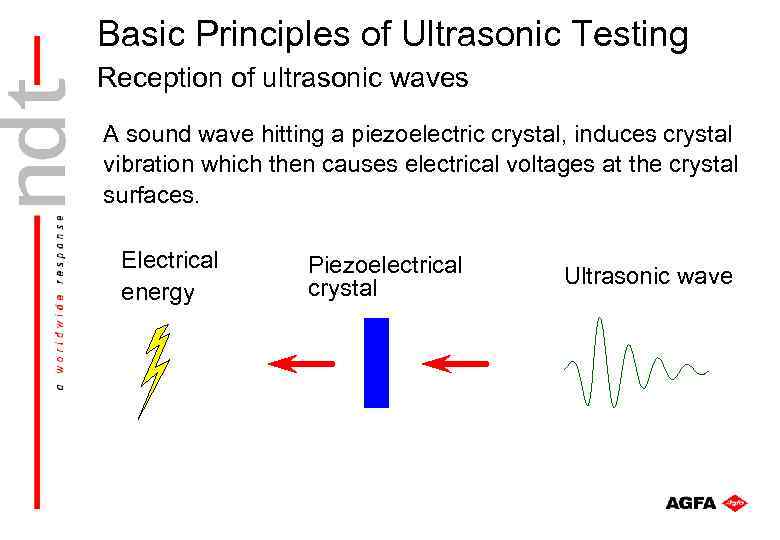

Basic Principles of Ultrasonic Testing Reception of ultrasonic waves A sound wave hitting a piezoelectric crystal, induces crystal vibration which then causes electrical voltages at the crystal surfaces. Electrical energy Piezoelectrical crystal Ultrasonic wave

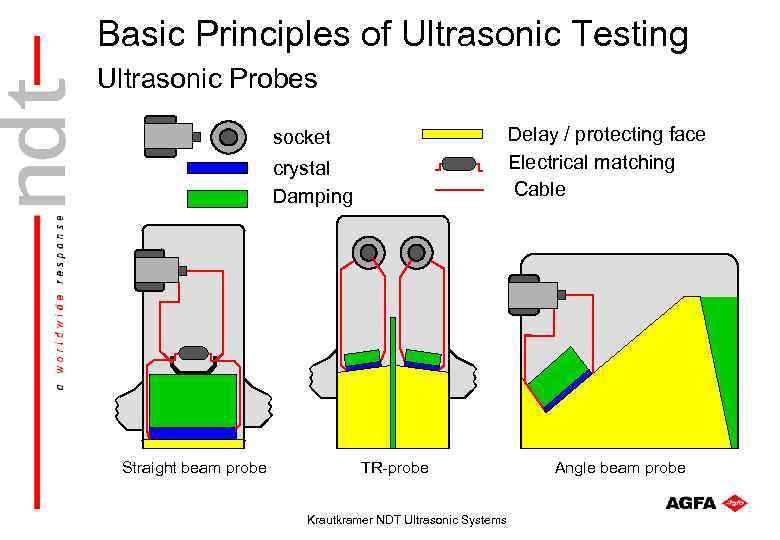

Basic Principles of Ultrasonic Testing Ultrasonic Probes Delay / protecting face Electrical matching Cable socket crystal Damping Straight beam probe TR-probe Krautkramer NDT Ultrasonic Systems Angle beam probe

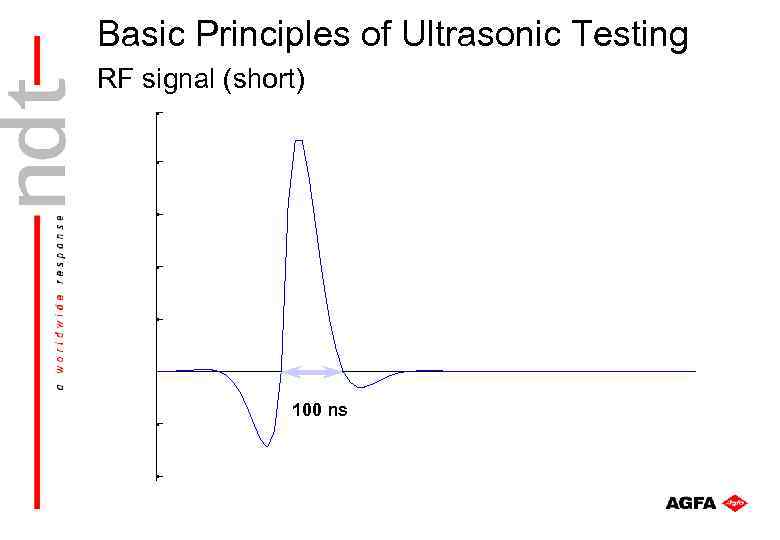

Basic Principles of Ultrasonic Testing RF signal (short) 100 ns

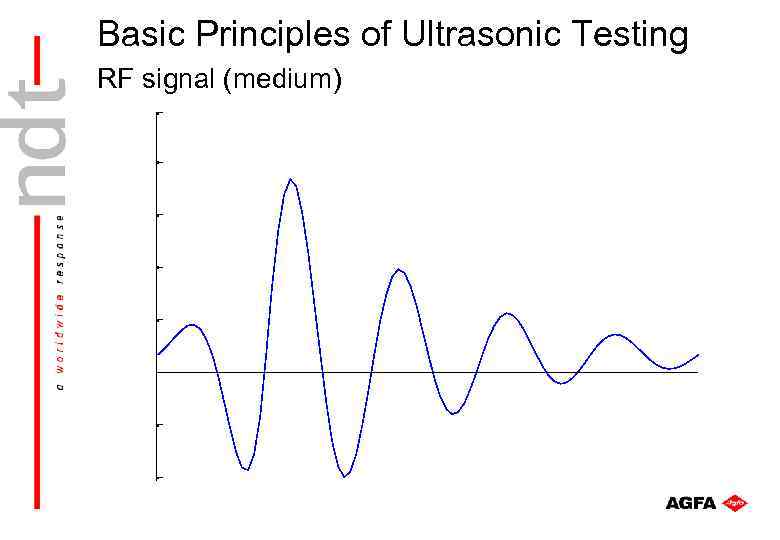

Basic Principles of Ultrasonic Testing RF signal (medium)

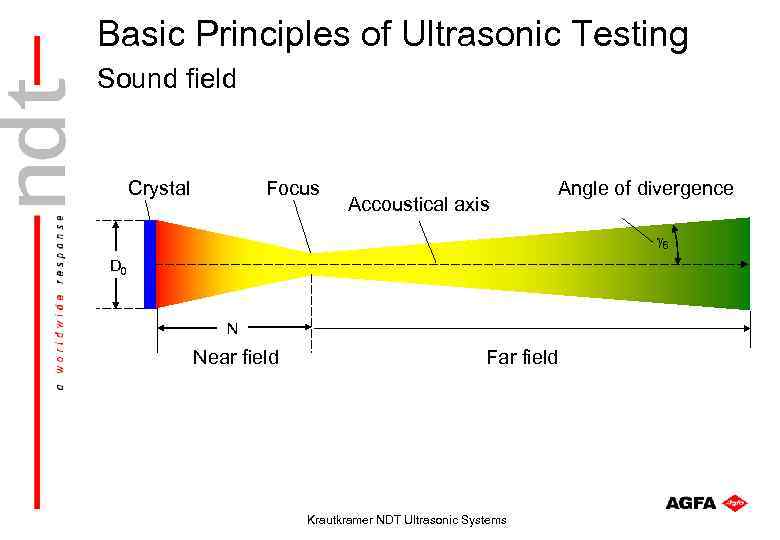

Basic Principles of Ultrasonic Testing Sound field Focus Crystal Accoustical axis Angle of divergence 6 D 0 N Near field Far field Krautkramer NDT Ultrasonic Systems

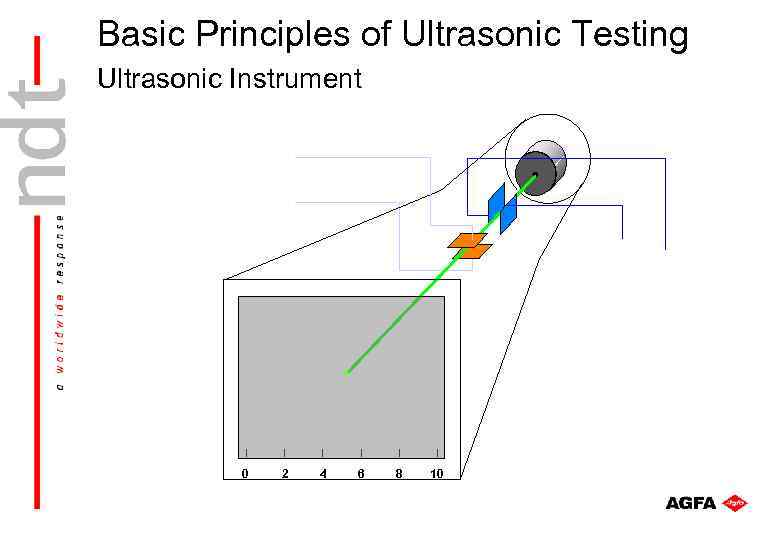

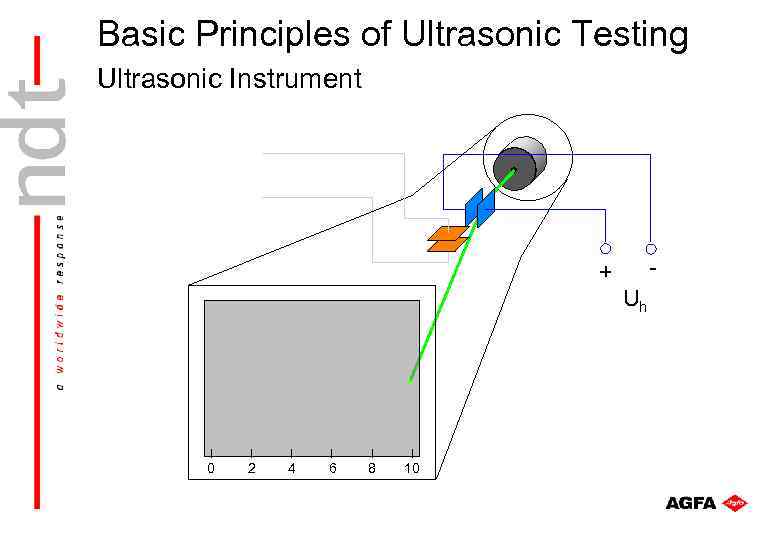

Basic Principles of Ultrasonic Testing Ultrasonic Instrument 0 2 4 6 8 10

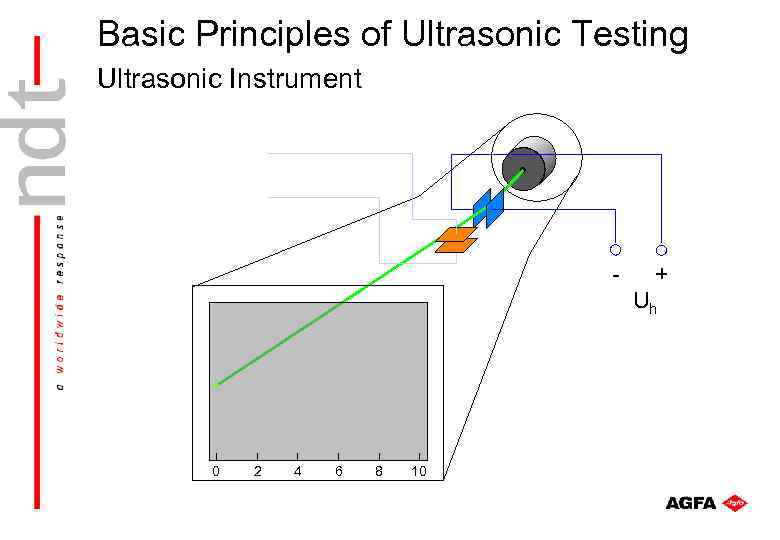

Basic Principles of Ultrasonic Testing Ultrasonic Instrument - + Uh 0 2 4 6 8 10

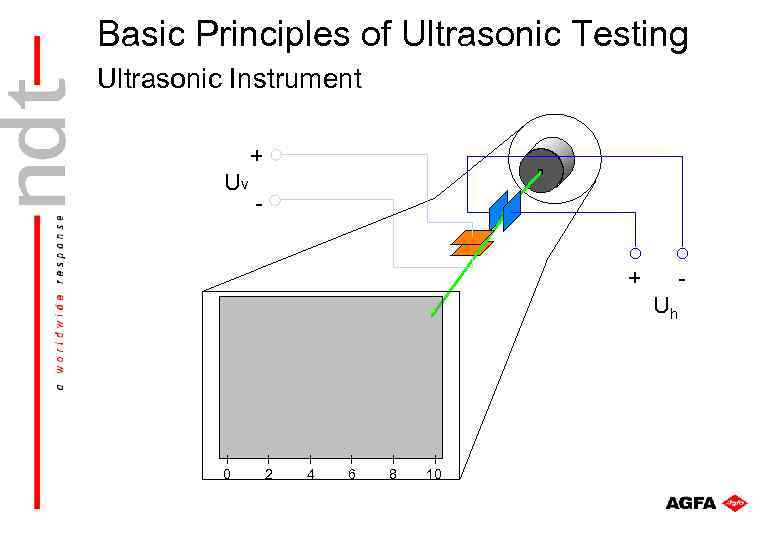

Basic Principles of Ultrasonic Testing Ultrasonic Instrument - + Uh 0 2 4 6 8 10

Basic Principles of Ultrasonic Testing Ultrasonic Instrument + Uv - + Uh 0 2 4 6 8 10

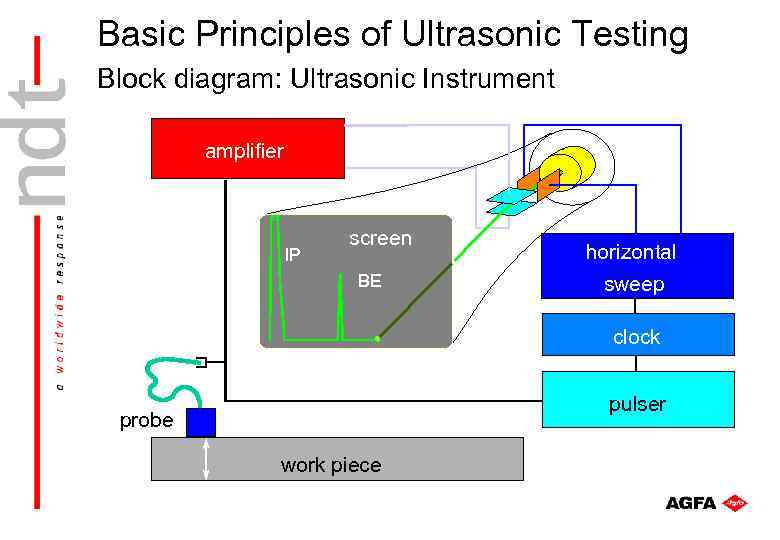

Basic Principles of Ultrasonic Testing Block diagram: Ultrasonic Instrument amplifier IP screen BE horizontal sweep clock pulser probe work piece

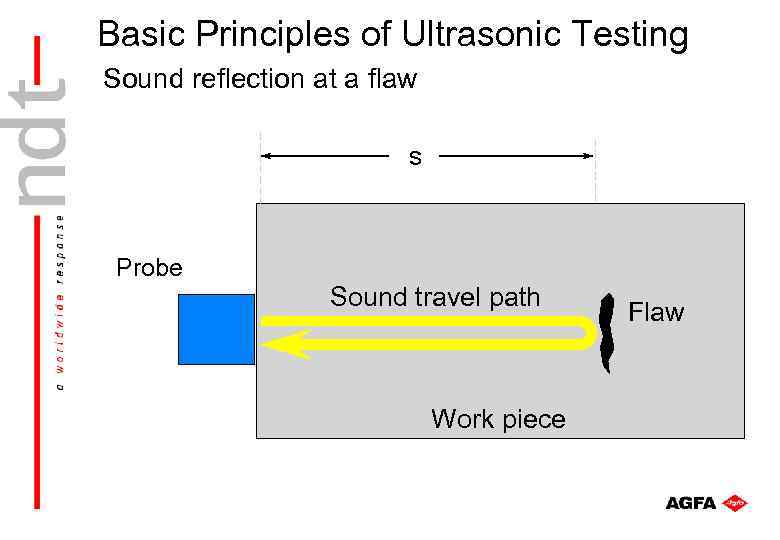

Basic Principles of Ultrasonic Testing Sound reflection at a flaw s Probe Sound travel path Work piece Flaw

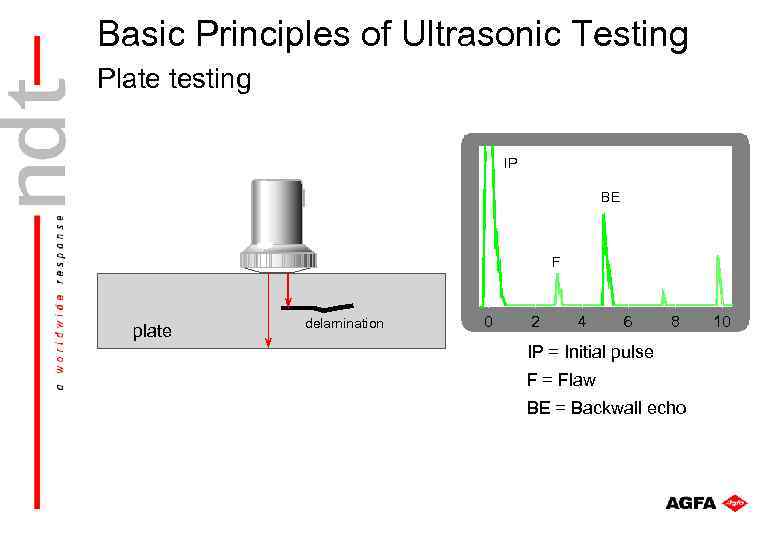

Basic Principles of Ultrasonic Testing Plate testing IP BE F plate delamination 0 2 4 6 8 IP = Initial pulse F = Flaw BE = Backwall echo 10

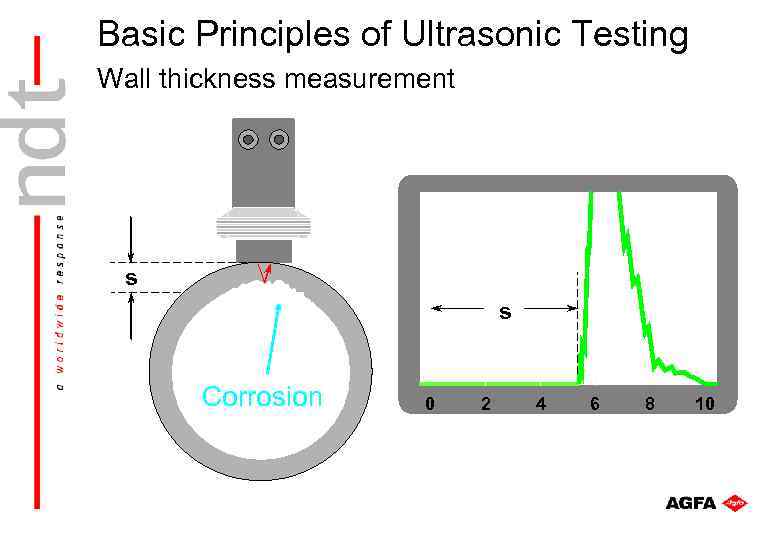

Basic Principles of Ultrasonic Testing Wall thickness measurement s s Corrosion 0 2 4 6 8 10

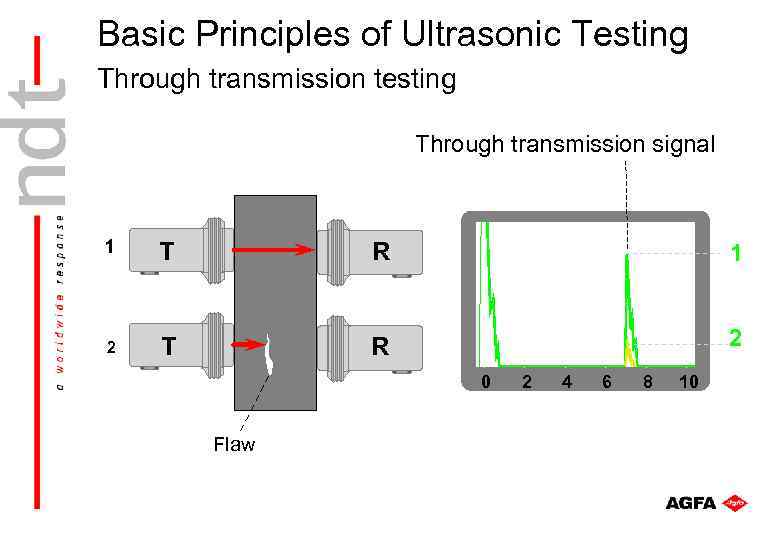

Basic Principles of Ultrasonic Testing Through transmission testing Through transmission signal 1 T R 1 2 T R 2 0 Flaw 2 4 6 8 10

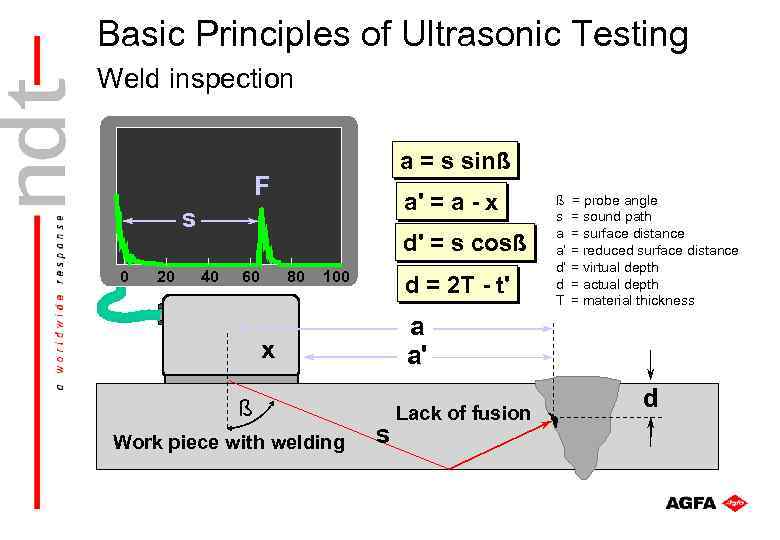

Basic Principles of Ultrasonic Testing Weld inspection a = s sinß F a' = a - x s 0 20 d' = s cosß 40 60 80 100 d = 2 T - t' a a' x ß Work piece with welding ß = probe angle s = sound path a = surface distance a‘ = reduced surface distance d‘ = virtual depth d = actual depth T = material thickness s Lack of fusion d

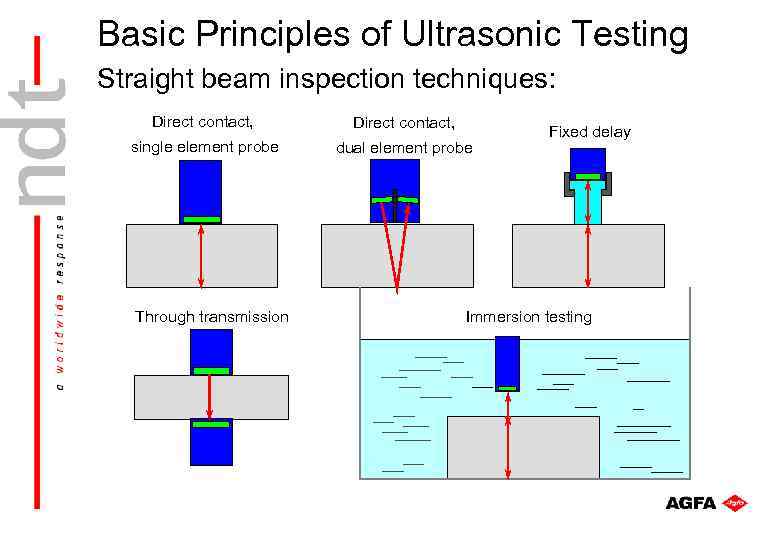

Basic Principles of Ultrasonic Testing Straight beam inspection techniques: Direct contact, single element probe dual element probe Through transmission Fixed delay Immersion testing

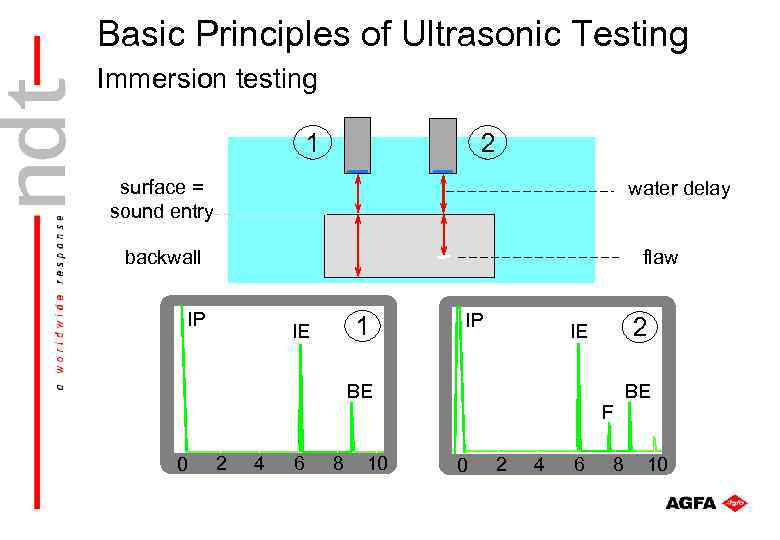

Basic Principles of Ultrasonic Testing Immersion testing 1 2 surface = sound entry water delay backwall flaw IP 1 IE IP BE 0 2 4 6 8 10 2 IE F 0 2 4 6 8 BE 10

Basic_Principle.ppt