f1153c1f7cb4f424a2d23f01c85f9d18.ppt

- Количество слайдов: 41

Basic Optics for the Laser Safety Officer LIA Practical Applications Seminar San Francisco, CA March 20, 2007 Leonard Migliore Coherent, Inc.

Electromagnetic Radiation • Electromagnetic Radiation is generated by motion of a charge • Maxwell’s Equations describe the behavior of electromagnetic radiation • Light, radio, X-rays, microwaves are all electromagnetic radiation • All ER travels at the speed c • Wavelength l=c/f

Wavelength and Frequency • l varies from 104 to 10 -10 meters • The wavelength of visible light ranges from 4 X 10 -7 to 7 X 10 -7 meters. This corresponds to frequencies of 4 X 1014 to 7. 5 X 1014 Hz • Ultraviolet light ranges from 10 -8 meters up to the visible band with frequences up to 3 X 1016 Hz • Infrared light goes from 7 X 10 -7 to 10 -3 meters, corresponding to frequencies of 3 X 1011 Hz • Electronic and molecular vibrations occur at frequencies of 1012 - 1016 Hz

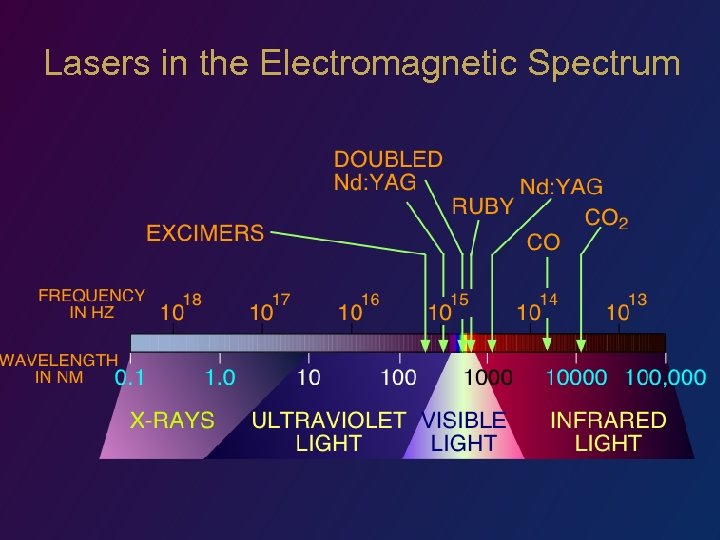

Lasers in the Electromagnetic Spectrum

Properties of Laser Light • Monochromatic • Coherent • Collimated

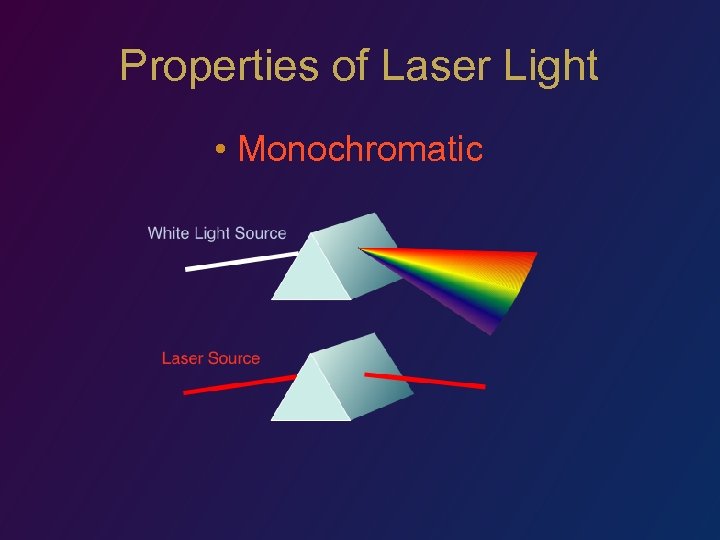

Properties of Laser Light • Monochromatic

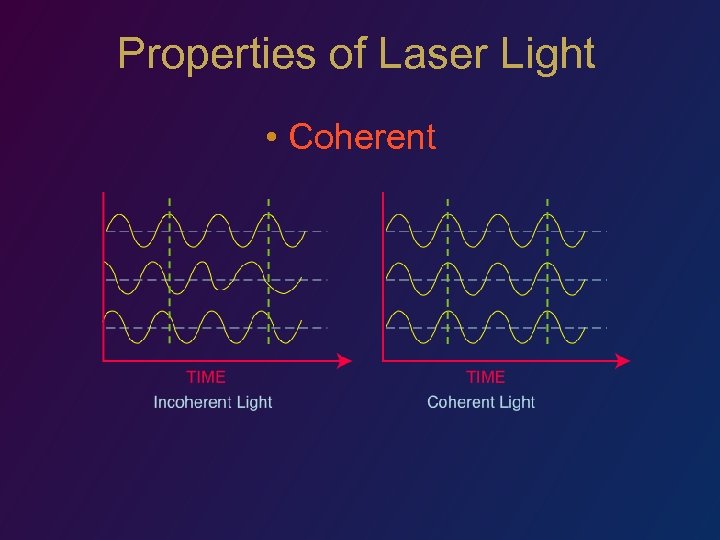

Properties of Laser Light • Coherent

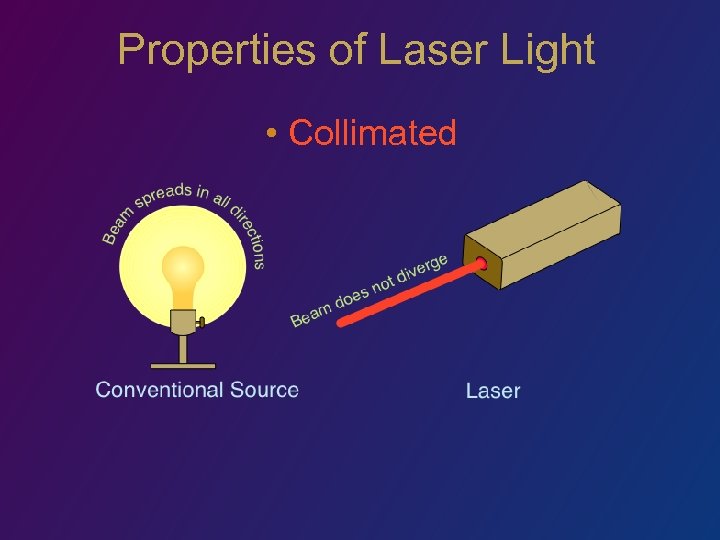

Properties of Laser Light • Collimated

Geometrical Optics Light travels in a straight line in a homogeneous medium Light is refracted and reflected at interfaces between materials

Reflection & Refraction

Total Internal Reflection q q

Lensmaker’s Formula

The Lens Equation

But why do real lenses look like this? To correct for: Spherical aberration Astigmatism Coma Field curvature Distortion Color correction Zeiss Planar

Spherical aberration Rays from the outer part of the lens focus at a different point than rays from the inner part of the lens

Focusing can also be accomplished with reflective optics

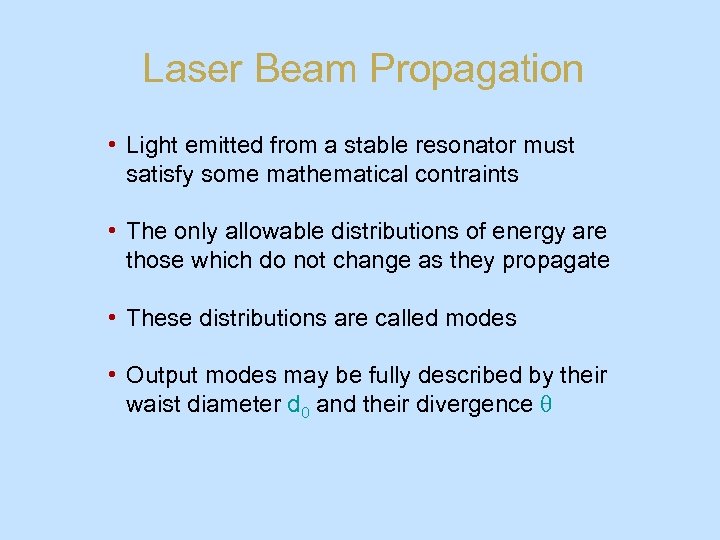

Laser Beam Propagation • Light emitted from a stable resonator must satisfy some mathematical contraints • The only allowable distributions of energy are those which do not change as they propagate • These distributions are called modes • Output modes may be fully described by their waist diameter d 0 and their divergence q

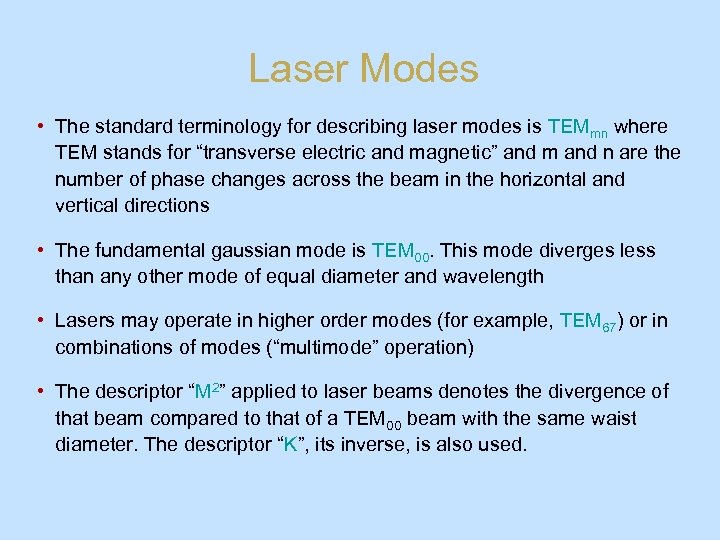

Laser Modes • The standard terminology for describing laser modes is TEMmn where TEM stands for “transverse electric and magnetic” and m and n are the number of phase changes across the beam in the horizontal and vertical directions • The fundamental gaussian mode is TEM 00. This mode diverges less than any other mode of equal diameter and wavelength • Lasers may operate in higher order modes (for example, TEM 67) or in combinations of modes (“multimode” operation) • The descriptor “M 2” applied to laser beams denotes the divergence of that beam compared to that of a TEM 00 beam with the same waist diameter. The descriptor “K”, its inverse, is also used.

Laser Beam Characteristics BEAM DIAMETER Dz BEAM WAIST DIAMETER D 0 FAR FIELD DIVERGENCE q LASER BEAM CENTERLINE z

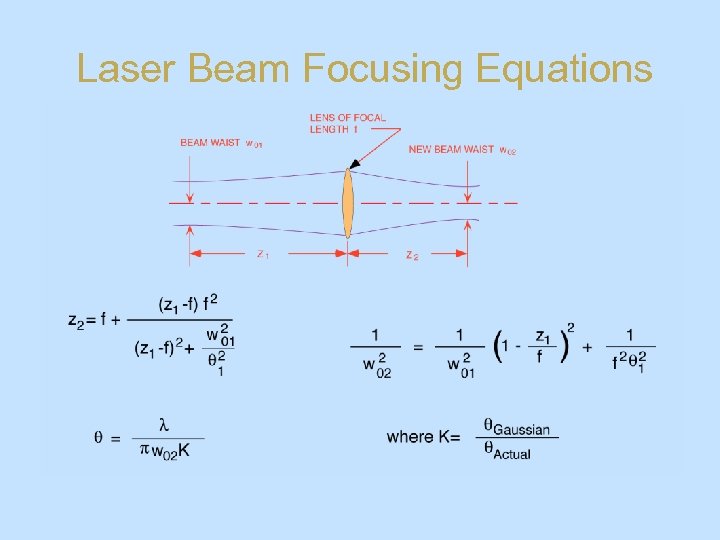

Laser Beam Focusing LENS OF FOCAL LENGTH f BEAM WAIST D 01 NEW BEAM WAIST D 02 Z 1 Z 2

Laser Beam Focusing Equations

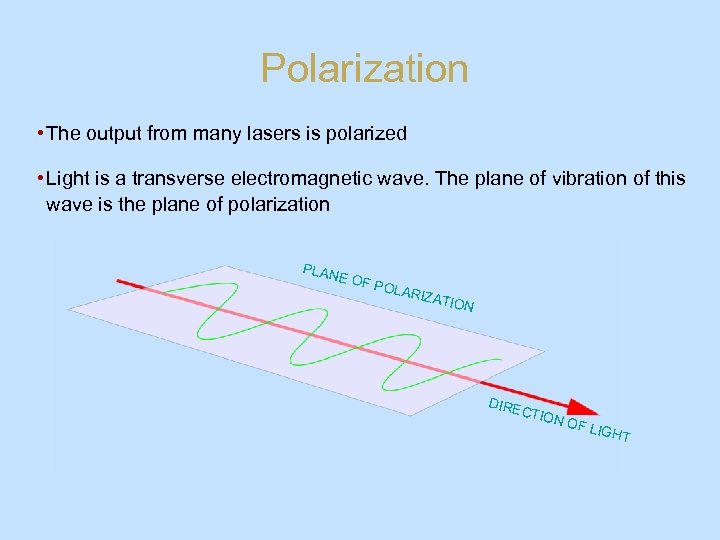

Polarization • The output from many lasers is polarized • Light is a transverse electromagnetic wave. The plane of vibration of this wave is the plane of polarization PLAN E OF POLA R IZATI ON DIRE CTIO N OF LIGH T

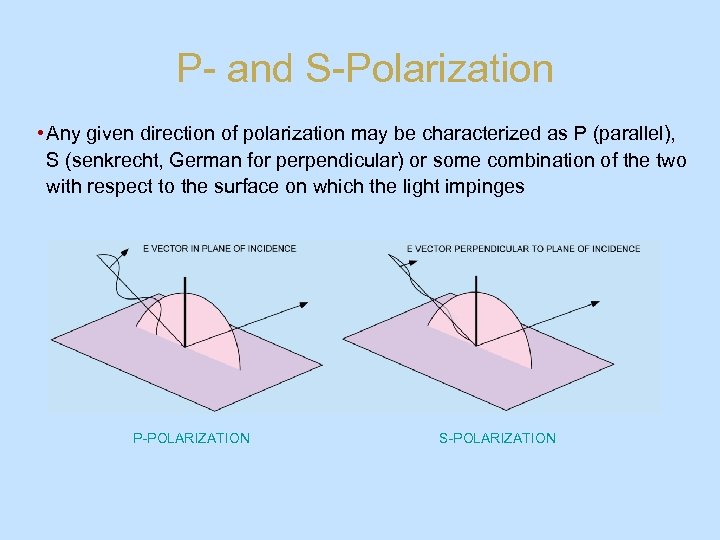

P- and S-Polarization • Any given direction of polarization may be characterized as P (parallel), S (senkrecht, German for perpendicular) or some combination of the two with respect to the surface on which the light impinges P-POLARIZATION S-POLARIZATION

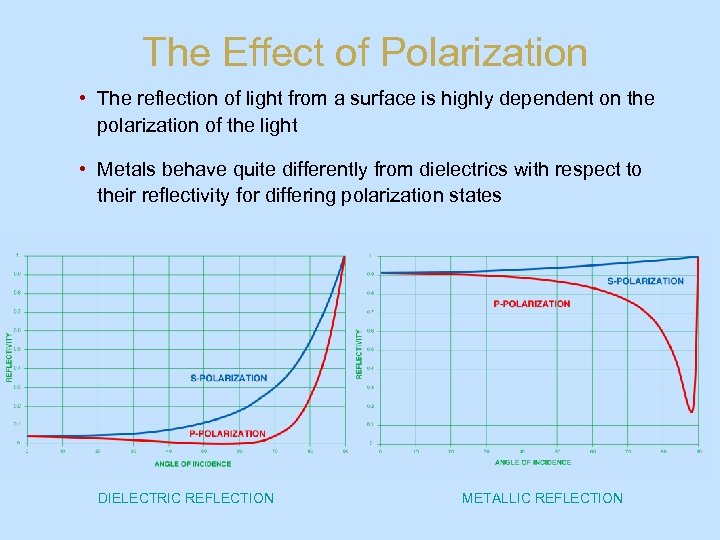

The Effect of Polarization • The reflection of light from a surface is highly dependent on the polarization of the light • Metals behave quite differently from dielectrics with respect to their reflectivity for differing polarization states DIELECTRIC REFLECTION METALLIC REFLECTION

Laser Beam Delivery • Laser output must be delivered to the work area for processing to be done • Free space beams are handled with lenses and mirrors • Lasers may also be delivered through fibers

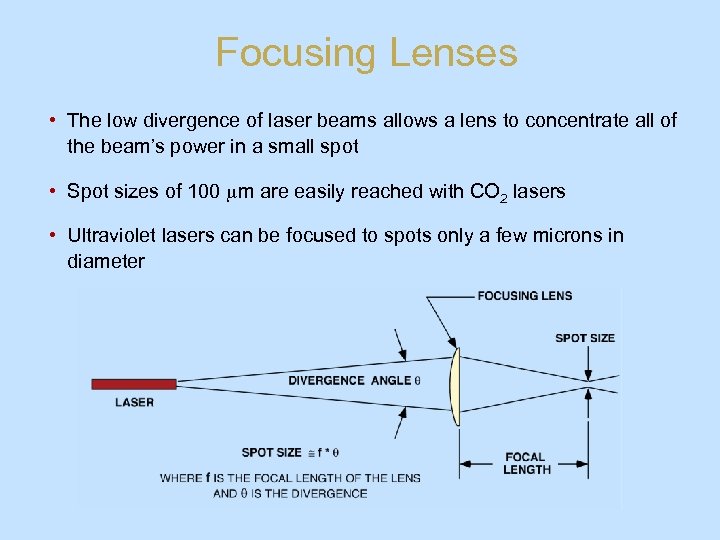

Focusing Lenses • The low divergence of laser beams allows a lens to concentrate all of the beam’s power in a small spot • Spot sizes of 100 mm are easily reached with CO 2 lasers • Ultraviolet lasers can be focused to spots only a few microns in diameter

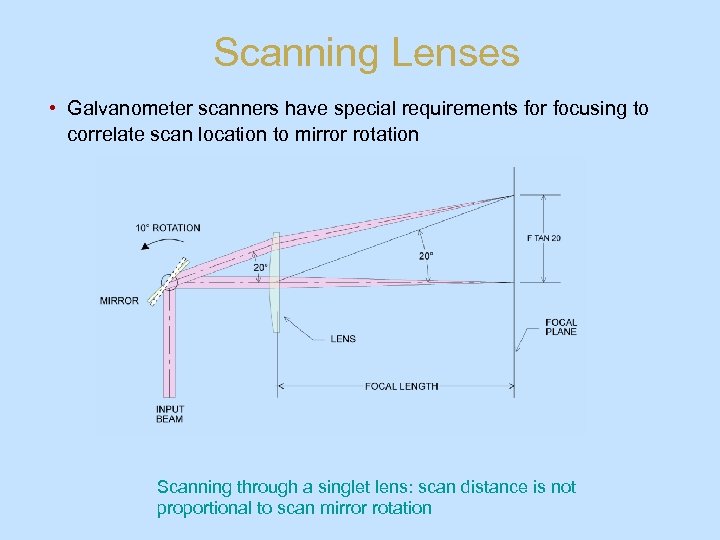

Scanning Lenses • Galvanometer scanners have special requirements for focusing to correlate scan location to mirror rotation Scanning through a singlet lens: scan distance is not proportional to scan mirror rotation

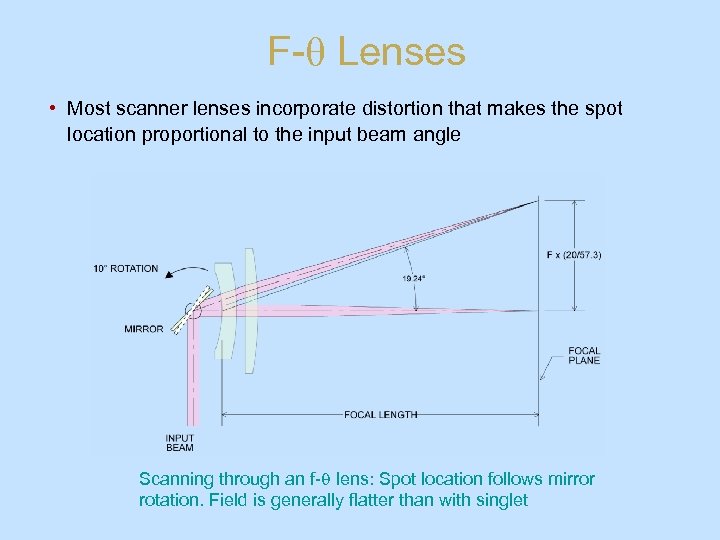

F-q Lenses • Most scanner lenses incorporate distortion that makes the spot location proportional to the input beam angle Scanning through an f-q lens: Spot location follows mirror rotation. Field is generally flatter than with singlet

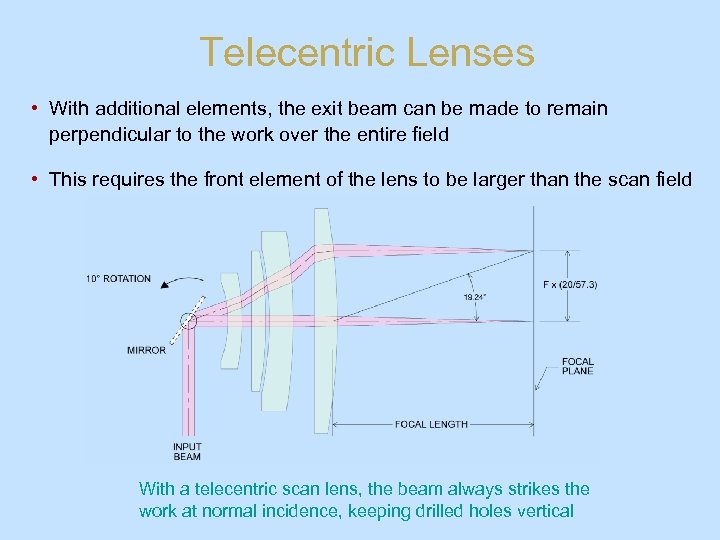

Telecentric Lenses • With additional elements, the exit beam can be made to remain perpendicular to the work over the entire field • This requires the front element of the lens to be larger than the scan field With a telecentric scan lens, the beam always strikes the work at normal incidence, keeping drilled holes vertical

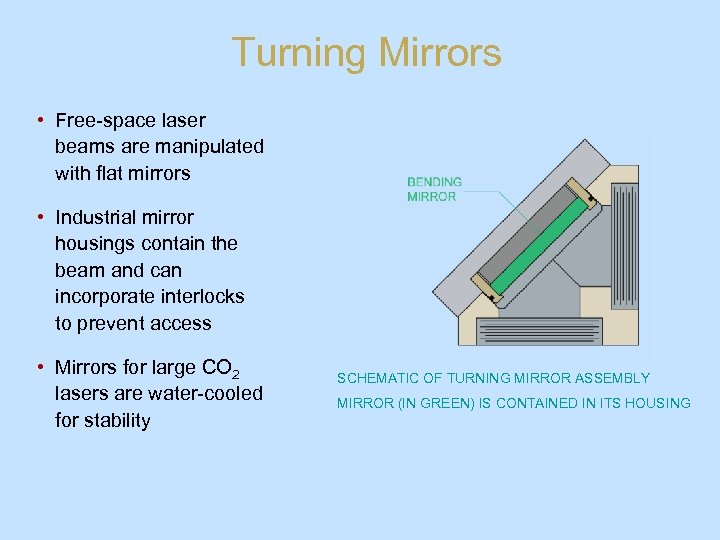

Turning Mirrors • Free-space laser beams are manipulated with flat mirrors • Industrial mirror housings contain the beam and can incorporate interlocks to prevent access • Mirrors for large CO 2 lasers are water-cooled for stability SCHEMATIC OF TURNING MIRROR ASSEMBLY MIRROR (IN GREEN) IS CONTAINED IN ITS HOUSING

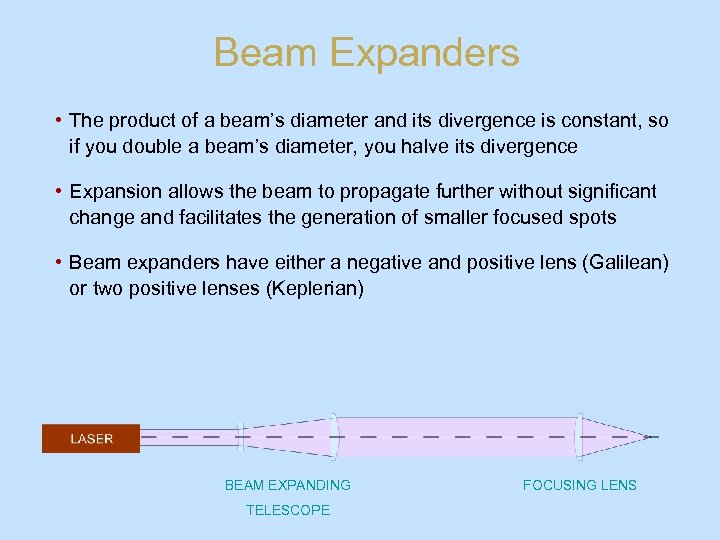

Beam Expanders • The product of a beam’s diameter and its divergence is constant, so if you double a beam’s diameter, you halve its divergence • Expansion allows the beam to propagate further without significant change and facilitates the generation of smaller focused spots • Beam expanders have either a negative and positive lens (Galilean) or two positive lenses (Keplerian) BEAM EXPANDING TELESCOPE FOCUSING LENS

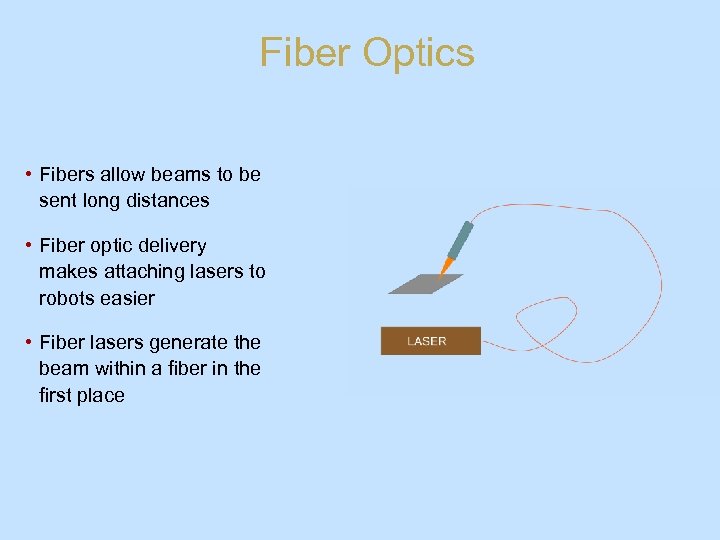

Fiber Optics • Fibers allow beams to be sent long distances • Fiber optic delivery makes attaching lasers to robots easier • Fiber lasers generate the beam within a fiber in the first place

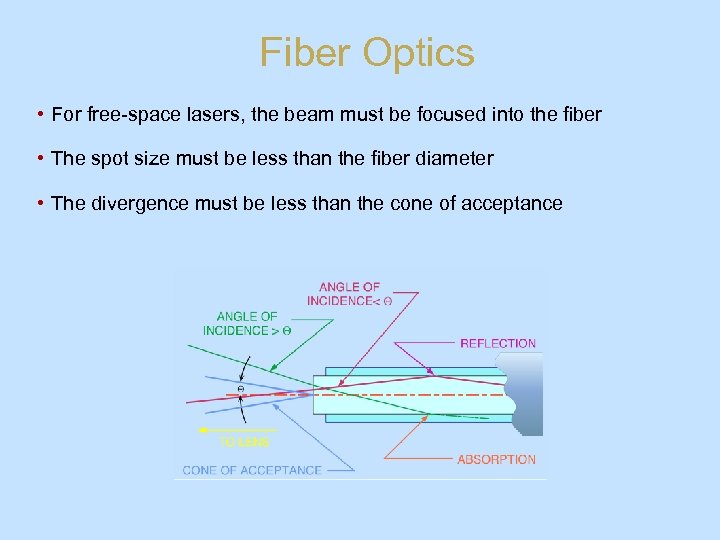

Fiber Optics • For free-space lasers, the beam must be focused into the fiber • The spot size must be less than the fiber diameter • The divergence must be less than the cone of acceptance

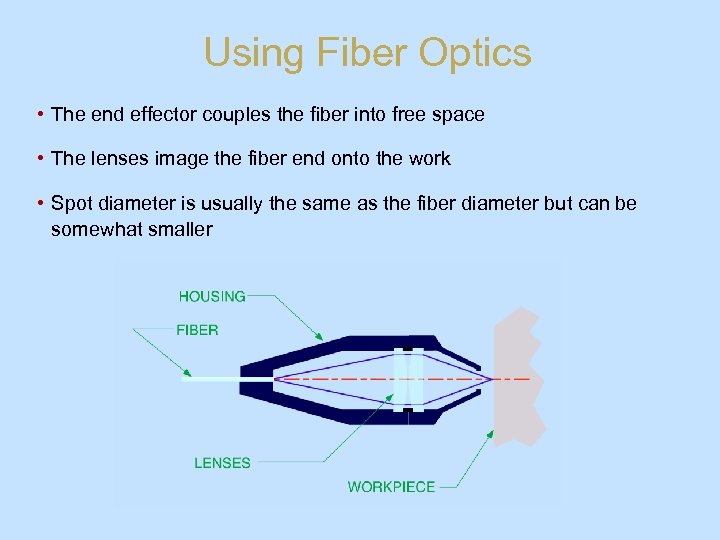

Using Fiber Optics • The end effector couples the fiber into free space • The lenses image the fiber end onto the work • Spot diameter is usually the same as the fiber diameter but can be somewhat smaller

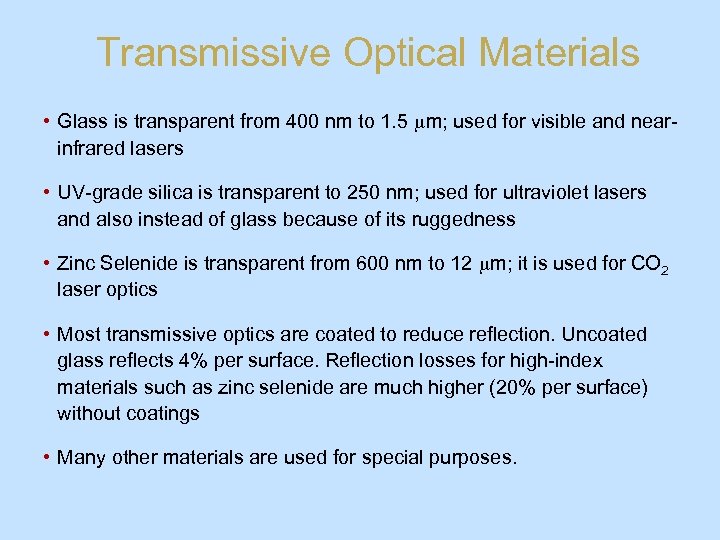

Transmissive Optical Materials • Glass is transparent from 400 nm to 1. 5 mm; used for visible and nearinfrared lasers • UV-grade silica is transparent to 250 nm; used for ultraviolet lasers and also instead of glass because of its ruggedness • Zinc Selenide is transparent from 600 nm to 12 mm; it is used for CO 2 laser optics • Most transmissive optics are coated to reduce reflection. Uncoated glass reflects 4% per surface. Reflection losses for high-index materials such as zinc selenide are much higher (20% per surface) without coatings • Many other materials are used for special purposes.

Mirror Substrates • Glass is commonly used for UV, visible and near-IR mirrors because it is easy to polish to a flat surface. Dielectric coatings are used to provide reflectivity at the desired wavelengths • Fused silica is also used where its low expansion helps to maintain the mirror figure • Silicon, copper, tungsten and molybdenum are used in high-power CO 2 lasers because of their high thermal conductivity. Silicon must be coated to reflect mid-infrared while the metals noted above have sufficient reflectivity without any coatings.

Industrial Applications • Lasers are used to cut, drill, weld and mark metals and non-metals • Most processes favor high power and high speed • Having the correct focused spot size on the work is usually critical to the success of the process

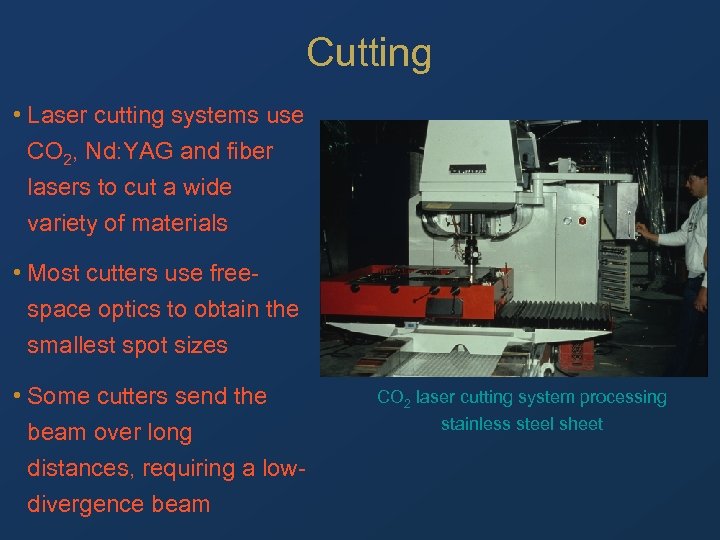

Cutting • Laser cutting systems use CO 2, Nd: YAG and fiber lasers to cut a wide variety of materials • Most cutters use freespace optics to obtain the smallest spot sizes • Some cutters send the beam over long distances, requiring a lowdivergence beam CO 2 laser cutting system processing stainless steel sheet

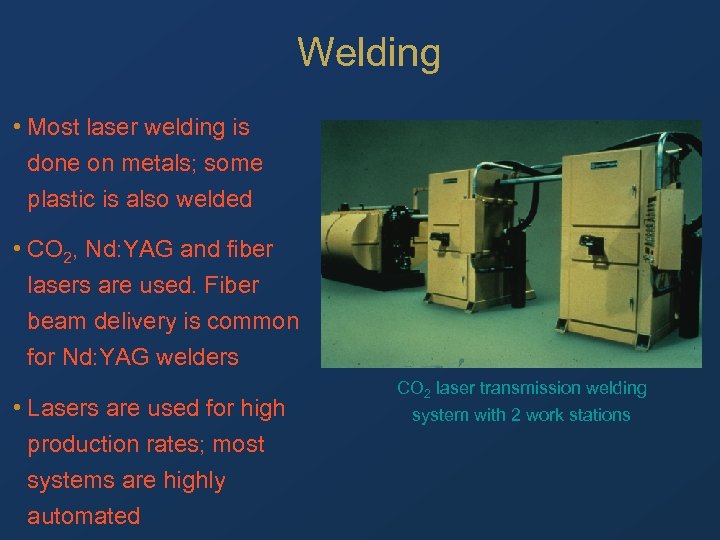

Welding • Most laser welding is done on metals; some plastic is also welded • CO 2, Nd: YAG and fiber lasers are used. Fiber beam delivery is common for Nd: YAG welders • Lasers are used for high production rates; most systems are highly automated CO 2 laser transmission welding system with 2 work stations

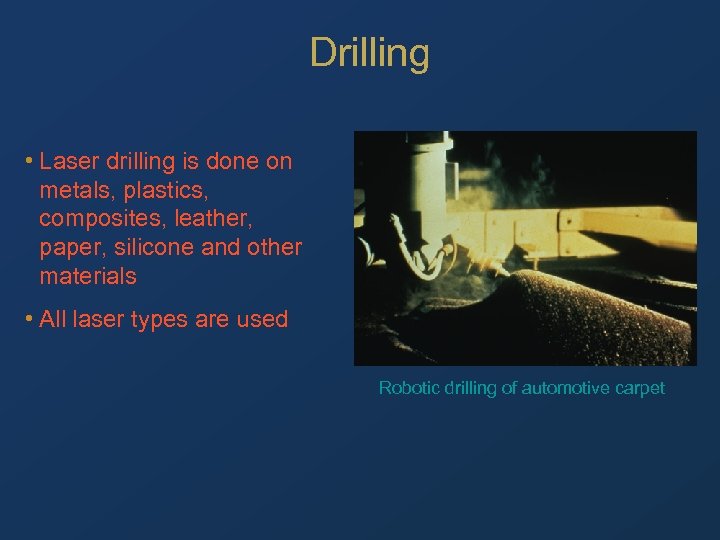

Drilling • Laser drilling is done on metals, plastics, composites, leather, paper, silicone and other materials • All laser types are used Robotic drilling of automotive carpet

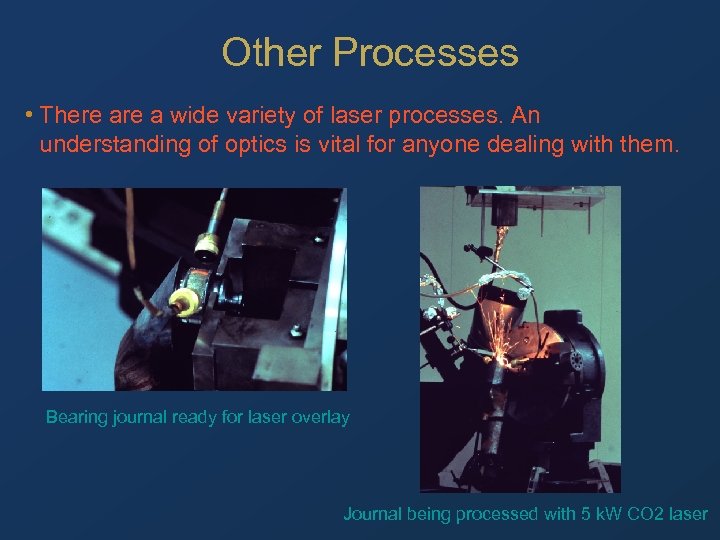

Other Processes • There a wide variety of laser processes. An understanding of optics is vital for anyone dealing with them. Bearing journal ready for laser overlay Journal being processed with 5 k. W CO 2 laser

f1153c1f7cb4f424a2d23f01c85f9d18.ppt