7f20b04821878c22b286ee1ce9a58b6b.ppt

- Количество слайдов: 40

Basic Elements of Explosion Protection in the EU Legislative Context ATEX Symposium 22 – 24 Eylül 2011, Ankara, Türkiye Dr. -Ing. Uwe Klausmeyer Physikalisch-Technische Bundesanstalt Braunschweig, Germany

The ATEX Regulation EU Directives of the „New Approach“ Legislative Framework, consisting of: - 94/9/EC (trade of equipment, ESRs) - 1999/92/EC (safety of workplace)

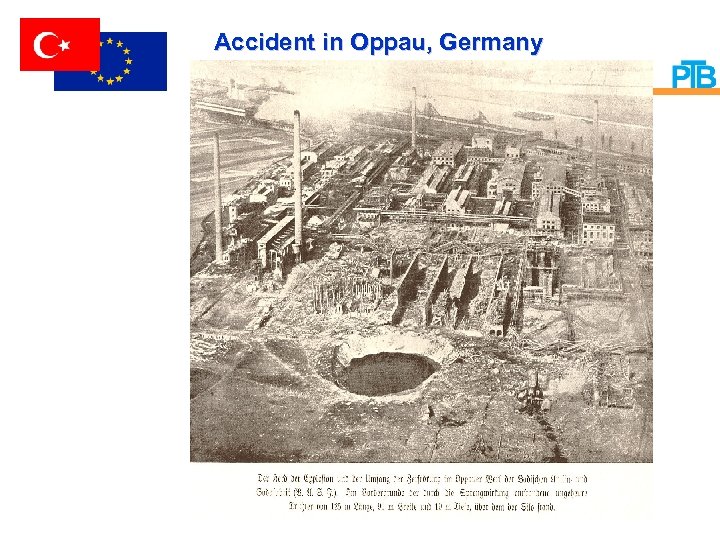

Accident in Oppau, Germany

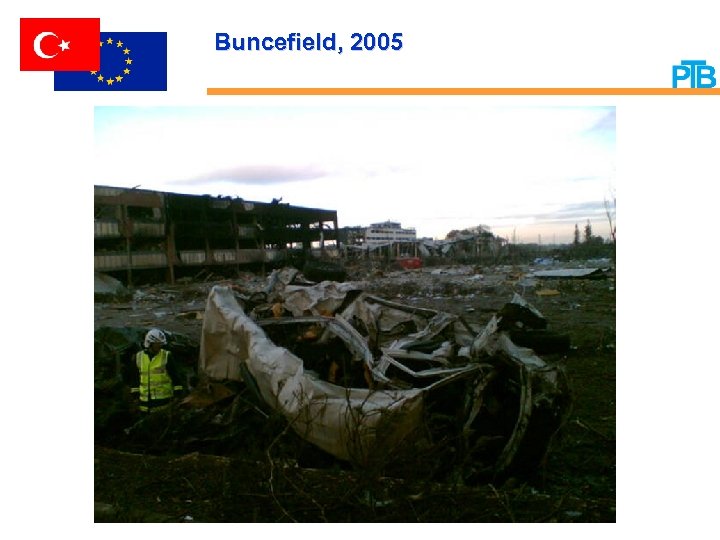

Accident in Buncefield‚UK, 2005

Buncefield, 2005

Buncefield, 2005

Accident at INEOS near Cologne, Germany 17 th of March, 2008 Has set fire to a methylacetate tank Pipeline of Ethylene is burning

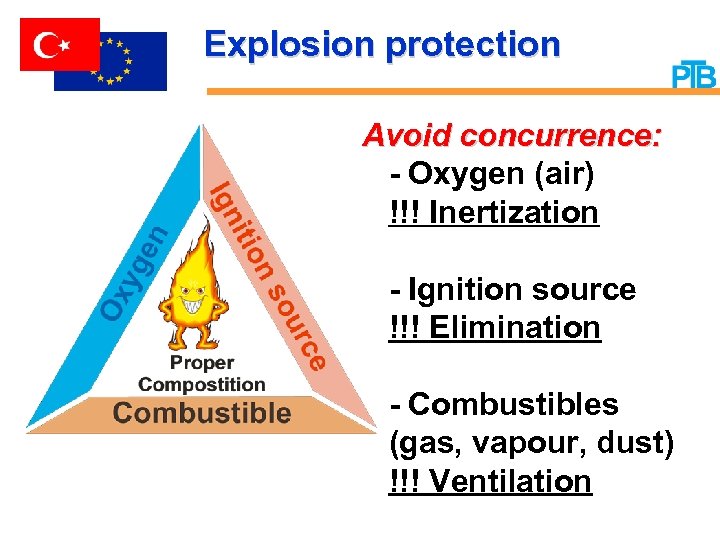

Explosion protection Avoid concurrence: - Oxygen (air) !!! Inertization - Ignition source !!! Elimination - Combustibles (gas, vapour, dust) !!! Ventilation

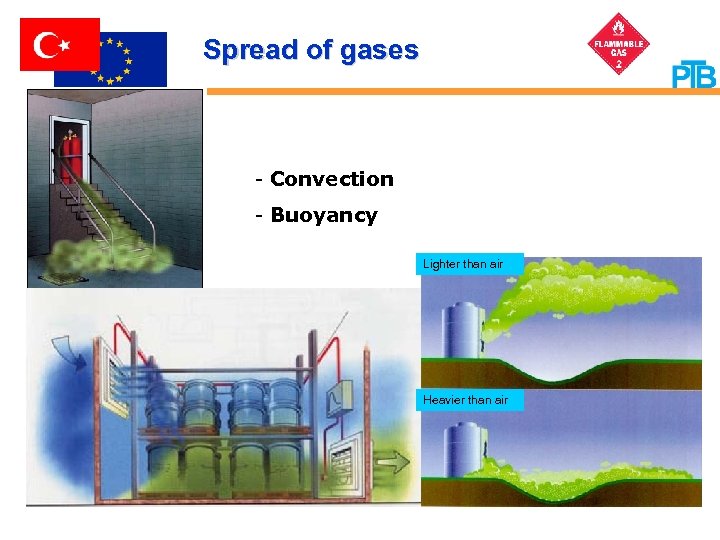

Spread of gases - Convection - Buoyancy Lighter than air Heavier than air

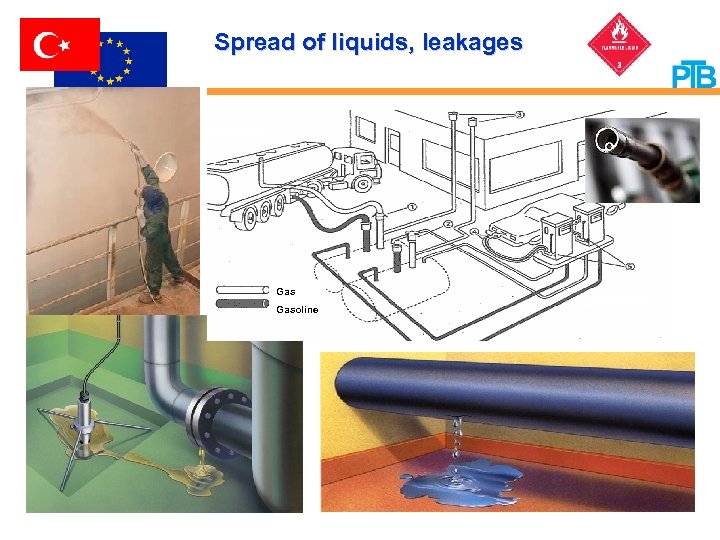

Spread of liquids, leakages Gasoline

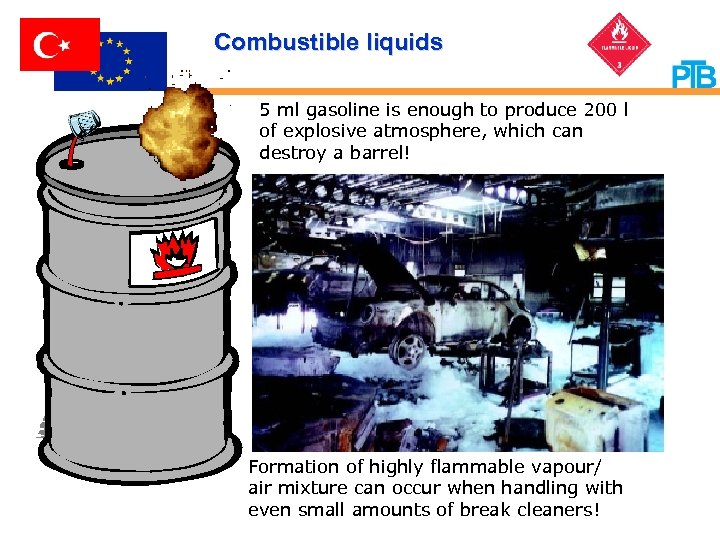

Combustible liquids 5 ml gasoline is enough to produce 200 l of explosive atmosphere, which can destroy a barrel! Formation of highly flammable vapour/ air mixture can occur when handling with even small amounts of break cleaners!

Spread of combustible dusts Dust layers with a thickness of 1 mm can be enough to produce explosive atmospheres!

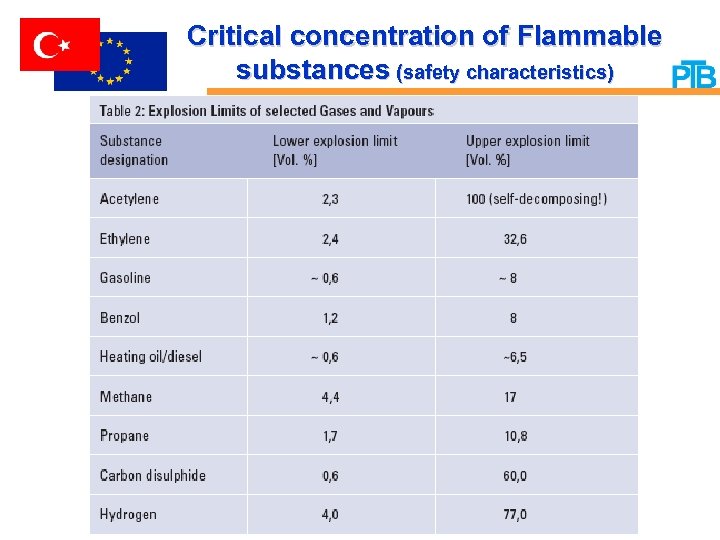

Critical concentration of Flammable substances (safety characteristics)

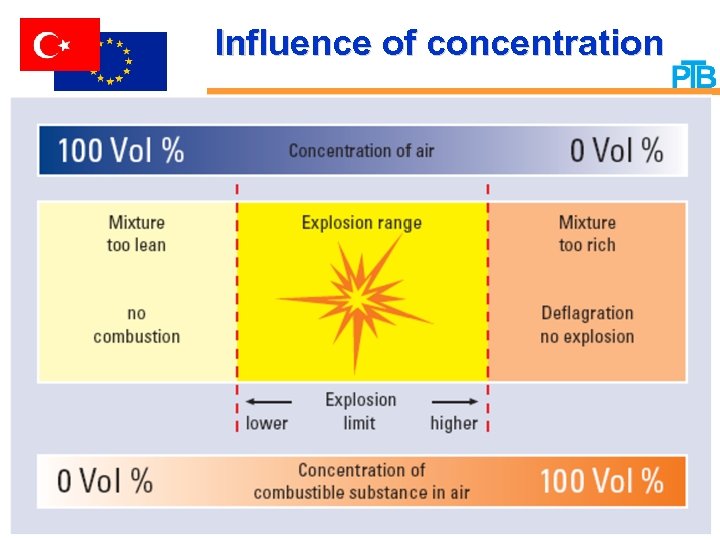

Influence of concentration

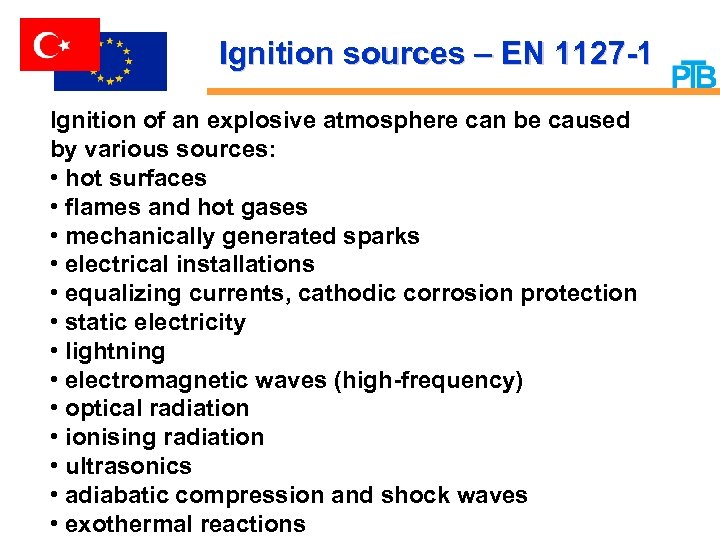

Ignition sources – EN 1127 -1 Ignition of an explosive atmosphere can be caused by various sources: • hot surfaces • flames and hot gases • mechanically generated sparks • electrical installations • equalizing currents, cathodic corrosion protection • static electricity • lightning • electromagnetic waves (high-frequency) • optical radiation • ionising radiation • ultrasonics • adiabatic compression and shock waves • exothermal reactions

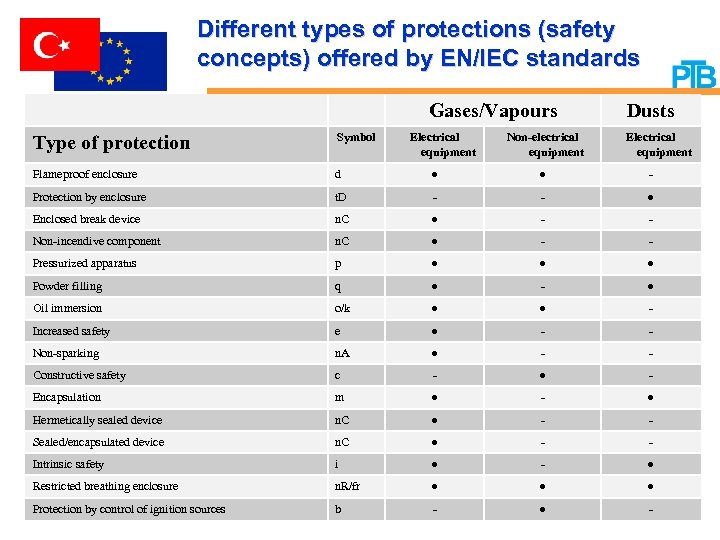

Different types of protections (safety concepts) offered by EN/IEC standards Gases/Vapours Electrical equipment Non-electrical equipment Dusts Type of protection Symbol Electrical equipment Flameproof enclosure d ● ● - Protection by enclosure t. D - - ● Enclosed break device n. C ● - - Non-incendive component n. C ● - - Pressurized apparatus p ● ● ● Powder filling q ● - ● Oil immersion o/k ● ● - Increased safety e ● - - Non-sparking n. A ● - - Constructive safety c - ● - Encapsulation m ● - ● Hermetically sealed device n. C ● - - Sealed/encapsulated device n. C ● - - Intrinsic safety i ● - ● Restricted breathing enclosure n. R/fr ● ● ● Protection by control of ignition sources b - ● -

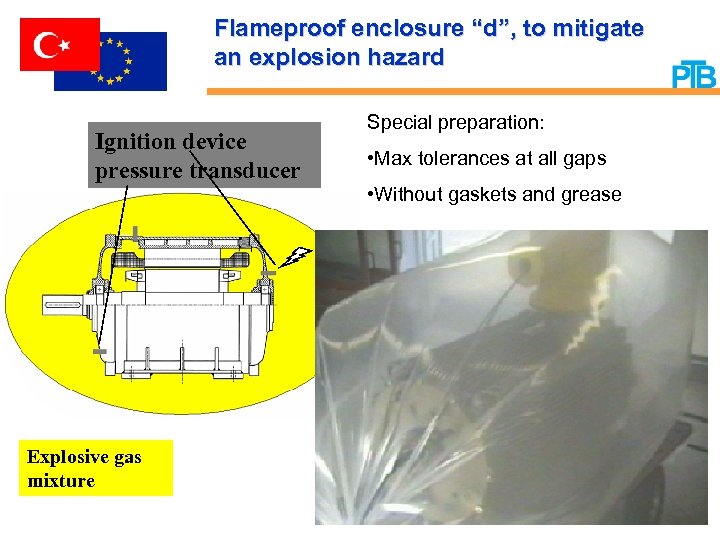

Flameproof enclosure “d”, to mitigate an explosion hazard Ignition device pressure transducer Explosive gas mixture Special preparation: • Max tolerances at all gaps • Without gaskets and grease

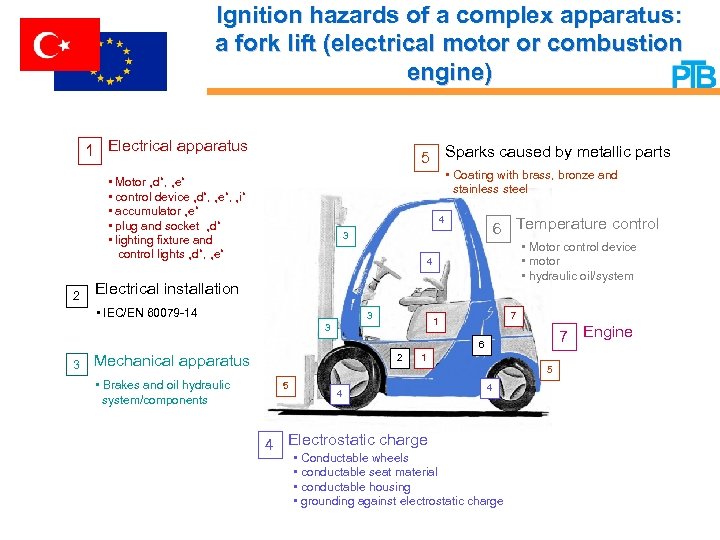

Ignition hazards of a complex apparatus: a fork lift (electrical motor or combustion engine) 1 Electrical apparatus 5 Sparks caused by metallic parts • Coating with brass, bronze and stainless steel • Motor „d“, „e“ • control device „d“, „e“, „i“ • accumulator „e“ • plug and socket „d“ • lighting fixture and control lights „d“, „e“ 2 4 6 Temperature control 3 • Motor control device • motor • hydraulic oil/system 4 Electrical installation • IEC/EN 60079 -14 3 7 1 3 7 Engine 6 3 Mechanical apparatus • Brakes and oil hydraulic system/components 2 1 5 5 4 4 Electrostatic charge 4 • Conductable wheels • conductable seat material • conductable housing • grounding against electrostatic charge

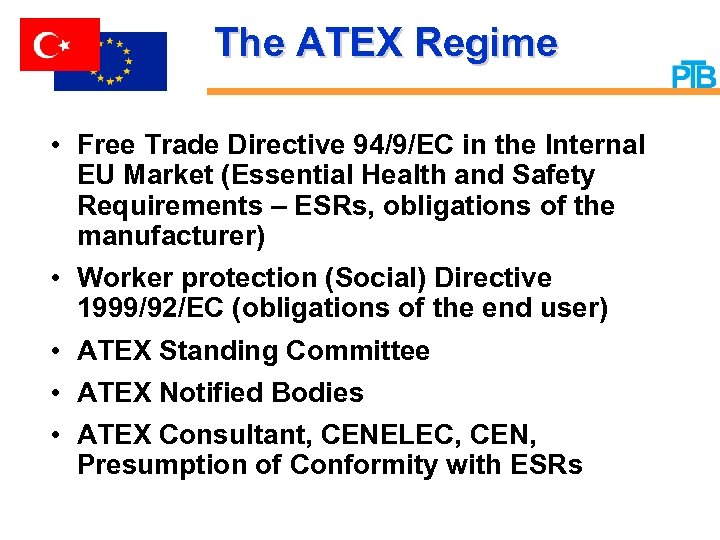

The ATEX Regime • Free Trade Directive 94/9/EC in the Internal EU Market (Essential Health and Safety Requirements – ESRs, obligations of the manufacturer) • Worker protection (Social) Directive 1999/92/EC (obligations of the end user) • ATEX Standing Committee • ATEX Notified Bodies • ATEX Consultant, CENELEC, CEN, Presumption of Conformity with ESRs

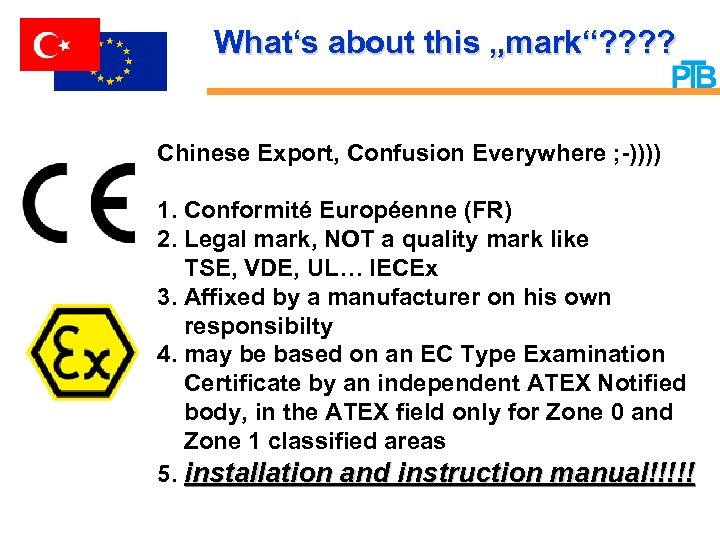

What‘s about this „mark“? ? Chinese Export, Confusion Everywhere ; -)))) 1. Conformité Européenne (FR) 2. Legal mark, NOT a quality mark like TSE, VDE, UL… IECEx 3. Affixed by a manufacturer on his own responsibilty 4. may be based on an EC Type Examination Certificate by an independent ATEX Notified body, in the ATEX field only for Zone 0 and Zone 1 classified areas 5. installation and instruction manual!!!!!

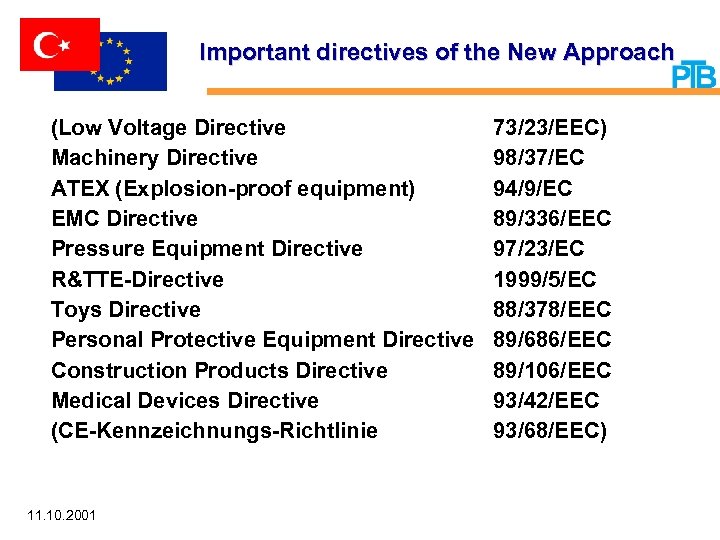

Important directives of the New Approach (Low Voltage Directive Machinery Directive ATEX (Explosion-proof equipment) EMC Directive Pressure Equipment Directive R&TTE-Directive Toys Directive Personal Protective Equipment Directive Construction Products Directive Medical Devices Directive (CE-Kennzeichnungs-Richtlinie 11. 10. 2001 73/23/EEC) 98/37/EC 94/9/EC 89/336/EEC 97/23/EC 1999/5/EC 88/378/EEC 89/686/EEC 89/106/EEC 93/42/EEC 93/68/EEC)

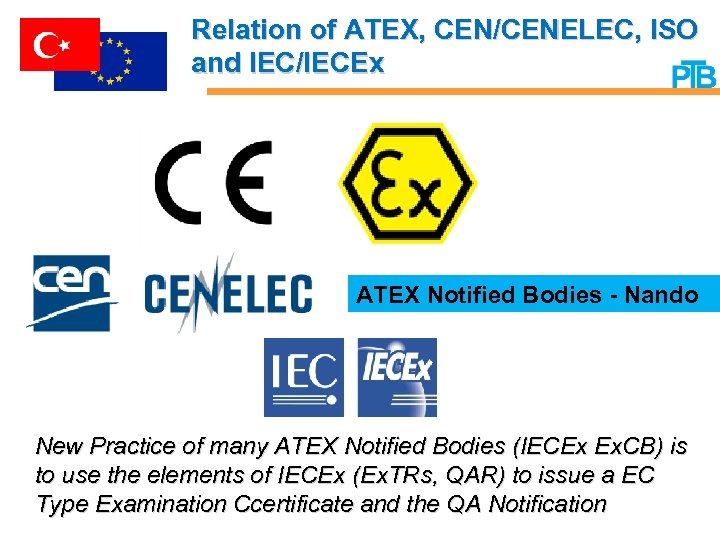

Relation of ATEX, CEN/CENELEC, ISO and IEC/IECEx ATEX Notified Bodies - Nando New Practice of many ATEX Notified Bodies (IECEx Ex. CB) is to use the elements of IECEx (Ex. TRs, QAR) to issue a EC Type Examination Ccertificate and the QA Notification

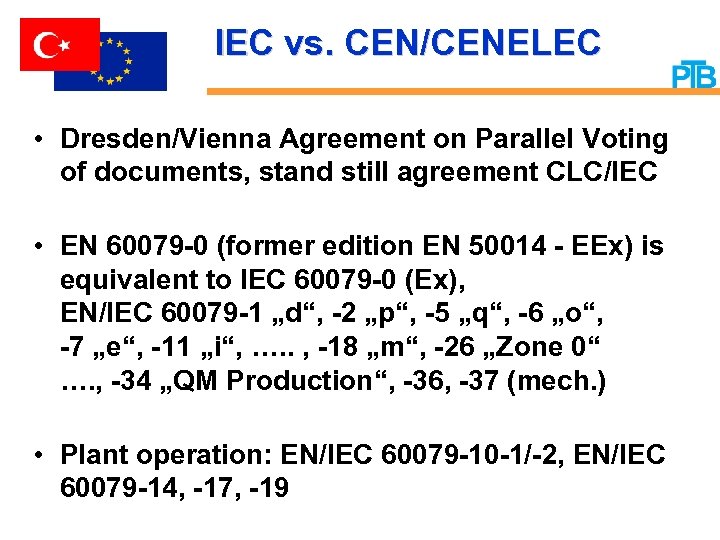

IEC vs. CEN/CENELEC • Dresden/Vienna Agreement on Parallel Voting of documents, stand still agreement CLC/IEC • EN 60079 -0 (former edition EN 50014 - EEx) is equivalent to IEC 60079 -0 (Ex), EN/IEC 60079 -1 „d“, -2 „p“, -5 „q“, -6 „o“, -7 „e“, -11 „i“, …. . , -18 „m“, -26 „Zone 0“ …. , -34 „QM Production“, -36, -37 (mech. ) • Plant operation: EN/IEC 60079 -10 -1/-2, EN/IEC 60079 -14, -17, -19

Safety concepts for equipment – older versions of the standards

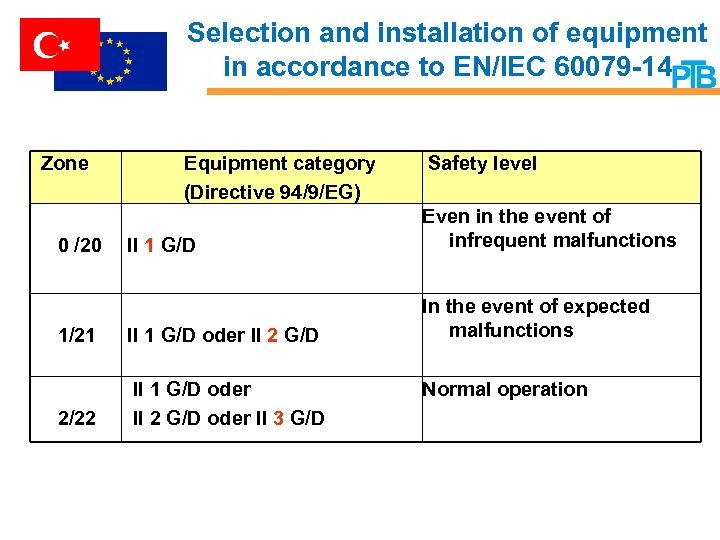

Selection and installation of equipment in accordance to EN/IEC 60079 -14 Zone Equipment category (Directive 94/9/EG) Safety level II 1 G/D Even in the event of infrequent malfunctions 1/21 II 1 G/D oder II 2 G/D In the event of expected malfunctions 2/22 II 1 G/D oder II 2 G/D oder II 3 G/D 0 /20 Normal operation

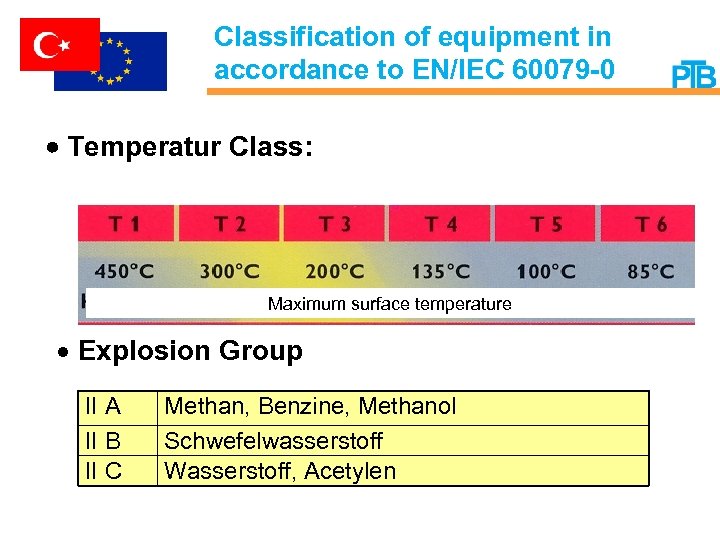

Classification of equipment in accordance to EN/IEC 60079 -0 Temperatur Class: Maximum surface temperature Explosion Group II A II B II C Methan, Benzine, Methanol Schwefelwasserstoff Wasserstoff, Acetylen

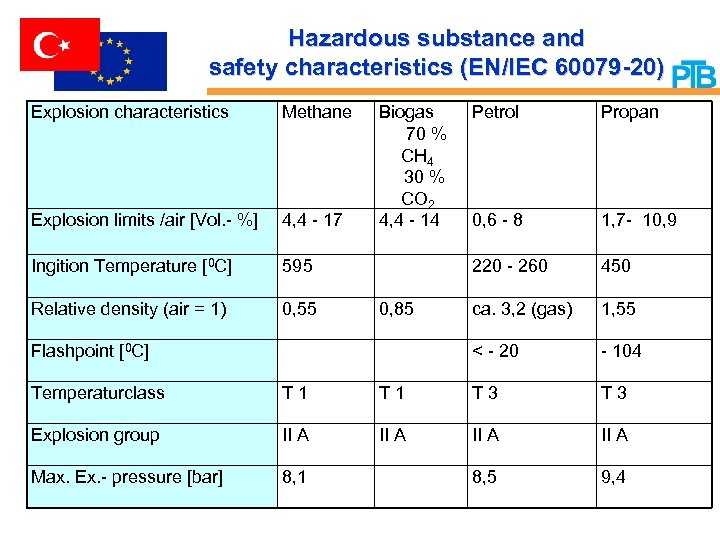

Hazardous substance and safety characteristics (EN/IEC 60079 -20) Explosion characteristics Methane Explosion limits /air [Vol. - %] 4, 4 - 17 Ingition Temperature [0 C] 595 Relative density (air = 1) 0, 55 Biogas 70 % CH 4 30 % CO 2 4, 4 - 14 0, 6 - 8 1, 7 - 10, 9 450 ca. 3, 2 (gas) 1, 55 < - 20 Flashpoint [0 C] Propan 220 - 260 0, 85 Petrol - 104 Temperaturclass T 1 T 3 Explosion group II A Max. Ex. - pressure [bar] 8, 1 8, 5 9, 4

Examples of 94/9 -equipment with EC Declaration of Conformity To be installed in accordance with IEC 60079 -14

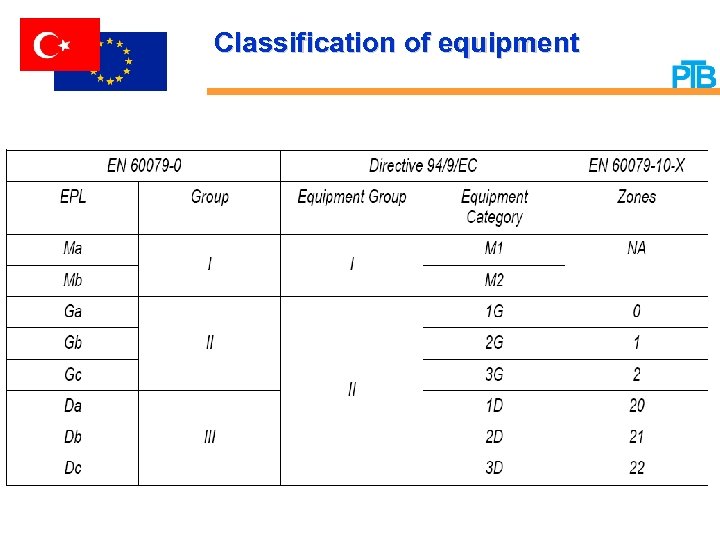

Classification of equipment

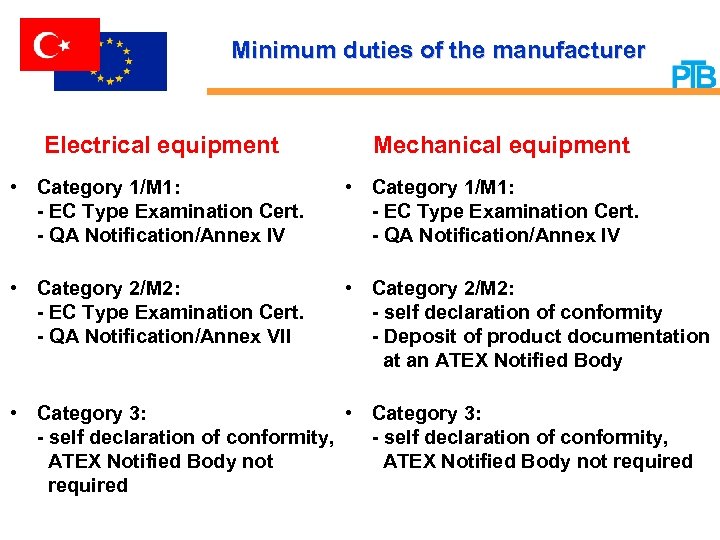

Minimum duties of the manufacturer Electrical equipment Mechanical equipment • Category 1/M 1: - EC Type Examination Cert. - QA Notification/Annex IV • Category 2/M 2: - EC Type Examination Cert. - QA Notification/Annex VII • Category 2/M 2: - self declaration of conformity - Deposit of product documentation at an ATEX Notified Body • Category 3: - self declaration of conformity, ATEX Notified Body not required

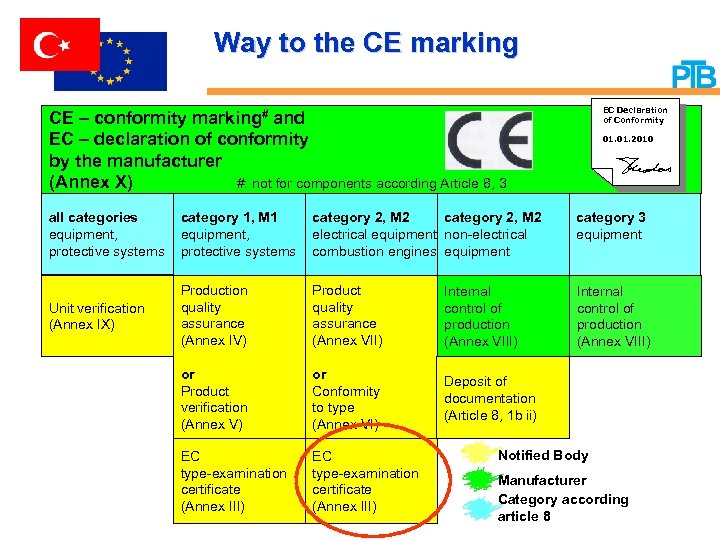

Way to the CE marking EC Declaration of Conformity CE – conformity marking# and EC – declaration of conformity by the manufacturer #: not for components according Article 8, 3 (Annex X) 01. 2010 all categories equipment, protective systems category 1, M 1 equipment, protective systems category 2, M 2 electrical equipment, non-electrical combustion engines equipment category 3 equipment Unit verification (Annex IX) Production quality assurance (Annex IV) Product quality assurance (Annex VII) Internal control of production (Annex VIII) or Product verification (Annex V) or Conformity to type (Annex VI) Deposit of documentation (Article 8, 1 b ii) EC type-examination certificate (Annex III) Notified Body Manufacturer Category according article 8

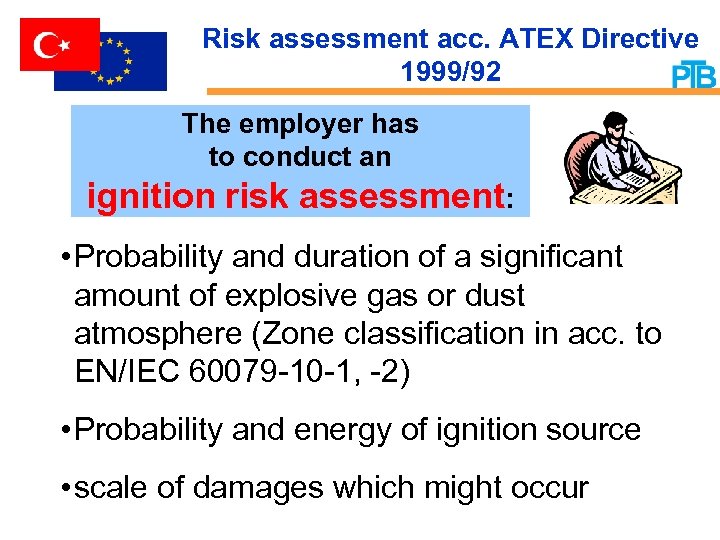

Risk assessment acc. ATEX Directive 1999/92 The employer has to conduct an ignition risk assessment: • Probability and duration of a significant amount of explosive gas or dust atmosphere (Zone classification in acc. to EN/IEC 60079 -10 -1, -2) • Probability and energy of ignition source • scale of damages which might occur

EU-Directive 1999/92/EG and IEC 60079 -10 -1 Zone 0 A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is present continuously or for long periods or frequently. Zone 1 A place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally. Zone 2 A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Directive 1999/92/EG and IEC 60079 -10 -2 Zone 20 A place in which an explosive atmosphere in the form of a cloud of combustable dust in air is present continously, or for long periods or frequently. Zone 21 A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally. Zone 22 A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

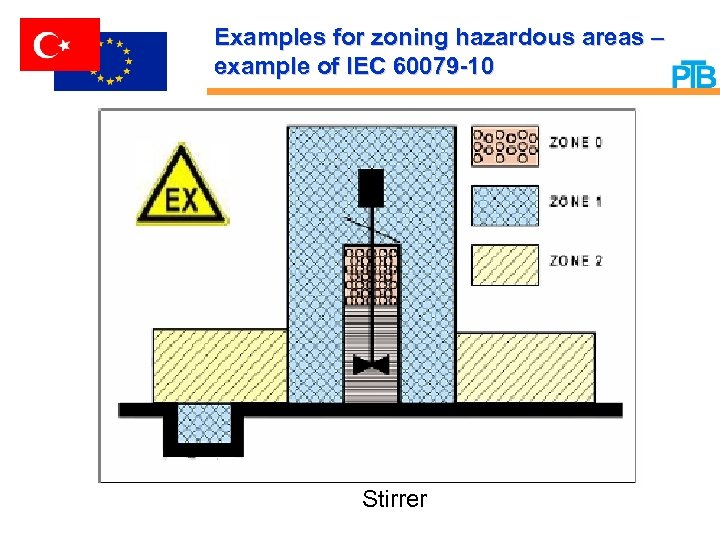

Examples for zoning hazardous areas – example of IEC 60079 -10 Stirrer

Examples of 94/9 -equipment with EC Declaration of Conformity CE – EU Dir. 94/9 marked equipment is required by the user‘s directive 1999/92

Directive 1999/92/EG (1) Documentation Explosion protection document: § description of the plant, the process, the activities and flammable material quantities § material data § results of the explosion risk assessment § Explosion protection measures § Organizational measures (training staff, …) Get assistance by NAMUR. de and NAMUR recommendation xyz

Directive 1999/92/EG (2) Maintenance • Ensure expertise of the personell Maintenance • Training and experience must be ensured IEC 60079 -17 • Prevent occurence of hazardous atmophere and -19 • install a fire monitor if necessary • Making sure before restarting that the explosion protection measures required for normal operation have been reactived • clean dust deposits from installed products

The ATEX Standing Committee • Representatives coming from Ministries of the EU Member States, Industry Associations, Ex. NB Group, Standardization Bodies CENELEC and CEN, ATEX Consultant, …. the Stakeholders • Interpretation of the Directives 94/9 and 1999/92 • Interface to other Directives, e. g. to the Machinery Directive • Meeting once a year in Brussels

ATEX Notified Body group The ATEX Notified Bodies – More than 60 ATEX Notified Bodies with similar scopes – but it is a national notification, not an accreditation in acc. with ISO/IEC standards – requirements for notification see annex XI of the 94/9 – general experience: no chance outside EU with such a notification, ISO/IEC 17025 and ISO Guide 65 are to be applied by internationally recognized ILAC/IAF accreditation bodies like TÜRKAK

7f20b04821878c22b286ee1ce9a58b6b.ppt