4cc9772102f6f0ff639dbb92bb6a1743.ppt

- Количество слайдов: 23

BASIC COAL FIRED BOILER ATTENDANCE TRAINING COURSE 1

OBJECTIVE TO TRAIN BOILER OPERATORS TO GENERATE STEAM SAFELY, EFFICIENTLY AND COST EFFECTIVELY 2

Minimum trainee requirements: • Good eye sight. • Good hearing. • Physically fit and mentally alert. • A sober disposition. • Ability to work and move around in confined spaces. • A tolerance to heat, loud noises and heights. • Literate 3

Dryden Combustion Present: BOILER OPERATOR TRAINING COURSE 4

BASIC SUBJECTS COVERED DURING THE TRAINING PROGRAMME • Example of some items covered during the Training Course which contribute to the efficient use and correct operation of your boiler 5

1. Identifying the component parts by name and knowing their function and how to test them. • • Gauge Glasses Mobreys Boiler Water treatment • • • Undergrate Dampers Different Valves Sootblowers Coal Handling Equipment Plus more …. 6

2. Preliminary checks undertaken by the operator before lighting up the boiler and raising steam pressure 7

PRELIMINARY CHECKS: • Coal • Water level • Water softener • Ash removal trolley • Chemicals • Grit removal trolley • Valve positions 8

3. The CORRECT way to light a fire and raise steam pressure: • Guillotine door height • Length of coal bed • Where to place the wood fire • All other relevant steps up to raising steam pressure 9

4. Maintaining steam pressure safely and efficiently: • Understanding correct air fuel ratios • Ash removal • Blowdown Procedure • and more…… cost impact saving approximately 10% of your current coal costs 10

5. Banking the fire correctly: • Correct tools to complete the task • Proper personal protection equipment for the tasks • Advantages: - Not to make a fire from start up again - Raise steam pressure without causing stress to the boiler. 11

6. Starting up from a banked fire: • Procedure on how to re-ignite correctly • Valve Positions • Damper Settings 12

7. Emergency procedures: • Power failure • Safety valve blow off • Shear pin failure • Broken gauge glass • Blowdown valve jams in the open position 13

8. Shutdown and standby procedure: • Correct shutting down of a for more than 18 hours. • boiler Short standby (30 mins or less) 14

9. Problems and remedies: • Identification of problem • Diagnosis of problem and apply correct remedies. • Protecting the boiler • Do not waste time and coal 15

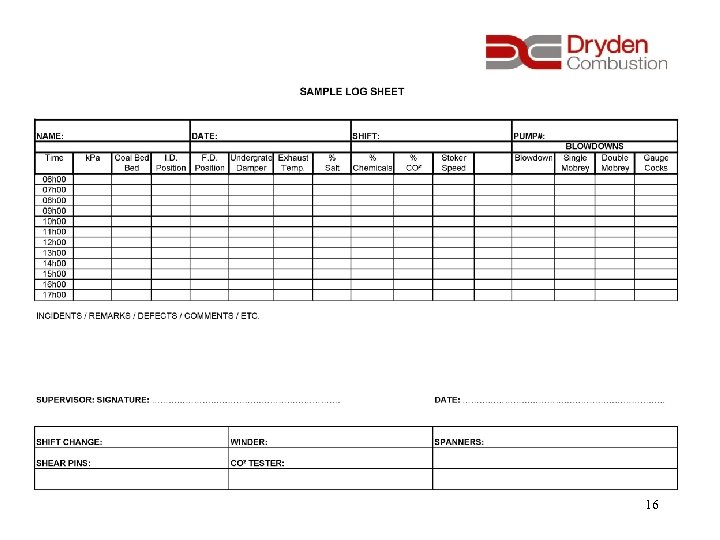

16

COURSE OPTIONS 17

BASIC BOILER OPERATORS COURSE Ø Preliminary Exam Written to Evaluate each Trainees Capability Ø Course conducted in English by a multi-lingual SETA registered Facilitator Ø Theory – conducted in a classroom together with DVD presentations Ø Practical training – conducted in the boiler house Ø Final Exam Ø Examinations evaluated by a SETA registered Assessor Ø Issuing of Certificate Ø Boiler Operator Cap to successful students Ø Written Report issued to the Department on each student 18

19

COURSE OPTIONS q q q Individual “on site” training course to be run at your factory on your boiler or Purchase DVD Training Course to be owned and run by the client, in their own time. Future training / refresher courses will then be at no additional costs to the Company or On site training of operators – backed up by the DVD Training Course – which shall remain on site for constant refresher courses for the operators at no additional cost 20

DURATION OF EACH COURSE Ø Each Course will take 5 days (40 hours) Ø Traveling to and from site will be additional 21

REQUIREMENTS 1. Classroom complete with tables and chairs, white board and markers 2. Availability of fully operational stand-by boiler for start / stop operation during practical training 3. Recommendation of a maximum of 8 students per class 22

23

4cc9772102f6f0ff639dbb92bb6a1743.ppt