059a9cf1f9e3fd5e04557774c7ce0550.ppt

- Количество слайдов: 37

Bar-coding in AP: Omni. Trax as a Full Middleware Solution Rodney Schmidt, MD, Ph. D Professor of Pathology, Director of Medical Informatics (Pathology) University of Washington, Seattle

Today’s Story Lessons from Omni. Trax – Lean processes and workflow – Deeper understanding of barcoding • Different levels of barcoding with different benefits – Measures of benefits • Quality and efficiency • Workflow dependent! – Current capabilities Trade-offs using a middleware solution Need for a bar-code standard

Disclosure • Bar-coding software developed at UW (Omni. Trax and Omni. Image) has been licensed by UW to Pathway Pathology Consultants for Power. Path end-users. • Dr. Schmidt and his team have a revenue-sharing agreement with UW. • Dr. Schmidt has a consulting agreement with Thermo. Fisher for educational talks. • No other financial relationships with hardware or software manufacturers.

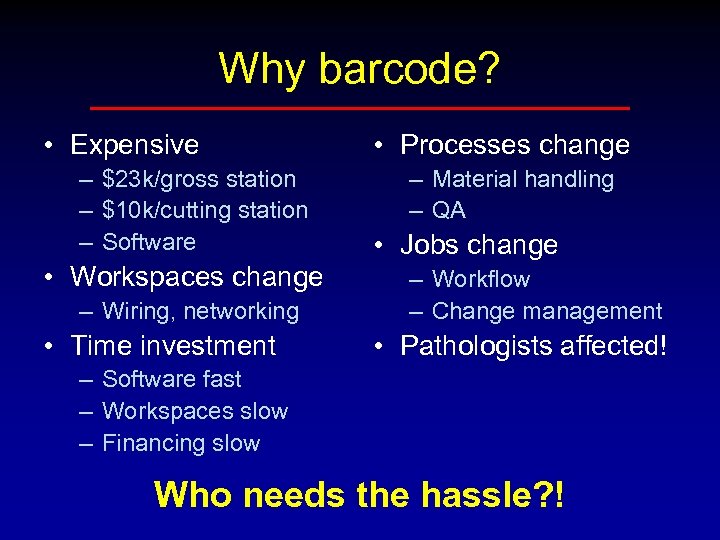

Why barcode? • Expensive – $23 k/gross station – $10 k/cutting station – Software • Workspaces change – Wiring, networking • Time investment • Processes change – Material handling – QA • Jobs change – Workflow – Change management • Pathologists affected! – Software fast – Workspaces slow – Financing slow Who needs the hassle? !

Why barcode? • Error reduction and patient safety – Errors labeling things – 1/300 (manual) to < 1/10, 000 (datamatrix) • Reduced medical-legal liability • Custodial responsibility & inventory control • Self-interested reasons – Helps you do your job faster – Reduced time wasted on error resolution – Indirect efficiencies because of better knowledge about where things are

What is Bar-coding? • Labeling – Putting barcodes on things – Technically easy, cheap (some methods) • Tracking – Location updates; inventory control – Added work; needs software; modest cost • Driving – Using barcodes to expedite workflow – Disruptive technology; expensive; LIS interoperability

Bringing Bar-coding to AP • Track slides (2005) – Eliminate the “lost slide” problem – Ease conference prep • Specimen labels (2006) – Tissue discards and tracking – Drive gross photography • Block creation and labeling (2008) – Automated JIT production of barcoded blocks – Gross room QA process and tracking • Slide creation and labeling (2008) – Automated JIT creation of barcoded slides – Facilitate workflow and QA • Eliminate all manual labeling (and errors) • Facilitate workflow – JIT information display

Achieved Benefits • Marked reduction in labeling errors • Improved inventory control (i. e. knowledge of where things are) • Direct savings of ~ 3 FTE • Indirect savings of >> 0. 5 FTE • Improved image collection and management (paperwork, gross, micro, EMs, IF, etc) • Increased job satisfaction

Bar-coding Options • Buy LIS-specific – Available? Capable? • Buy 3 rd party solution (middleware) – Available? Capable? • Build LIS-specific middleware – Can be quick. Investment. • Build LIS-agnostic middleware – Most complex; most control

Design Principles • No scanning without benefit – User acceptance; minimal training • No manual data entry – Eliminate human errors • Use barcodes to drive workflow – Efficiency • Make nothing until it’s needed – Eliminate handling and error opportunities • No assumptions – only trust scan events – Quality timestamps, locations, personnel • Leverage LIS • LIS-agnostic design

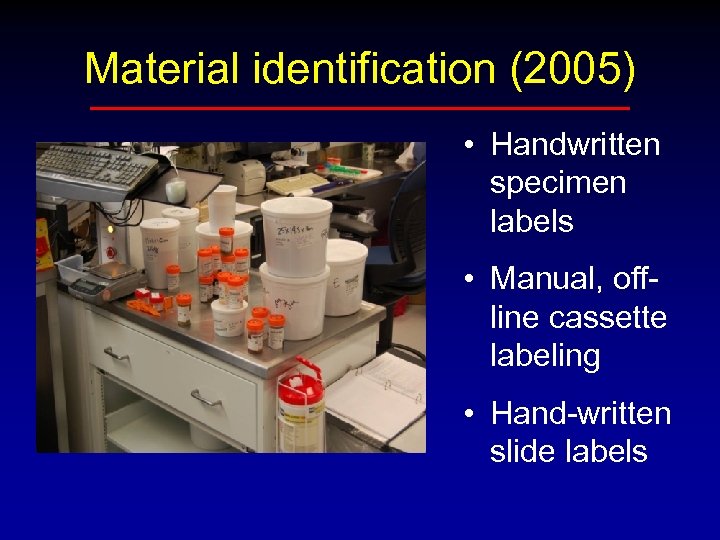

Material identification (2005) • Handwritten specimen labels • Manual, offline cassette labeling • Hand-written slide labels

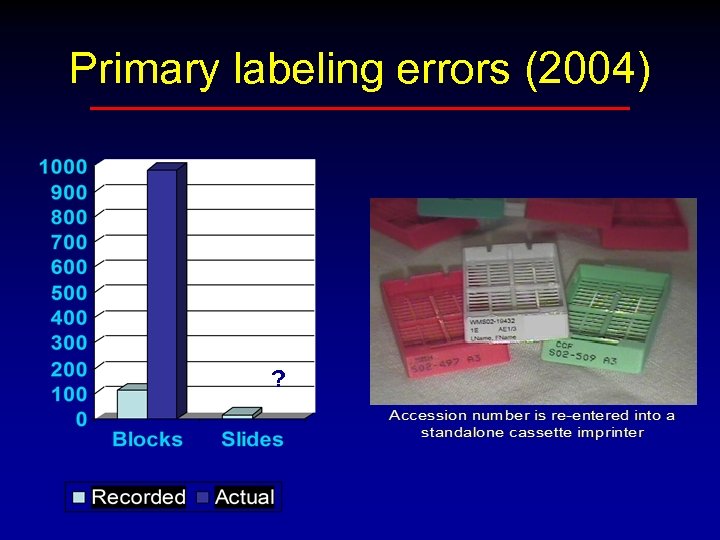

Primary labeling errors (2004) ?

Targets – Gross Room • Foolproof labeling – No human labeling/data entry • Reduced dependence on support staff – Off-hours availability – Redirection of support personnel • Reduced waste of cassettes • Grossing step at least as fast as current • (Record timestamps) The unsupervised Resident!

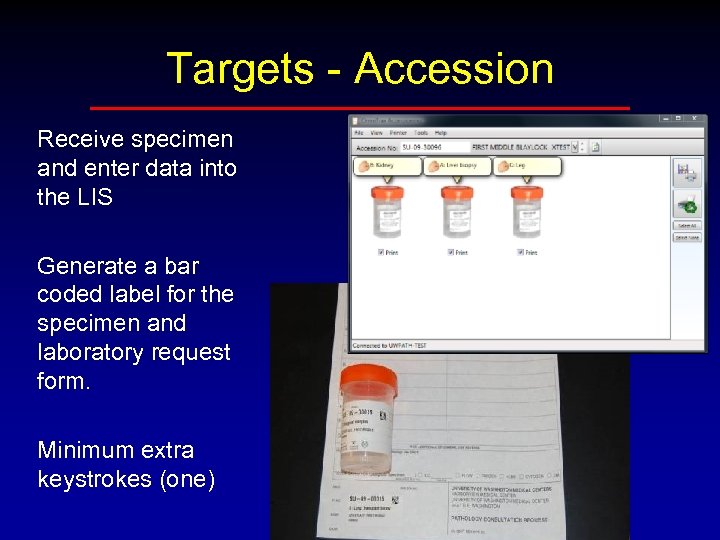

Targets - Accession Receive specimen and enter data into the LIS Generate a bar coded label for the specimen and laboratory request form. Minimum extra keystrokes (one)

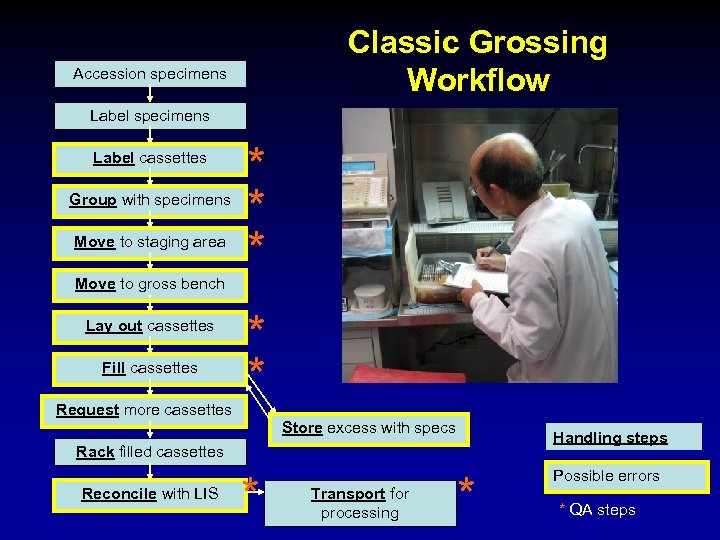

Classic Grossing Workflow Accession specimens Label cassettes Group with specimens Move to staging area Move to gross bench Lay out cassettes Fill cassettes Request more cassettes * * * Store excess with specs Handling steps Rack filled cassettes Reconcile with LIS * Transport for processing * Possible errors * QA steps

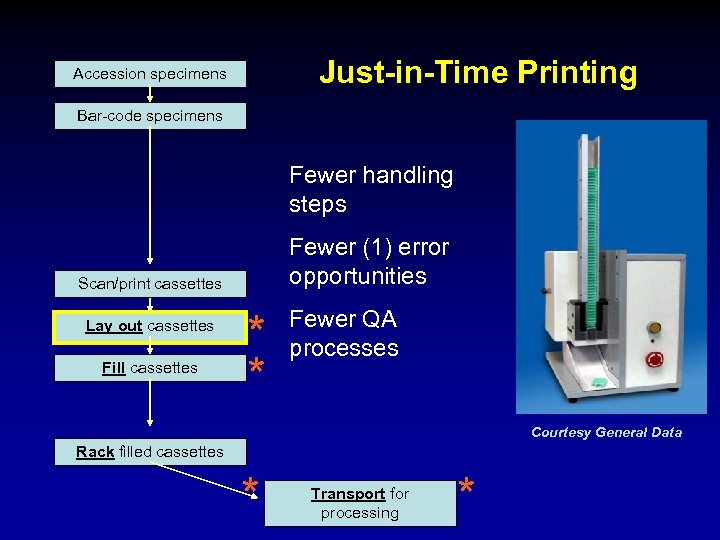

Just-in-Time Printing Accession specimens Bar-code specimens Fewer handling steps Fewer (1) error opportunities Scan/print cassettes Lay out cassettes Fill cassettes * * Fewer QA processes Courtesy General Data Rack filled cassettes * Transport for processing *

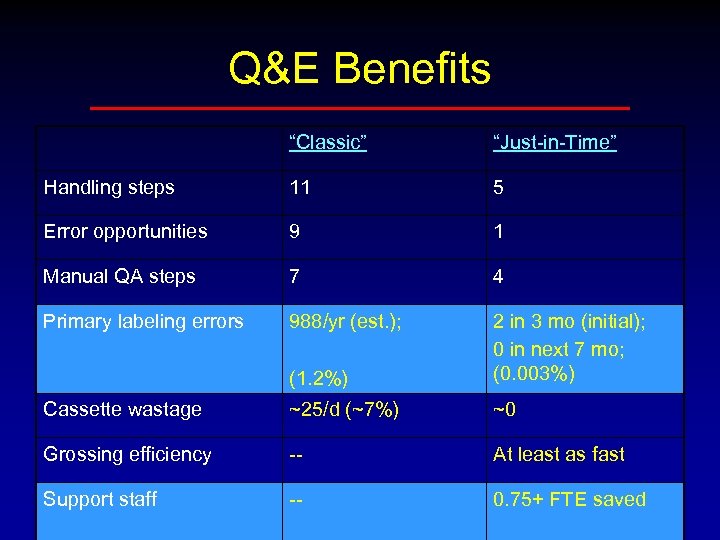

Q&E Benefits “Classic” “Just-in-Time” Handling steps 11 5 Error opportunities 9 1 Manual QA steps 7 4 Primary labeling errors 988/yr (est. ); (1. 2%) 2 in 3 mo (initial); 0 in next 7 mo; (0. 003%) Cassette wastage ~25/d (~7%) ~0 Grossing efficiency -- At least as fast Support staff -- 0. 75+ FTE saved

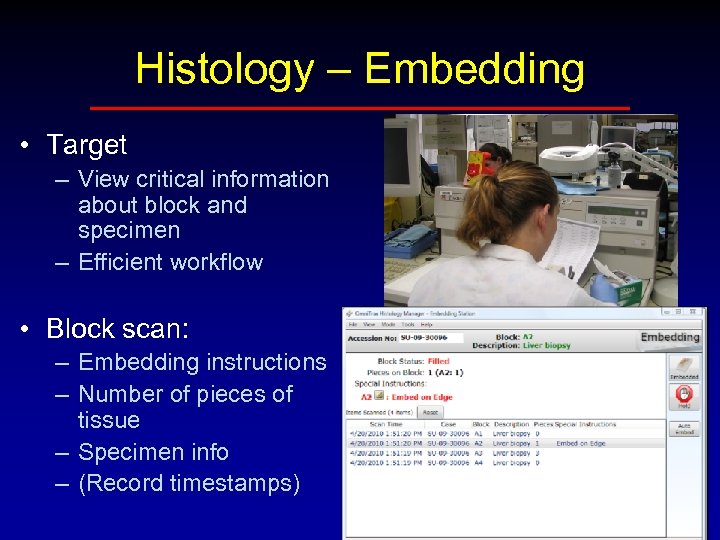

Histology – Embedding • Target – View critical information about block and specimen – Efficient workflow • Block scan: – Embedding instructions – Number of pieces of tissue – Specimen info – (Record timestamps)

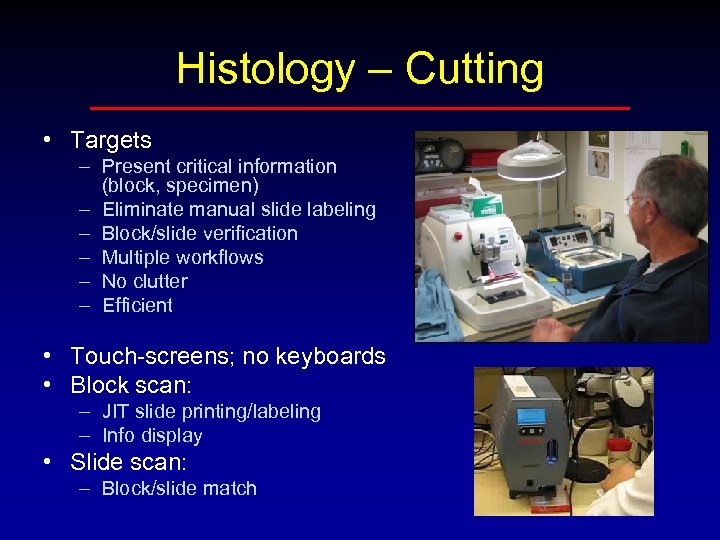

Histology – Cutting • Targets – Present critical information (block, specimen) – Eliminate manual slide labeling – Block/slide verification – Multiple workflows – No clutter – Efficient • Touch-screens; no keyboards • Block scan: – JIT slide printing/labeling – Info display • Slide scan: – Block/slide match

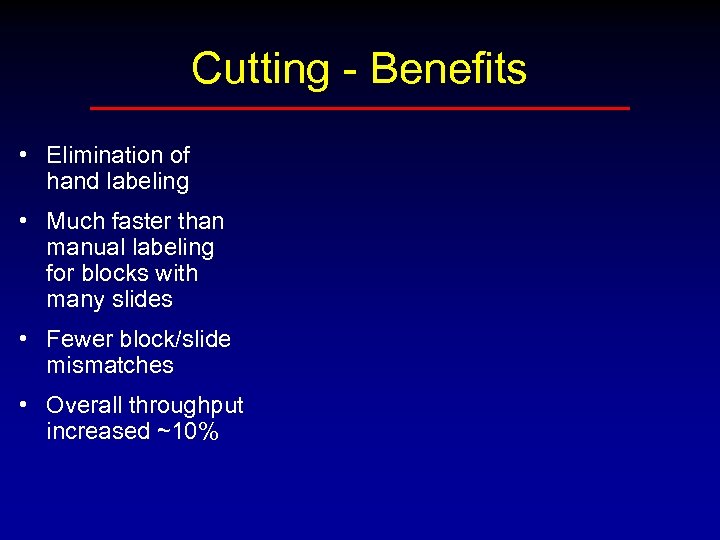

Cutting - Benefits • Elimination of hand labeling • Much faster than manual labeling for blocks with many slides • Fewer block/slide mismatches • Overall throughput increased ~10%

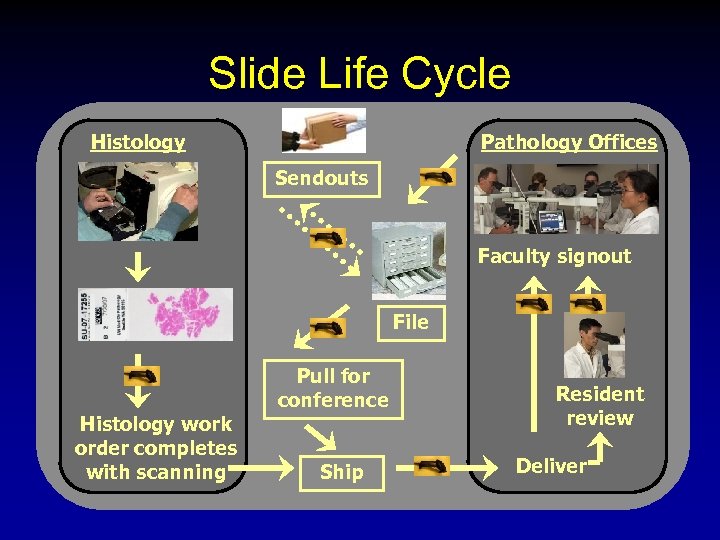

Slide Life Cycle Histology Pathology Offices Sendouts Faculty signout File Histology work order completes with scanning Pull for conference Ship Resident review Deliver

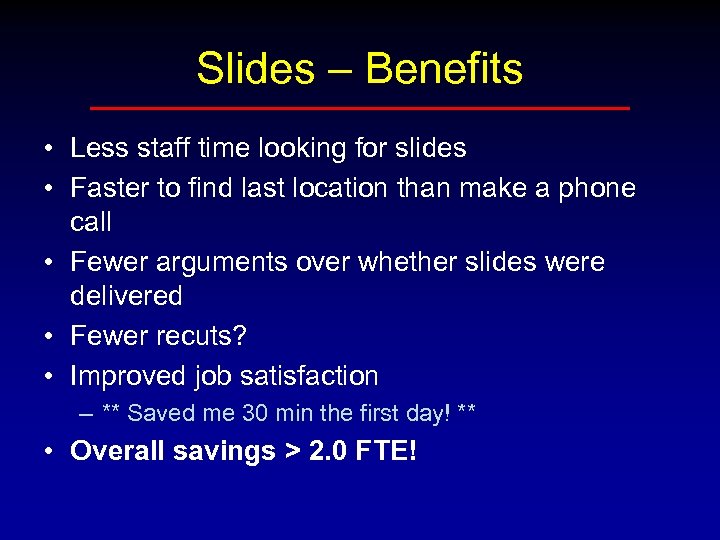

Slides – Benefits • Less staff time looking for slides • Faster to find last location than make a phone call • Fewer arguments over whether slides were delivered • Fewer recuts? • Improved job satisfaction – ** Saved me 30 min the first day! ** • Overall savings > 2. 0 FTE!

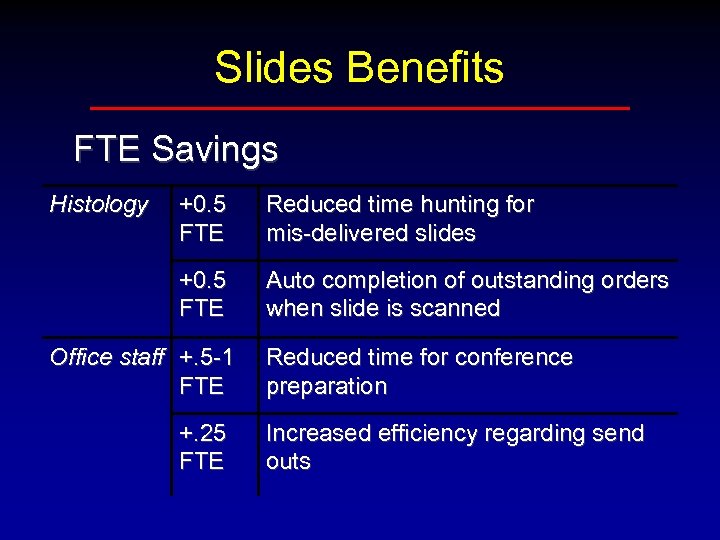

Slides Benefits FTE Savings Histology +0. 5 FTE Reduced time hunting for mis-delivered slides +0. 5 FTE Auto completion of outstanding orders when slide is scanned Office staff +. 5 -1 FTE +. 25 FTE Reduced time for conference preparation Increased efficiency regarding send outs

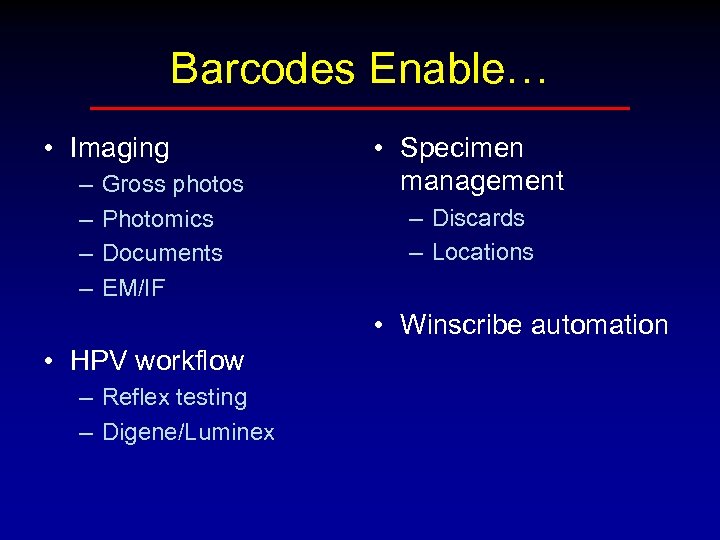

Barcodes Enable… • Imaging – – Gross photos Photomics Documents EM/IF • Specimen management – Discards – Locations • Winscribe automation • HPV workflow – Reflex testing – Digene/Luminex

Targets - Specimens • Discards – Accurate – Efficient – Documented • Track location • Drive photography

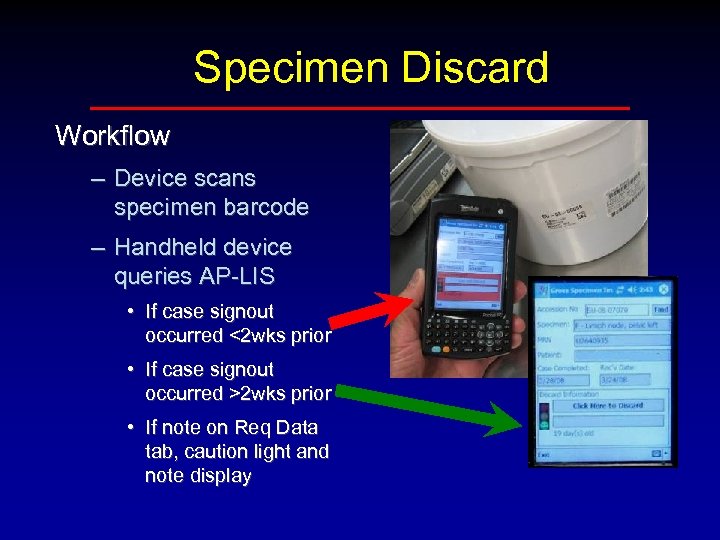

Specimen Discard Workflow – Device scans specimen barcode – Handheld device queries AP-LIS • If case signout occurred <2 wks prior • If case signout occurred >2 wks prior • If note on Req Data tab, caution light and note display

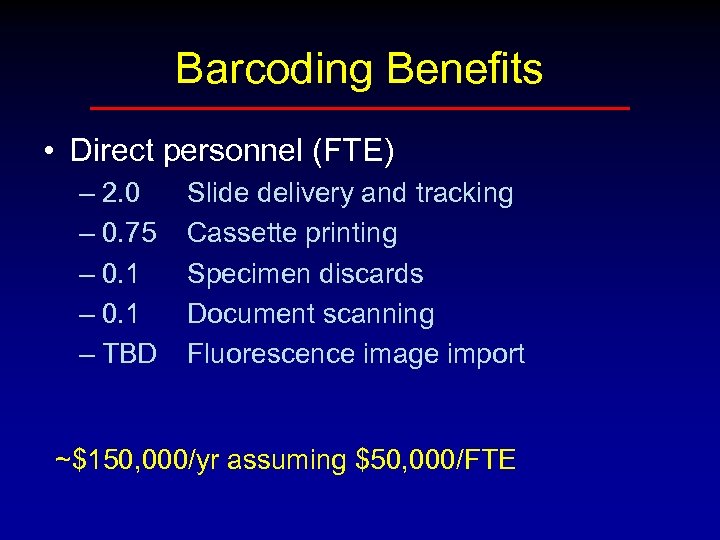

Barcoding Benefits • Direct personnel (FTE) – 2. 0 – 0. 75 – 0. 1 – TBD Slide delivery and tracking Cassette printing Specimen discards Document scanning Fluorescence image import ~$150, 000/yr assuming $50, 000/FTE

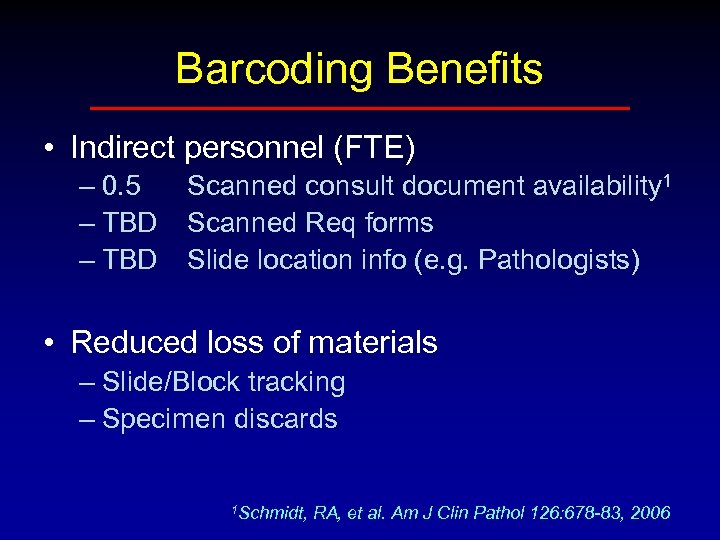

Barcoding Benefits • Indirect personnel (FTE) – 0. 5 – TBD Scanned consult document availability 1 Scanned Req forms Slide location info (e. g. Pathologists) • Reduced loss of materials – Slide/Block tracking – Specimen discards 1 Schmidt, RA, et al. Am J Clin Pathol 126: 678 -83, 2006

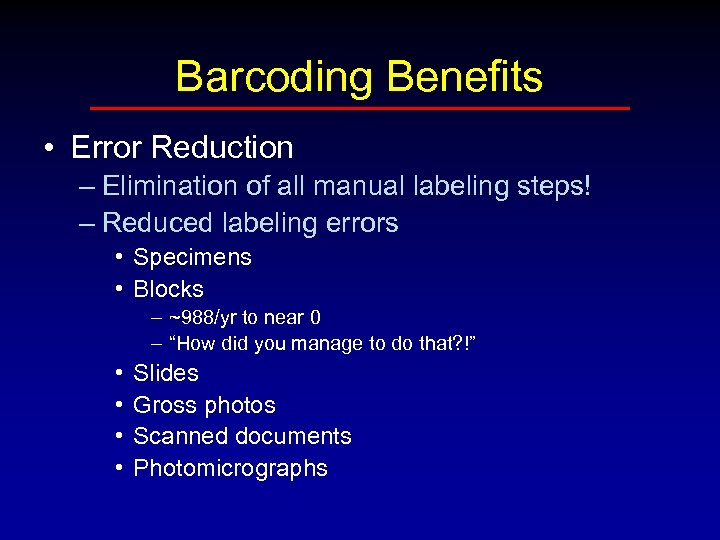

Barcoding Benefits • Error Reduction – Elimination of all manual labeling steps! – Reduced labeling errors • Specimens • Blocks – ~988/yr to near 0 – “How did you manage to do that? !” • • Slides Gross photos Scanned documents Photomicrographs

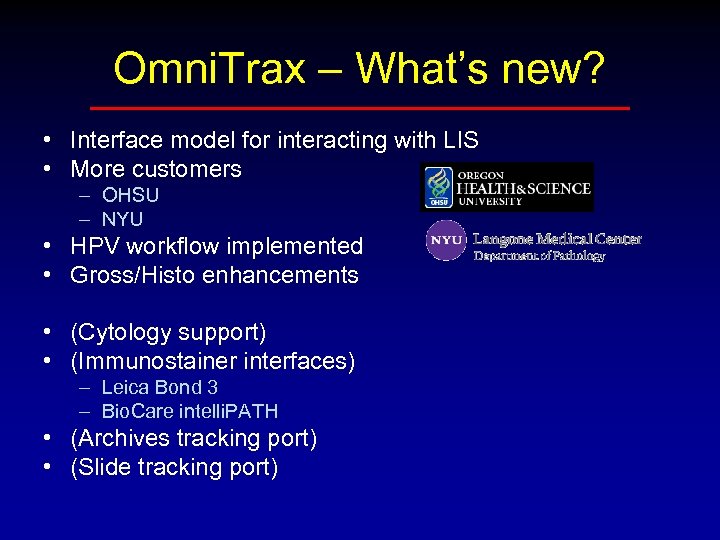

Omni. Trax – What’s new? • Interface model for interacting with LIS • More customers – OHSU – NYU • HPV workflow implemented • Gross/Histo enhancements • (Cytology support) • (Immunostainer interfaces) – Leica Bond 3 – Bio. Care intelli. PATH • (Archives tracking port) • (Slide tracking port)

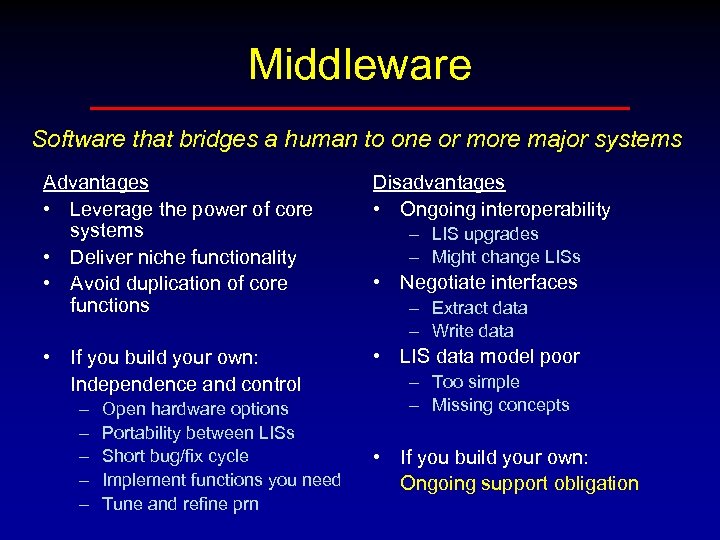

Middleware Software that bridges a human to one or more major systems Advantages • Leverage the power of core systems • Deliver niche functionality • Avoid duplication of core functions Disadvantages • Ongoing interoperability • If you build your own: Independence and control • LIS data model poor – – – Open hardware options Portability between LISs Short bug/fix cycle Implement functions you need Tune and refine prn – LIS upgrades – Might change LISs • Negotiate interfaces – Extract data – Write data – Too simple – Missing concepts • If you build your own: Ongoing support obligation

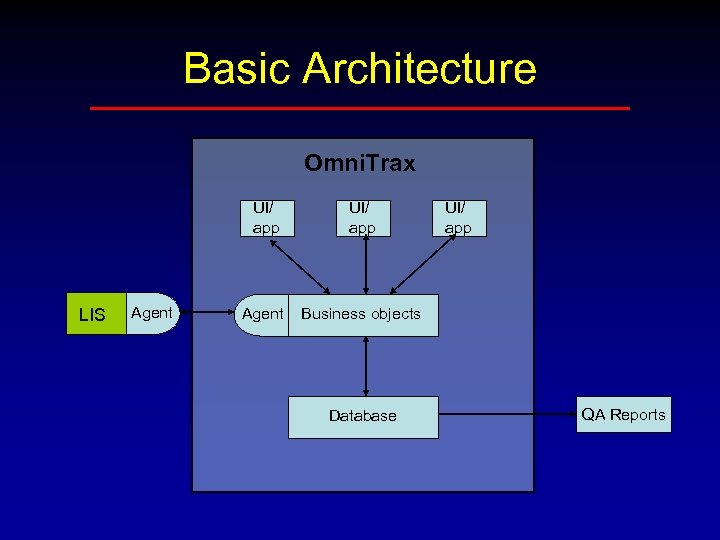

Basic Architecture Omni. Trax UI/ app LIS Agent UI/ app Agent Business objects Database UI/ app QA Reports

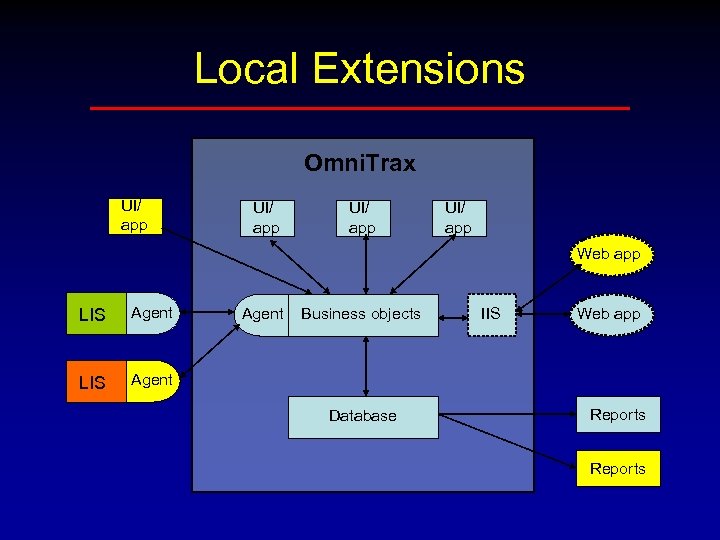

Local Extensions Omni. Trax UI/ app Web app LIS Agent Business objects Database IIS Web app Reports

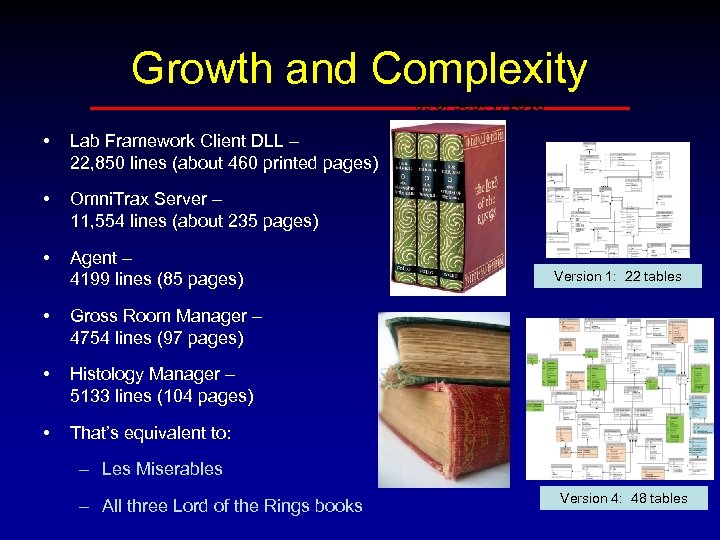

Growth and Complexity as of Sept 7, 2010 • Lab Framework Client DLL – 22, 850 lines (about 460 printed pages) • Omni. Trax Server – 11, 554 lines (about 235 pages) • Agent – 4199 lines (85 pages) • Gross Room Manager – 4754 lines (97 pages) • Histology Manager – 5133 lines (104 pages) • Version 1: 22 tables That’s equivalent to: – Les Miserables – All three Lord of the Rings books Version 4: 48 tables

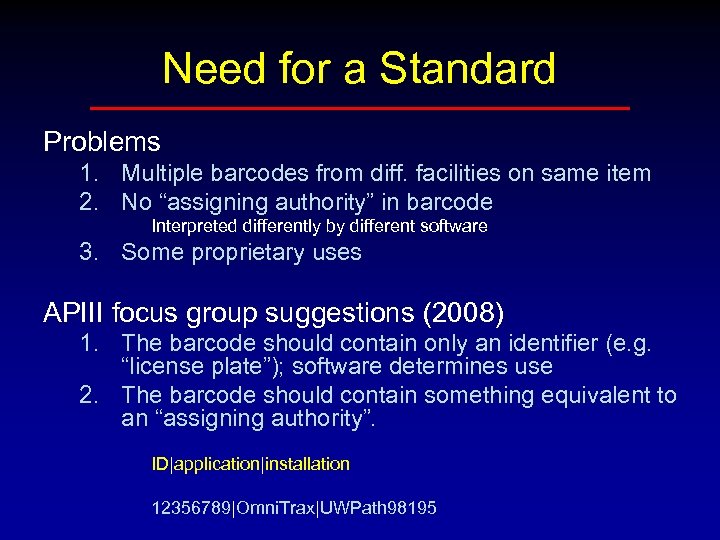

Need for a Standard Problems 1. Multiple barcodes from diff. facilities on same item 2. No “assigning authority” in barcode Interpreted differently by different software 3. Some proprietary uses APIII focus group suggestions (2008) 1. The barcode should contain only an identifier (e. g. “license plate”); software determines use 2. The barcode should contain something equivalent to an “assigning authority”. ID|application|installation 12356789|Omni. Trax|UWPath 98195

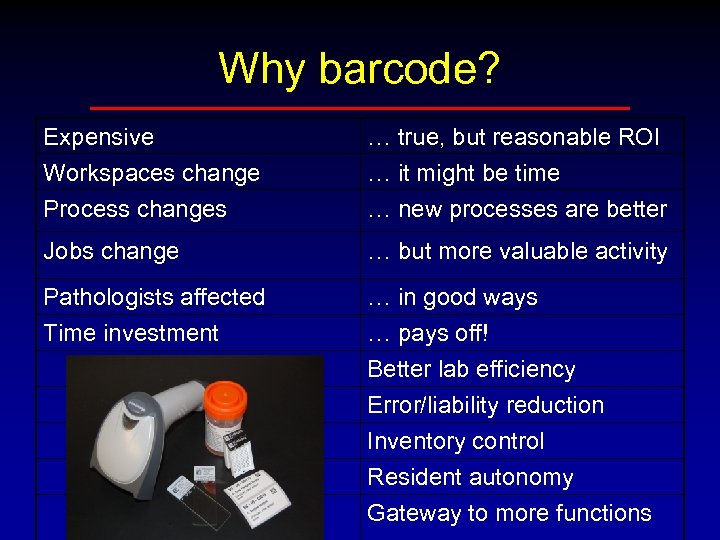

Why barcode? Expensive Workspaces change Process changes … true, but reasonable ROI … it might be time … new processes are better Jobs change … but more valuable activity Pathologists affected Time investment … in good ways … pays off! Better lab efficiency Error/liability reduction Inventory control Resident autonomy Gateway to more functions

Acknowledgements • • • Phil Nguyen Kevin Fleming Rosy Changchien Chris Magnusson Victor Tobias • General Data • Thermo-Fisher • Accu-Place • • • Dr. Erin Grimm Dan Luff Steve Rath Pam Selz Kim Simmons All the Techs and Office Folks!

059a9cf1f9e3fd5e04557774c7ce0550.ppt