4e476f5a5cfe1b89571c6429e272d43e.ppt

- Количество слайдов: 35

BAOSTEEL BAC 2013, Shanghai (China) TOPOCROM® – Texturing: Technology and Advantages Thomas Routschek Salzgitter Flachstahl Gmb. H, Salzgitter (Germany) Karl Müll TOPOCROM Systems AG, Weinfelden (Switzerland)

Structure of Presentation Ø TOPOCROM® - Electroplating Technology ◄◄◄ Ø Demands of the automotive industry on the surface structure of cold rolled sheet metal Ø Requirements of the steelmaking industry for texturing technology of working rolls for skin passing mills Ø PRETEX Surface Structure: Prospects

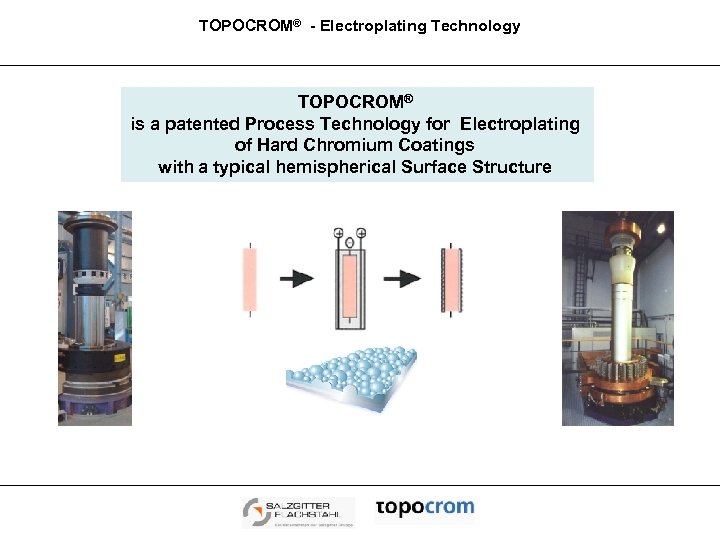

TOPOCROM® - Electroplating Technology TOPOCROM® is a patented Process Technology for Electroplating of Hard Chromium Coatings with a typical hemispherical Surface Structure

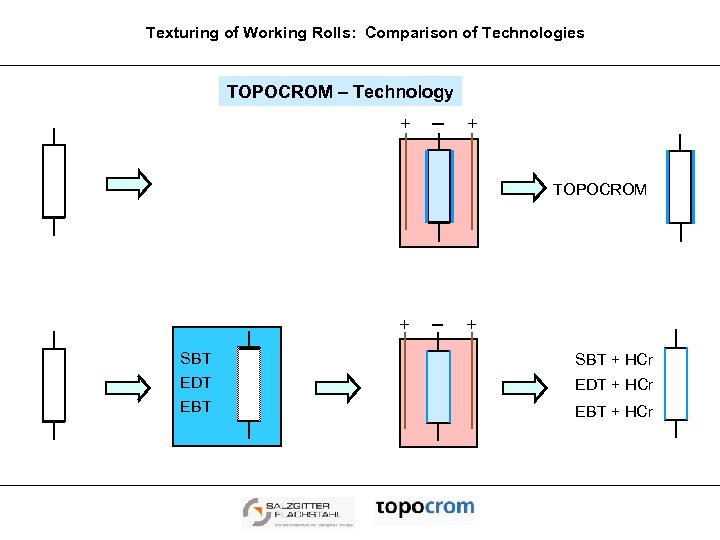

Texturing of Working Rolls: Comparison of Technologies TOPOCROM – Technology + + TOPOCROM + SBT EDT EBT + SBT + HCr EDT + HCr _ EBT + HCr

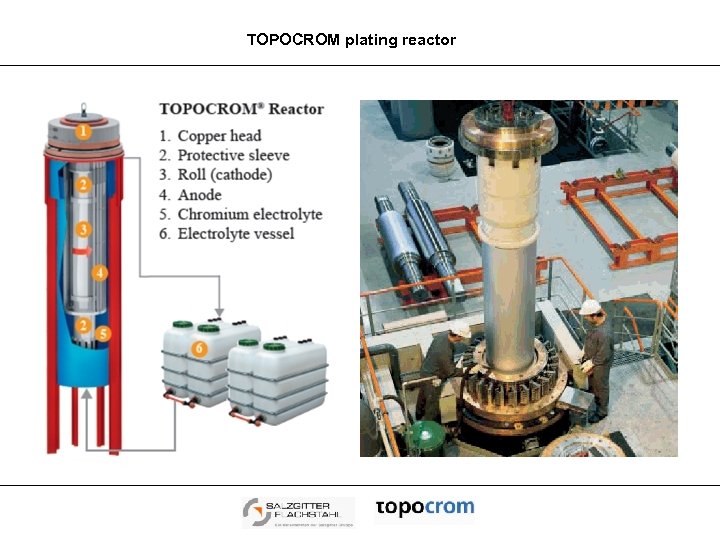

TOPOCROM plating reactor

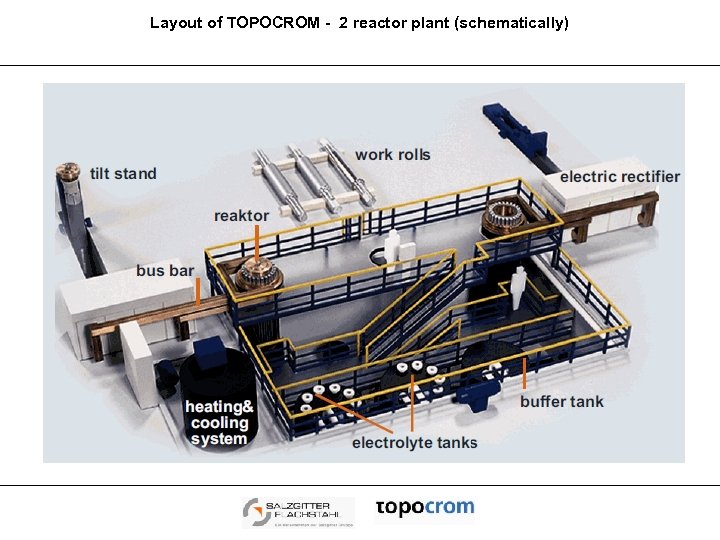

Layout of TOPOCROM - 2 reactor plant (schematically)

TOPOCROM Facility for Steel Works Salzgitter Flachstahl, Salzgitter/Germany Startup in 1996 POSCO, Gwangyang/South Korea Startup in 2009

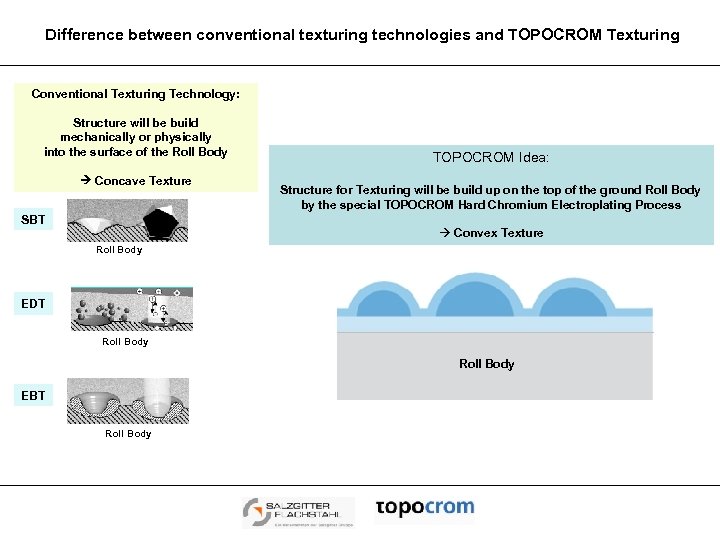

Difference between conventional texturing technologies and TOPOCROM Texturing Conventional Texturing Technology: Structure will be build mechanically or physically into the surface of the Roll Body Concave Texture TOPOCROM Idea: Structure for Texturing will be build up on the top of the ground Roll Body by the special TOPOCROM Hard Chromium Electroplating Process SBT Convex Texture Roll Body EDT Roll Body EBT Roll Body

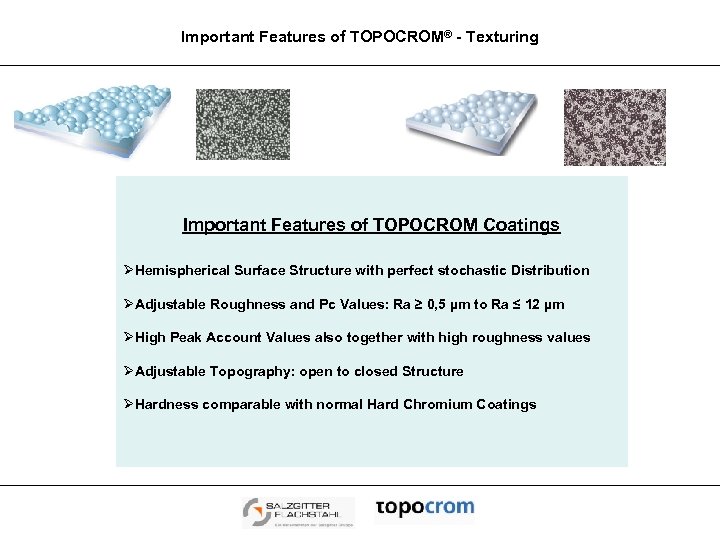

Important Features of TOPOCROM® - Texturing Important Features of TOPOCROM Coatings ØHemispherical Surface Structure with perfect stochastic Distribution ØAdjustable Roughness and Pc Values: Ra ≥ 0, 5 µm to Ra ≤ 12 µm ØHigh Peak Account Values also together with high roughness values ØAdjustable Topography: open to closed Structure ØHardness comparable with normal Hard Chromium Coatings

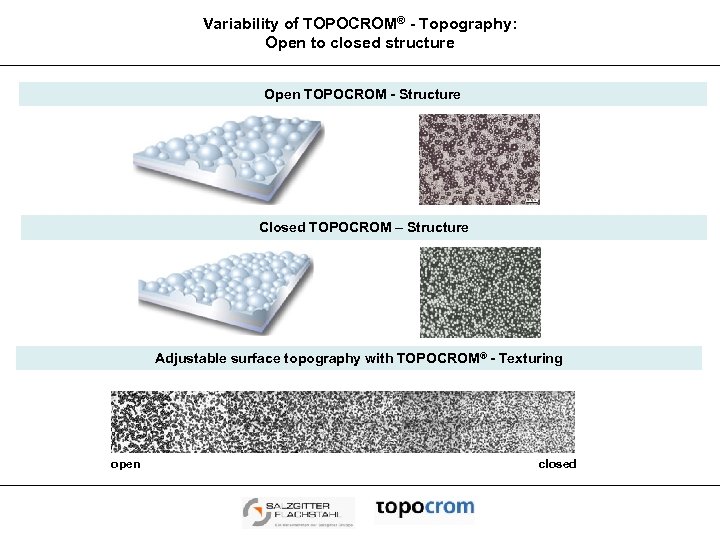

Variability of TOPOCROM® - Topography: Open to closed structure Open TOPOCROM - Structure Closed TOPOCROM – Structure Adjustable surface topography with TOPOCROM® - Texturing open closed

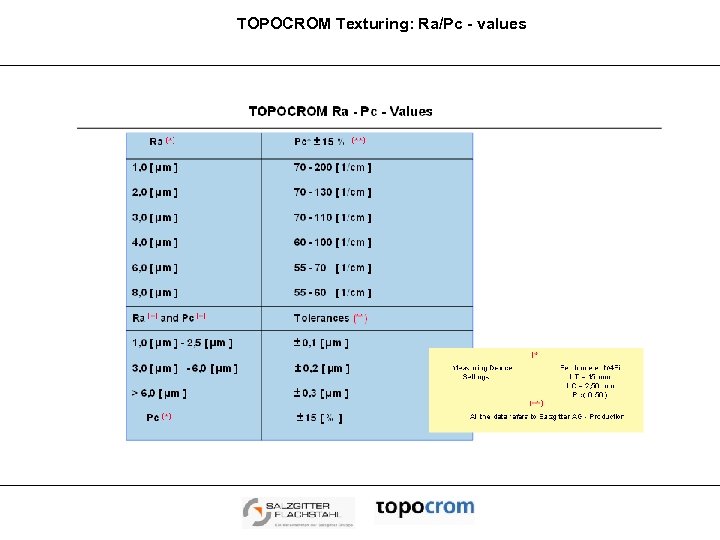

TOPOCROM Texturing: Ra/Pc - values

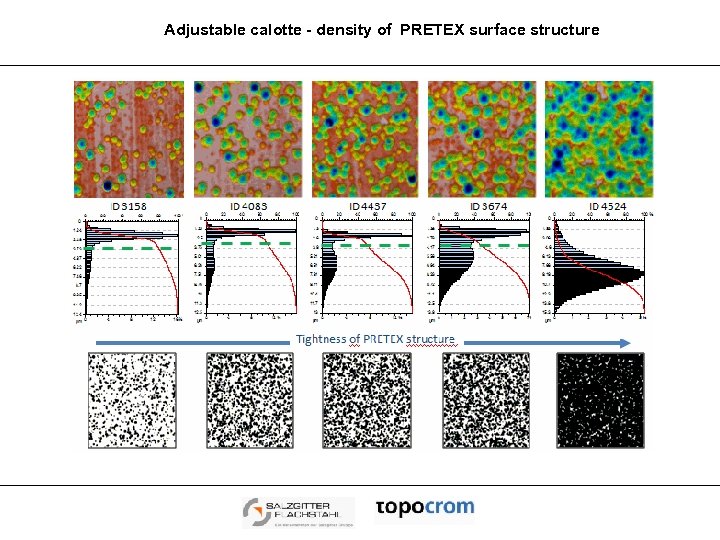

Adjustable calotte - density of PRETEX surface structure

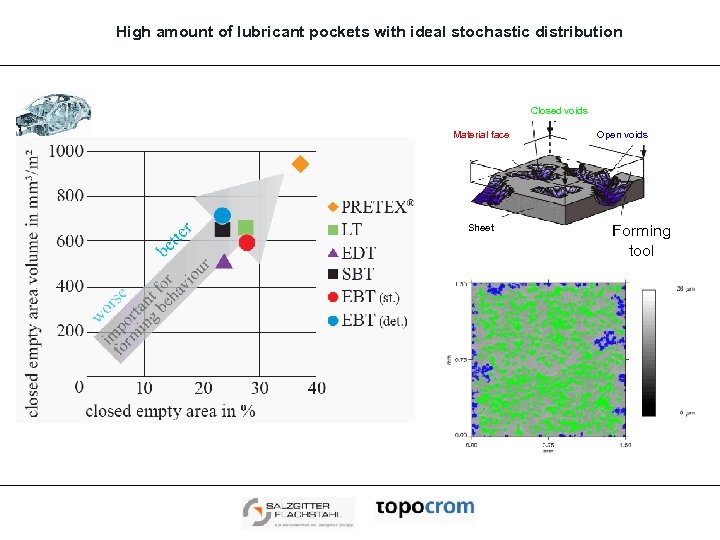

High amount of lubricant pockets with ideal stochastic distribution Closed voids Material face Sheet Open voids Forming tool

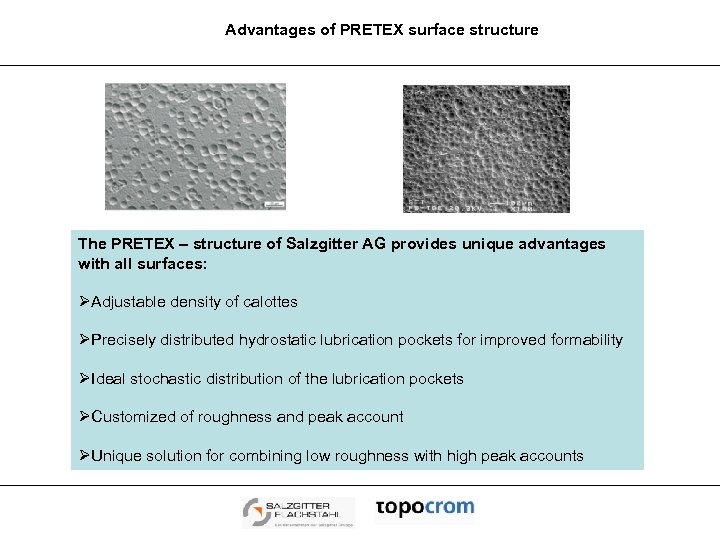

Advantages of PRETEX surface structure The PRETEX – structure of Salzgitter AG provides unique advantages with all surfaces: ØAdjustable density of calottes ØPrecisely distributed hydrostatic lubrication pockets for improved formability ØIdeal stochastic distribution of the lubrication pockets ØCustomized of roughness and peak account ØUnique solution for combining low roughness with high peak accounts

Structure of Presentation Ø TOPOCROM® - Electroplating Technology Ø Demands of the automotive industry on the surface structure ◄◄◄ of cold rolled sheet metal Ø Requirements of the steelmaking industry for texturing technology of working rolls for skin passing mills Ø PRETEX Surface Structure: Prospects

Increasing demands of the automotive industry on the sheet metal surface structure Actual and future demands of the automotive industry on the sheet metal surface structure ØImproved appearance of painted metal sheet surfaces ØCost saving with paint systems without filler ØImproved formability ØVery low abrasion in the forming tool ØStable surface characteristics along the entire strip width and length

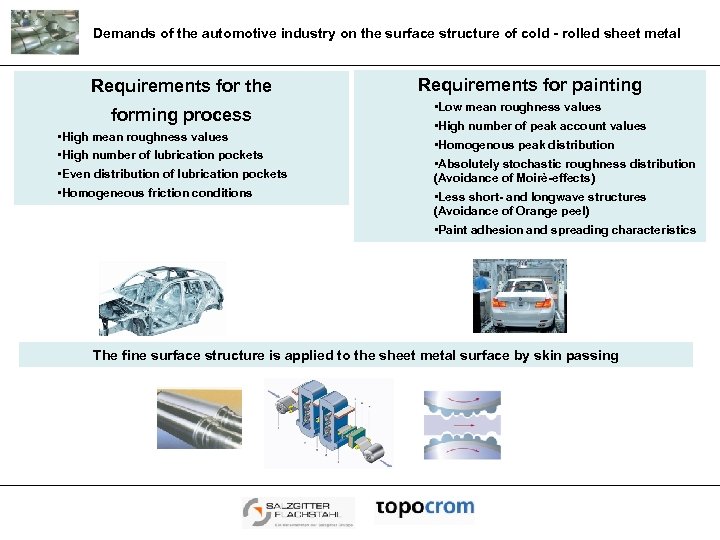

Demands of the automotive industry on the surface structure of cold - rolled sheet metal Requirements for the forming process • High mean roughness values • High number of lubrication pockets • Even distribution of lubrication pockets • Homogeneous friction conditions Requirements for painting • Low mean roughness values • High number of peak account values • Homogenous peak distribution • Absolutely stochastic roughness distribution (Avoidance of Moirè-effects) • Less short- and longwave structures (Avoidance of Orange peel) • Paint adhesion and spreading characteristics The fine surface structure is applied to the sheet metal surface by skin passing

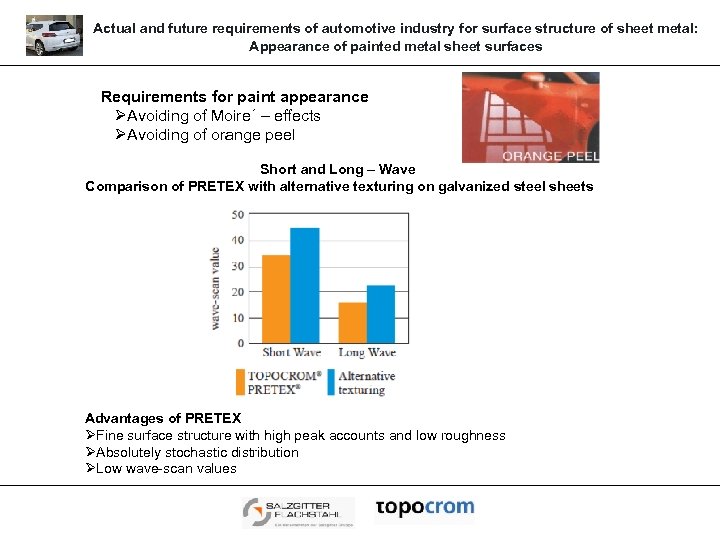

Actual and future requirements of automotive industry for surface structure of sheet metal: Appearance of painted metal sheet surfaces Requirements for paint appearance ØAvoiding of Moire΄ – effects ØAvoiding of orange peel Short and Long – Wave Comparison of PRETEX with alternative texturing on galvanized steel sheets Advantages of PRETEX ØFine surface structure with high peak accounts and low roughness ØAbsolutely stochastic distribution ØLow wave-scan values

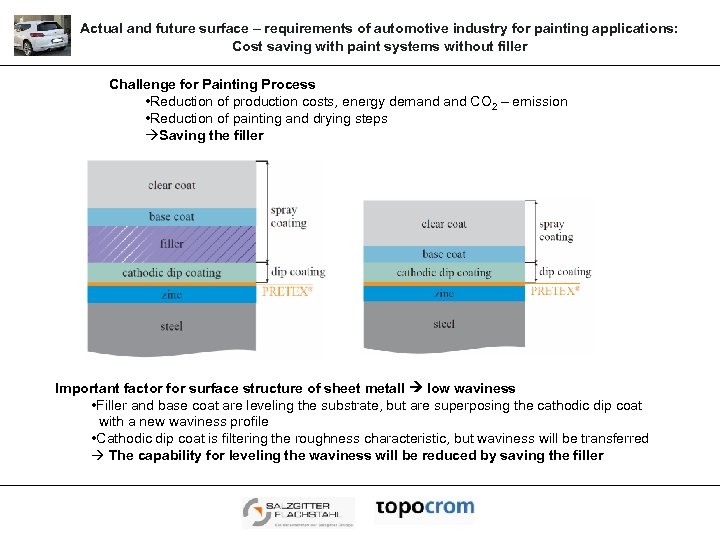

Actual and future surface – requirements of automotive industry for painting applications: Cost saving with paint systems without filler Challenge for Painting Process • Reduction of production costs, energy demand CO 2 – emission • Reduction of painting and drying steps Saving the filler Important factor for surface structure of sheet metall low waviness • Filler and base coat are leveling the substrate, but are superposing the cathodic dip coat with a new waviness profile • Cathodic dip coat is filtering the roughness characteristic, but waviness will be transferred The capability for leveling the waviness will be reduced by saving the filler

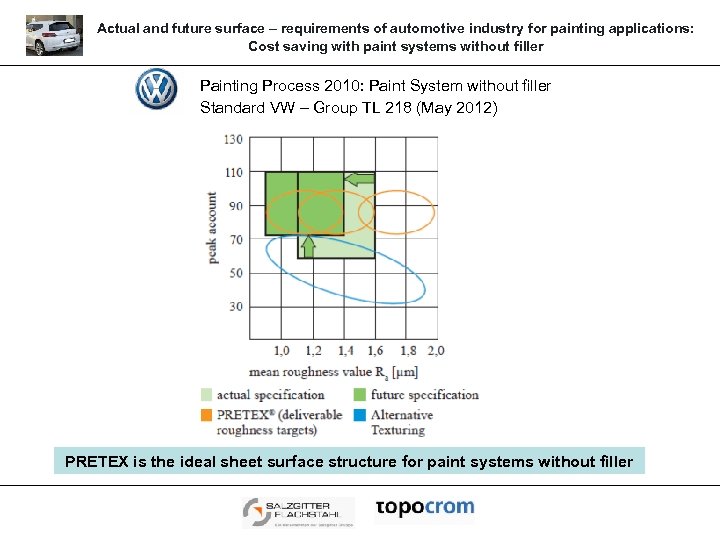

Actual and future surface – requirements of automotive industry for painting applications: Cost saving with paint systems without filler Painting Process 2010: Paint System without filler Standard VW – Group TL 218 (May 2012) PRETEX is the ideal sheet surface structure for paint systems without filler

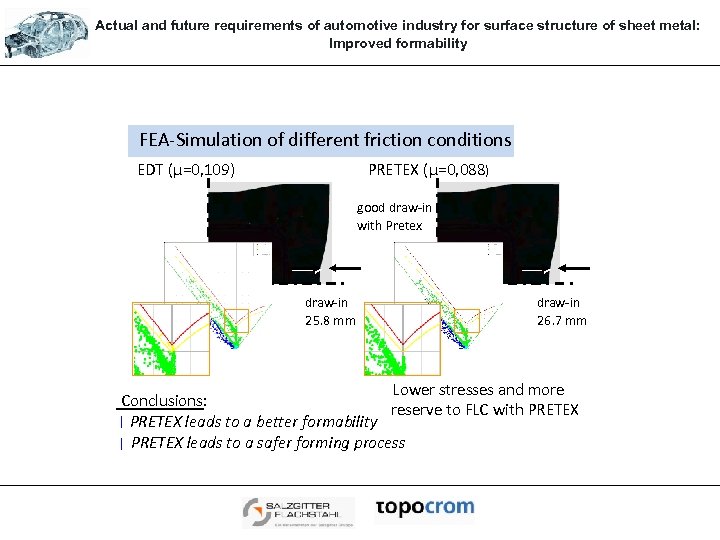

Actual and future requirements of automotive industry for surface structure of sheet metal: Improved formability FEA-Simulation of different friction conditions EDT (µ=0, 109) PRETEX (µ=0, 088) good draw-in with Pretex draw-in 25. 8 mm draw-in 26. 7 mm Lower stresses and more Conclusions: reserve to FLC with PRETEX leads to a better formability l l PRETEX leads to a safer forming process

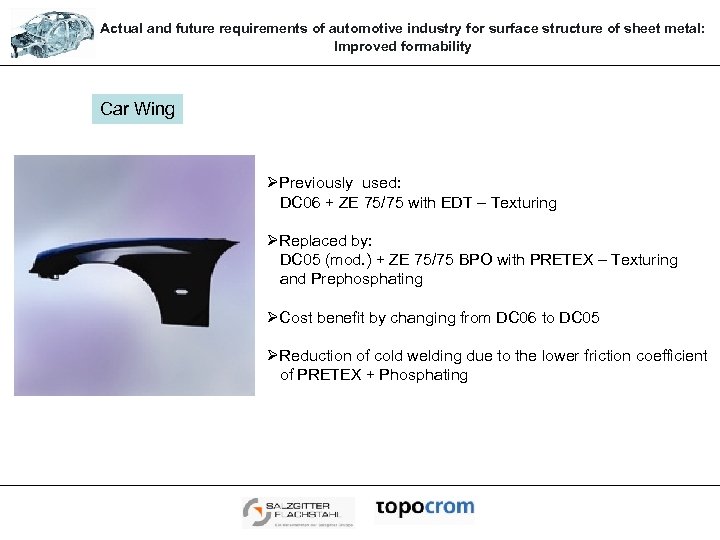

Actual and future requirements of automotive industry for surface structure of sheet metal: Improved formability Car Wing ØPreviously used: DC 06 + ZE 75/75 with EDT – Texturing ØReplaced by: DC 05 (mod. ) + ZE 75/75 BPO with PRETEX – Texturing and Prephosphating ØCost benefit by changing from DC 06 to DC 05 ØReduction of cold welding due to the lower friction coefficient of PRETEX + Phosphating

Actual and future requirements of automotive industry for surface structure of sheet metal: Less abrasion in the forming tool Body-contoured seat ØPreviously used: DC 05 with SBT – Texturing ØReplaced by: DC 05 with PRETEX – Texturing ØCost neutral in steel price Ø 30% reducing of lubrication volume ØReduced cleaning work before cathodic dip coating

Structure of Presentation Ø TOPOCROM® - Electroplating Technology Ø Demands of the automotive industry on the surface structure of cold rolled sheet metal Ø Requirements of the steelmaking industry for texturing technology ◄◄◄ of working rolls for skin passing mills Ø PRETEX Surface Structure: Prospects

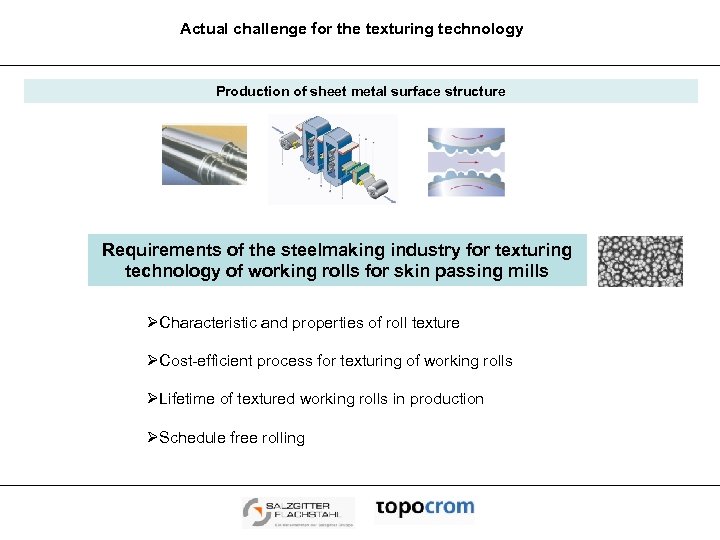

Actual challenge for the texturing technology Production of sheet metal surface structure Requirements of the steelmaking industry for texturing technology of working rolls for skin passing mills ØCharacteristic and properties of roll texture ØCost-efficient process for texturing of working rolls ØLifetime of textured working rolls in production ØSchedule free rolling

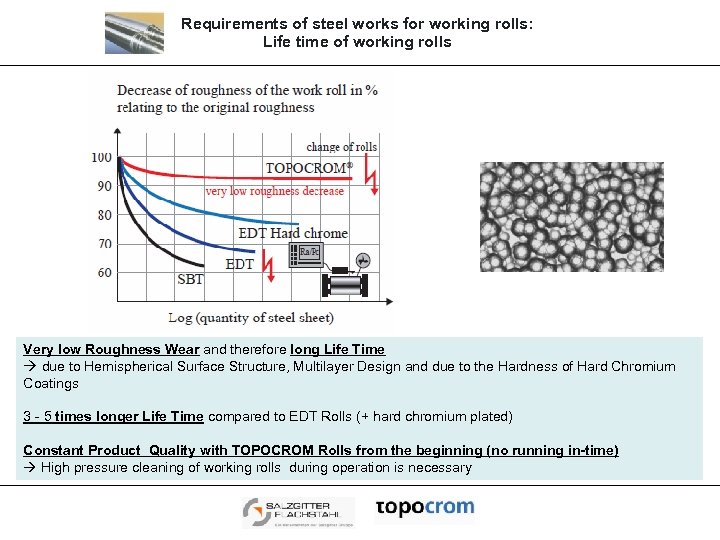

Requirements of steel works for working rolls: Life time of working rolls Very low Roughness Wear and therefore long Life Time due to Hemispherical Surface Structure, Multilayer Design and due to the Hardness of Hard Chromium Coatings 3 - 5 times longer Life Time compared to EDT Rolls (+ hard chromium plated) Constant Product Quality with TOPOCROM Rolls from the beginning (no running in-time) High pressure cleaning of working rolls during operation is necessary

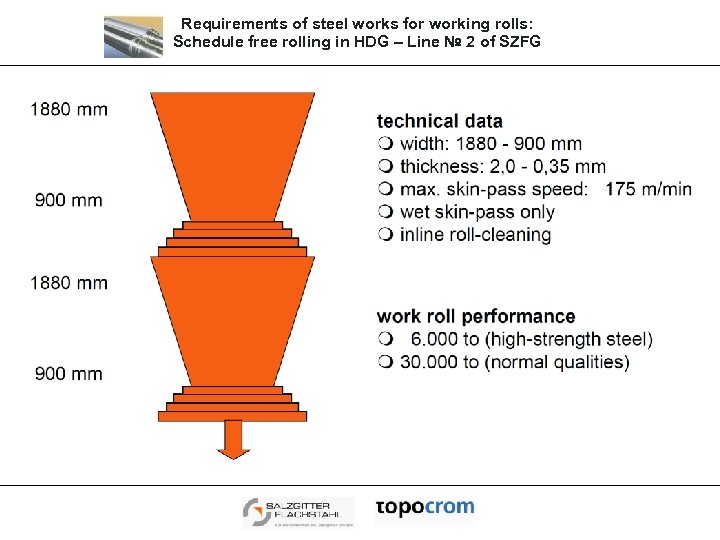

Requirements of steel works for working rolls: Schedule free rolling in HDG – Line № 2 of SZFG

TOPOCROM – Texturing Technology: Benefits for Steelmakers • Quality advantages for customers regarding formability and paint appearance • Customized adjustment of all structure parameters • Constant high surface quality of the metal sheets • Stable surface characteristics along the entire strip width and length • Reliable reproducibility • Significant increased Roll Life Time • Reduced number of roll changes • Remarkable reduction in grinding and texturing costs • Increased total service life of the roll and total productivity due to less grinding operations • Reduction of roll inventory • Higher productivity • Reduced costs • High wear resistance of TOPOCROM – Rolls allows Schedule Free Rolling • Increased productivity/higher mill availability • Reduction of roll inventory • Modest technological invest • Low capital and manufacturing costs

TOPOCROM® - PRETEX Surface Structure: Advantages for the automotive industry Advantages of PRETEX – Steel Sheet Surface Structure for Forming: • Low Friction Coefficient • Building of closed Lubricant Pockets • High amount of Closed Lubricant Pockets with equal Distribution improves formability and reduces abrasion in forming tools. • Customized surface structure/roughness/peak account Advantages for Painting: • Perfect Stochastic Distribution (no Moiré – Effect) • High Peak Count Values (Pc) together with higher Roughness Values • Homogenous Peak Distribution • Less Short Wave/Long Wave structures improve painting appearance TOPOCROM structured Sheets: Trade Names PRETEX® of Salzgitter AG and POSTEX® of POSCO

Structure of the Presentation Ø TOPOCROM® - Electroplating Technology Ø Demands of the automotive industry on the surface structure of cold rolled sheet metal Ø Requirements of the steelmaking industry for texturing technology of working rolls for skin passing mills Ø PRETEX Surface Structure: Prospects ◄◄◄

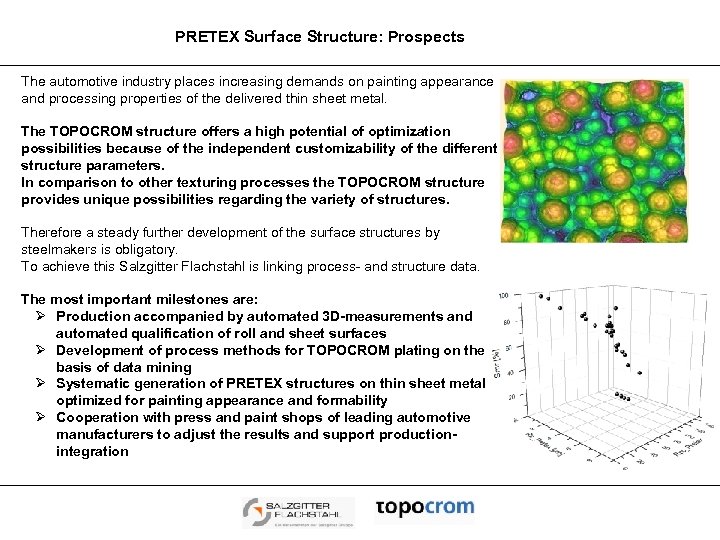

PRETEX Surface Structure: Prospects The automotive industry places increasing demands on painting appearance and processing properties of the delivered thin sheet metal. The TOPOCROM structure offers a high potential of optimization possibilities because of the independent customizability of the different structure parameters. In comparison to other texturing processes the TOPOCROM structure provides unique possibilities regarding the variety of structures. Therefore a steady further development of the surface structures by steelmakers is obligatory. To achieve this Salzgitter Flachstahl is linking process- and structure data. The most important milestones are: Ø Production accompanied by automated 3 D-measurements and automated qualification of roll and sheet surfaces Ø Development of process methods for TOPOCROM plating on the basis of data mining Ø Systematic generation of PRETEX structures on thin sheet metal optimized for painting appearance and formability Ø Cooperation with press and paint shops of leading automotive manufacturers to adjust the results and support productionintegration

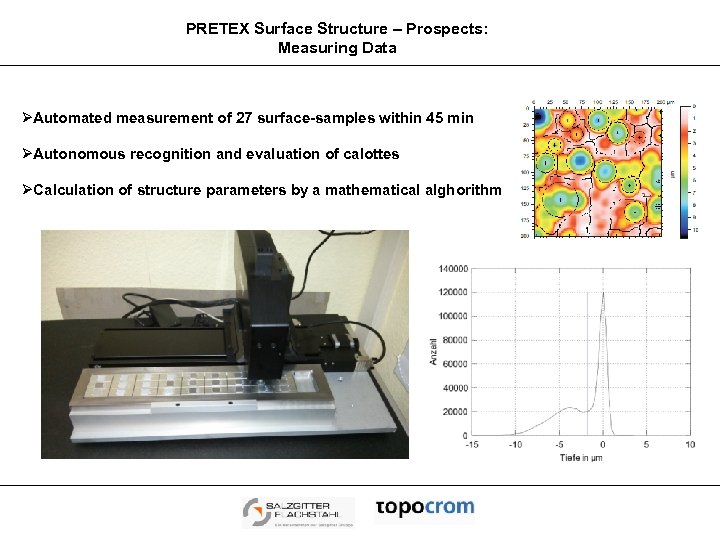

PRETEX Surface Structure – Prospects: Measuring Data ØAutomated measurement of 27 surface-samples within 45 min ØAutonomous recognition and evaluation of calottes ØCalculation of structure parameters by a mathematical alghorithm

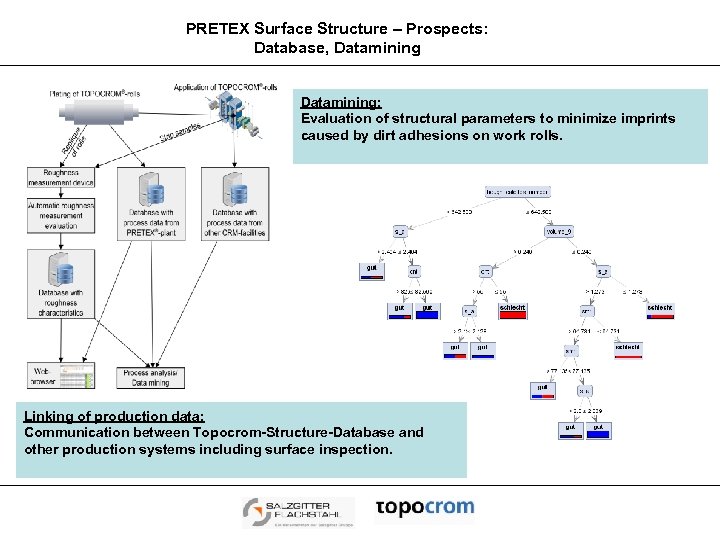

PRETEX Surface Structure – Prospects: Database, Datamining: Evaluation of structural parameters to minimize imprints caused by dirt adhesions on work rolls. Linking of production data: Communication between Topocrom-Structure-Database and other production systems including surface inspection.

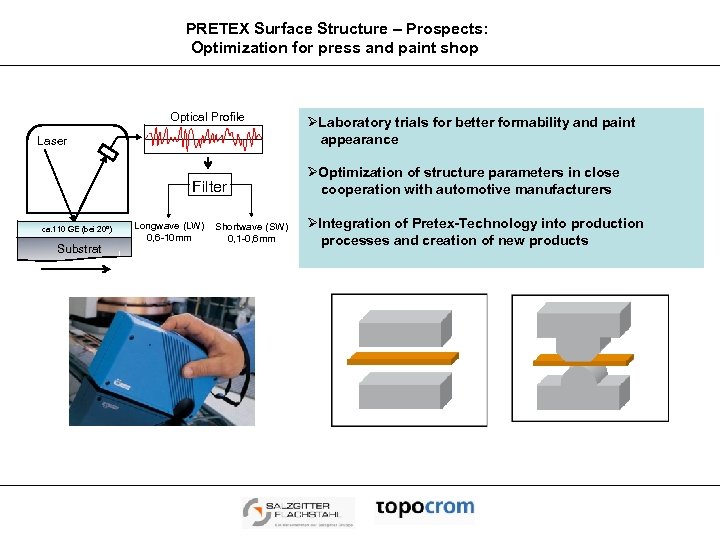

PRETEX Surface Structure – Prospects: Optimization for press and paint shop Optical Profile Laser Filter ca. 110 GE (bei 20°) Substrat Longwave (LW) 0, 6 -10 mm Shortwave (SW) 0, 1 -0, 6 mm ØLaboratory trials for better formability and paint appearance ØOptimization of structure parameters in close cooperation with automotive manufacturers ØIntegration of Pretex-Technology into production processes and creation of new products

BAOSTEEL BAC 2013, Shanghai (China) TOPOCROM® – Texturing: Technology and Advantages Thomas Routschek Salzgitter Flachstahl, Salzgitter (Germany) Karl Müll TOPOCROM Systems AG, Weinfelden (Switzerland)

4e476f5a5cfe1b89571c6429e272d43e.ppt