dd5c0d96c5c10d91bbc2897687108a68.ppt

- Количество слайдов: 51

Bangalore 1 MBA, Semester 2 Operations Management Ms. Aarti Mehta Sharma

Bangalore 2

Bangalore 3 Inventory Management EOQ, EBQ Types of inventory

Inventory Bangalore • Stock of any item or resource used in an organisation • Inventory system is the set of policies and controls that monitor levels of inventory and determine what levels should be maintained 4

Bangalore Inventory management Inventory is working capital - How much to keep ? - When to store ? - When to order ? - How large the order should be ? 5

If not being able to fill the order … • • Bangalore Cancel the order Buy from another dealer and resell Postpone order Rearrange deliveries to various customers so that no goodwill is lost TO AVOID THE ABOVE - INVENTORY MANAGEMENT 6

Purpose • • Bangalore To maintain independence of operations To meet variation in product demand To allow flexibility in production scheduling To provide a safeguard for variation in raw material delivery time • To take advantage of economic purchase order size ( larger shipment – lower price per unit ) 7

Bangalore Kinds 8 • • Production Inventories MRO Inventories In Process Inventories Finished Goods Inventories

Production Inventory Bangalore • Items that contribute to or become part of a firms product output - Raw materials - Finished goods - Component parts - Supplies 9

MRO Inventories Bangalore Maintenance, repair, and operating supplies which are consumed in the production process but which do not become part of the product (eg. Lubricating oil, soap, machine repair parts) 10

Bangalore In Process Inventories Semi Finished products found at various stages in the production operation 11

Bangalore Finished goods Inventories Completed products ready for shipment 12

Costs Bangalore • Holding costs : costs for storage, handling, insurance, pilferage, breakage, depreciation, taxes • Setup : while making different products cost of necessary materials, equipment, paperwork 13

Bangalore • Ordering Costs : managerial and clerical costs to prepare the production orders • Shortage costs : when the stock of an item is depleted, an order for that item must either wait until the stock is replenished or be cancelled. Higher inventory/ higher storage ---- higher costs 14

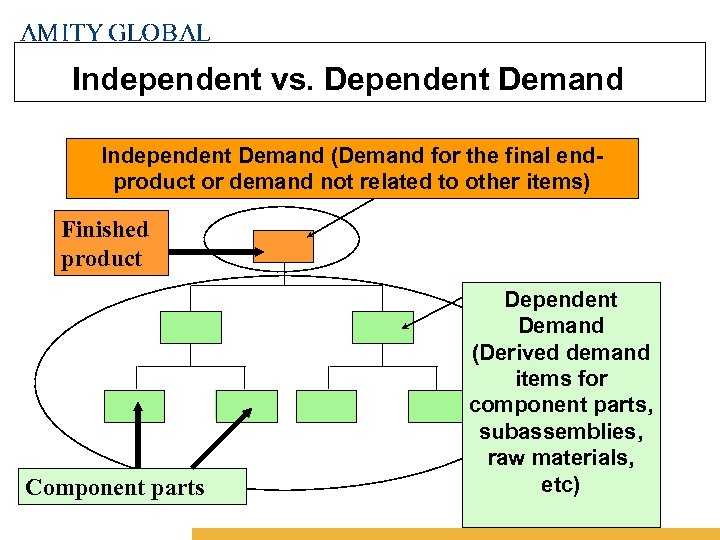

Bangalore Independent vs. Dependent Demand Independent Demand (Demand for the final endproduct or demand not related to other items) Finished product E(1) Component parts Dependent Demand (Derived demand items for component parts, subassemblies, raw materials, etc)

Bangalore 16

Demand Bangalore • Independent Demand : Demands for various items are unrelated to each other • Dependent Demand : need for any item is a direct result of the demand for some other item For Eg: if output is 400 cars per day, demand ---2000 tyres (min) 17

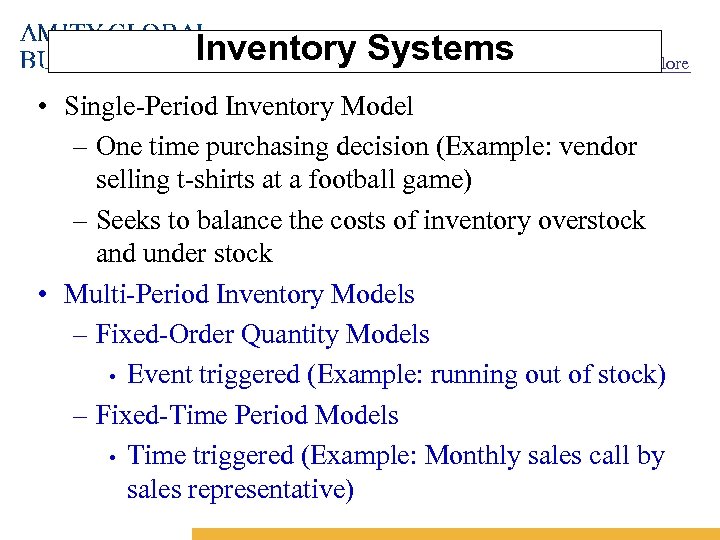

Inventory Systems Bangalore • Single-Period Inventory Model – One time purchasing decision (Example: vendor selling t-shirts at a football game) – Seeks to balance the costs of inventory overstock and under stock • Multi-Period Inventory Models – Fixed-Order Quantity Models • Event triggered (Example: running out of stock) – Fixed-Time Period Models • Time triggered (Example: Monthly sales call by sales representative)

Two approaches to multi period inventory systems Bangalore 19 • Fixed order Quantity System (Q system) • Fixed order period system (P system)

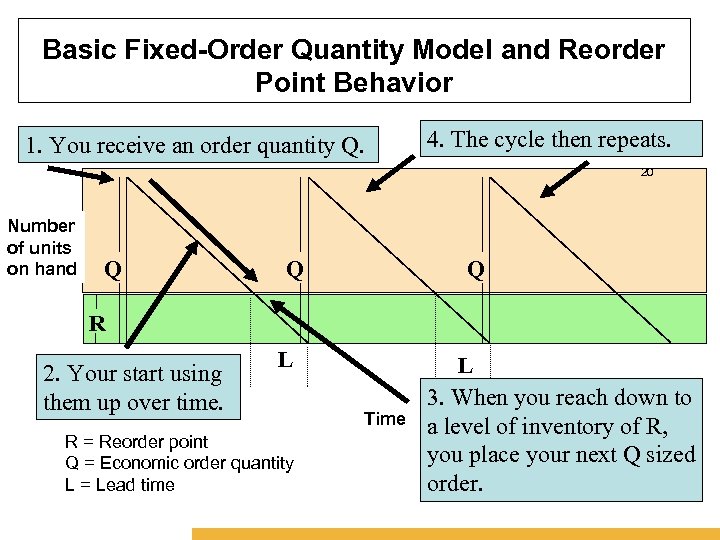

Basic Fixed-Order Quantity Model and Reorder Bangalore Point Behavior 1. You receive an order quantity Q. 4. The cycle then repeats. 20 Number of units on hand Q Q Q R 2. Your start using them up over time. L R = Reorder point Q = Economic order quantity L = Lead time Time L 3. When you reach down to a level of inventory of R, you place your next Q sized order.

Bangalore Optimal Order Quantity • • A = annual consumption of a material Q = quantity of one order L = Lead time for supply Cc / Ch = cost of carrying an inventory of one unit per year 21

Bangalore • Cp/Co= cost of procurement ordering per order • Total Cost = carrying cost + ordering cost = Cc ×Q/2 + Cp × A/Q 22

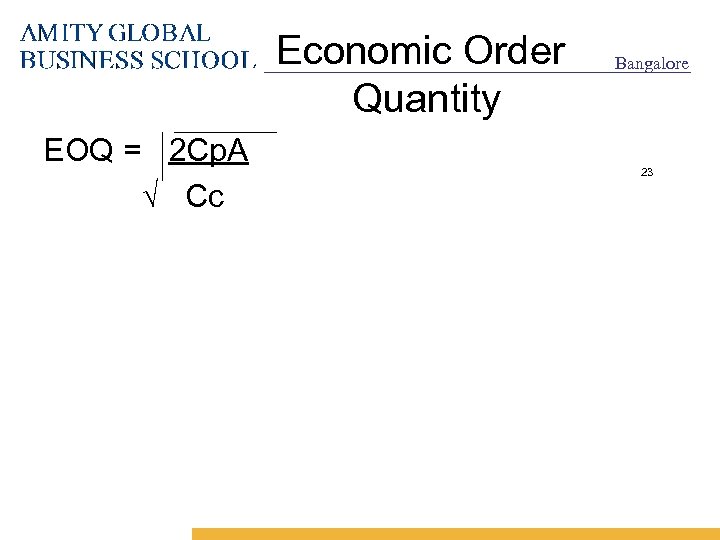

Economic Order Quantity EOQ = 2 Cp. A √ Cc Bangalore 23

Assumptions of EOQ formula Bangalore • Material has a uniform rate of consumption • Material is supplied without fail Thus, no variation in supply and demand is assumed 24

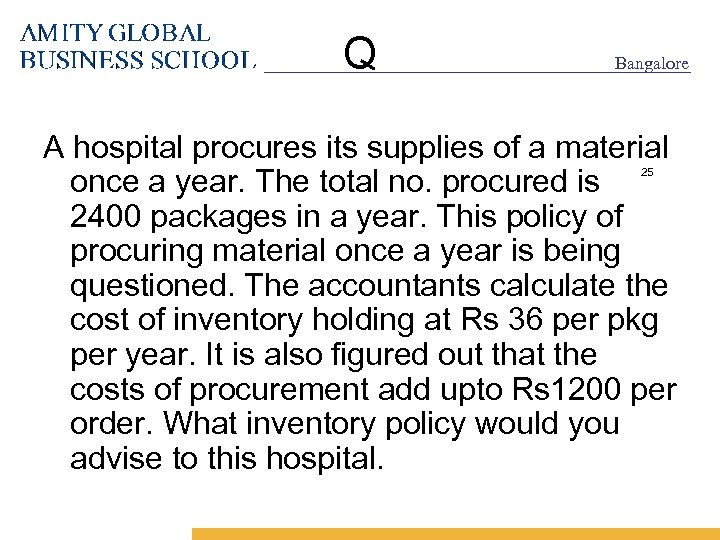

Q Bangalore A hospital procures its supplies of a material once a year. The total no. procured is 2400 packages in a year. This policy of procuring material once a year is being questioned. The accountants calculate the cost of inventory holding at Rs 36 per pkg per year. It is also figured out that the costs of procurement add upto Rs 1200 per order. What inventory policy would you advise to this hospital. 25

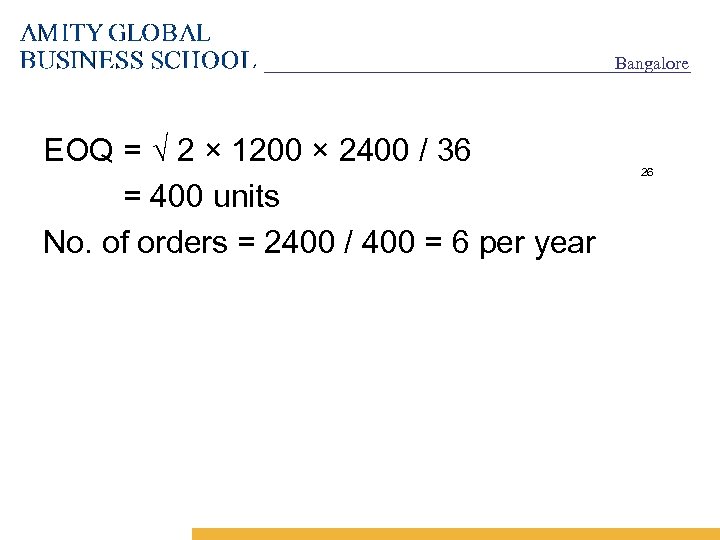

Bangalore EOQ = √ 2 × 1200 × 2400 / 36 = 400 units No. of orders = 2400 / 400 = 6 per year 26

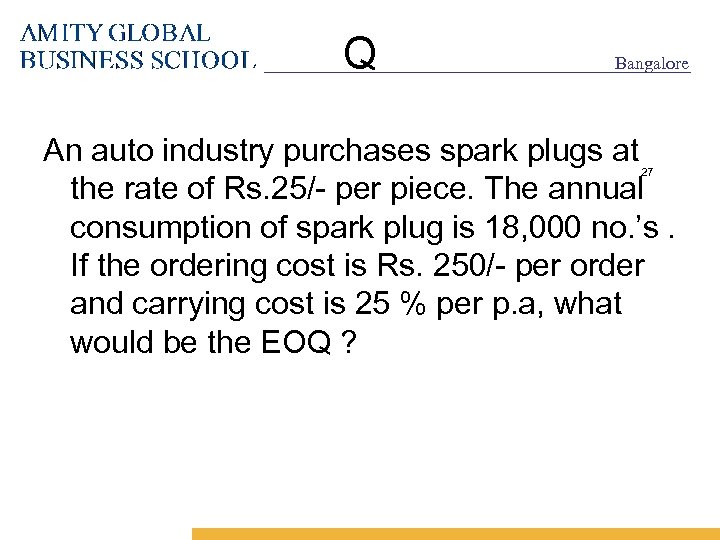

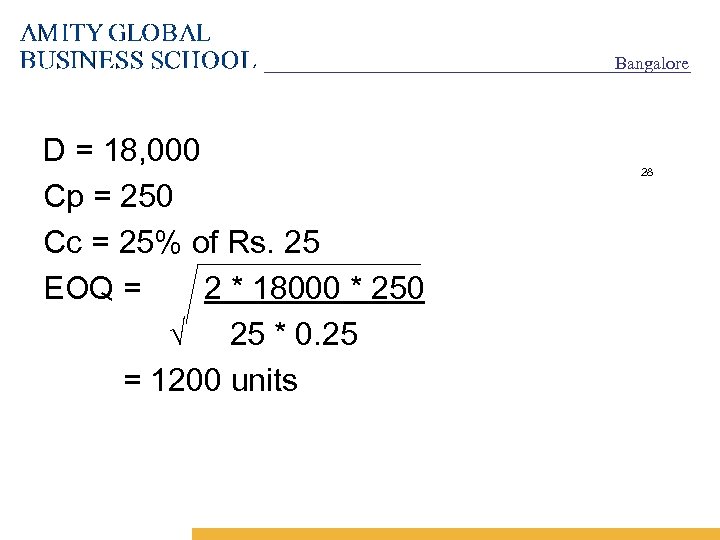

Q Bangalore An auto industry purchases spark plugs at the rate of Rs. 25/- per piece. The annual consumption of spark plug is 18, 000 no. ’s. If the ordering cost is Rs. 250/- per order and carrying cost is 25 % per p. a, what would be the EOQ ? 27

Bangalore D = 18, 000 Cp = 250 Cc = 25% of Rs. 25 EOQ = 2 * 18000 * 250 √ 25 * 0. 25 = 1200 units 28

Bangalore Economic batch quantity (EBQ), also called "optimal batch quantity" or economic production quantity is a measure used to determine the quantity of units that can be produced at minimum average costs in a given batch or production run. 29

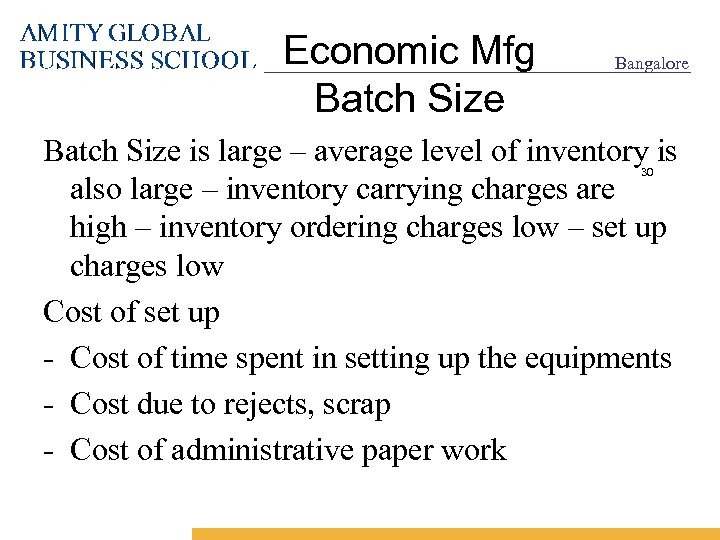

Economic Mfg Batch Size Bangalore Batch Size is large – average level of inventory is also large – inventory carrying charges are high – inventory ordering charges low – set up charges low Cost of set up - Cost of time spent in setting up the equipments - Cost due to rejects, scrap - Cost of administrative paper work 30

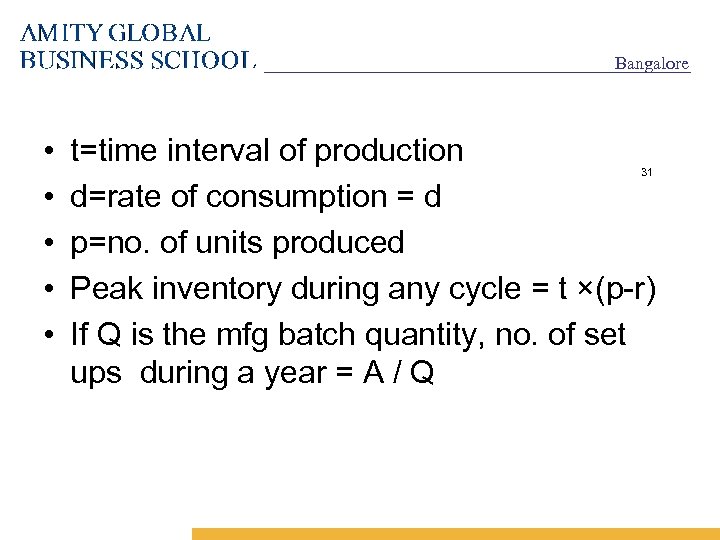

Bangalore • • • t=time interval of production d=rate of consumption = d p=no. of units produced Peak inventory during any cycle = t ×(p-r) If Q is the mfg batch quantity, no. of set ups during a year = A / Q 31

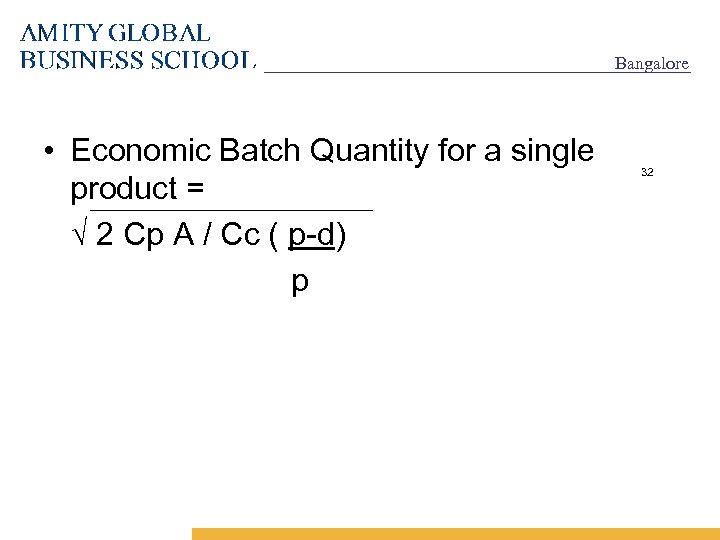

Bangalore • Economic Batch Quantity for a single product = √ 2 Cp A / Cc ( p-d) p 32

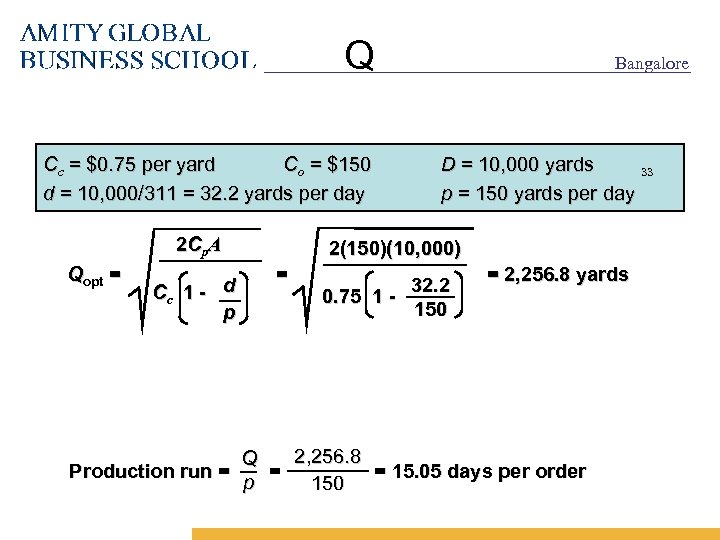

Q Cc = $0. 75 per yard Co = $150 d = 10, 000/311 = 32. 2 yards per day 2 Cp A Qopt = Cc 1 - d p Bangalore D = 10, 000 yards 33 p = 150 yards per day 2(150)(10, 000) = 32. 2 0. 75 1 150 = 2, 256. 8 yards 2, 256. 8 Q Production run = = = 15. 05 days per order p 150

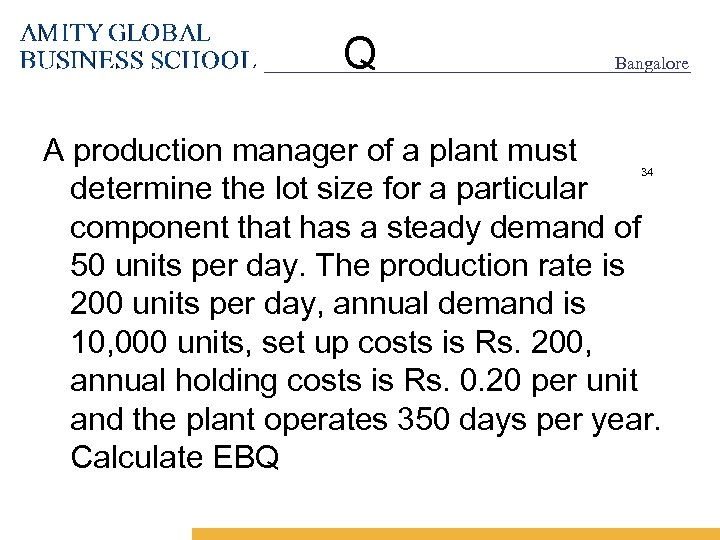

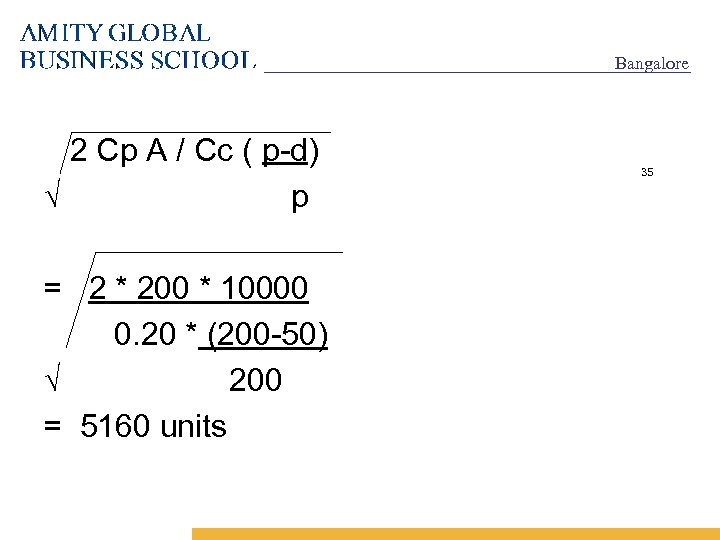

Q Bangalore A production manager of a plant must determine the lot size for a particular component that has a steady demand of 50 units per day. The production rate is 200 units per day, annual demand is 10, 000 units, set up costs is Rs. 200, annual holding costs is Rs. 0. 20 per unit and the plant operates 350 days per year. Calculate EBQ 34

Bangalore 2 Cp A / Cc ( p-d) √ p = 2 * 200 * 10000 0. 20 * (200 -50) √ 200 = 5160 units 35

Classification of Materials Bangalore • Items of inventory are classified into A, B, C or other classes for selective management control • Depending upon - necessity of control - relative importance of material - particular characteristic of matl 36

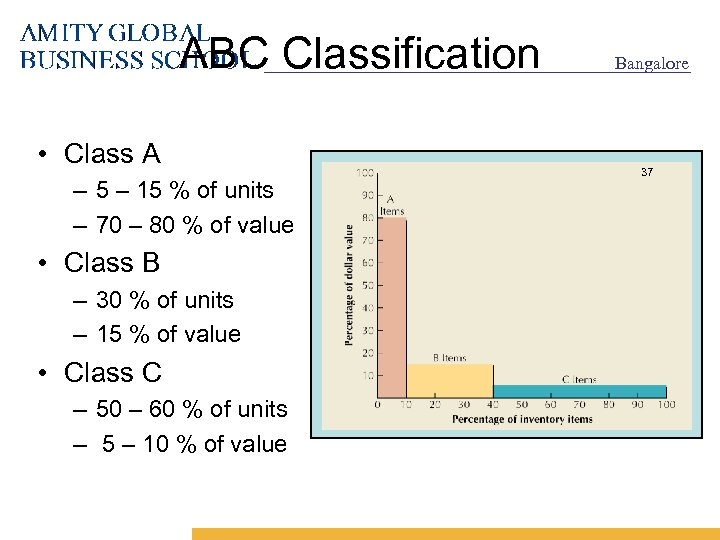

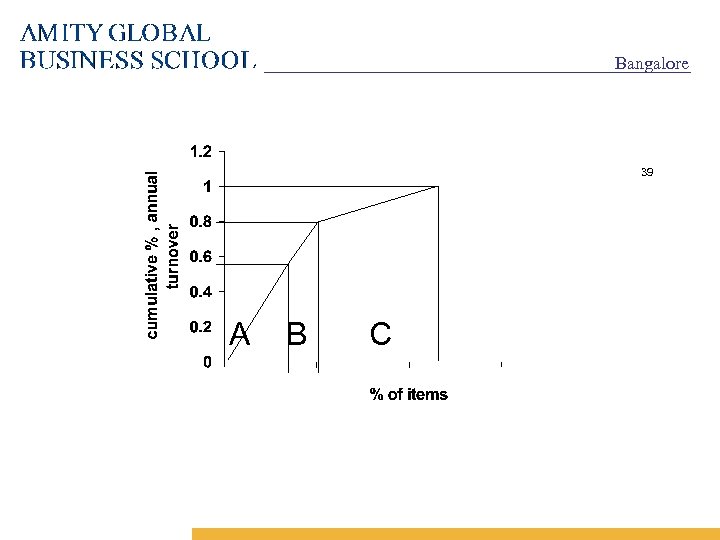

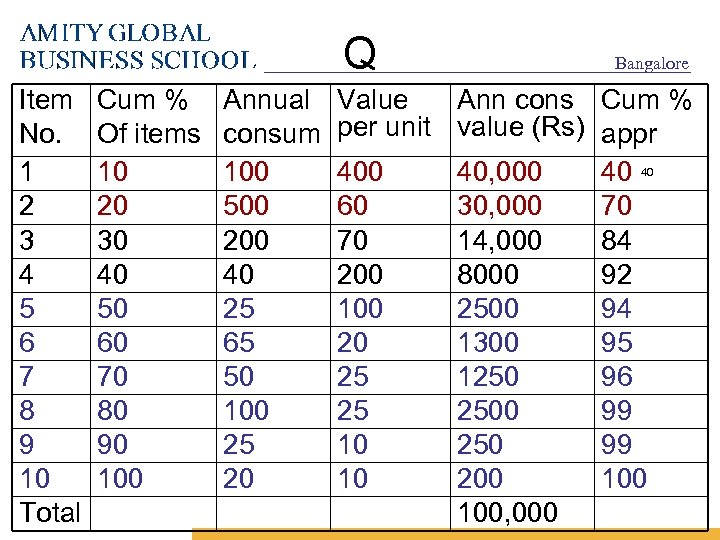

ABC Classification • Class A – 5 – 15 % of units – 70 – 80 % of value • Class B – 30 % of units – 15 % of value • Class C – 50 – 60 % of units – 5 – 10 % of value Bangalore 37

Bangalore ABC Analysis • Based upon relative importance of the materials • Basis : price / criticality / non availability / weight • Annual consumption value of the items 38

Bangalore 39 A B C

Q Item No. 1 2 3 4 5 6 7 8 9 10 Total Cum % Of items 10 20 30 40 50 60 70 80 90 100 Annual consum 100 500 200 40 25 65 50 100 25 20 Bangalore Value Ann cons Cum % per unit value (Rs) appr 400 40, 000 40 60 30, 000 70 70 14, 000 84 200 8000 92 100 2500 94 20 1300 95 25 1250 96 25 2500 99 10 250 99 10 200 100, 000 40

Probabilistic Inventory Models Bangalore In reality, the demand is not uniform, it follows some prob distn. We minimise the expected costs rather than the actual costs. 41

Eg : Bangalore The demand for a newspaper does not follow a fixed pattern. The associated prob distn may be discrete or continuous. For each unsold newspaper there will be a penalty marginal cost of surplus/unit C 1 = purchase price/unit – salvagevalue/unit For each shortage unit, there will be a penalty which is given by the formula marginal cost of shortage/unit C 2 = selling price/unit – purchase price/unit 42

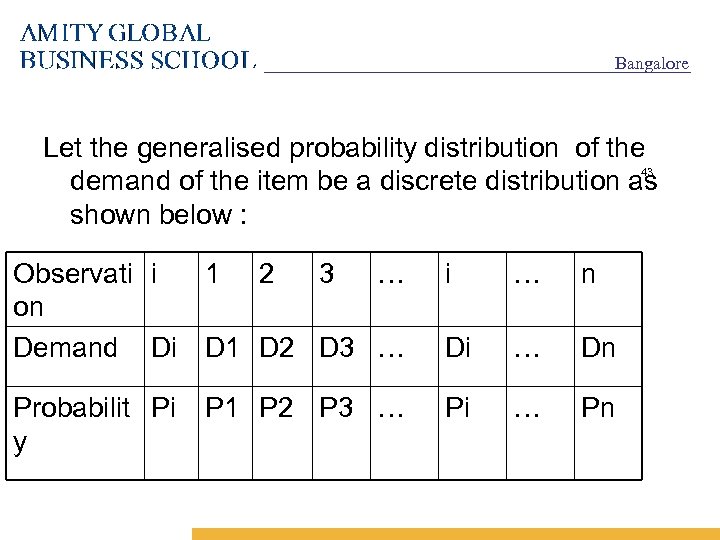

Bangalore Let the generalised probability distribution of the demand of the item be a discrete distribution as shown below : 43 Observati i 1 2 3 … on Demand Di D 1 D 2 D 3 … i … n Di … Dn Probabilit Pi y Pi … Pn P 1 P 2 P 3 …

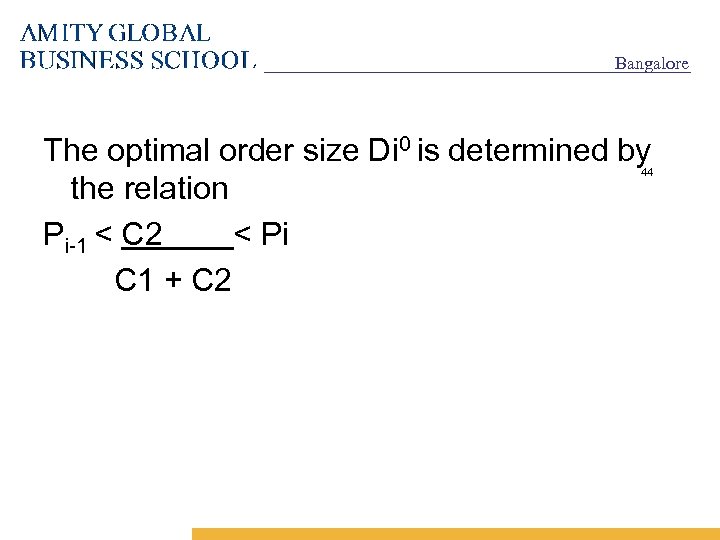

Bangalore The optimal order size Di 0 is determined by the relation Pi-1 < C 2 < Pi C 1 + C 2 44

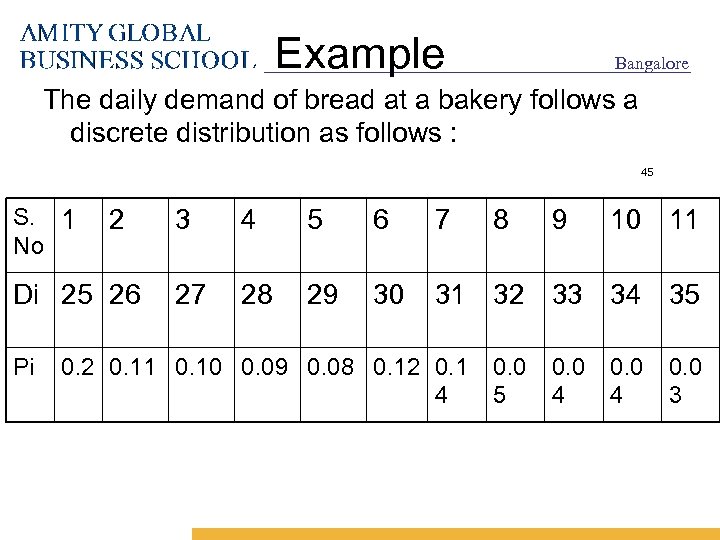

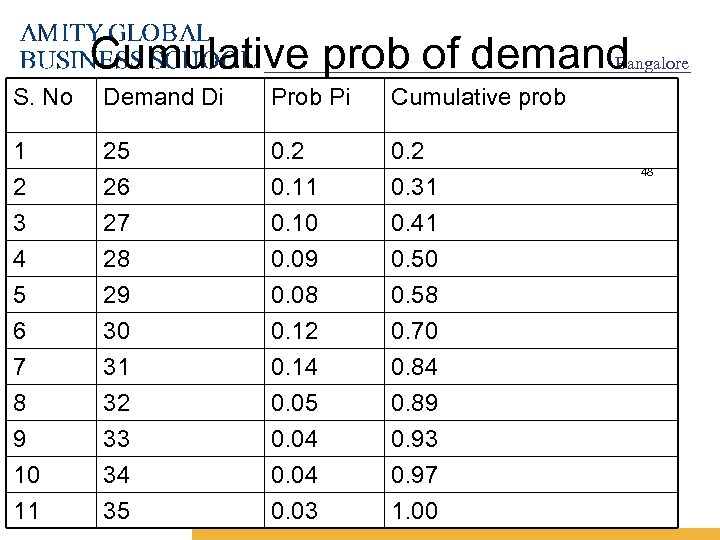

Example Bangalore The daily demand of bread at a bakery follows a discrete distribution as follows : 45 S. 1 No 2 Di 25 26 Pi 3 4 5 6 7 27 28 29 30 31 32 33 34 35 0. 2 0. 11 0. 10 0. 09 0. 08 0. 12 0. 1 4 8 0. 0 5 9 0. 0 4 10 11 0. 0 4 0. 0 3

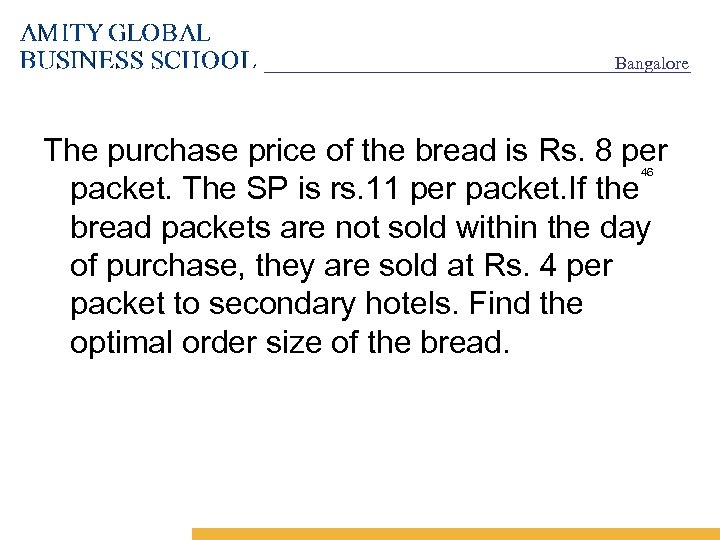

Bangalore The purchase price of the bread is Rs. 8 per packet. The SP is rs. 11 per packet. If the bread packets are not sold within the day of purchase, they are sold at Rs. 4 per packet to secondary hotels. Find the optimal order size of the bread. 46

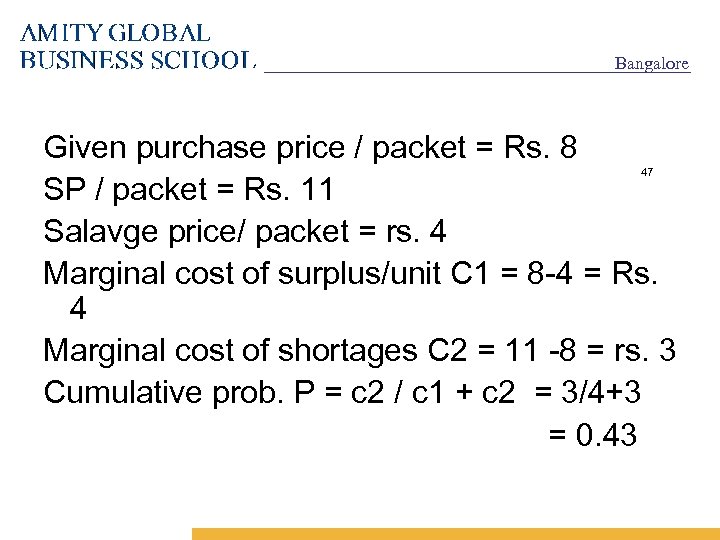

Bangalore Given purchase price / packet = Rs. 8 SP / packet = Rs. 11 Salavge price/ packet = rs. 4 Marginal cost of surplus/unit C 1 = 8 -4 = Rs. 4 Marginal cost of shortages C 2 = 11 -8 = rs. 3 Cumulative prob. P = c 2 / c 1 + c 2 = 3/4+3 = 0. 43 47

Cumulative prob of demand Bangalore S. No Demand Di Prob Pi Cumulative prob 1 2 25 26 0. 2 0. 11 0. 2 0. 31 3 4 5 6 7 8 9 10 11 27 28 29 30 31 32 33 34 35 0. 10 0. 09 0. 08 0. 12 0. 14 0. 05 0. 04 0. 03 0. 41 0. 50 0. 58 0. 70 0. 84 0. 89 0. 93 0. 97 1. 00 48

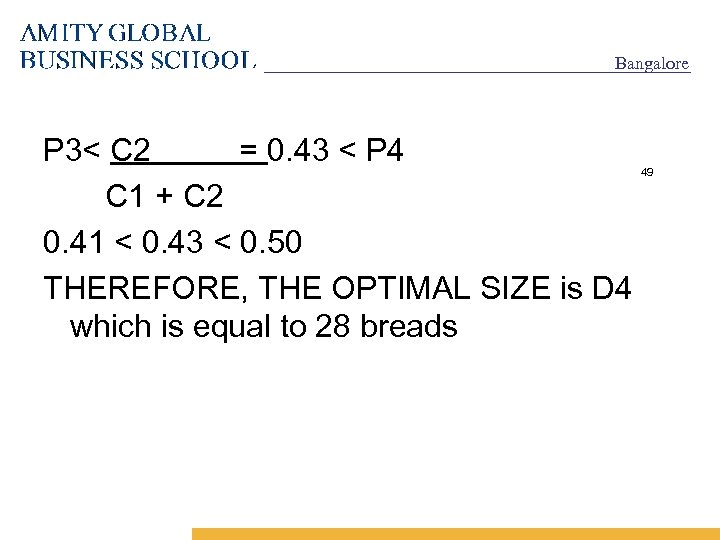

Bangalore P 3< C 2 = 0. 43 < P 4 C 1 + C 2 0. 41 < 0. 43 < 0. 50 THEREFORE, THE OPTIMAL SIZE is D 4 which is equal to 28 breads 49

Consideration of Uncertainities • Variable sales • Delay in supplies of raw material • Buffer stock – extra stock Bangalore 50

Explicit Bangalore Consideration of shortage costs Inventory control is the trade off between different costs : • Cost of not having the material in the quantity that is reqd – understocking cost • Cost of keeping excess material in stock for fear of demand rate variations - overstocking cost 51

dd5c0d96c5c10d91bbc2897687108a68.ppt