abf55cb5b92c3ef306a64f20c33b1d64.ppt

- Количество слайдов: 73

Bamboo as a Material for Housing and Buildings – Indian Experience Building Materials and Technology Promotion Council Ministry of Housing & Urban Poverty Alleviation Government of India

Traditional use of Wood and Bamboo

Forest Cover in India • 329 m hectares land area • 63. 34 m hectares notified as forest – 19. 15% • Dense forest - 11% • Open forest - 8% • Mangrove 0. 15% - Therefore, there is a need to save forest timber.

Bamboo Addresses THREE Major National Concerns ECOLOGICAL SECURITY: conservation of forests through timber substitution, alternate materials to non-biodegradable & high energy consuming materials like metals and plastics SUSTAINABLE FOOD SECURITY: bamboo based agro forestry system, maintenance of soil fertility of adjoining agricultural lands, and bamboo shoots LIVELIHOOD SECURITY: generation of employment in planting and primary processing for manufacturing mat based composites and other market driven bamboo products

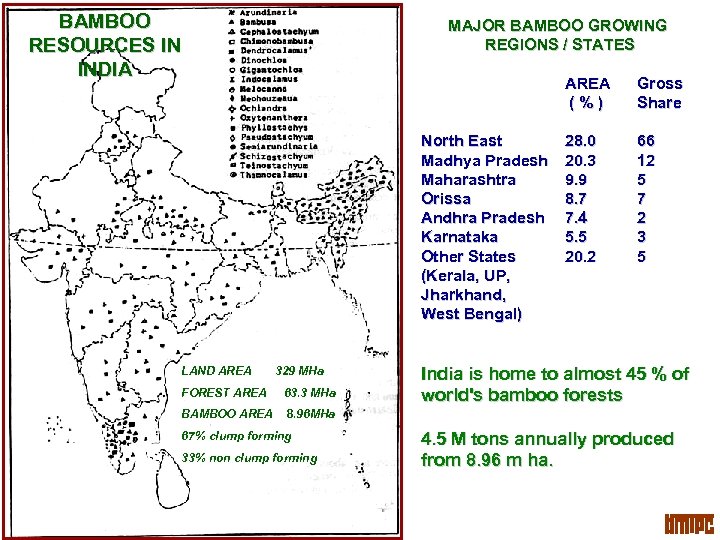

BAMBOO RESOURCES IN INDIA MAJOR BAMBOO GROWING REGIONS / STATES AREA (%) North East Madhya Pradesh Maharashtra Orissa Andhra Pradesh Karnataka Other States (Kerala, UP, Jharkhand, West Bengal) LAND AREA 329 MHa FOREST AREA 63. 3 MHa BAMBOO AREA Gross Share 28. 0 20. 3 9. 9 8. 7 7. 4 5. 5 20. 2 66 12 5 7 2 3 5 India is home to almost 45 % of world's bamboo forests 8. 96 MHa 67% clump forming 33% non clump forming 4. 5 M tons annually produced from 8. 96 m ha.

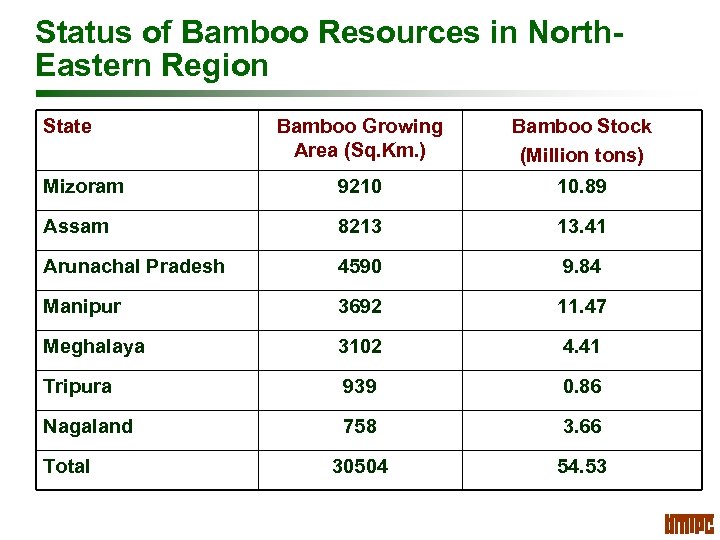

Status of Bamboo Resources in North. Eastern Region State Bamboo Growing Area (Sq. Km. ) Bamboo Stock (Million tons) Mizoram 9210 10. 89 Assam 8213 13. 41 Arunachal Pradesh 4590 9. 84 Manipur 3692 11. 47 Meghalaya 3102 4. 41 Tripura 939 0. 86 Nagaland 758 3. 66 30504 54. 53 Total

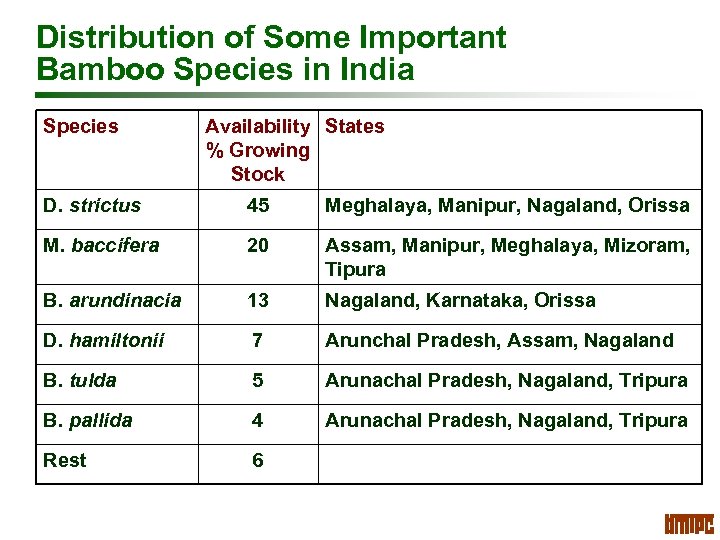

Distribution of Some Important Bamboo Species in India Species Availability States % Growing Stock D. strictus 45 Meghalaya, Manipur, Nagaland, Orissa M. baccifera 20 Assam, Manipur, Meghalaya, Mizoram, Tipura B. arundinacia 13 Nagaland, Karnataka, Orissa D. hamiltonii 7 Arunchal Pradesh, Assam, Nagaland B. tulda 5 Arunachal Pradesh, Nagaland, Tripura B. pallida 4 Arunachal Pradesh, Nagaland, Tripura Rest 6

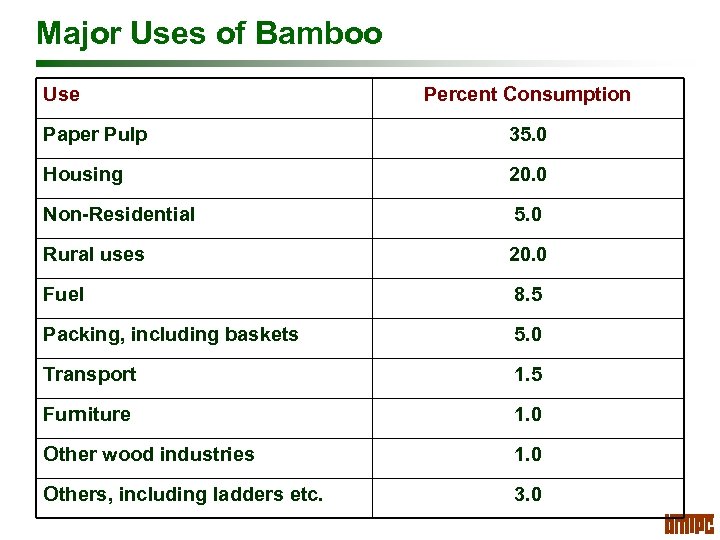

Major Uses of Bamboo Use Percent Consumption Paper Pulp 35. 0 Housing 20. 0 Non-Residential 5. 0 Rural uses 20. 0 Fuel 8. 5 Packing, including baskets 5. 0 Transport 1. 5 Furniture 1. 0 Other wood industries 1. 0 Others, including ladders etc. 3. 0

Characteristics affecting usefulness of bamboo as construction material - the strength of bamboo culms their straightness lightness combined with hardeners range and size of hollowers with good physical and mechanical properties, low shrinkage and average density, it is well suited to replace wood in several applications

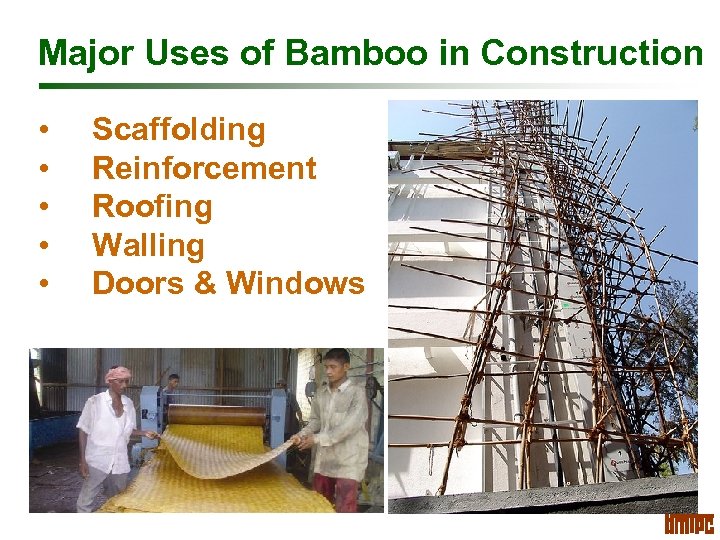

Major Uses of Bamboo in Construction • • • Scaffolding Reinforcement Roofing Walling Doors & Windows

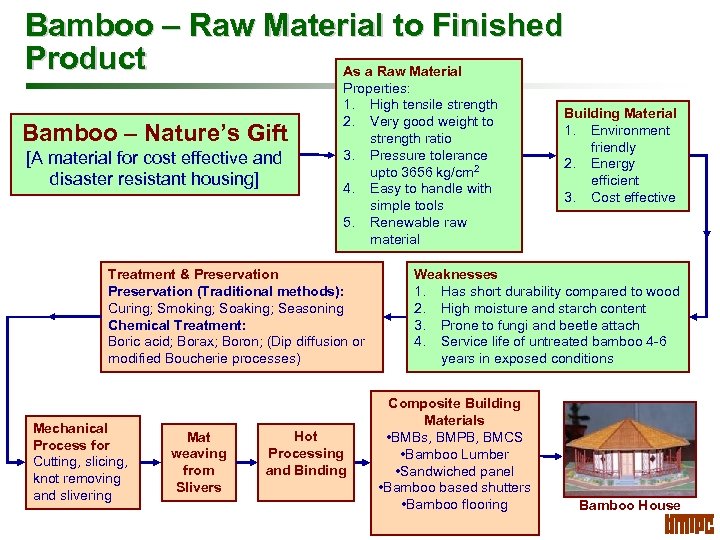

Bamboo – Raw Material to Finished Product As a Raw Material Bamboo – Nature’s Gift [A material for cost effective and disaster resistant housing] Properties: 1. High tensile strength 2. Very good weight to strength ratio 3. Pressure tolerance upto 3656 kg/cm 2 4. Easy to handle with simple tools 5. Renewable raw material Treatment & Preservation (Traditional methods): Curing; Smoking; Soaking; Seasoning Chemical Treatment: Boric acid; Borax; Boron; (Dip diffusion or modified Boucherie processes) Mechanical Process for Cutting, slicing, knot removing and slivering Mat weaving from Slivers Hot Processing and Binding Building Material 1. Environment friendly 2. Energy efficient 3. Cost effective Weaknesses 1. Has short durability compared to wood 2. High moisture and starch content 3. Prone to fungi and beetle attach 4. Service life of untreated bamboo 4 -6 years in exposed conditions Composite Building Materials • BMBs, BMPB, BMCS • Bamboo Lumber • Sandwiched panel • Bamboo based shutters • Bamboo flooring Bamboo House

Indian Specifications for Bamboo & Bamboo Products IS 14588 : 1999 Specification for Bamboo Mat Veneer Composite for General Purposes IS 13958 : 1994 Specification for Bamboo Mat Board for General Purposes IS 1902 : 1993 Code of Practice for Preservation of Bamboo and Cane for non-structural purposes IS 10145 : 1982 Specification for Bamboo Supports for Camouflaging Equipment IS 9096 : 1979 Code of Practice for Preservation of Bamboo and Cane for Structural purposes IS 8242 : 1976 Method of Tests for Split Bamboo IS 8295 : 1976 Specification for Bamboo Chicks ; Part 1 Fine, Part 2 Coarse IS 7344 : 1974 Specification for Bamboo Tent Pole IS 6874 : 1973 Method of Tests for Round Bamboo IS 15476 : 2004 Specification for Bamboo Mat Corrugated Sheets

Bamboo has lower natural durability against attack of fungi and insects - requires treatment to increase durability difficult to be treated by normal preservative methods in dry conditions. Best carried out in green conditions. IS 9096: 2006 : Code of Practice for preservation of bamboo for structural purpose Covers : Type of preservations, Treatment procedure for structural purposes like post, scaffolding, walls, trusses etc.

Preservatives Recommended - Coal Tar Creosote - Copper – chrome - arsenic compositions - Acid- cupric – chromate composition - Copper – chrome- born composition - Boni Acid – boxes - Copper zinc – napthanate Abietates

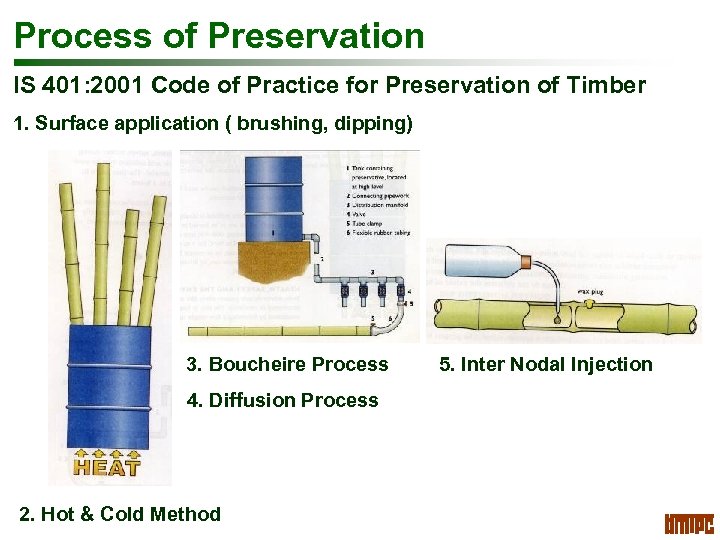

Process of Preservation IS 401: 2001 Code of Practice for Preservation of Timber 1. Surface application ( brushing, dipping) 3. Boucheire Process 4. Diffusion Process 2. Hot & Cold Method 5. Inter Nodal Injection

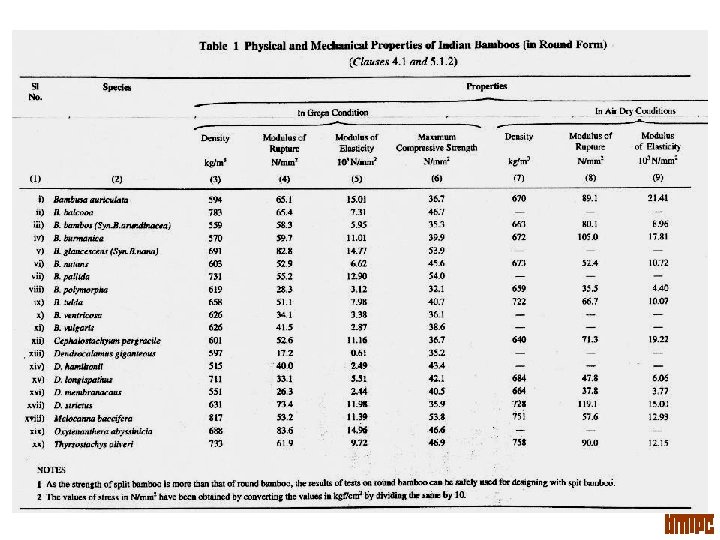

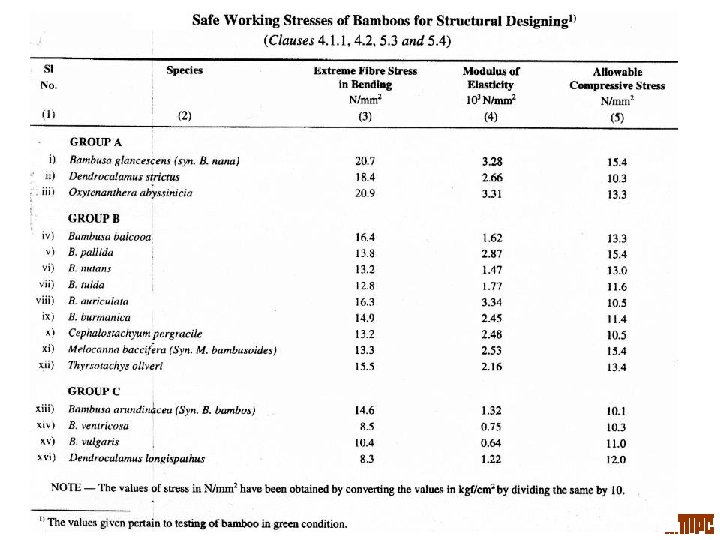

Structural Provision of Bamboo Part 6 : Structural Design Section 3: Timber and Bamboo: 3 B. Bamboo National Building Code. Material Specification - Physical and mechanical properties of 20 species of bamboo 16 species found suitable for structural purpose and densified in Group A, B, C.

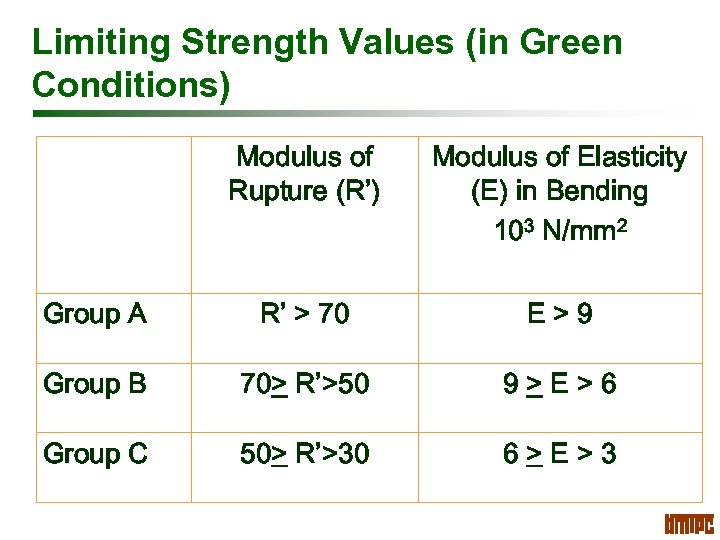

Limiting Strength Values (in Green Conditions) Modulus of Rupture (R’) Modulus of Elasticity (E) in Bending 103 N/mm 2 Group A R’ > 70 E>9 Group B 70> R’>50 9>E>6 Group C 50> R’>30 6>E>3

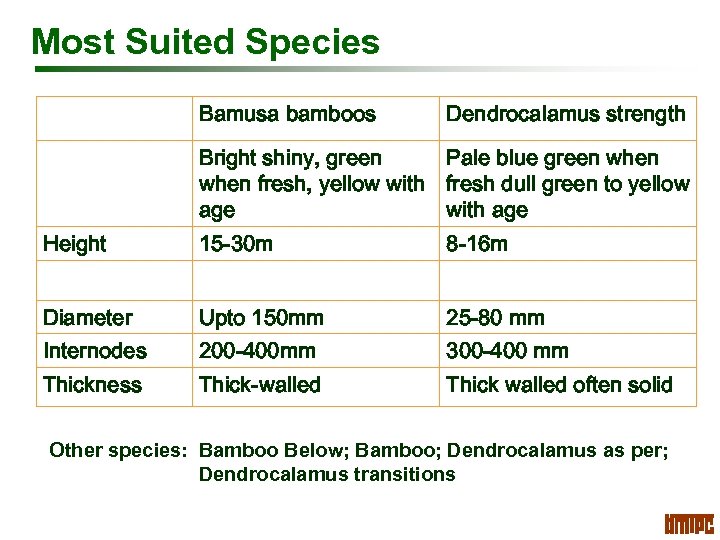

Most Suited Species Bamusa bamboos Dendrocalamus strength Bright shiny, green Pale blue green when fresh, yellow with fresh dull green to yellow age with age Height 15 -30 m 8 -16 m Diameter Upto 150 mm 25 -80 mm Internodes 200 -400 mm 300 -400 mm Thickness Thick-walled Thick walled often solid Other species: Bamboo Below; Bamboo; Dendrocalamus as per; Dendrocalamus transitions

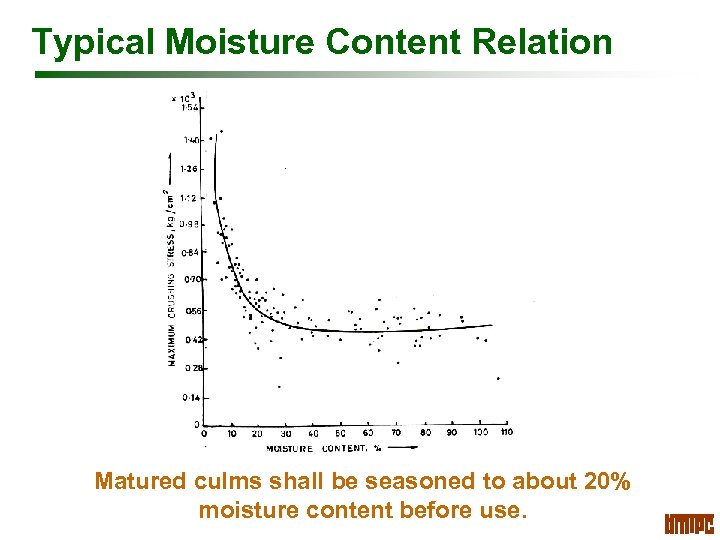

Typical Moisture Content Relation Matured culms shall be seasoned to about 20% moisture content before use.

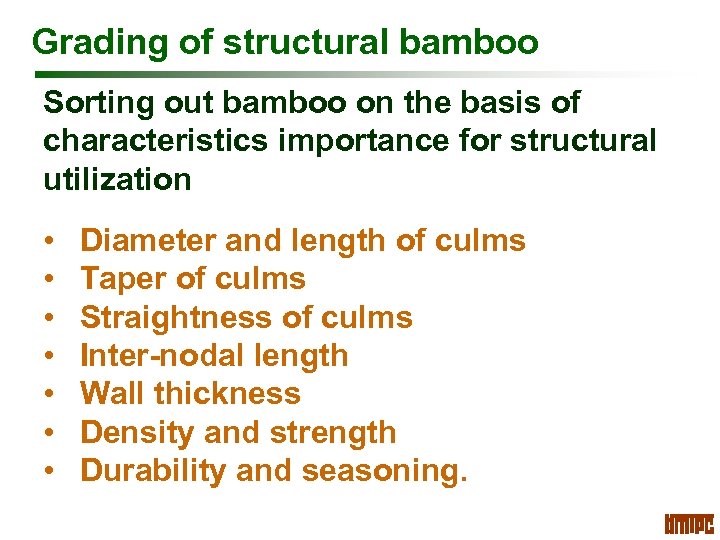

Grading of structural bamboo Sorting out bamboo on the basis of characteristics importance for structural utilization • • Diameter and length of culms Taper of culms Straightness of culms Inter-nodal length Wall thickness Density and strength Durability and seasoning.

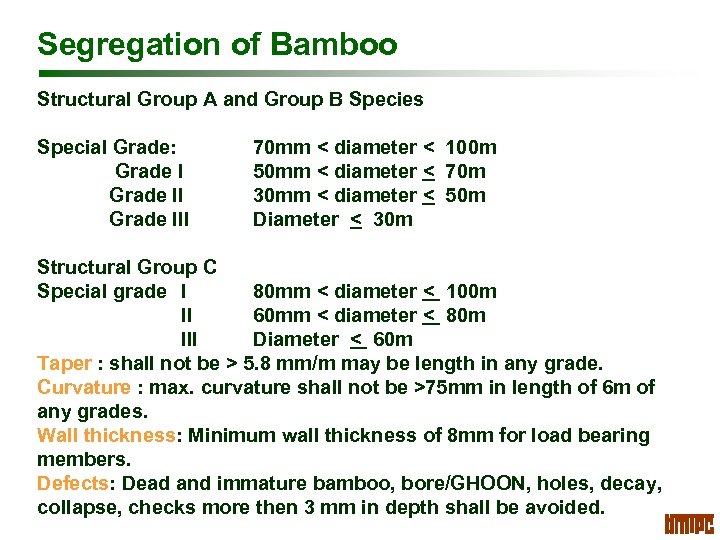

Segregation of Bamboo Structural Group A and Group B Species Special Grade: Grade III 70 mm < diameter < 100 m 50 mm < diameter < 70 m 30 mm < diameter < 50 m Diameter < 30 m Structural Group C Special grade I 80 mm < diameter < 100 m II 60 mm < diameter < 80 m III Diameter < 60 m Taper : shall not be > 5. 8 mm/m may be length in any grade. Curvature : max. curvature shall not be >75 mm in length of 6 m of any grades. Wall thickness: Minimum wall thickness of 8 mm for load bearing members. Defects: Dead and immature bamboo, bore/GHOON, holes, decay, collapse, checks more then 3 mm in depth shall be avoided.

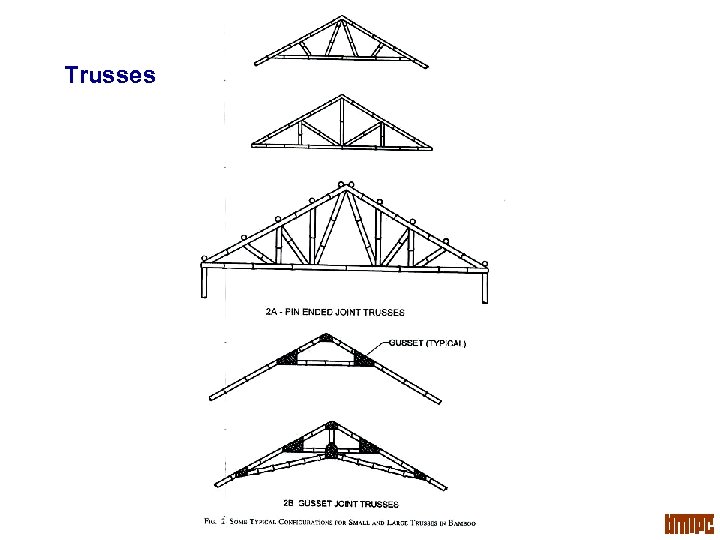

Trusses

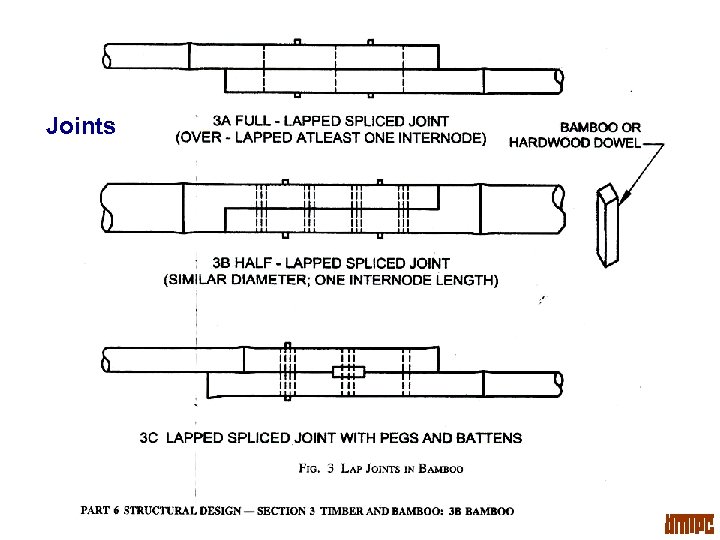

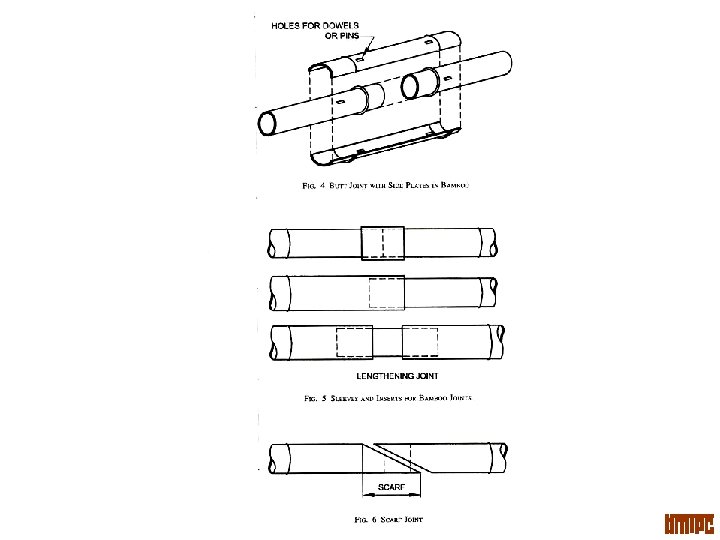

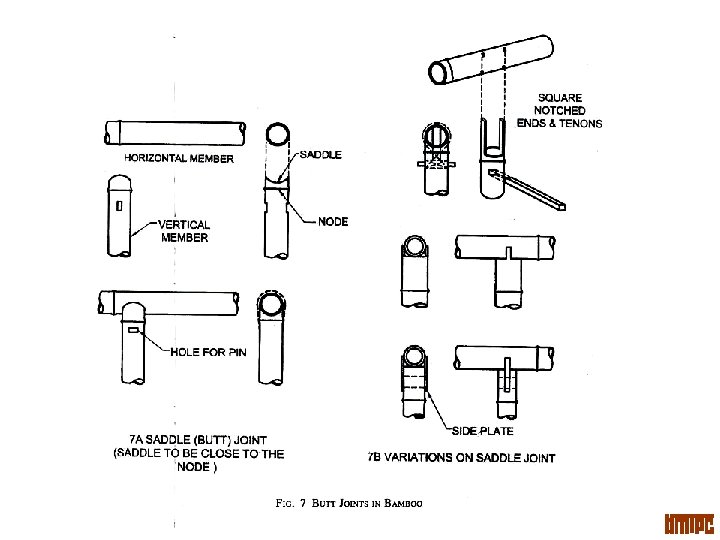

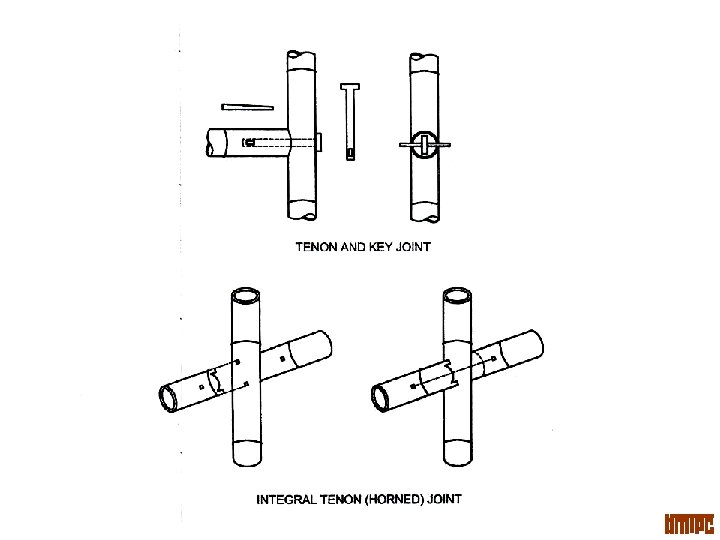

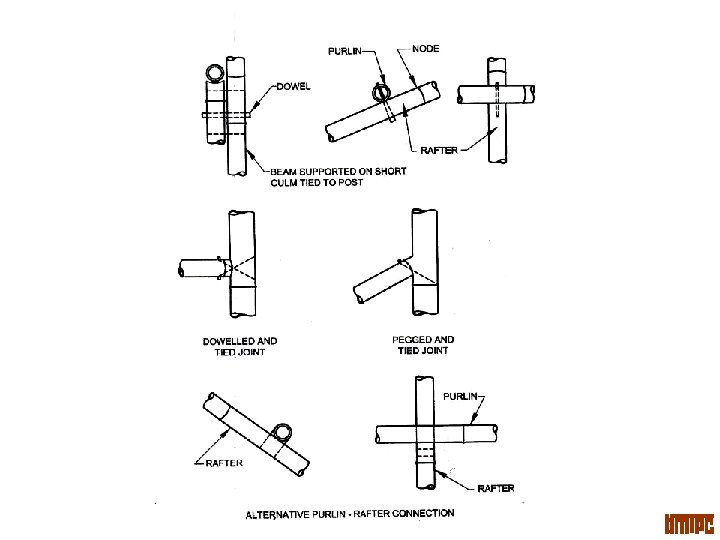

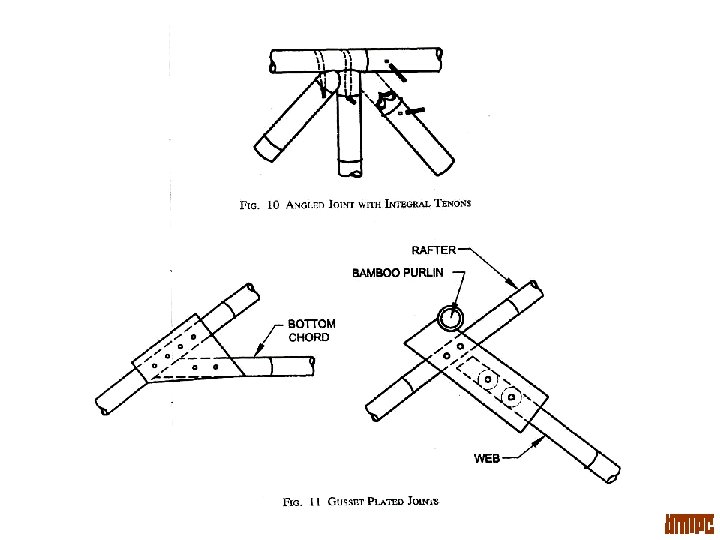

Joints

BMTPC’ Initiative For Application of Bamboo in Housing

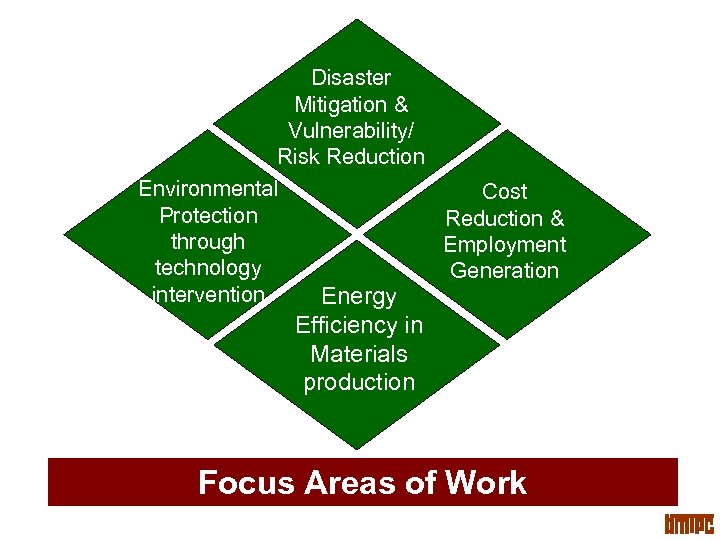

Disaster Mitigation & Vulnerability/ Risk Reduction Environmental Cost Protection Reduction & through Employment technology Generation intervention Energy Efficiency in Materials production Focus Areas of Work

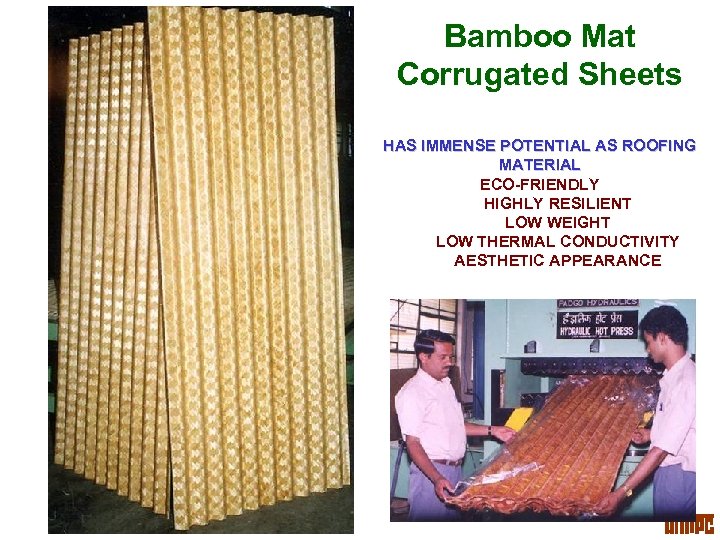

Bamboo Mat Corrugated Sheets HAS IMMENSE POTENTIAL AS ROOFING MATERIAL ECO-FRIENDLY HIGHLY RESILIENT LOW WEIGHT LOW THERMAL CONDUCTIVITY AESTHETIC APPEARANCE

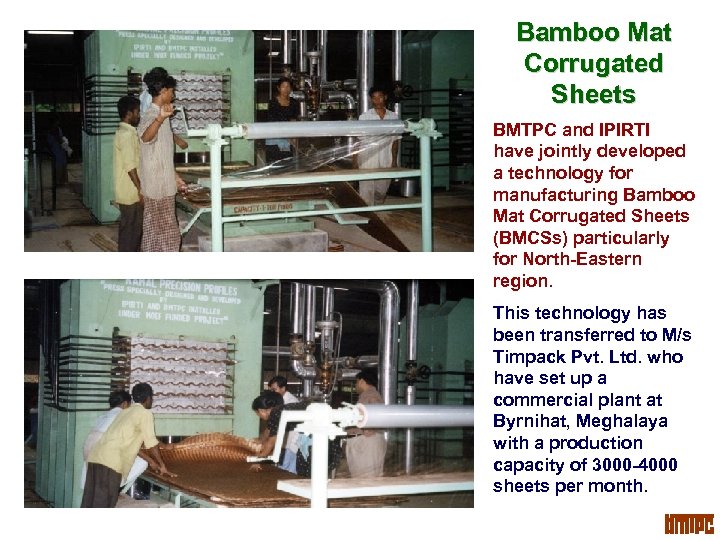

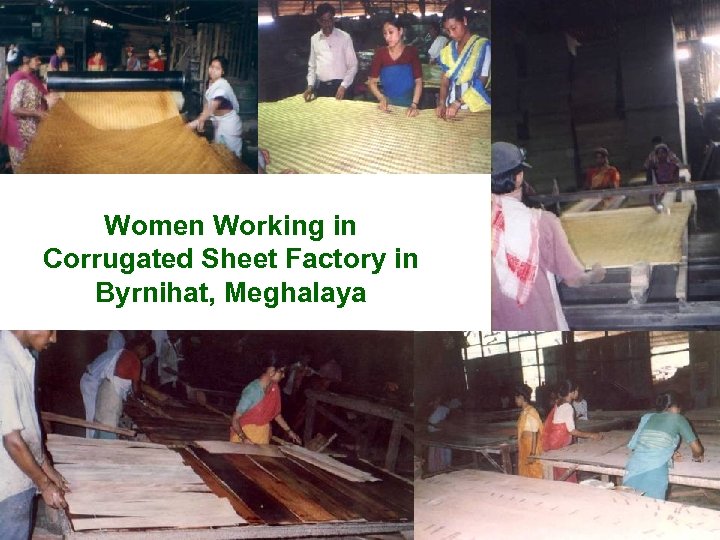

Bamboo Mat Corrugated Sheets BMTPC and IPIRTI have jointly developed a technology for manufacturing Bamboo Mat Corrugated Sheets (BMCSs) particularly for North-Eastern region. This technology has been transferred to M/s Timpack Pvt. Ltd. who have set up a commercial plant at Byrnihat, Meghalaya with a production capacity of 3000 -4000 sheets per month.

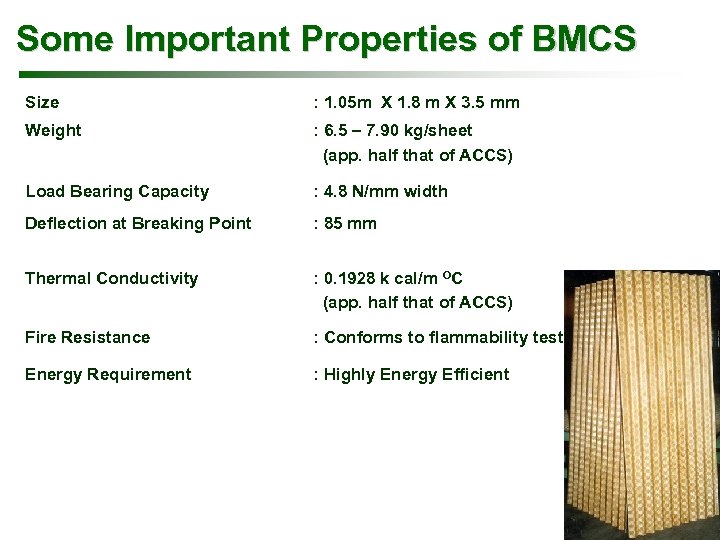

Some Important Properties of BMCS Size : 1. 05 m X 1. 8 m X 3. 5 mm Weight : 6. 5 – 7. 90 kg/sheet (app. half that of ACCS) Load Bearing Capacity : 4. 8 N/mm width Deflection at Breaking Point : 85 mm Thermal Conductivity : 0. 1928 k cal/m OC (app. half that of ACCS) Fire Resistance : Conforms to flammability test Energy Requirement : Highly Energy Efficient

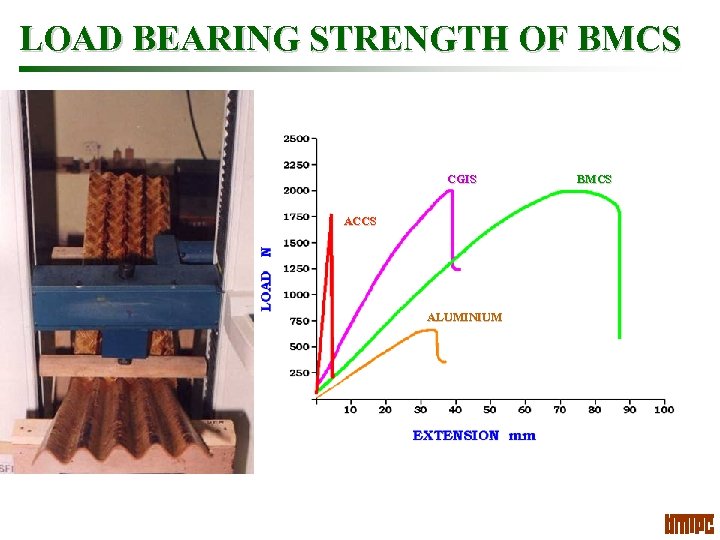

LOAD BEARING STRENGTH OF BMCS CGIS ACCS ALUMINIUM BMCS

Women Working in Corrugated Sheet Factory in Byrnihat, Meghalaya

BMCS at TERRACE CAFÉ DFID NEW DELHI October, 2000

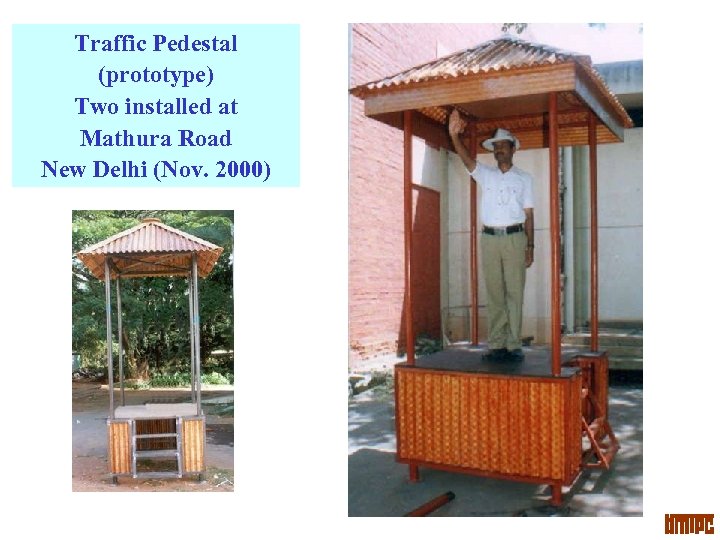

Traffic Pedestal (prototype) Two installed at Mathura Road New Delhi (Nov. 2000)

Use of Bamboo in Housing & Building Construction ‘Bamboo - A material for cost effective and disaster resistant housing used for construction of demonstration buildings and structures’

Demonstration House (plinth area 290 sq. ft. ) at IPIRTI, Bangalore March 2001

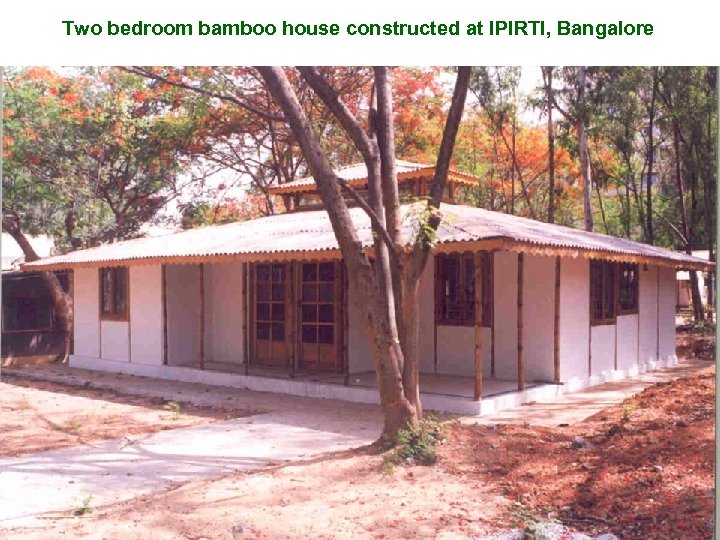

Two bedroom bamboo house constructed at IPIRTI, Bangalore Design: Mrs. Neelam Manjunath, Mansaram Architects, Bangalore Construction Agency: KARNIK, Bangalore Total Built Up Area : 897 Sq. Ft. Construction Cost : Rs. 2, 75, 000 (Rs. 307 per sq. ft. )

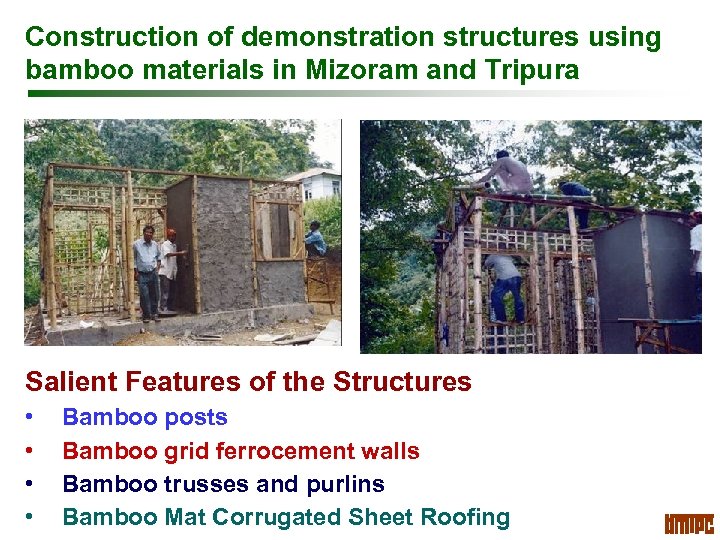

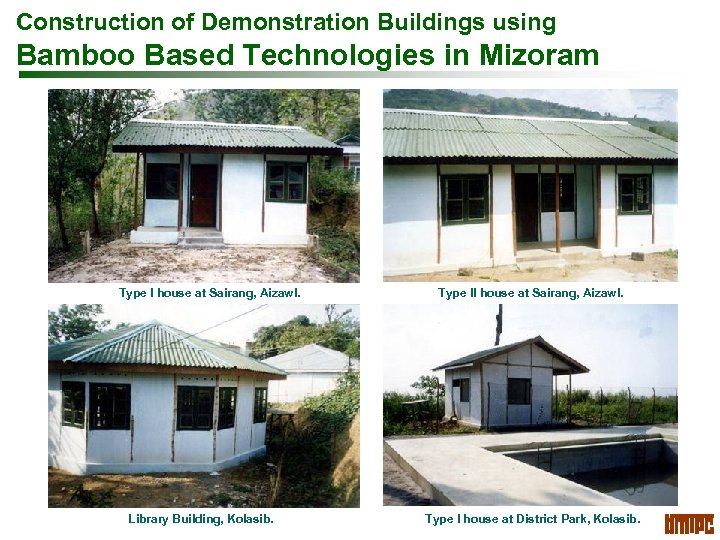

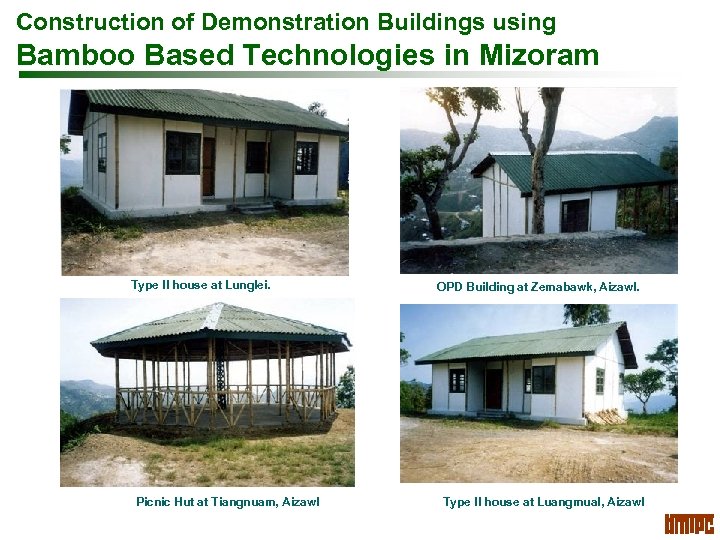

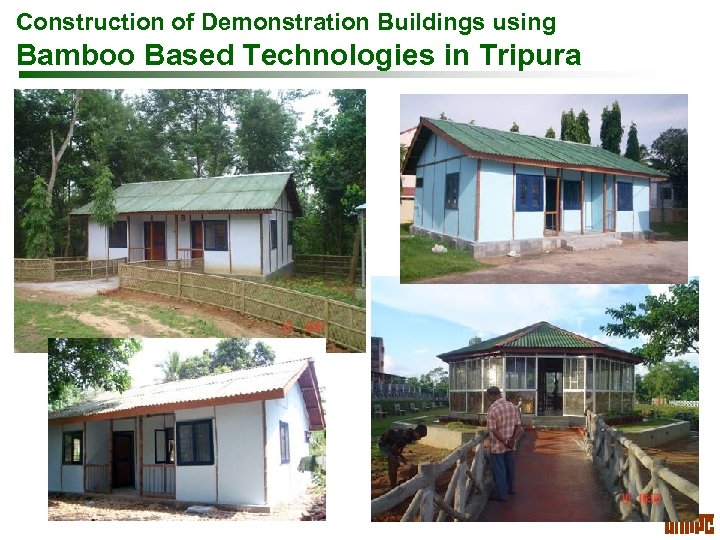

Construction of demonstration structures using bamboo materials in Mizoram and Tripura Salient Features of the Structures • • Bamboo posts Bamboo grid ferrocement walls Bamboo trusses and purlins Bamboo Mat Corrugated Sheet Roofing

Construction of Demonstration Buildings using Bamboo Based Technologies in Mizoram Type I house at Sairang, Aizawl. Library Building, Kolasib. Type II house at Sairang, Aizawl. Type I house at District Park, Kolasib.

Construction of Demonstration Buildings using Bamboo Based Technologies in Mizoram Type II house at Lunglei. Picnic Hut at Tiangnuam, Aizawl OPD Building at Zemabawk, Aizawl. Type II house at Luangmual, Aizawl

Construction of Demonstration Buildings using Bamboo Based Technologies in Tripura

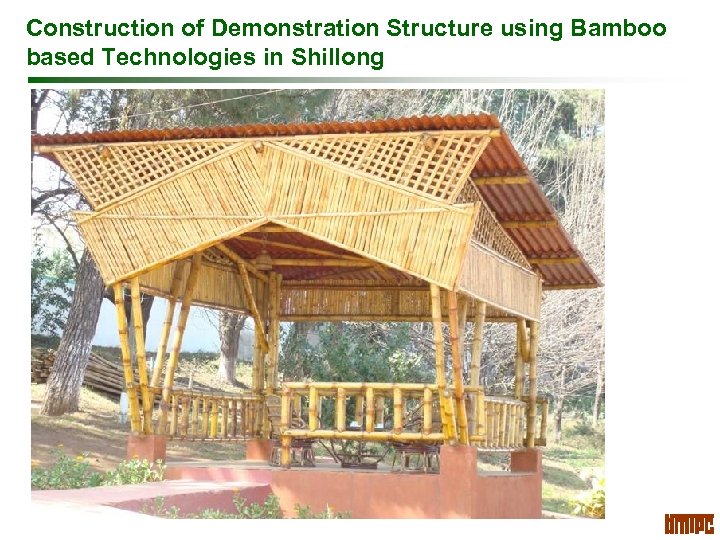

Construction of Demonstration Structure using Bamboo based Technologies in Shillong

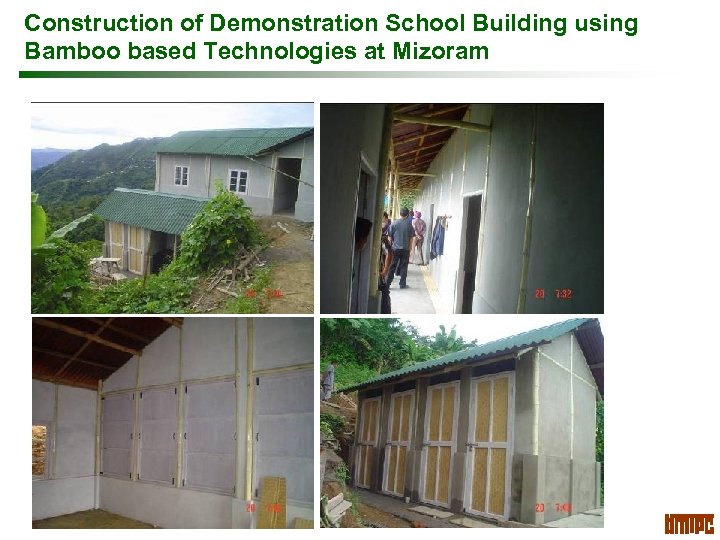

Construction of Demonstration School Building using Bamboo based Technologies at Mizoram

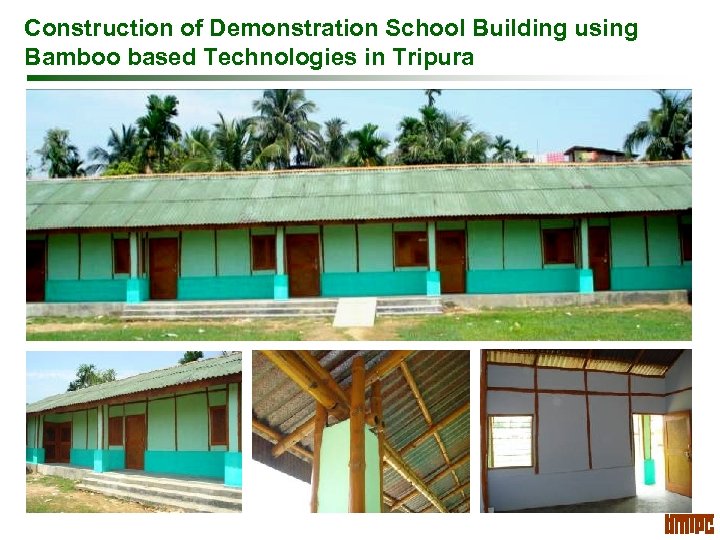

Construction of Demonstration School Building using Bamboo based Technologies in Tripura

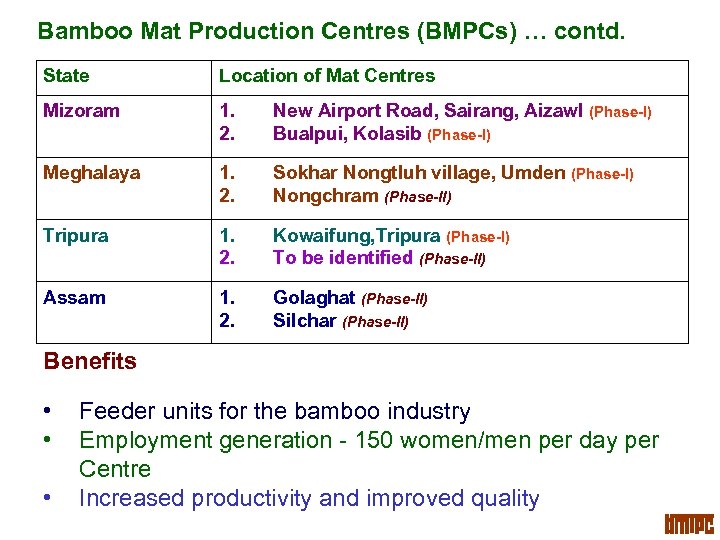

Establishment of Bamboo Mat Production Centres (BMPCs) BMTPC in cooperation with CBTC and State Govts. is establishing 8 BMPCs in the States of Mizoram, Meghalaya, Tripura & Assam Objectives 1. To set up Bamboo Mat Production Centres for uninterrupted supply of mats to manufacturing units of bamboo based building components for increasing the productivity and improving quality. 2. To provide training in Mat production.

Bamboo Mat Production Centres (BMPCs) … contd. State Location of Mat Centres Mizoram 1. 2. New Airport Road, Sairang, Aizawl (Phase-I) Bualpui, Kolasib (Phase-I) Meghalaya 1. 2. Sokhar Nongtluh village, Umden (Phase-I) Nongchram (Phase-II) Tripura 1. 2. Kowaifung, Tripura (Phase-I) To be identified (Phase-II) Assam 1. 2. Golaghat (Phase-II) Silchar (Phase-II) Benefits • • • Feeder units for the bamboo industry Employment generation - 150 women/men per day per Centre Increased productivity and improved quality

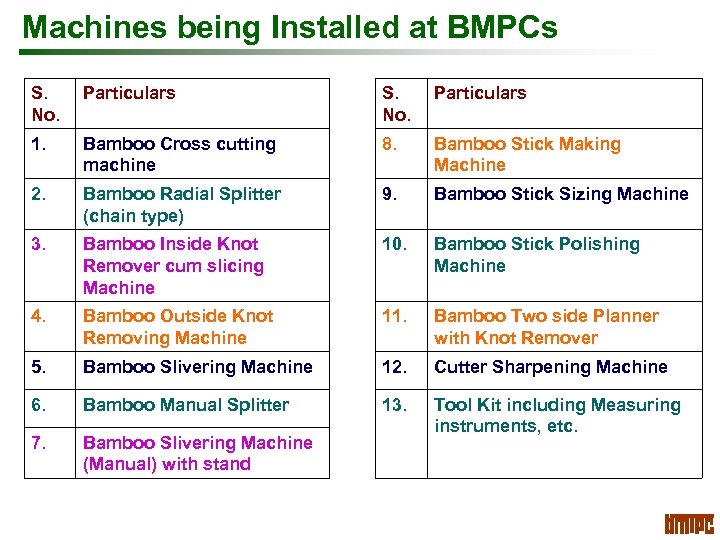

Machines being Installed at BMPCs S. No. Particulars 1. Bamboo Cross cutting machine 8. Bamboo Stick Making Machine 2. Bamboo Radial Splitter (chain type) 9. Bamboo Stick Sizing Machine 3. Bamboo Inside Knot Remover cum slicing Machine 10. Bamboo Stick Polishing Machine 4. Bamboo Outside Knot Removing Machine 11. Bamboo Two side Planner with Knot Remover 5. Bamboo Slivering Machine 12. Cutter Sharpening Machine 6. Bamboo Manual Splitter 13. 7. Bamboo Slivering Machine (Manual) with stand Tool Kit including Measuring instruments, etc.

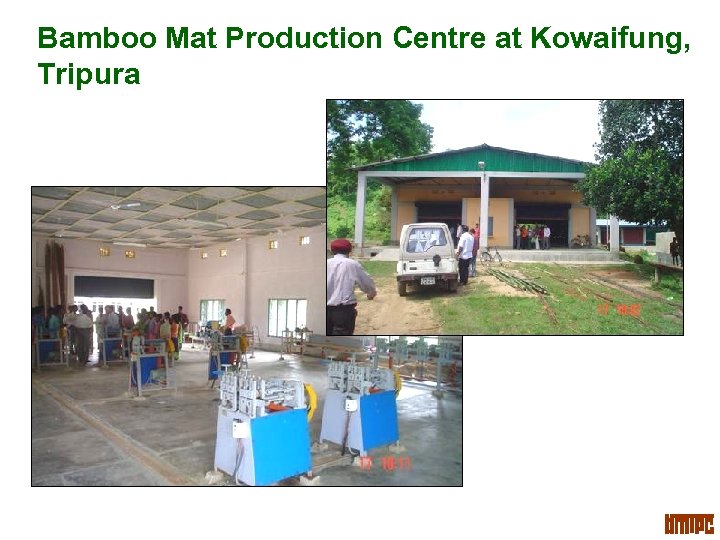

Bamboo Mat Production Centre at Kowaifung, Tripura

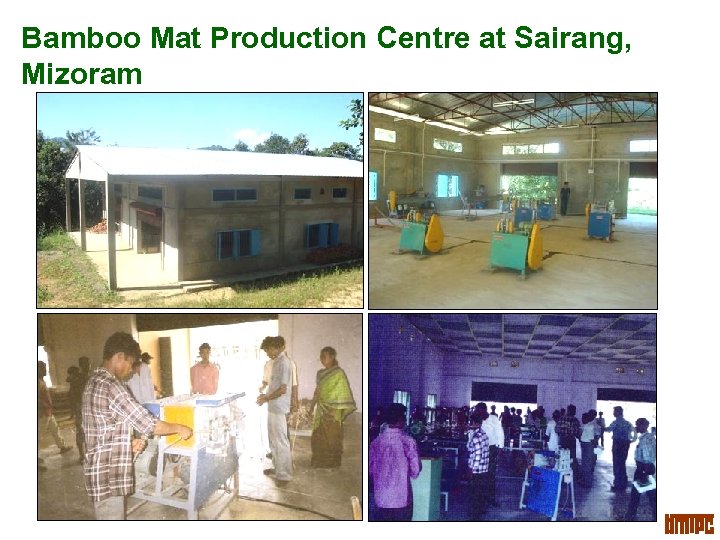

Bamboo Mat Production Centre at Sairang, Mizoram

Bamboo Mat Production Centre at Bualpui, Mizoram

Bamboo Mat Production Centre at Vill. Sohkar Nongtluh, Meghalaya

Management of BMPCs • A tripartite Mo. U between BMTPC, CBTC and local partners identified by the respective State Govts. • The local partners providing infrastructure facilities such as land development, boundary wall/fencing, storage space for raw material and finishes goods, water & electric connections and working capital for running the Centre at their own cost. • All the machinery, equipment and shed is being provided by BMTPC. • The training of the managers/supervisors/workers of the respective BMPCs are being provided by CBTC.

Production Capacity of BMPCs • The production capacity of each BMPC will be 200 mats per day. • It is estimated that the Centres will be able to produce the mat at a very reasonable price. • This will provide employment generation of nearly 150 women/men per day i. e. 45, 000 women/men days per year per Centre. • Besides the above, the Centres can also generate income by supplying bamboo sticks made out of bamboo waste, to the artisans for making handicraft items.

New Technology Development

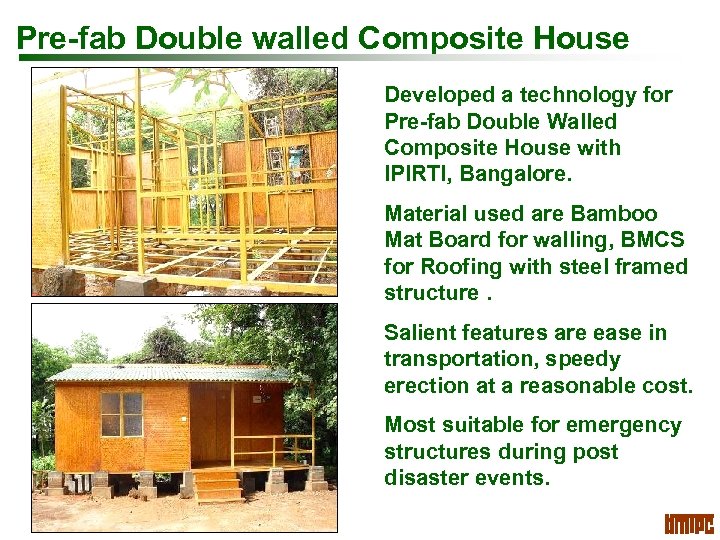

Pre-fab Double walled Composite House Developed a technology for Pre-fab Double Walled Composite House with IPIRTI, Bangalore. Material used are Bamboo Mat Board for walling, BMCS for Roofing with steel framed structure. Salient features are ease in transportation, speedy erection at a reasonable cost. Most suitable for emergency structures during post disaster events.

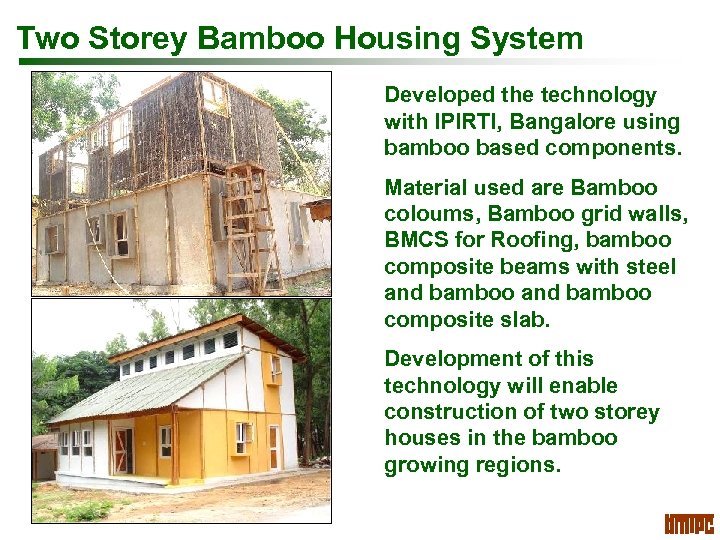

Two Storey Bamboo Housing System Developed the technology with IPIRTI, Bangalore using bamboo based components. Material used are Bamboo coloums, Bamboo grid walls, BMCS for Roofing, bamboo composite beams with steel and bamboo composite slab. Development of this technology will enable construction of two storey houses in the bamboo growing regions.

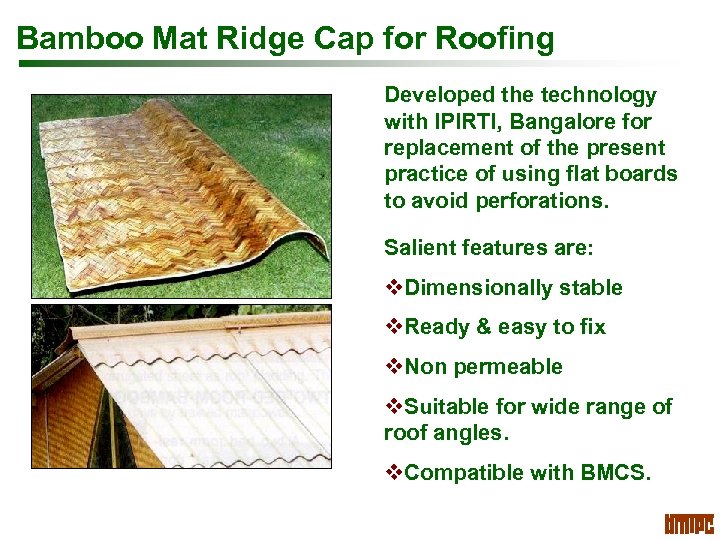

Bamboo Mat Ridge Cap for Roofing Developed the technology with IPIRTI, Bangalore for replacement of the present practice of using flat boards to avoid perforations. Salient features are: v. Dimensionally stable v. Ready & easy to fix v. Non permeable v. Suitable for wide range of roof angles. v. Compatible with BMCS.

Other projects completed in NE Region v Construction of 2 Cafeteria Buildings in Kisama, Nagaland. v Construction of 2 demonstration structures using bamboo based technologies in Shillong, Meghalaya v Organisation of number of training programmes on bamboo based technologies. v Preparation of detailed feasibility reports for production ofbamboo based components like BMCS, BMB etc.

Ongoing Activities in NE Region v Setting up of Bamboo Mat Production Centre in Mopaya village, Deomali, Arunachal Pradesh v Setting up of Bamboo Mother Park in collaboration with CBTC at Byrnihat, Meghalaya v Setting up of Bamboo Mat Production centre at Nongchram , Garo Hills, Meghalaya v Construction of demonstration structures using bamboo based technologies v Setting up of Technology Demonstration cum Production Centre at Tripura v Development of technology for Flattened Bamboo Lumbers for structural applications.

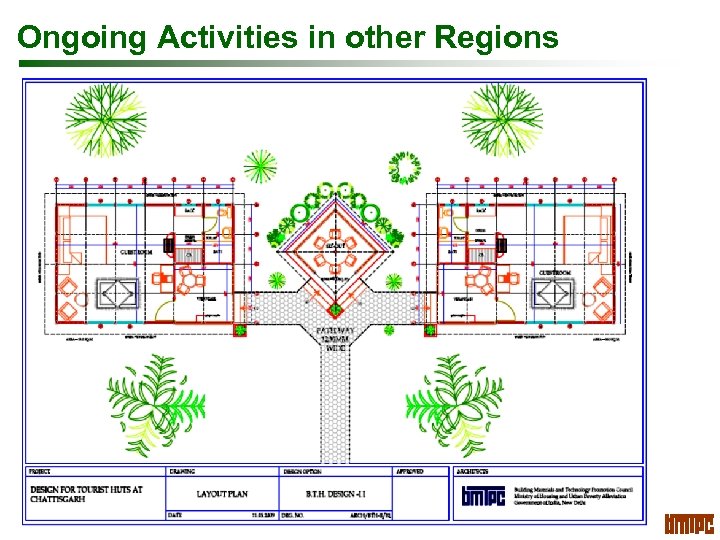

Ongoing Activities in other Regions

Ongoing Activities in other Regions

Challenges ahead • Increasing durability • Developing efficient jointing system • Developing prefab system • Developing composite system to deal with natural hazards • Growing bamboo of structural grade • Setting up of more production centers • Studying other bamboo which are available but not used in construction • Capacity building of artisans

Thank you for your kind attention www. bmtpc. Creating Enabling Environment for Affordable Housing org for All

abf55cb5b92c3ef306a64f20c33b1d64.ppt