666474d02d3d0289faa1ac900c2f4eba.ppt

- Количество слайдов: 22

BAM - Berlin Reduction of Radiation Exposure by Modern Methods of Digital Industrial Radiography Uwe EWERT, Barbara SÖLTER, Bernhard REDMER, Uwe ZSCHERPEL, Matthias PURSCHKE August 2006 Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 1

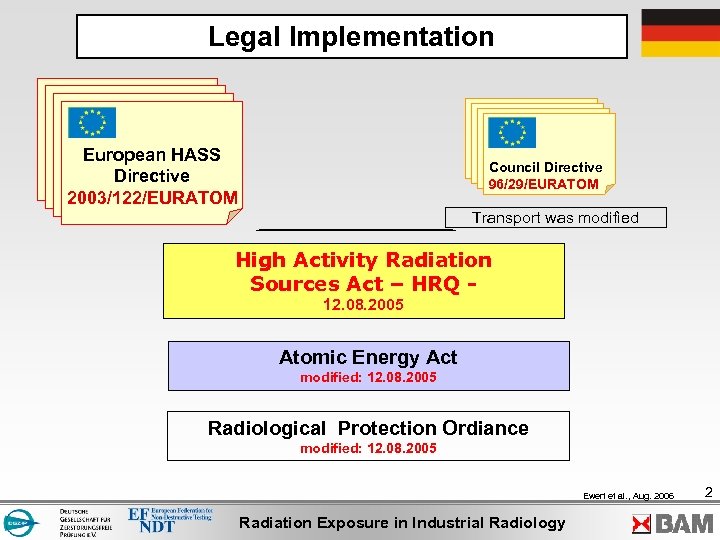

Legal Implementation European HASS Directive 2003/122/EURATOM Council Directive 96/29/EURATOM Transport was modified High Activity Radiation Sources Act – HRQ 12. 08. 2005 Atomic Energy Act modified: 12. 08. 2005 Radiological Protection Ordiance modified: 12. 08. 2005 Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 2

Reduction of Dose for Population and Limitations for Transport • New stringent European (Euratom Basic Norm 1996) and national standards on radiation protection limit annual personnel dosage • Reduction of annual effective dose for • population (1 m. Sv old: 1. 5 m. Sv) • NDT personal (20 m. Sv old: 50 m. Sv) • Further limitation in handling and transport of gamma sources • New act (High Activity Radiation Sources Act) on surveillance of highly radioactive sources • All this regulations limit the application of mobile radiological methods in its conventional way • New digital detectors enable reduction of dosage in industrial radiology without lost of testing quality • New opportunities of digital industrial radiology enhances the application area Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 3

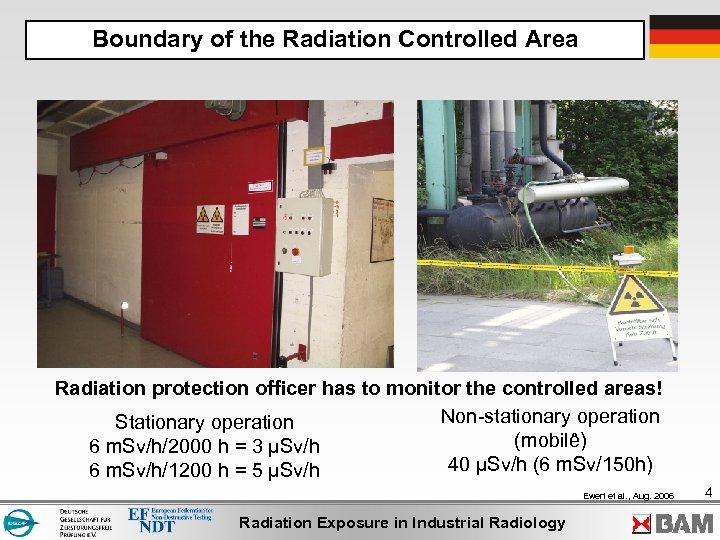

Boundary of the Radiation Controlled Area Radiation protection officer has to monitor the controlled areas! Non-stationary operation Stationary operation (mobilê) 6 m. Sv/h/2000 h = 3 µSv/h 40 µSv/h (6 m. Sv/150 h) 6 m. Sv/h/1200 h = 5 µSv/h Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 4

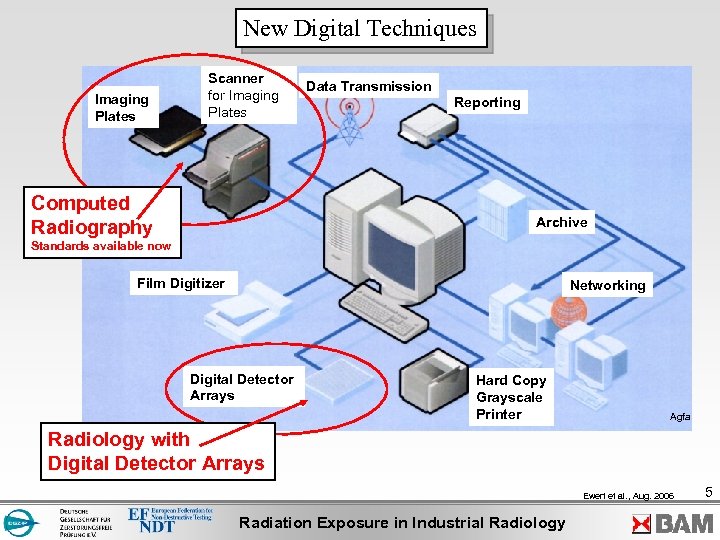

New Digital Techniques Imaging Plates Scanner for Imaging Plates Computed Radiography Data Transmission Reporting Archive Standards available now Film Digitizer Networking Digital Detector Arrays Hard Copy Grayscale Printer Agfa Radiology with Digital Detector Arrays Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 5

Filmless Radiography Computed Radiography with Phosphor Imaging Plates Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 6

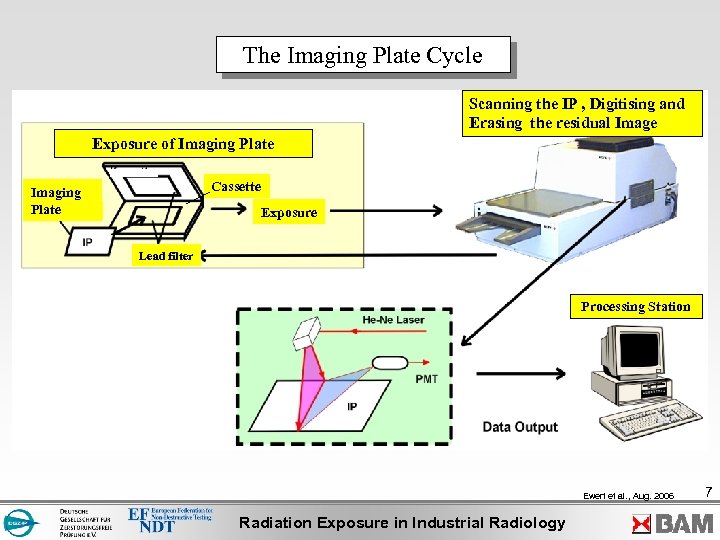

The Imaging Plate Cycle Scanning the IP , Digitising and Erasing the residual Image Exposure of Imaging Plate Cassette Imaging Plate Exposure Lead filter Processing Station Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 7

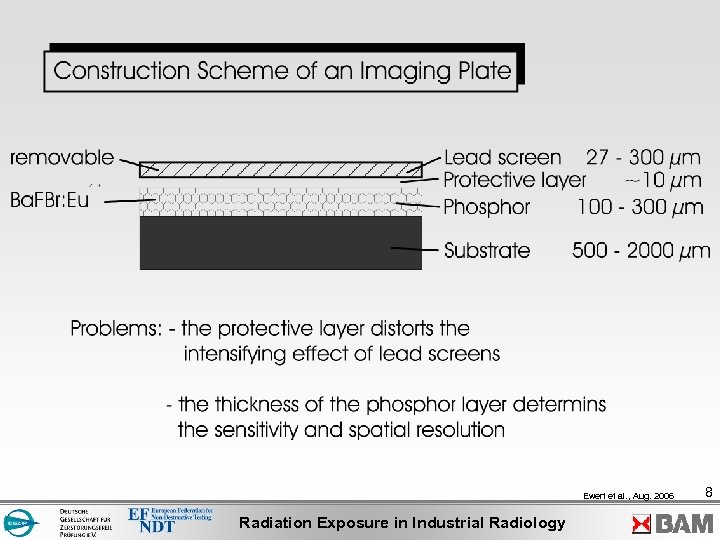

Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 8

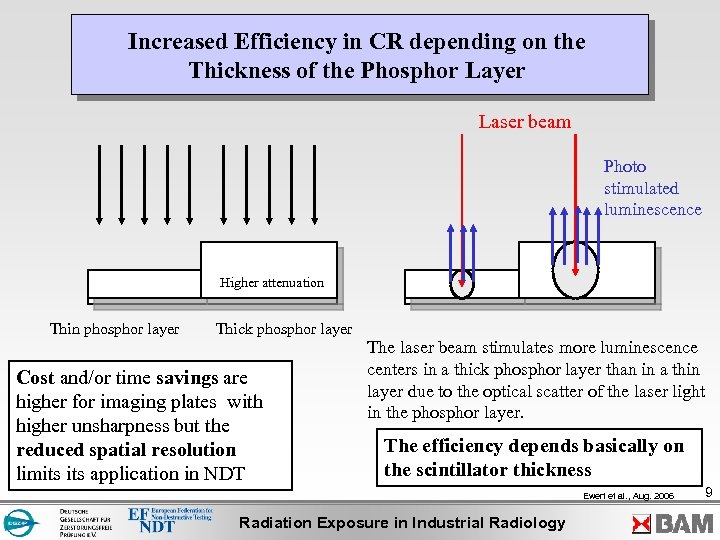

Increased Efficiency in CR depending on the Thickness of the Phosphor Layer Laser beam Photo stimulated luminescence Higher attenuation Thin phosphor layer Thick phosphor layer Cost and/or time savings are higher for imaging plates with higher unsharpness but the reduced spatial resolution limits application in NDT The laser beam stimulates more luminescence centers in a thick phosphor layer than in a thin layer due to the optical scatter of the laser light in the phosphor layer. The efficiency depends basically on the scintillator thickness Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 9

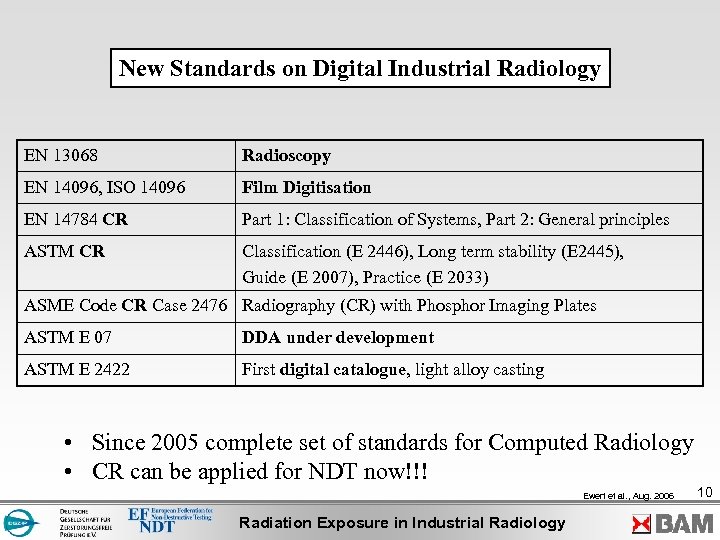

New Standards on Digital Industrial Radiology EN 13068 Radioscopy EN 14096, ISO 14096 Film Digitisation EN 14784 CR Part 1: Classification of Systems, Part 2: General principles ASTM CR Classification (E 2446), Long term stability (E 2445), Guide (E 2007), Practice (E 2033) ASME Code CR Case 2476 Radiography (CR) with Phosphor Imaging Plates ASTM E 07 DDA under development ASTM E 2422 First digital catalogue, light alloy casting • Since 2005 complete set of standards for Computed Radiology • CR can be applied for NDT now!!! Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 10

Filmless Radiography Some CR Applications Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 11

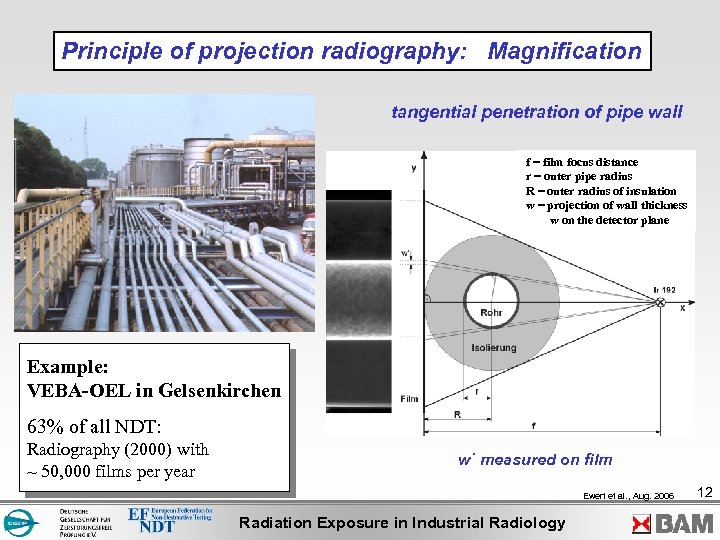

Principle of projection radiography: Magnification tangential penetration of pipe wall f = film focus distance r = outer pipe radius R = outer radius of insulation w = projection of wall thickness w on the detector plane Example: VEBA-OEL in Gelsenkirchen 63% of all NDT: Radiography (2000) with ~ 50, 000 films per year w` measured on film Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 12

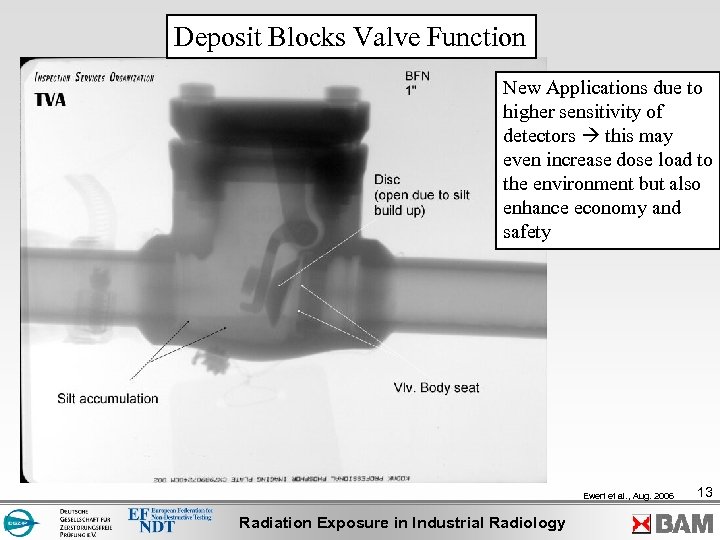

Deposit Blocks Valve Function New Applications due to higher sensitivity of detectors this may even increase dose load to the environment but also enhance economy and safety Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 13

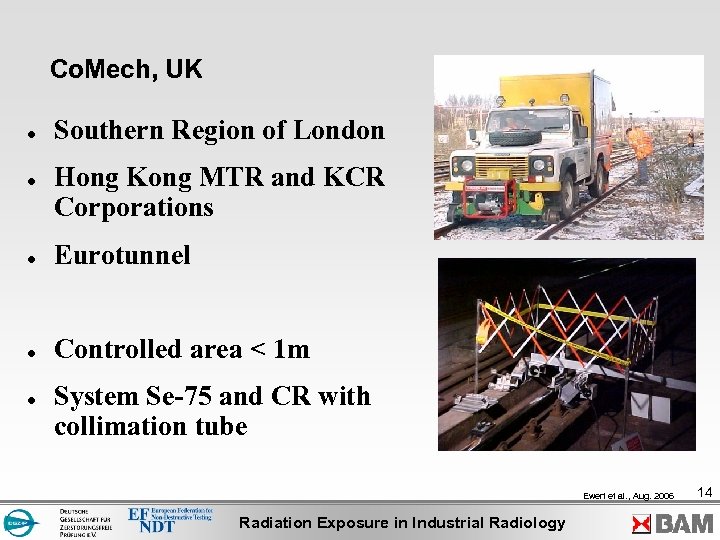

Co. Mech, UK l l Southern Region of London Hong Kong MTR and KCR Corporations l Eurotunnel l Controlled area < 1 m l System Se-75 and CR with collimation tube Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 14

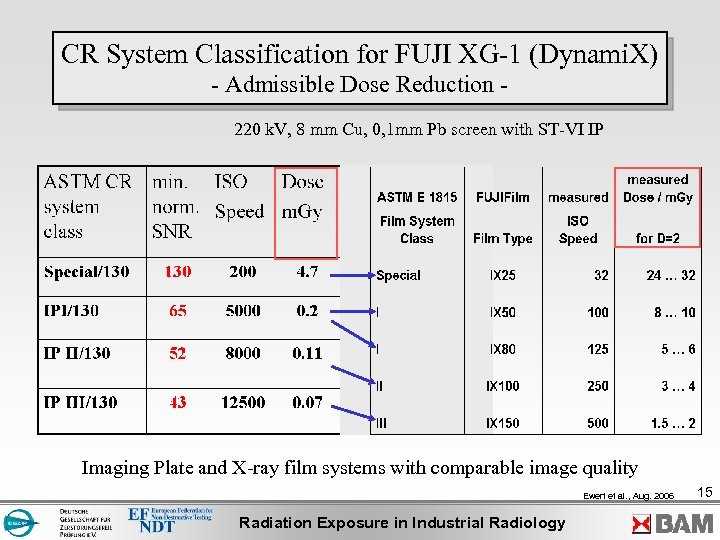

CR System Classification for FUJI XG-1 (Dynami. X) - Admissible Dose Reduction 220 k. V, 8 mm Cu, 0, 1 mm Pb screen with ST-VI IP Imaging Plate and X-ray film systems with comparable image quality Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 15

Filmless Radiography Digital Detector Arrays The new High Contrast Sensitivity Technique Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 16

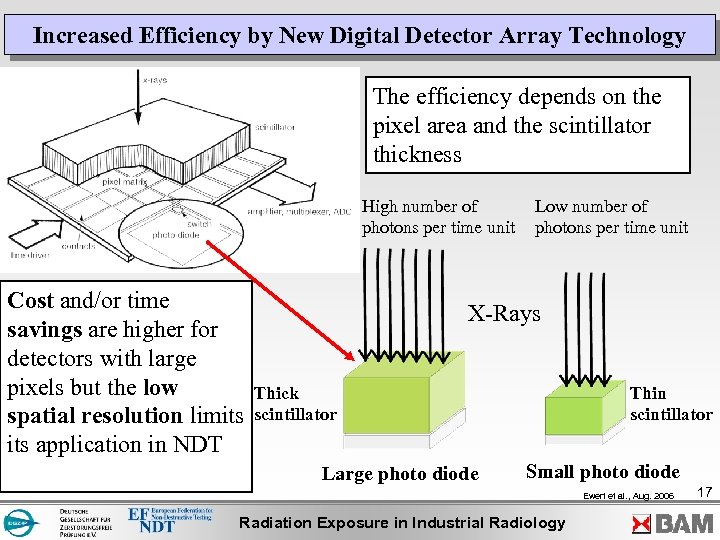

Increased Efficiency by New Digital Detector Array Technology The efficiency depends on the pixel area and the scintillator thickness High number of photons per time unit Cost and/or time savings are higher for detectors with large pixels but the low spatial resolution limits application in NDT Low number of photons per time unit X-Rays Thick scintillator Large photo diode Thin scintillator Small photo diode Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 17

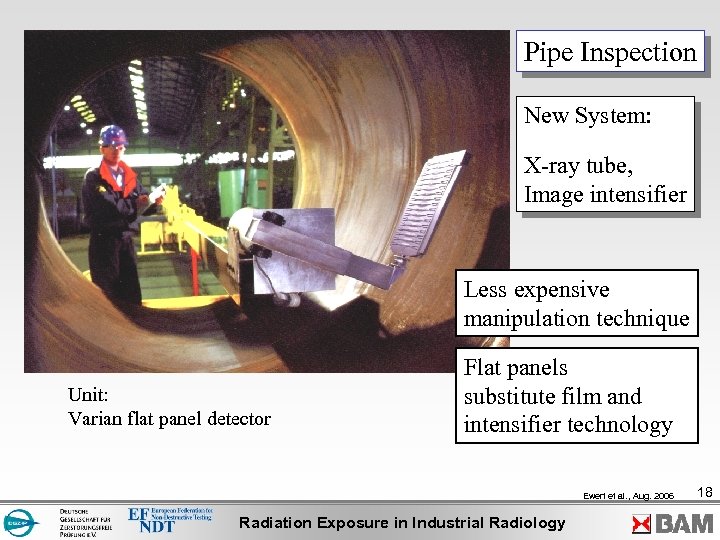

Pipe Inspection New System: X-ray tube, Image intensifier Less expensive manipulation technique Unit: Varian flat panel detector Flat panels substitute film and intensifier technology Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 18

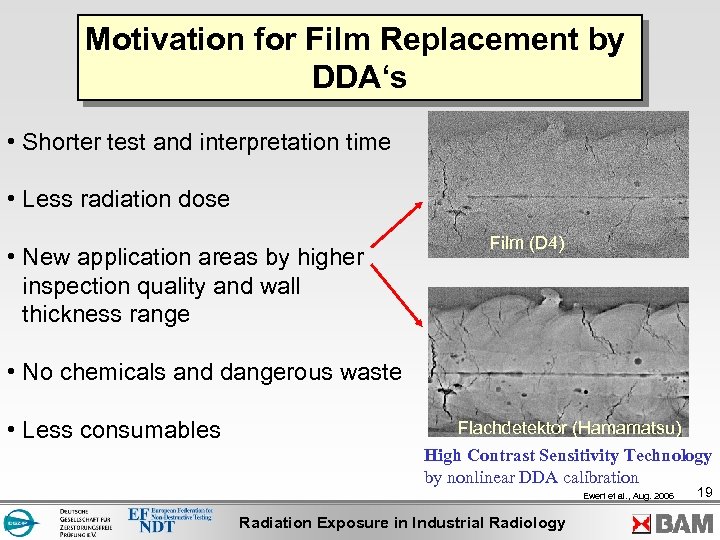

Motivation for Film Replacement by DDA‘s • Shorter test and interpretation time • Less radiation dose • New application areas by higher inspection quality and wall thickness range Film (D 4) • No chemicals and dangerous waste • Less consumables Flachdetektor (Hamamatsu) High Contrast Sensitivity Technology by nonlinear DDA calibration Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 19

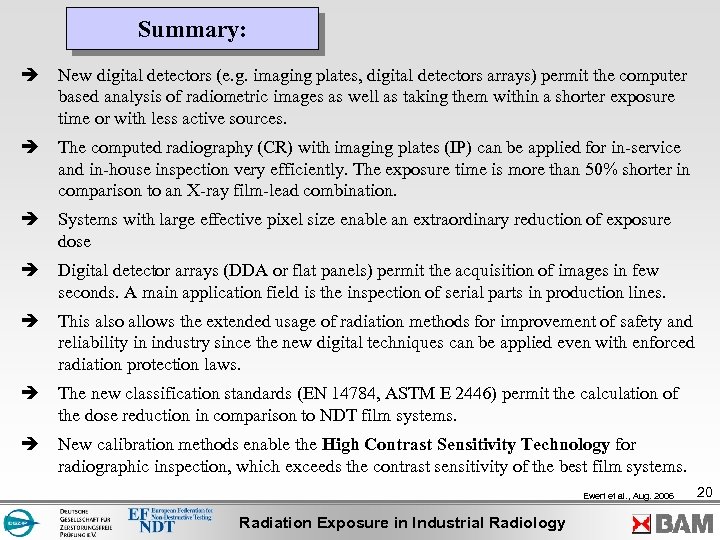

Summary: è New digital detectors (e. g. imaging plates, digital detectors arrays) permit the computer based analysis of radiometric images as well as taking them within a shorter exposure time or with less active sources. è The computed radiography (CR) with imaging plates (IP) can be applied for in-service and in-house inspection very efficiently. The exposure time is more than 50% shorter in comparison to an X-ray film-lead combination. è Systems with large effective pixel size enable an extraordinary reduction of exposure dose è Digital detector arrays (DDA or flat panels) permit the acquisition of images in few seconds. A main application field is the inspection of serial parts in production lines. è This also allows the extended usage of radiation methods for improvement of safety and reliability in industry since the new digital techniques can be applied even with enforced radiation protection laws. è The new classification standards (EN 14784, ASTM E 2446) permit the calculation of the dose reduction in comparison to NDT film systems. è New calibration methods enable the High Contrast Sensitivity Technology for radiographic inspection, which exceeds the contrast sensitivity of the best film systems. Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 20

End BAM-Berlin, Lab. VIII. 3 Unter den Eichen 87 12005 Berlin Tel. (030) 81041831 FAX (030) 811 5089 e-mail: uwe. ewert@bam. de http: //www. bam. de Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 21

Ewert et al. , Aug. 2006 Radiation Exposure in Industrial Radiology 22

666474d02d3d0289faa1ac900c2f4eba.ppt