72b437e4f8b1ab3080dc9b17ed5ca915.ppt

- Количество слайдов: 33

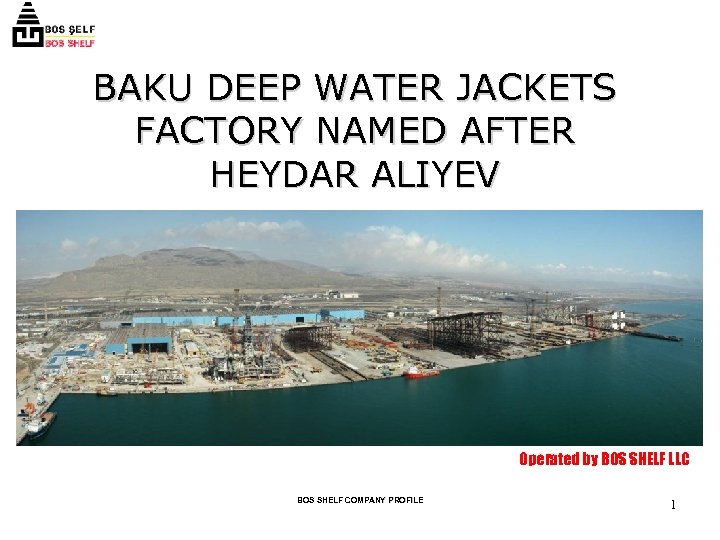

BAKU DEEP WATER JACKETS FACTORY NAMED AFTER HEYDAR ALIYEV Operated by BOS SHELF LLC BOS SHELF COMPANY PROFILE 1

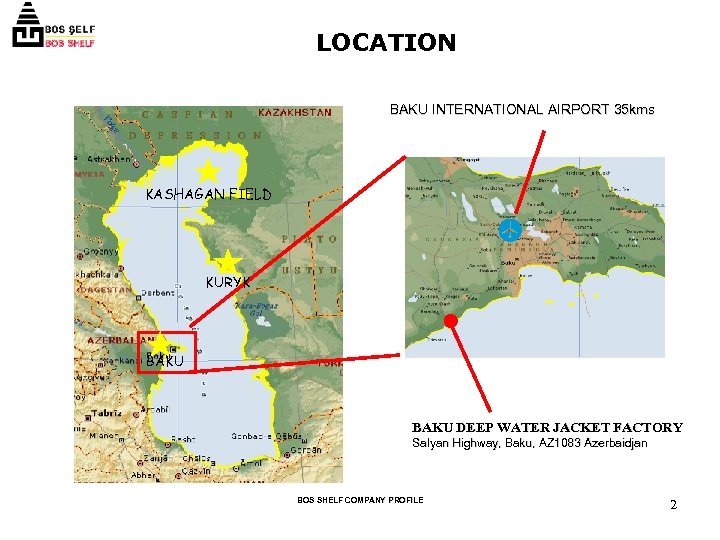

LOCATION BAKU INTERNATIONAL AIRPORT 35 kms KASHAGAN FIELD KURYK BAKU DEEP WATER JACKET FACTORY Salyan Highway, Baku, AZ 1083 Azerbaidjan BOS SHELF COMPANY PROFILE 2

TRACK RECORDS & ACHIEVEMENTS BOS SHELF COMPANY PROFILE 3

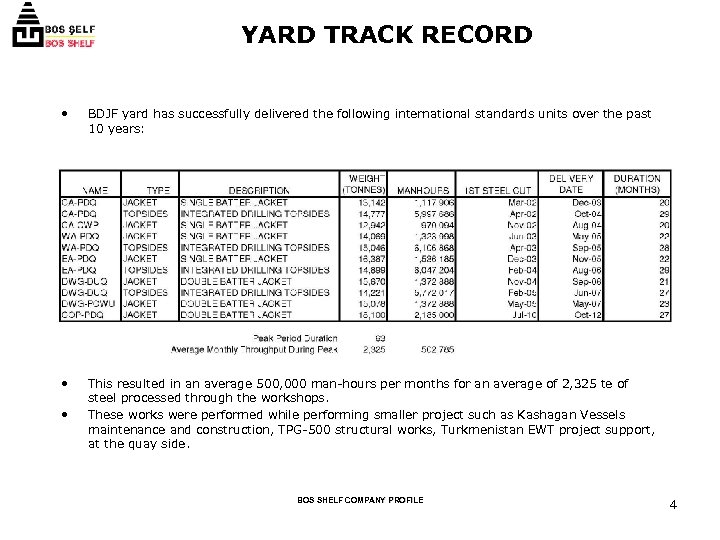

YARD TRACK RECORD • BDJF yard has successfully delivered the following international standards units over the past 10 years: • This resulted in an average 500, 000 man-hours per months for an average of 2, 325 te of steel processed through the workshops. These works were performed while performing smaller project such as Kashagan Vessels maintenance and construction, TPG-500 structural works, Turkmenistan EWT project support, at the quay side. • BOS SHELF COMPANY PROFILE 4

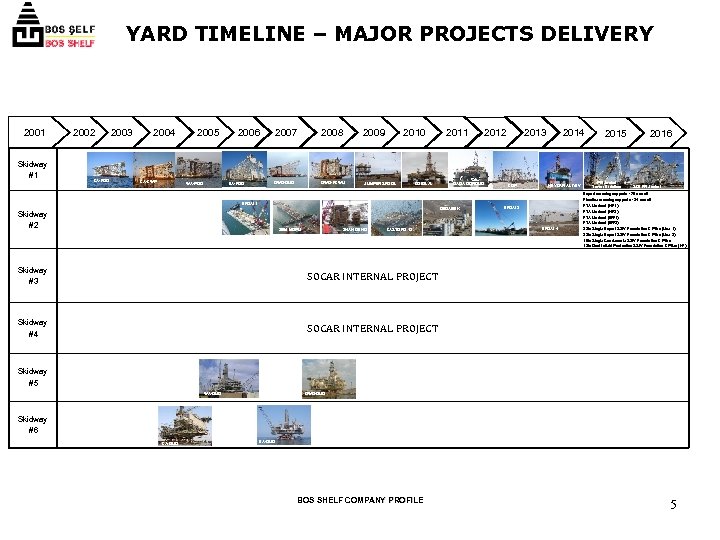

YARD TIMELINE – MAJOR PROJECTS DELIVERY 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2013 2014 2012 2015 COP Skidway #1 CA-PDQ CA-CWP EA-PDQ WA-PDQ DWG-DUQ DWG-PCWU JUMPER SPOOL ISTIGLAL ERSAI 1 DADA GORGUD GEDABEK Skidway #2 SBM MOPU SHAH DENIZ CASTORO 12 Skidway #3 HEYDAR ALIYEV DADA GORGUD ERSAI 2 ERSAI 4 HEYDAR ALIYEV PR Jacket Tower Erection SD 2 PR Jacket Export crossing supports - 75 nos off Flowline crossing supports - 24 nos off FTA Mudmat (NF 1) FTA Mudmat (NF 2) FTA Mudmat (WF 1) FTA Mudmat (WF 2) 32 in Single Export SSIV Foundation & Piles (Line 1) 32 in Single Export SSIV Foundation & Piles (Line 2) 16 in Single Condensate SSIV Foundation & Piles 12 in Dual Infield Production SSIV Foundation & Piles (NF) SOCAR INTERNAL PROJECT Skidway #4 COP 2016 SOCAR INTERNAL PROJECT Skidway #5 WA-DUQ DWG-DUQ Skidway #6 CA-DUQ EA-DUQ BOS SHELF COMPANY PROFILE 5

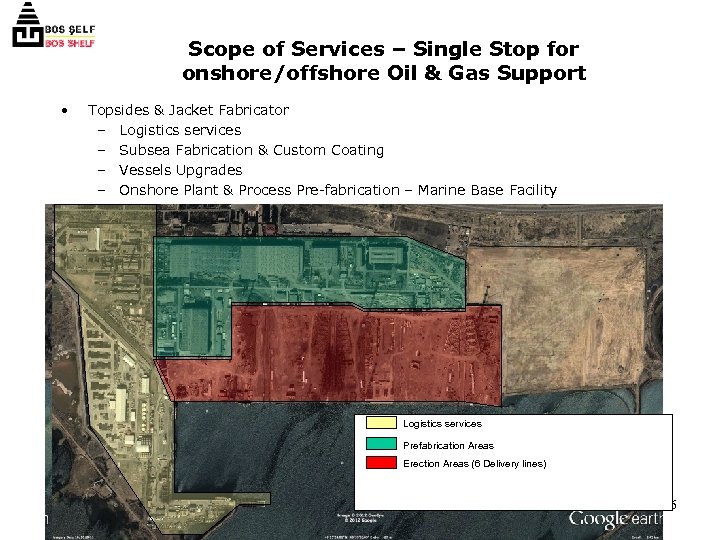

Scope of Services – Single Stop for onshore/offshore Oil & Gas Support • Topsides & Jacket Fabricator – Logistics services – Subsea Fabrication & Custom Coating – Vessels Upgrades – Onshore Plant & Process Pre-fabrication – Marine Base Facility Logistics services Prefabrication Areas Erection Areas (6 Delivery lines) BOS SHELF COMPANY PROFILE 6

KEY ATTRIBUTES FOR SUCCESS TO FACILITATE SUCCESSFUL PERFORMANCE OF MAJOR PROJECTS, BOS SHELF CAN DEPLOY THE FOLLOWING COMBINATION OF ATTRIBUTES: ü HSES AS A MANAGEMENT PRIORITY. ü QUALITY DRIVEN PRODUCTION METHODS. ü THE MOST EXTENSIVE PRODUCTION FACILITY IN THE CASPIAN REGION, FULLY REFURBISHED IN 2001. ü INTERNATIONALLY ACKNOWLEDGED EXPERTISE & RESOURCES. BOS SHELF COMPANY PROFILE 7

HEALTH, SAFETY AND ENVIRONMENT BOS SHELF COMPANY PROFILE 8

BOS SHELF POLICIES HEALTH, SAFETY AND ENVIRONMENT POLICY BOS Shelf has developed various polices in conjunction with Management Commitment. The BOS Shelf HSE Policies are defined by Management, with regard to the requirements of the Health, Safety and Environment Management Systems. BOS SHELF COMPANY PROFILE 9

BOS SHELF POLICIES TRANSPORT POLICY USE OF PLANT EQUIPMENT AND TOOL POLICY SUSTANCES ABUSE POLICY BOS SHELF COMPANY PROFILE 10

HEALTH, SAFETY AND ENVIRONMENTAL CERTIFICATION BOS Shelf Management System is certified ISO 18001: 2007 and ISO 14001: 2004 BOS SHELF COMPANY PROFILE 11

QUALITY BOS SHELF COMPANY PROFILE 12

QUALITY POLICY The BOS Shelf Quality Policy is defined by ISO 9001 -2008 and Management commitment with regard to Customer Satisfaction and the requirements for Quality BOS SHELF COMPANY PROFILE 13

ISO CERTIFICATION BOS SHELF Quality Management System is certified to ISO 9001: 2008 Welders are qualified by ABS Europe. BOS SHELF COMPANY PROFILE 14

RMRS CERTIFIED SYSTEM BOS SHELF Management system is also certified by RMRS is the reference body for Caspian Works. BOS SHELF COMPANY PROFILE 15

FACILITIES BOS SHELF COMPANY PROFILE 16

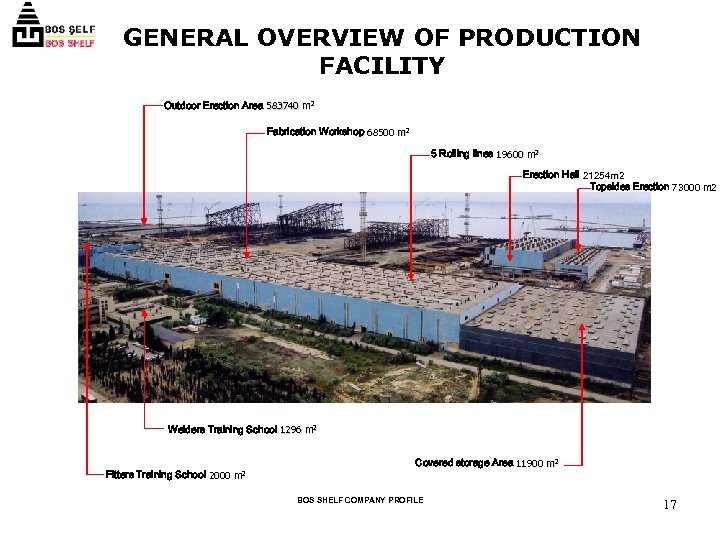

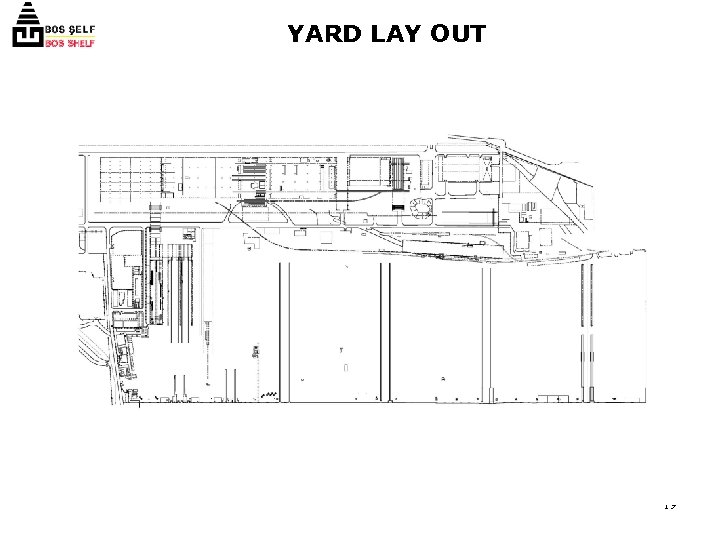

GENERAL OVERVIEW OF PRODUCTION FACILITY Outdoor Erection Area 583740 m 2 Fabrication Workshop 68500 m 2 5 Rolling lines 19600 m 2 Erection Hall 21254 m 2 Topsides Erection 73000 m 2 Welders Training School 1296 m 2 Fitters Training School 2000 m 2 Covered storage Area 11900 m 2 BOS SHELF COMPANY PROFILE 17

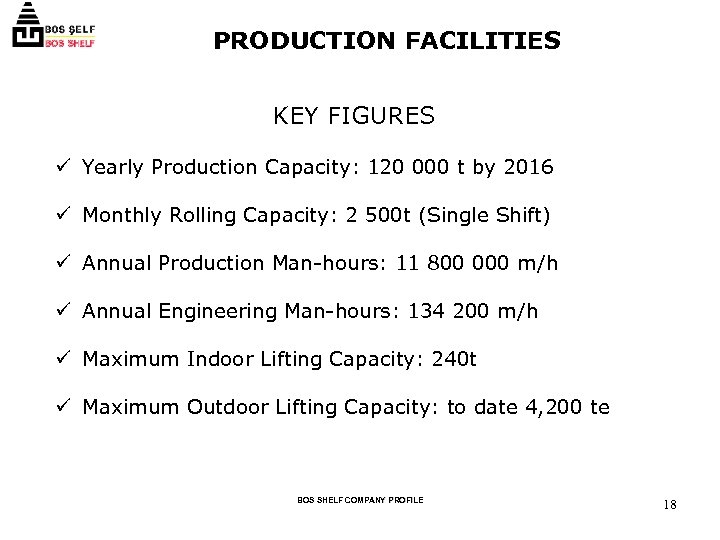

PRODUCTION FACILITIES KEY FIGURES ü Yearly Production Capacity: 120 000 t by 2016 ü Monthly Rolling Capacity: 2 500 t (Single Shift) ü Annual Production Man-hours: 11 800 000 m/h ü Annual Engineering Man-hours: 134 200 m/h ü Maximum Indoor Lifting Capacity: 240 t ü Maximum Outdoor Lifting Capacity: to date 4, 200 te BOS SHELF COMPANY PROFILE 18

YARD LAY OUT BOS SHELF COMPANY PROFILE 19

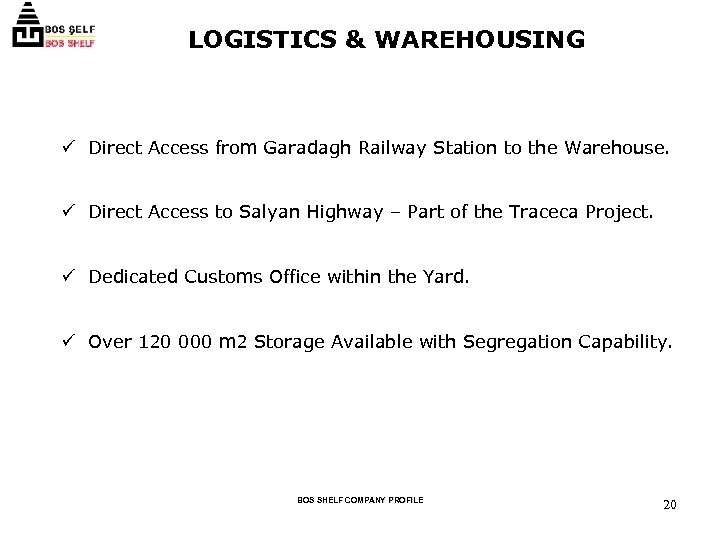

LOGISTICS & WAREHOUSING ü Direct Access from Garadagh Railway Station to the Warehouse. ü Direct Access to Salyan Highway – Part of the Traceca Project. ü Dedicated Customs Office within the Yard. ü Over 120 000 m 2 Storage Available with Segregation Capability. BOS SHELF COMPANY PROFILE 20

STEEL PREPARATION FACILITY ü 2 Blasting Machines ü 4 SAF Multihead Burning Tables ü 3 Computer Assisted Cutting Machine MEGATOME. ü 2 Automatic Saws for Beams BOS SHELF COMPANY PROFILE 21

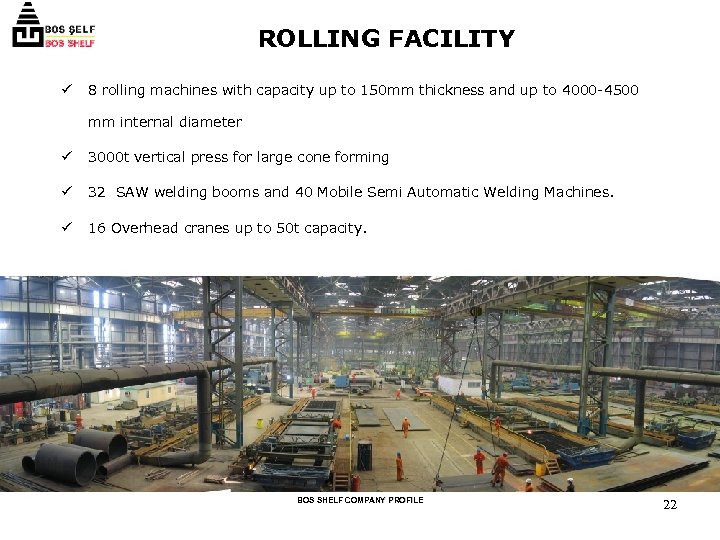

ROLLING FACILITY ü 8 rolling machines with capacity up to 150 mm thickness and up to 4000 -4500 mm internal diameter ü 3000 t vertical press for large cone forming ü 32 SAW welding booms and 40 Mobile Semi Automatic Welding Machines. ü 16 Overhead cranes up to 50 t capacity. BOS SHELF COMPANY PROFILE 22

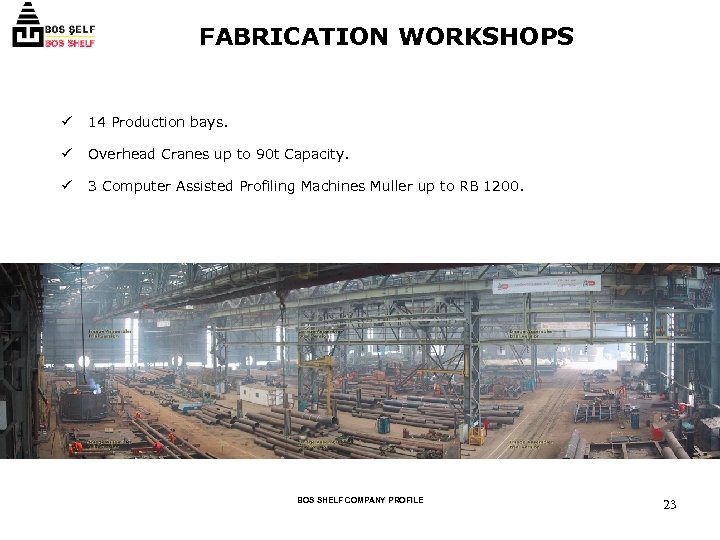

FABRICATION WORKSHOPS ü 14 Production bays. ü Overhead Cranes up to 90 t Capacity. ü 3 Computer Assisted Profiling Machines Muller up to RB 1200. BOS SHELF COMPANY PROFILE 23

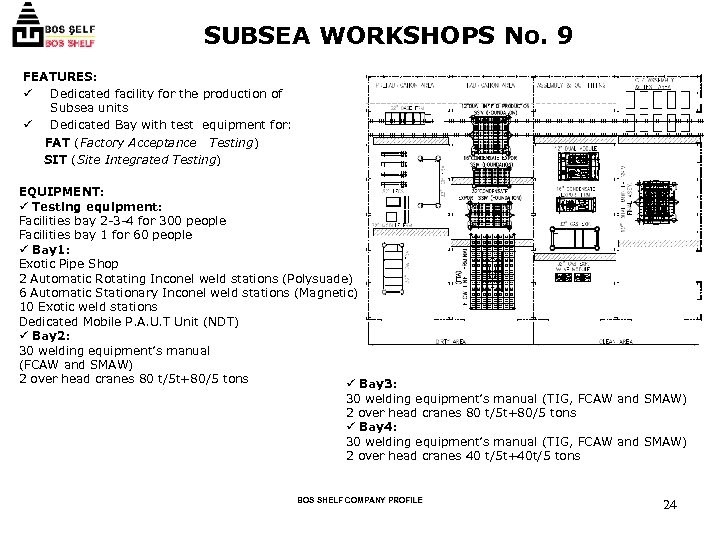

SUBSEA WORKSHOPS No. 9 FEATURES: ü Dedicated facility for the production of Subsea units ü Dedicated Bay with test equipment for: FAT (Factory Acceptance Testing) SIT (Site Integrated Testing) EQUIPMENT: ü Testing equipment: Facilities bay 2 -3 -4 for 300 people Facilities bay 1 for 60 people ü Bay 1: Exotic Pipe Shop 2 Automatic Rotating Inconel weld stations (Polysuade) 6 Automatic Stationary Inconel weld stations (Magnetic) 10 Exotic weld stations Dedicated Mobile P. A. U. T Unit (NDT) ü Bay 2: 30 welding equipment’s manual (FCAW and SMAW) 2 over head cranes 80 t/5 t+80/5 tons ü Bay 3: 30 welding equipment’s manual (TIG, FCAW and SMAW) 2 over head cranes 80 t/5 t+80/5 tons ü Bay 4: 30 welding equipment’s manual (TIG, FCAW and SMAW) 2 over head cranes 40 t/5 t+40 t/5 tons BOS SHELF COMPANY PROFILE 24

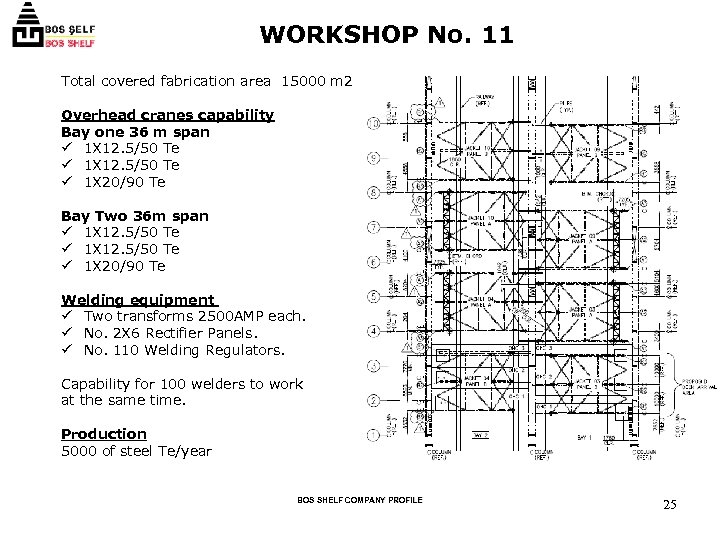

WORKSHOP No. 11 Total covered fabrication area 15000 m 2 Overhead cranes capability Bay one 36 m span ü 1 X 12. 5/50 Te ü 1 X 20/90 Te Bay Two 36 m span ü 1 X 12. 5/50 Te ü 1 X 20/90 Te Welding equipment ü Two transforms 2500 AMP each. ü No. 2 X 6 Rectifier Panels. ü No. 110 Welding Regulators. Capability for 100 welders to work at the same time. Production 5000 of steel Te/year BOS SHELF COMPANY PROFILE 25

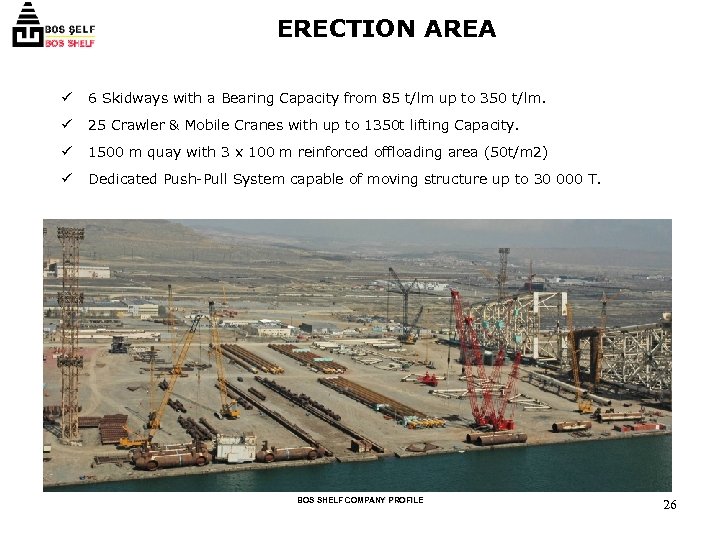

ERECTION AREA ü 6 Skidways with a Bearing Capacity from 85 t/lm up to 350 t/lm. ü 25 Crawler & Mobile Cranes with up to 1350 t lifting Capacity. ü 1500 m quay with 3 x 100 m reinforced offloading area (50 t/m 2) ü Dedicated Push-Pull System capable of moving structure up to 30 000 T. BOS SHELF COMPANY PROFILE 26

PAINTING/BLASTING EXISTING FACILITIES ü Recoverable Blast medium ü Monthly Capacity of up to 12 000 m 2. ü Adjacent Area for Expansion. üTemperature Controlled. üEnvironmentally & VOC Compliant Paints. üT. S. A. Capability BOS SHELF COMPANY PROFILE 27

NEW PAINTING FACILITIES ü Dedicated to blocks ü Consisting of three (3) separated areas: • one (1) for grit blasting, • one (1) for priming, coating and curing • one (1) custom coating ü Each bay shall be 25 m width by 36 m, 72 m & 42 m respectfully. ü The overall building size shall be 180 m x 25 m. BOS SHELF COMPANY PROFILE 28

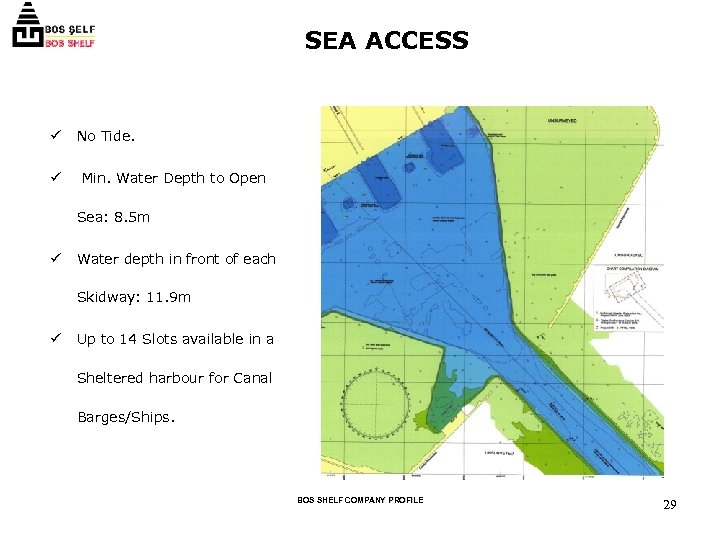

SEA ACCESS ü ü No Tide. Min. Water Depth to Open Sea: 8. 5 m ü Water depth in front of each Skidway: 11. 9 m ü Up to 14 Slots available in a Sheltered harbour for Canal Barges/Ships. BOS SHELF COMPANY PROFILE 29

HUMAN RESOURCES BOS SHELF COMPANY PROFILE 30

Yard Organisation Chart BOS SHELF COMPANY PROFILE 31

HUMAN RESOURCES ü A multi-national skilled team. • Average 15 years experience in Offshore Industry. • 7 nationalities represented. ü An intensive training program. • Over 95 000 training hours per year. • Integrated Fitters and Welders Training Center BOS SHELF COMPANY PROFILE 32

EXTENSIVE TRAINING CAPACITY & PROGRAMS ü 1 Welding Training Center with a yearly capacity of training of up to 360 welders 1 G to 6 GR. ü 1 Fitter Training Center with a yearly capacity of training of up to 900 Junior Fitters. ü 1 Fully Equipped Training Room with Multimedia Capabilities. ü 60 Training Modules available for Staff and Workforce qualification permanent improvement. BOS SHELF COMPANY PROFILE 33

72b437e4f8b1ab3080dc9b17ed5ca915.ppt