dba0586e8fa226ec05a78a45f9af7404.ppt

- Количество слайдов: 25

Baker Jardine Petroleum Engineering & Software Gas Lift Diagnostics A New Approach Daniel Lucas-Clements Baker Jardine

Introduction Baker Jardine Update PIPESIM Update Gas Lift Diagnostics in Context Baker Jardine Petroleum Engineering & Software

Baker Jardine Petroleum Engineering & Software PIPESIM / Baker Jardine Update Baker Jardine acquired by Schlumberger April 2001 Continue to Focus on PIPESIM Suite and Prod. Man Plus Integration with SLB Products e. g. Eclipse, OFM, Finder… PIPESIM 2000 launched. Development project to rewrite program interface. Integration under one user interface.

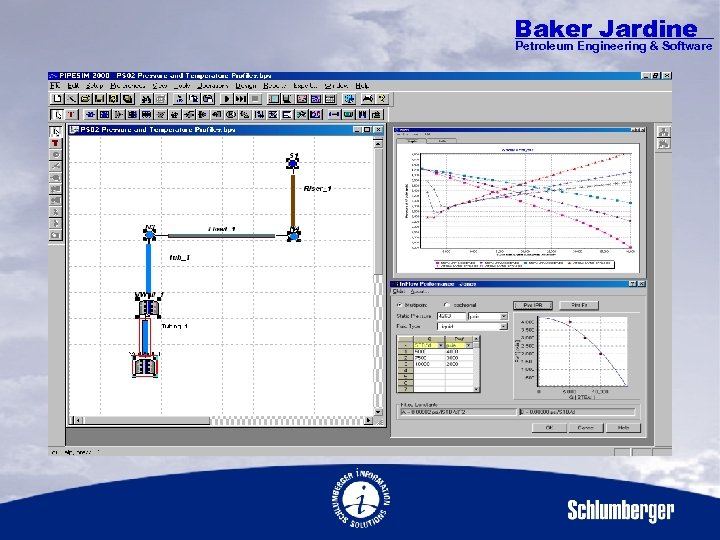

Baker Jardine Petroleum Engineering & Software

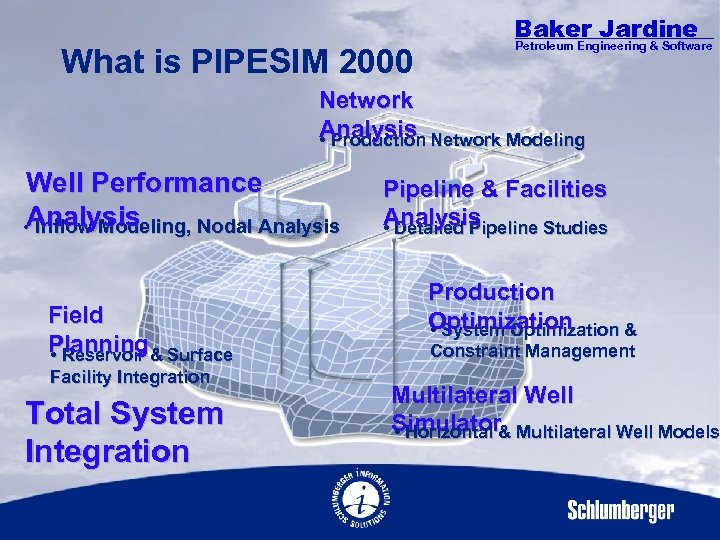

What is PIPESIM 2000 Baker Jardine Petroleum Engineering & Software Network Analysis Network Modeling • Production Well Performance Analysis • Inflow Modeling, Nodal Analysis Field Planning& Surface • Reservoir Facility Integration Total System Integration Pipeline & Facilities Analysis • Detailed Pipeline Studies Production Optimization • System Optimization & Constraint Management Multilateral Well Simulator& Multilateral Well Models • Horizontal

Field Planning Tool Baker Jardine Petroleum Engineering & Software Allows PIPESIM 2000 Well / Network models to be linked with detailed reservoir descriptions Built-in models: Look-up tables, Blackoil / Compositional Material balance models Reservoir models: Eclipse 100 / 300 and others Allows time-stepping of the coupled model through field life Includes field planning events controlled via an easy to use graphical user interface Time based events Conditional events

Baker Jardine Petroleum Engineering & Software Gas Lift Diagnostics

Gas Lift Diagnostics Baker Jardine Petroleum Engineering & Software What is happening down hole? Is my well working correctly? Can my well be more efficient? What data do I have? What do I need to correct the problem? Can I correct the problem without intervention? Do I need to collect further data? Can I justify the chosen course of action?

Traditional Approach Baker Jardine Petroleum Engineering & Software Analyse well by well – No targeting Analyse well when new data available Mostly analyse after Flowing P&T survey Occasionally analyse with new well test First analysis leads to more data gathering Initiates use of chart recorders Cycle times on well optimisations can be long

Production Challenges The Challenge Better surveillance Faster problem diagnosis Optimum production operations The Method Data management Apply simulation Baker Jardine Petroleum Engineering & Software

Prod. Man Features Baker Jardine Petroleum Engineering & Software Data Management Well tests, field data, SCADA & DCS data Automated collection Presentation and trending to operators Simulation Conversion of data into information with PIPESIM 2000 Automated Surveillance Diagnostics Constraint Management Real-Time Optimization

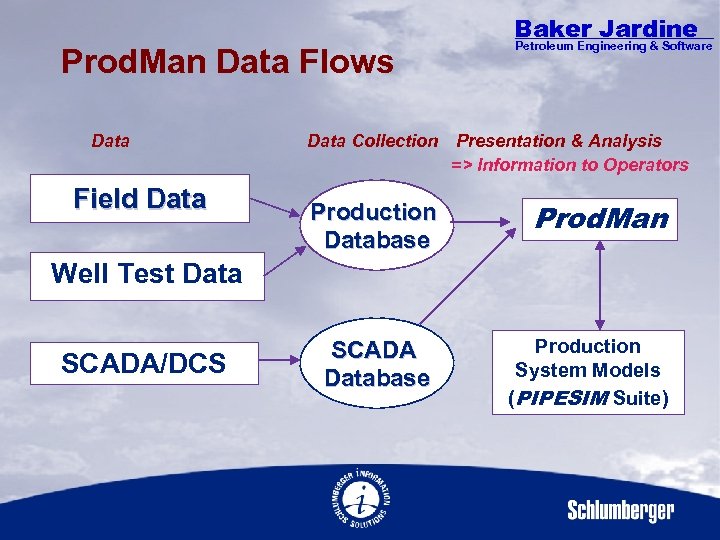

Prod. Man Data Flows Data Field Data Collection Production Database Baker Jardine Petroleum Engineering & Software Presentation & Analysis => Information to Operators Prod. Man Well Test Data SCADA/DCS SCADA Database Production System Models (PIPESIM Suite)

What’s Changing? Baker Jardine Petroleum Engineering & Software Field Automation Real time data on Engineers Desk Cheaper controls for continuous control People Issues Fewer operational staff Monitoring more information Tend to be “Fire fighting”

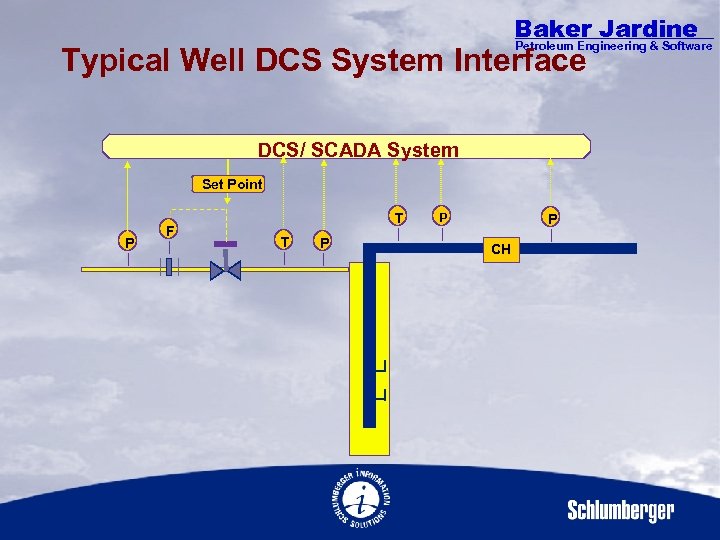

Baker Jardine Petroleum Engineering & Software Typical Well DCS System Interface DCS/ SCADA System Set Point P F T T P P P CH

Prod. Man Gas Lift Diagnostic Baker Jardine Petroleum Engineering & Software Determine the status of each gas lift valve and how much gas is being passed Automatic data retrieval Batch processing to screen large numbers of wells Analysis capability to diagnose individual wells

Gas Lift Diagnostic Baker Jardine Petroleum Engineering & Software Design Philosophy Use simulation to determine information Use real-time and offline data Design system to short list potential problem wells Allows large numbers of wells to be monitored Use available data Increase in data provides enhanced diagnostic

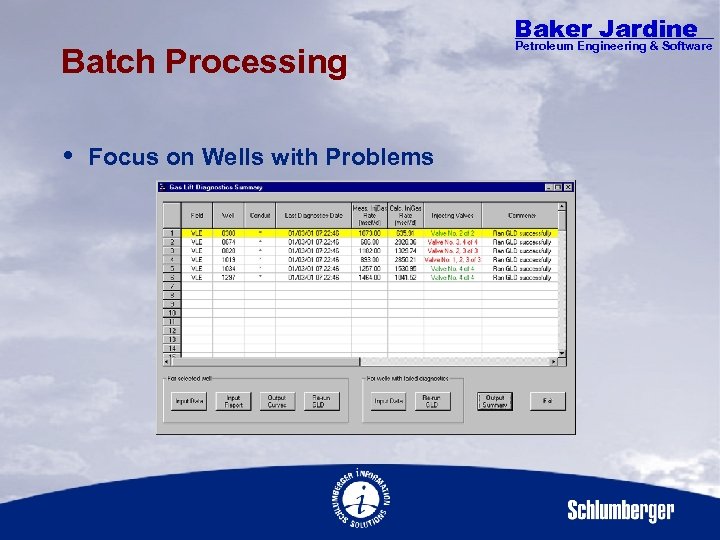

Batch Processing Focus on Wells with Problems Baker Jardine Petroleum Engineering & Software

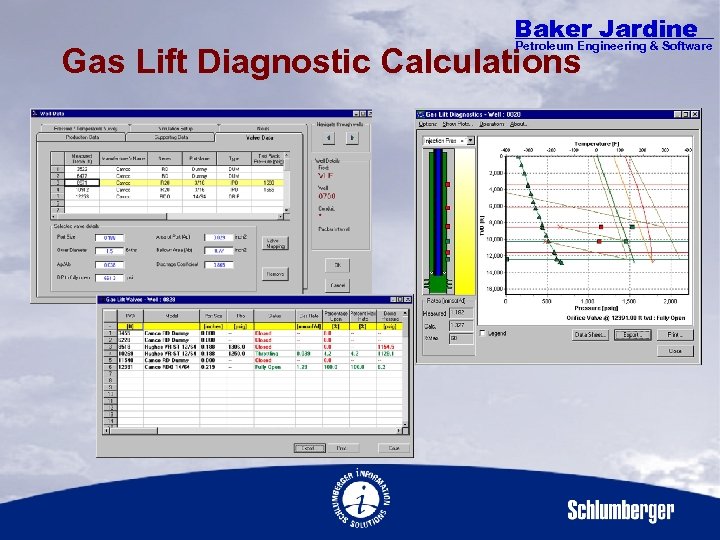

Baker Jardine Petroleum Engineering & Software Gas Lift Diagnostic Calculations

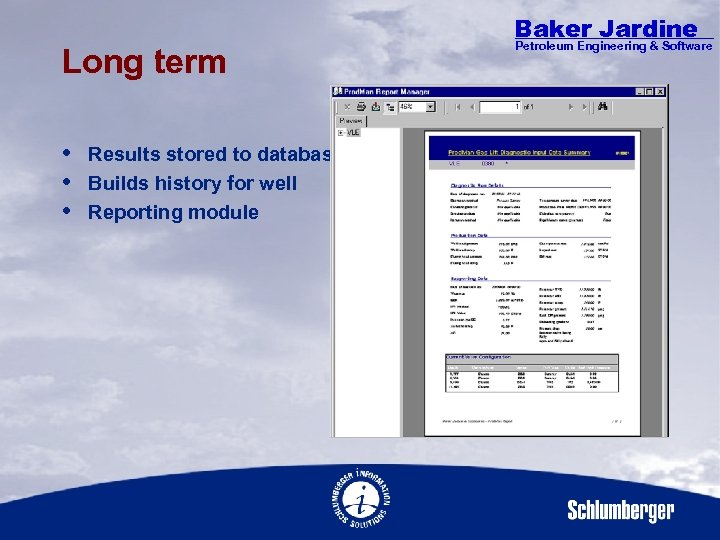

Long term Results stored to database Builds history for well Reporting module Baker Jardine Petroleum Engineering & Software

Baker Jardine Petroleum Engineering & Software Prod. Man Gas Lift Diagnostic One Part of Prod. Man

Prod. Man Focus • • Calculating unmeasured variables Comparing measured to calculated values Production Diagnostics • • • Petroleum Engineering & Software Production Surveillance • • Baker Jardine Well test analysis On-line Gas Lift Diagnostics Production Optimization • Field wide production optimization • Reacting to hourly changes in equipment availability

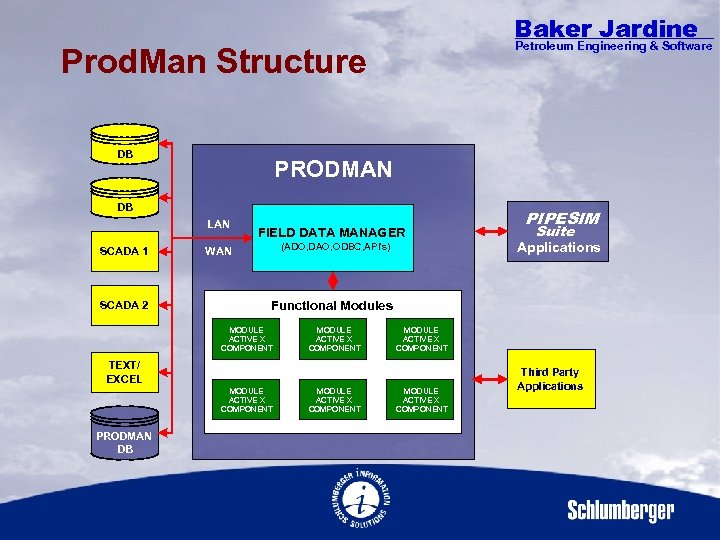

Baker Jardine Petroleum Engineering & Software Prod. Man Structure DB PRODMAN DB LAN SCADA 1 SCADA 2 FIELD DATA MANAGER (ADO, DAO, ODBC, API's) WAN Suite Applications Functional Modules MODULE ACTIVE X COMPONENT TEXT/ EXCEL MODULE ACTIVE X COMPONENT PRODMAN DB PIPESIM MODULE ACTIVE X COMPONENT Third Party Applications

Baker Jardine Petroleum Engineering & Software Other Gas Lift Based Modules Validation of well tests Well Performance Analysis Module Field Wide gas lift optimisation Constraint calculation Dual String optimization Retrieval / Return of data to control system

Related Modules ESP Diagnostic Data Processing Process Material Balance Production Allocation Long term monitoring Inflow Performance Baker Jardine Petroleum Engineering & Software

Conclusions Baker Jardine Petroleum Engineering & Software Automation is multiplying data availability Analysis must capture value in data Tools should focus on presenting The problems wells The complete picture to understand the problem The Challenge – Are you making the most of your data?

dba0586e8fa226ec05a78a45f9af7404.ppt