ff7a4a754706c3b1b9b0131f61e8b264.ppt

- Количество слайдов: 27

BAE SYSTEMS Overview of Systems Engineering at BAE SYSTEMS & ALENIA MARCONI SYSTEMS By Leigh Watton Friday 27 th July 2001 3/18/2018/MS 115 -01

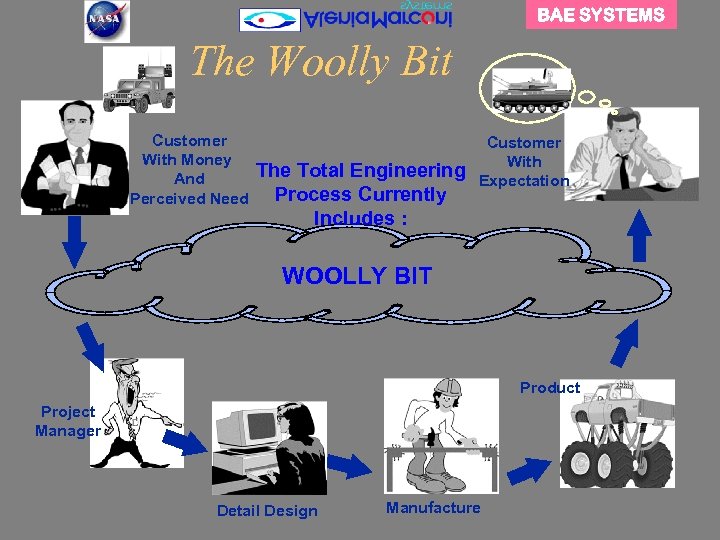

BAE SYSTEMS The Woolly Bit Customer With Money And Perceived Need The Total Engineering Process Currently Includes : Customer With Expectation WOOLLY BIT Product Project Manager Detail Design Manufacture

BAE SYSTEMS Complexity Scale Width The total complexity of the system exceeds one person’s ‘Brainful’

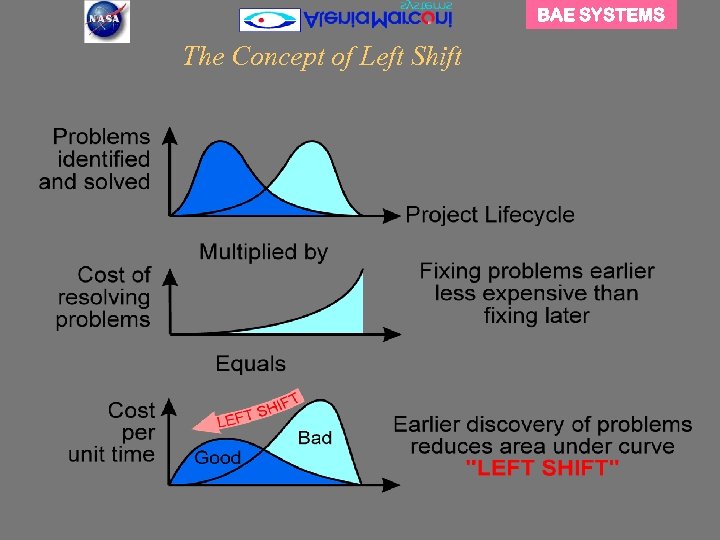

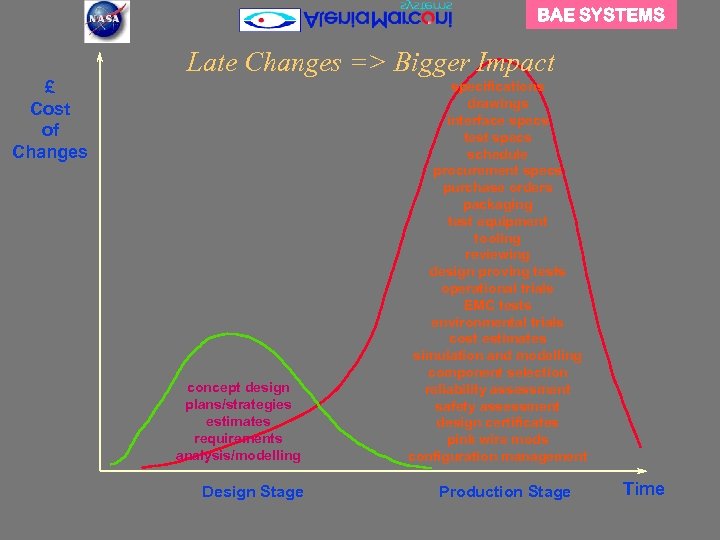

BAE SYSTEMS The Concept of Left Shift

BAE SYSTEMS £ Cost of Changes Late Changes => Bigger Impact concept design plans/strategies estimates requirements analysis/modelling Design Stage specifications drawings interface specs test specs schedule procurement specs purchase orders packaging test equipment tooling reviewing design proving tests operational trials EMC tests environmental trials cost estimates simulation and modelling component selection reliability assessment safety assessment design certificates pink wire mods configuration management Production Stage Time

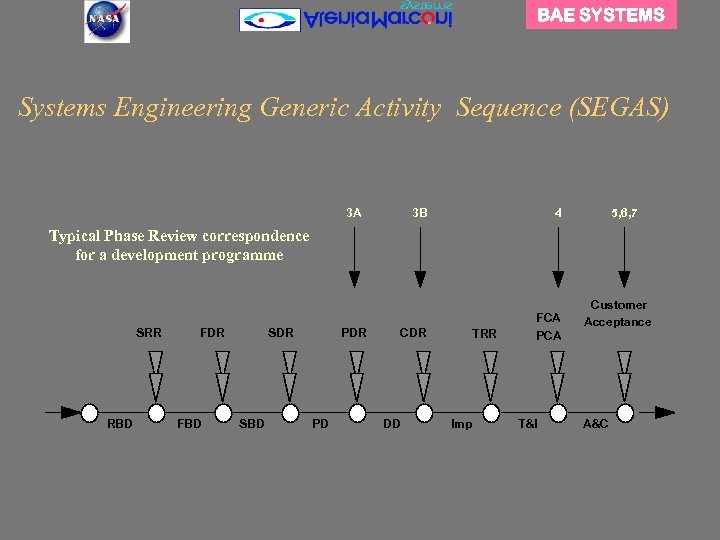

BAE SYSTEMS Systems Engineering Generic Activity Sequence (SEGAS) 3 A 3 B 4 CDR FCA PCA 5, 6, 7 Typical Phase Review correspondence for a development programme SRR RBD FDR FBD SDR SBD PDR PD DD TRR Imp T&I Customer Acceptance A&C

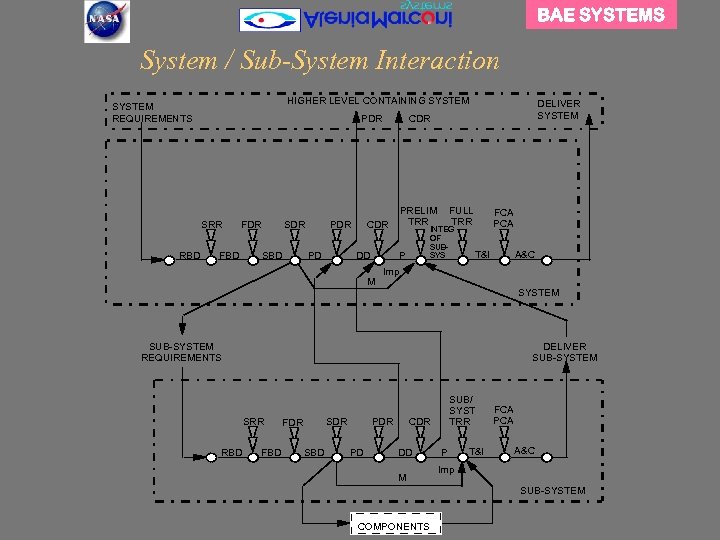

BAE SYSTEMS System / Sub-System Interaction HIGHER LEVEL CONTAINING SYSTEM REQUIREMENTS PDR SRR RBD FDR FBD SDR SBD PDR PD CDR DD FULL TRR PRELIM TRR CDR INTEG OF SUBSYS P M DELIVER SYSTEM FCA PCA T&I A&C Imp SYSTEM SUB-SYSTEM REQUIREMENTS DELIVER SUB-SYSTEM SRR RBD FBD SDR FDR SBD PDR PD SUB/ SYST TRR CDR DD M P T&I FCA PCA A&C Imp SUB-SYSTEM COMPONENTS

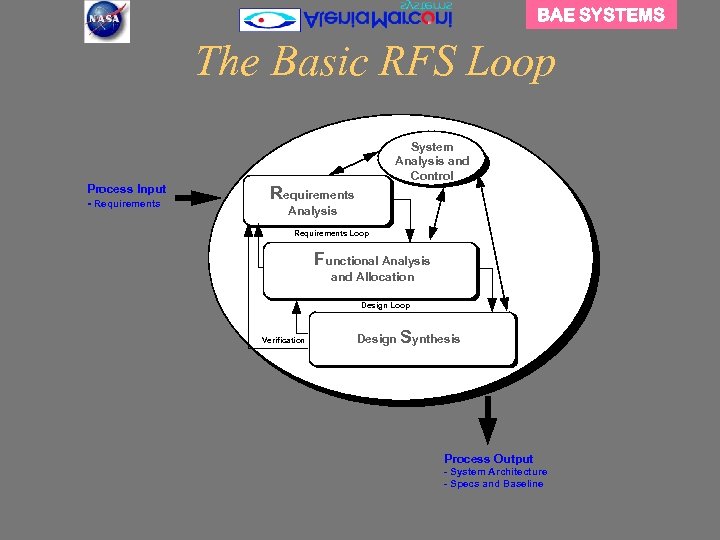

BAE SYSTEMS The Basic RFS Loop Process Input - Requirements System Analysis & Control Analysis and (Balance) Control Requirements Analysis Requirements Loop Functional Analysis and Allocation Design Loop Verification Design Synthesis Process Output - System Architecture - Specs and Baseline

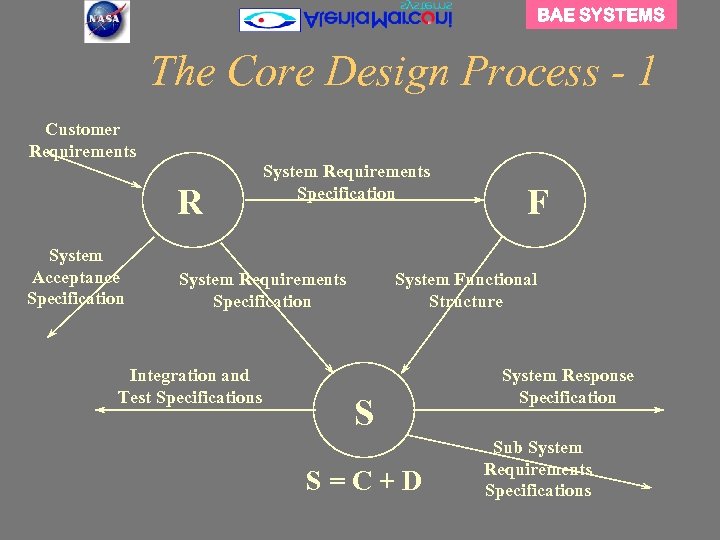

BAE SYSTEMS The Core Design Process - 1 Customer Requirements R System Acceptance Specification System Requirements Specification Integration and Test Specifications F System Functional Structure S S=C+D System Response Specification Sub System Requirements Specifications

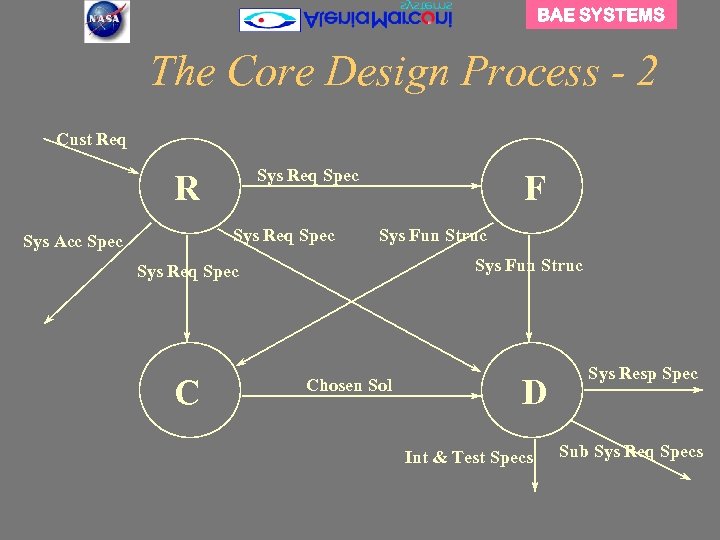

BAE SYSTEMS The Core Design Process - 2 Cust Req Sys Req Spec R Sys Req Spec Sys Acc Spec F Sys Fun Struc Sys Req Spec C Chosen Sol D Int & Test Specs Sys Resp Spec Sub Sys Req Specs

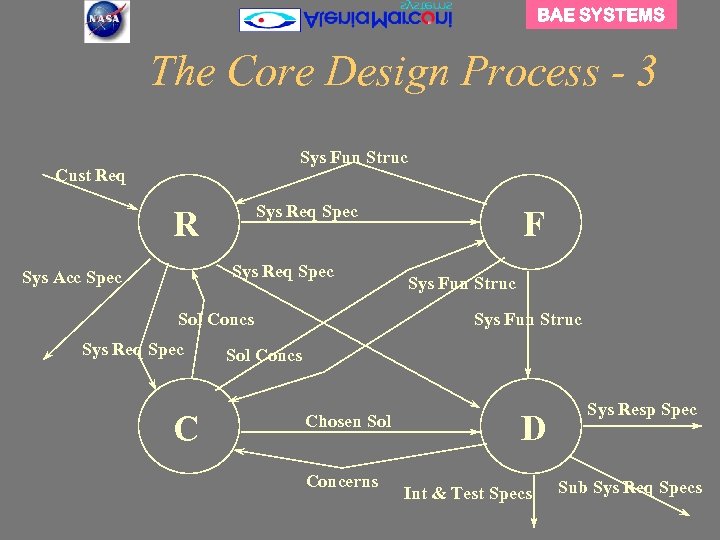

BAE SYSTEMS The Core Design Process - 3 Sys Fun Struc Cust Req Sys Req Spec R Sys Req Spec Sys Acc Spec Sol Concs Sys Req Spec C F Sys Fun Struc Sol Concs Chosen Sol Concerns D Int & Test Specs Sys Resp Spec Sub Sys Req Specs

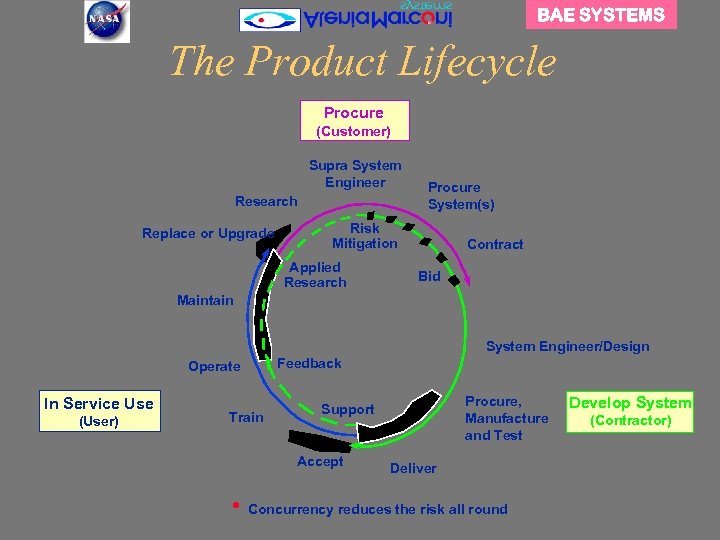

BAE SYSTEMS The Product Lifecycle Procure (Customer) Supra System Engineer Research Replace or Upgrade Procure System(s) Risk Mitigation Applied Research Contract Bid Maintain System Engineer/Design Feedback Operate In Service Use (User) Train Accept • Procure, Manufacture and Test Support Deliver Concurrency reduces the risk all round Develop System (Contractor)

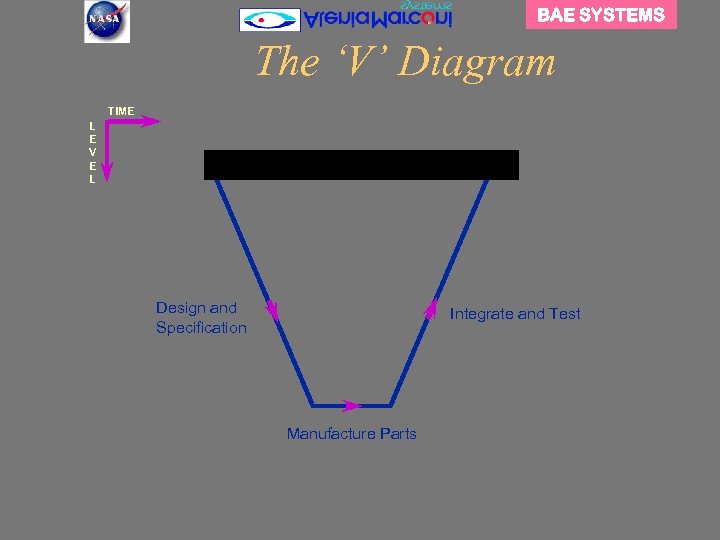

BAE SYSTEMS The ‘V’ Diagram TIME L E V E L Design and Specification Integrate and Test Manufacture Parts

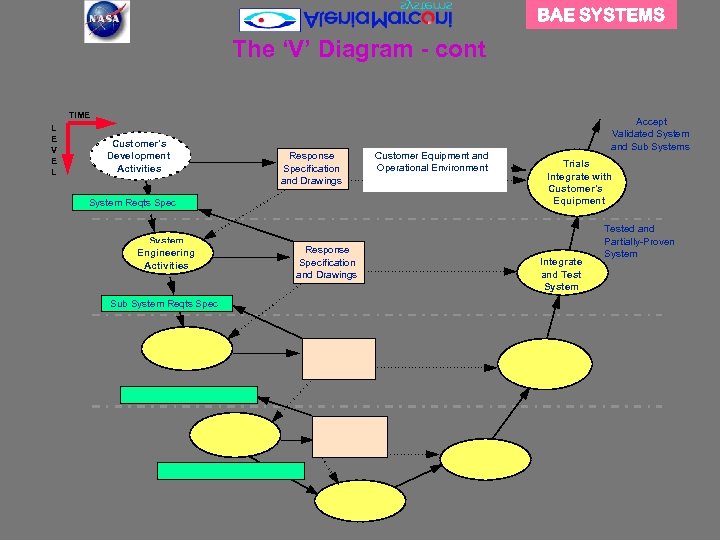

BAE SYSTEMS The ‘V’ Diagram - cont TIME L E V E L Customer's Development Activities Response Specification and Drawings System Reqts Spec System Engineering Activities Sub System Reqts Spec Response Specification and Drawings Customer Equipment and Operational Environment Accept Validated System and Sub Systems Trials Integrate with Customer's Equipment Integrate and Test System Tested and Partially-Proven System

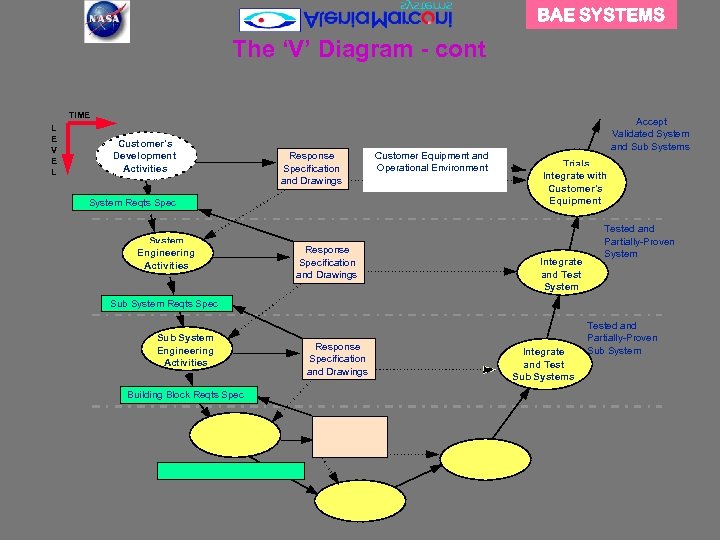

BAE SYSTEMS The ‘V’ Diagram - cont TIME L E V E L Customer's Development Activities Response Specification and Drawings System Reqts Spec System Engineering Activities Response Specification and Drawings Customer Equipment and Operational Environment Accept Validated System and Sub Systems Trials Integrate with Customer's Equipment Integrate and Test System Tested and Partially-Proven System Sub System Reqts Spec Sub System Engineering Activities Building Block Reqts Spec Response Specification and Drawings Integrate and Test Sub Systems Tested and Partially-Proven Sub System

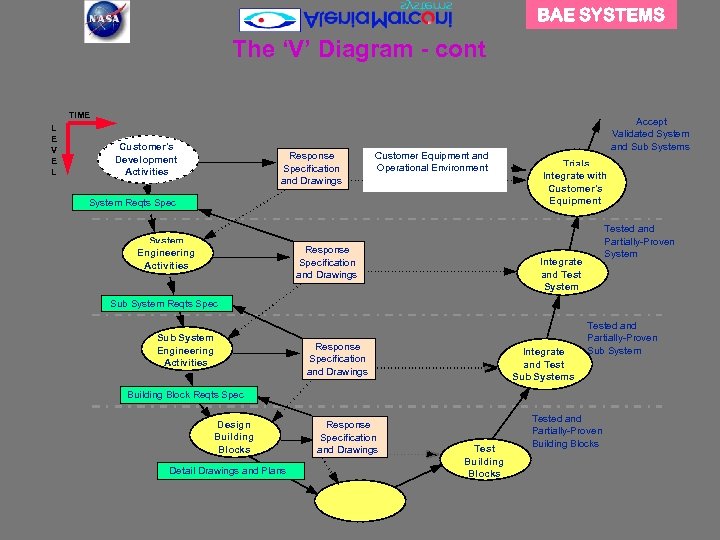

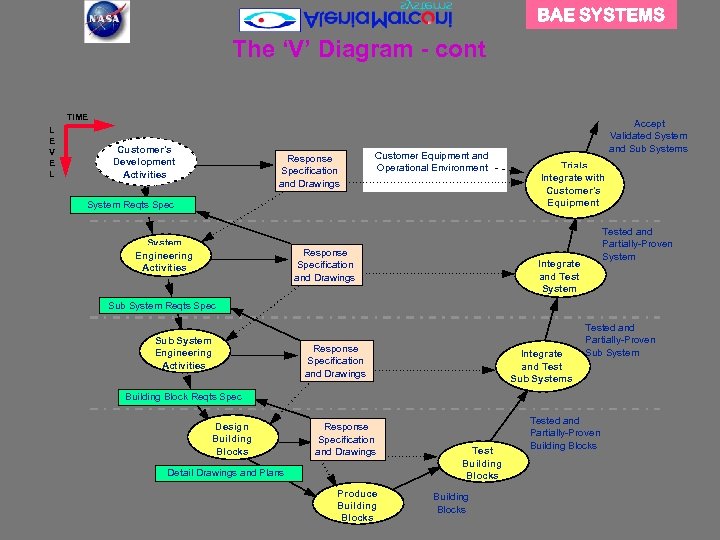

BAE SYSTEMS The ‘V’ Diagram - cont TIME L E V E L Customer's Development Activities Response Specification and Drawings Customer Equipment and Operational Environment System Reqts Spec System Engineering Activities Response Specification and Drawings Accept Validated System and Sub Systems Trials Integrate with Customer's Equipment Tested and Partially-Proven System Integrate and Test System Sub System Reqts Spec Sub System Engineering Activities Response Specification and Drawings Integrate and Test Sub Systems Tested and Partially-Proven Sub System Building Block Reqts Spec Design Building Blocks Detail Drawings and Plans Response Specification and Drawings Test Building Blocks Tested and Partially-Proven Building Blocks

BAE SYSTEMS The ‘V’ Diagram - cont TIME L E V E L Customer's Development Activities Response Specification and Drawings Customer Equipment and Operational Environment System Reqts Spec System Engineering Activities Response Specification and Drawings Accept Validated System and Sub Systems Trials Integrate with Customer's Equipment Tested and Partially-Proven System Integrate and Test System Sub System Reqts Spec Sub System Engineering Activities Response Specification and Drawings Integrate and Test Sub Systems Tested and Partially-Proven Sub System Building Block Reqts Spec Design Building Blocks Response Specification and Drawings Detail Drawings and Plans Produce Building Blocks Tested and Partially-Proven Building Blocks

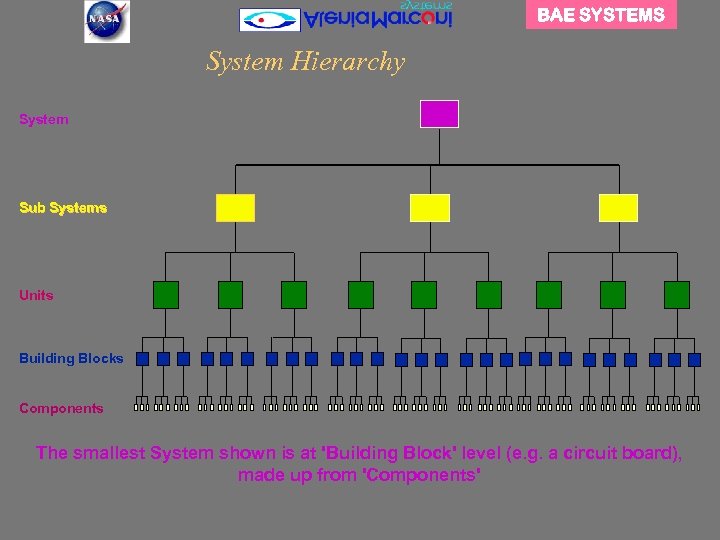

BAE SYSTEMS System Hierarchy System Sub Systems Units Building Blocks Components The smallest System shown is at 'Building Block' level (e. g. a circuit board), made up from 'Components'

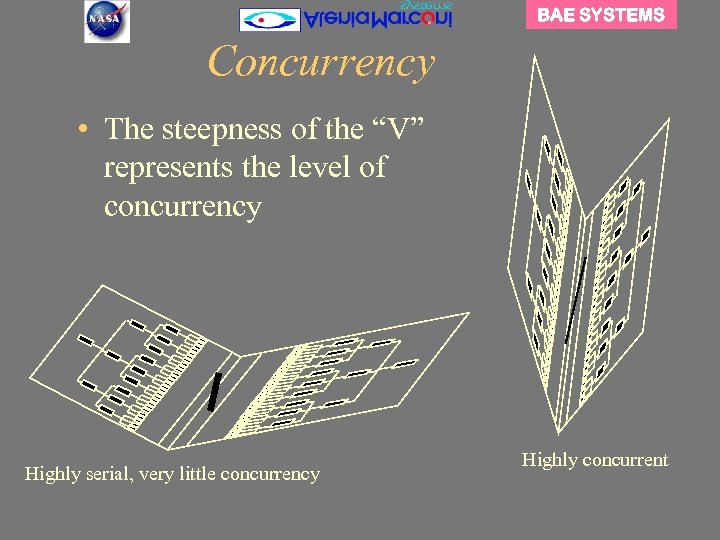

BAE SYSTEMS Concurrency • The steepness of the “V” represents the level of concurrency Highly serial, very little concurrency Highly concurrent

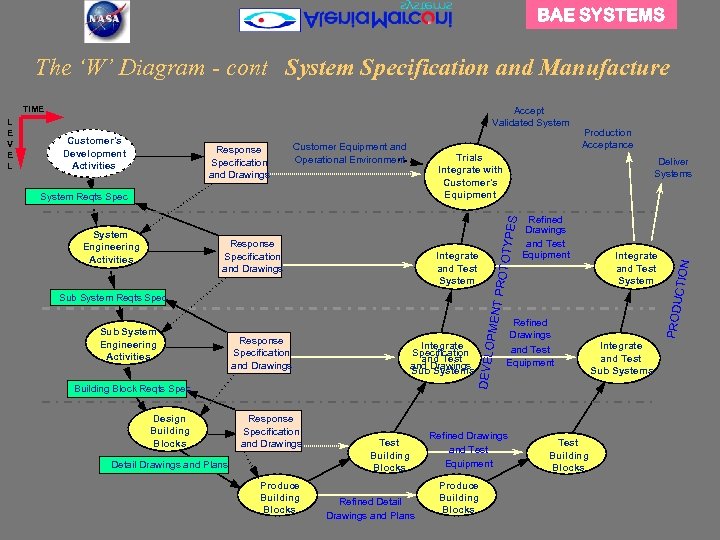

BAE SYSTEMS The ‘W’ Diagram - cont System Specification and Manufacture Accept Validated System Integrate Specification and Test and Drawings Sub Systems Building Block Reqts Spec Design Building Blocks Response Specification and Drawings Detail Drawings and Plans Produce Building Blocks Test Building Blocks Refined Detail Drawings and Plans DEVEL Response Specification and Drawings OPME Sub System Reqts Spec Refined Drawings and Test Equipment Produce Building Blocks Test Building Blocks Integrate and Test System N Integrate and Test System Refined Drawings and Test Equipment PROD Response Specification and Drawings Sub System Engineering Activities Deliver Systems PES System Reqts Spec System Engineering Activities Production Acceptance Trials Integrate with Customer's Equipment OTOTY Response Specification and Drawings Customer Equipment and Operational Environment NT PR Customer's Development Activities UCTIO TIME L E V E L Integrate and Test Sub Systems

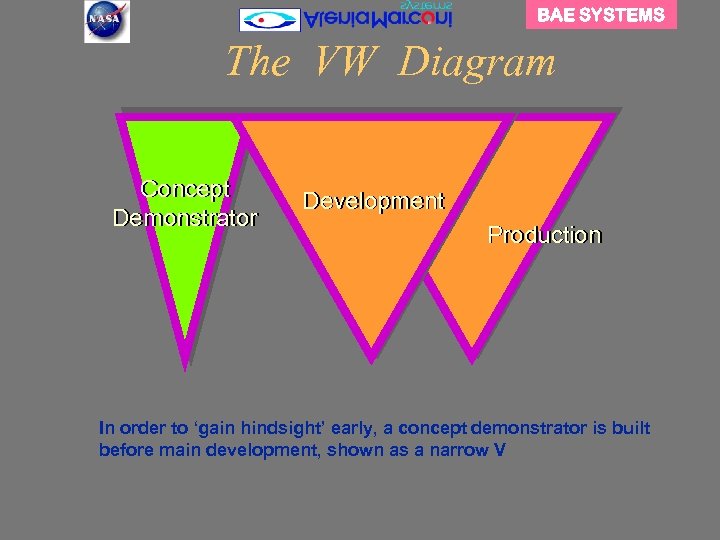

BAE SYSTEMS The VW Diagram Concept Demonstrator Development Production In order to ‘gain hindsight’ early, a concept demonstrator is built before main development, shown as a narrow V

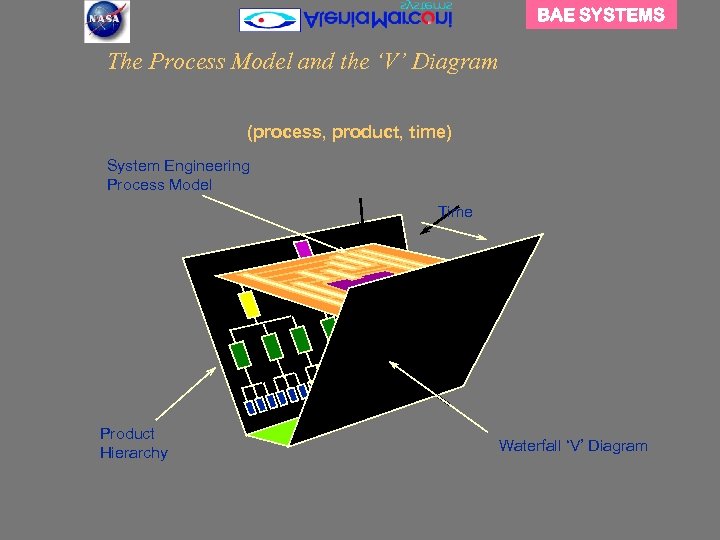

BAE SYSTEMS The Process Model and the ‘V’ Diagram (process, product, time) System Engineering Process Model Time Product Hierarchy Waterfall ‘V’ Diagram

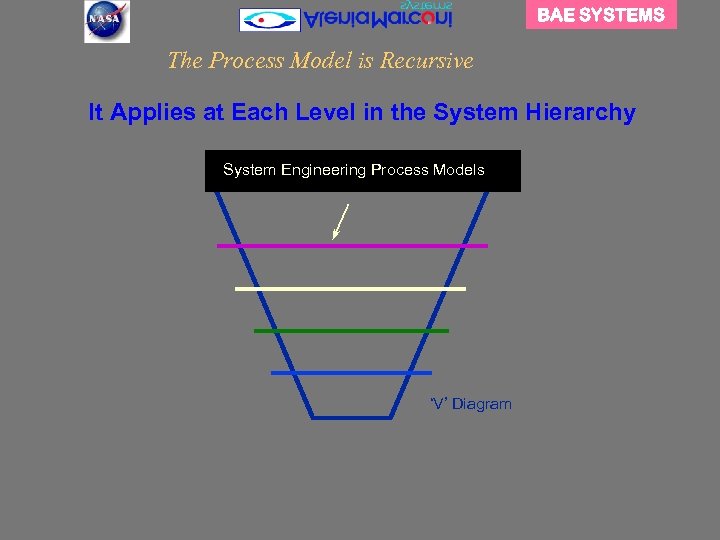

BAE SYSTEMS The Process Model is Recursive It Applies at Each Level in the System Hierarchy System Engineering Process Models ‘V’ Diagram

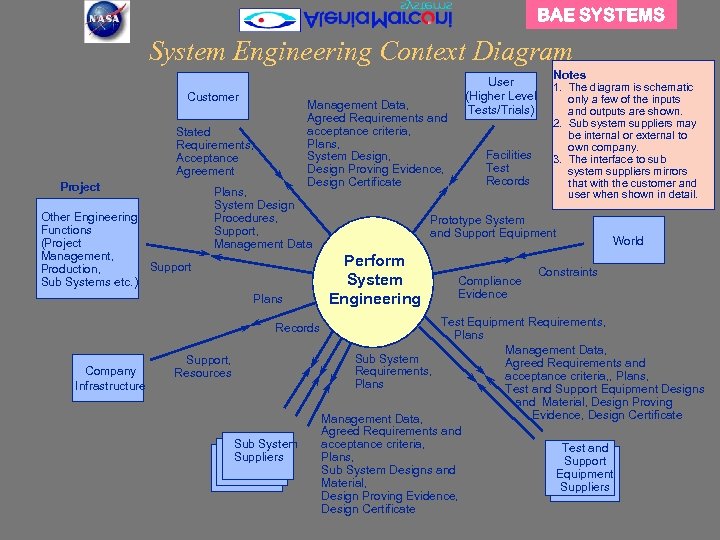

BAE SYSTEMS System Engineering Context Diagram Customer Management Data, Agreed Requirements and acceptance criteria, Plans, System Design, Design Proving Evidence, Design Certificate Stated Requirements, Acceptance Agreement Project Other Engineering Functions (Project Management, Support Production, Sub Systems etc. ) Plans, System Design Procedures, Support, Management Data Plans Records Company Infrastructure Support, Resources Sub System Suppliers User (Higher Level Tests/Trials) Facilities Test Records Notes 1. The diagram is schematic only a few of the inputs and outputs are shown. 2. Sub system suppliers may be internal or external to own company. 3. The interface to sub system suppliers mirrors that with the customer and user when shown in detail. Prototype System and Support Equipment Perform System Engineering Compliance Evidence World Constraints Test Equipment Requirements, Plans Management Data, Sub System Agreed Requirements and Requirements, acceptance criteria, , Plans Test and Support Equipment Designs and Material, Design Proving Evidence, Design Certificate Management Data, Agreed Requirements and acceptance criteria, Test and Plans, Support Sub System Designs and Equipment Material, Suppliers Design Proving Evidence, Design Certificate

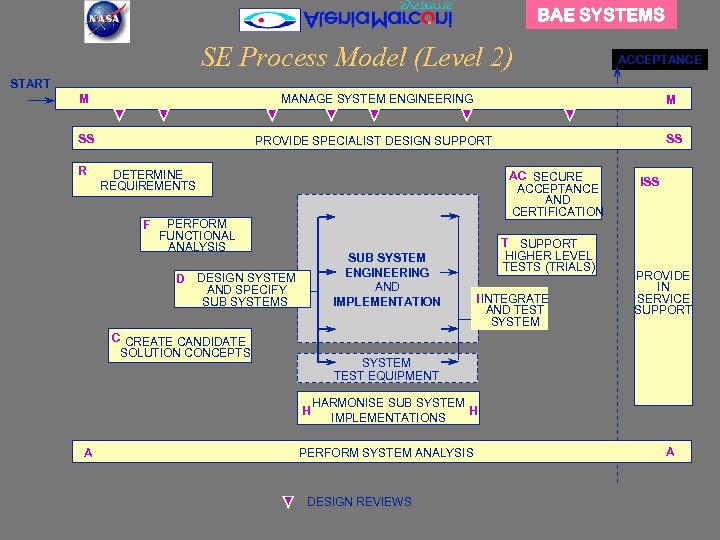

BAE SYSTEMS SE Process Model (Level 2) ACCEPTANCE START M MANAGE SYSTEM ENGINEERING SS PROVIDE SPECIALIST DESIGN SUPPORT R DETERMINE REQUIREMENTS F SUB SYSTEM ENGINEERING AND IMPLEMENTATION DESIGN SYSTEM AND SPECIFY SUB SYSTEMS C CREATE CANDIDATE SOLUTION CONCEPTS M SS AC SECURE ACCEPTANCE AND CERTIFICATION PERFORM FUNCTIONAL ANALYSIS D T SUPPORT HIGHER LEVEL TESTS (TRIALS) I INTEGRATE AND TEST SYSTEM ISS PROVIDE IN SERVICE SUPPORT SYSTEM TEST EQUIPMENT H A F HARMONISE SUB SYSTEM H IMPLEMENTATIONS PERFORM SYSTEM ANALYSIS DESIGN REVIEWS E A

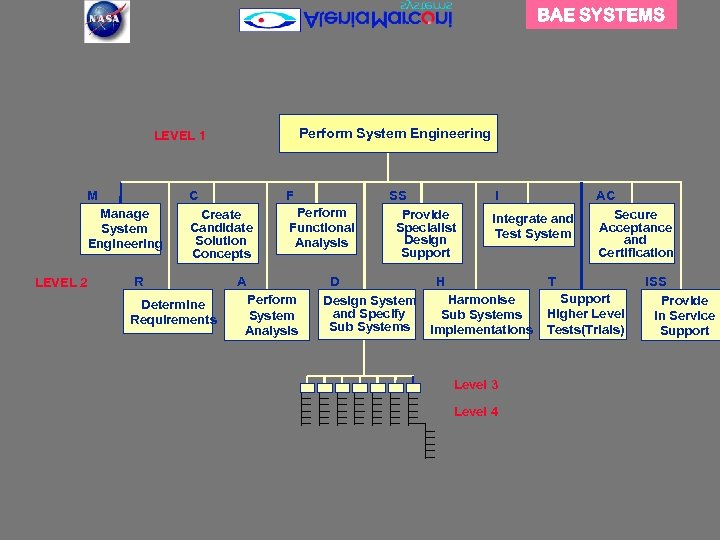

BAE SYSTEMS Perform System Engineering LEVEL 1 M C F Manage System Engineering Create Candidate Solution Concepts Perform Functional Analysis LEVEL 2 R Determine Requirements A Perform System Analysis SS Provide Specialist Design Support D Design System and Specify Sub Systems I Integrate and Test System H AC Secure Acceptance and Certification T Harmonise Sub Systems Implementations Level 3 Level 4 Support Higher Level Tests(Trials) ISS Provide In Service Support

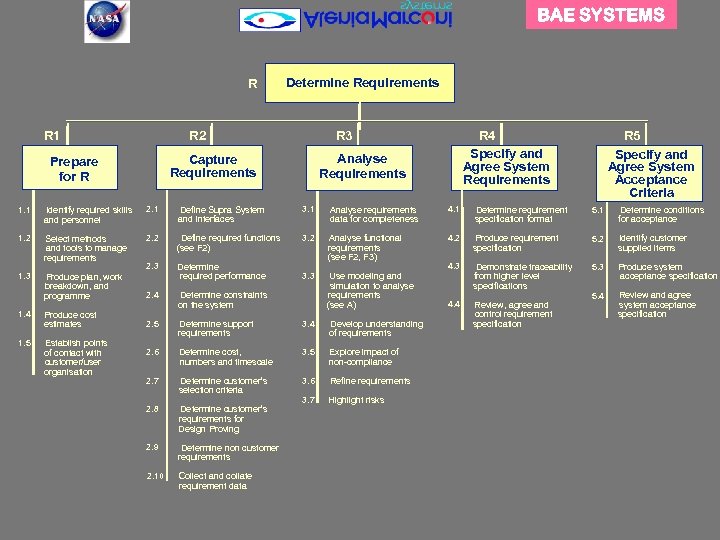

BAE SYSTEMS R R 1 Determine Requirements R 2 R 3 Analyse Requirements Capture Requirements Prepare for R R 4 Specify and Agree System Requirements R 5 Specify and Agree System Acceptance Criteria 1. 1 Identify required skills and personnel 2. 1 Define Supra System and interfaces 3. 1 Analyse requirements data for completeness 4. 1 Determine requirement specification format 5. 1 Determine conditions for acceptance 1. 2 Select methods and tools to manage requirements 2. 2 Define required functions (see F 2) 3. 2 4. 2 Produce requirement specification 5. 2 Identify customer supplied items 1. 3 2. 3 3. 3 Produce system acceptance specification 4. 4 Produce cost estimates 2. 5 3. 4 Establish points of contact with customer/user organisation Develop understanding of requirements Review and agree system acceptance specification 1. 5 Determine support requirements Review, agree and control requirement specification 5. 4 1. 4 Determine constraints on the system Demonstrate traceability from higher level specifications 5. 3 2. 4 Use modeling and simulation to analyse requirements (see A) 4. 3 Produce plan, work breakdown, and programme Determine required performance Analyse functional requirements (see F 2, F 3) 2. 6 Determine cost, numbers and timescale 3. 5 Explore impact of non-compliance 2. 7 Determine customer’s selection criteria 3. 6 Refine requirements 2. 8 Determine customer’s requirements for Design Proving 3. 7 Highlight risks 2. 9 Determine non customer requirements 2. 10 Collect and collate requirement data

ff7a4a754706c3b1b9b0131f61e8b264.ppt