75cbbcbc1754658999f421cc5bf4df07.ppt

- Количество слайдов: 16

B A S I C Innovative Technologies from Brazil and the Challenge for South-South Cooperation Jacques Marcovitch Universidade de São Paulo Brazil B A S I C

1. Technology and GHG Emissions Reduction l Sugar and Alcohol ¡ ¡ l Steel Industry ¡ ¡ ¡ l Sugarcane bagasse energy co-generation. Biofuels: ethanol production and distribution Pig iron made from coal produced from certified renewable forests Wood carbonization process in charcoal production to mitigate methane emissions Co-generation of energy with recuperation of LDG (Lindz-Donawitz Gas) gas Landfills ¡ Biogas generation in landfill to flare and/or to produce electric energy B A S I C

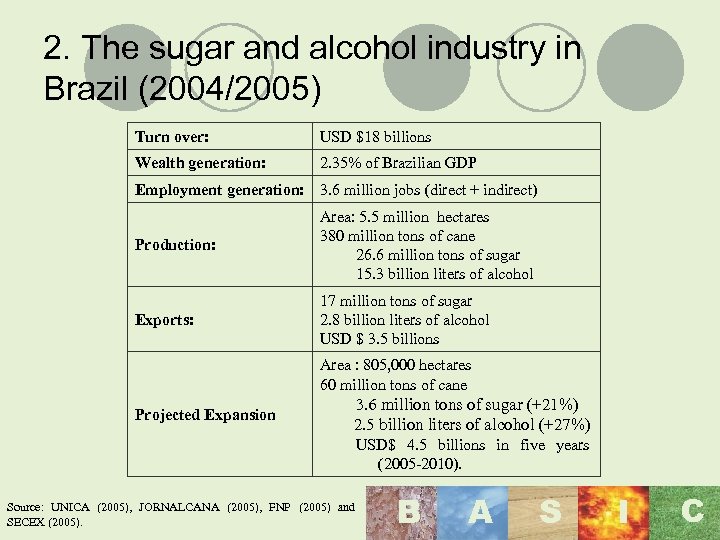

2. The sugar and alcohol industry in Brazil (2004/2005) Turn over: USD $18 billions Wealth generation: 2. 35% of Brazilian GDP Employment generation: 3. 6 million jobs (direct + indirect) Production: Area: 5. 5 million hectares 380 million tons of cane 26. 6 million tons of sugar 15. 3 billion liters of alcohol Exports: 17 million tons of sugar 2. 8 billion liters of alcohol USD $ 3. 5 billions Area : 805, 000 hectares 60 million tons of cane Projected Expansion 3. 6 million tons of sugar (+21%) 2. 5 billion liters of alcohol (+27%) USD$ 4. 5 billions in five years (2005 -2010). Source: UNICA (2005), JORNALCANA (2005), FNP (2005) and SECEX (2005). B A S I C

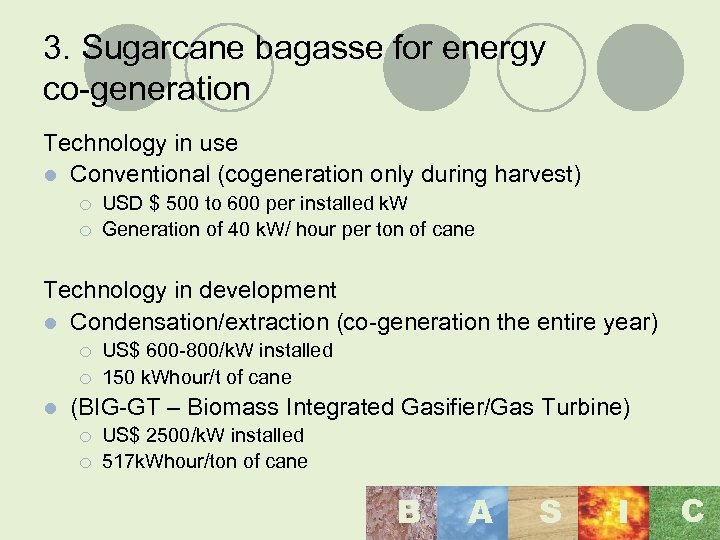

3. Sugarcane bagasse for energy co-generation Technology in use l Conventional (cogeneration only during harvest) ¡ ¡ USD $ 500 to 600 per installed k. W Generation of 40 k. W/ hour per ton of cane Technology in development l Condensation/extraction (co-generation the entire year) ¡ ¡ l US$ 600 -800/k. W installed 150 k. Whour/t of cane (BIG-GT – Biomass Integrated Gasifier/Gas Turbine) ¡ ¡ US$ 2500/k. W installed 517 k. Whour/ton of cane B A S I C

3. 1. Co-generation of energy Each ton of cane produces 140 kg of dry bagasse mass, 90% of which is used to produce energy at the mill. l Between 1980 and 2000, alcohol and sugar mills in Brazil evolved from a dependency on 40% 50% purchased electrical energy to self-reliance. l Self-reliance, with a balance between bagasse availability and production energy needs and also an excess of up to 10 k. Wh/t of cane. l B A S I C

3. 1. Co-generation of energy (cont) l Potential of 4. 000 - 5. 000 MW for 350 million tons (Mt) of cane per year. ¡ l Itaipu – 18 turbines – individual capacity of 715 MW Recent situation ¡ ¡ ¡ 184 self-reliant producers of the alcohol and sugar sector In 2003, installed capacity of 1. 582 MW, about 10% of the Brazilian thermoelectric capacity In 2002, trade of an excess of 5. 360 GWh (1, 6% of the consumption of electricity in Brazil) B A S I C

4. Ethanol as biofuel Tecnology for Ethanol Production Car Technology using Biofuels B A S I C

4. 1 Ethanol Production l Technology has reached full maturity; ¡ ¡ l Considerable progress made between 70’s and 90’s Productivity: 4, 200 liters per hectare of cane (1980) 6, 350 liters per hectare of cane (2003). Efficiency in the conversion of saccharose to ethanol ¡ ¡ Extraction and treatment of the juice (grinding) Fermentation Distillation Consumption of energy and water. B A S I C

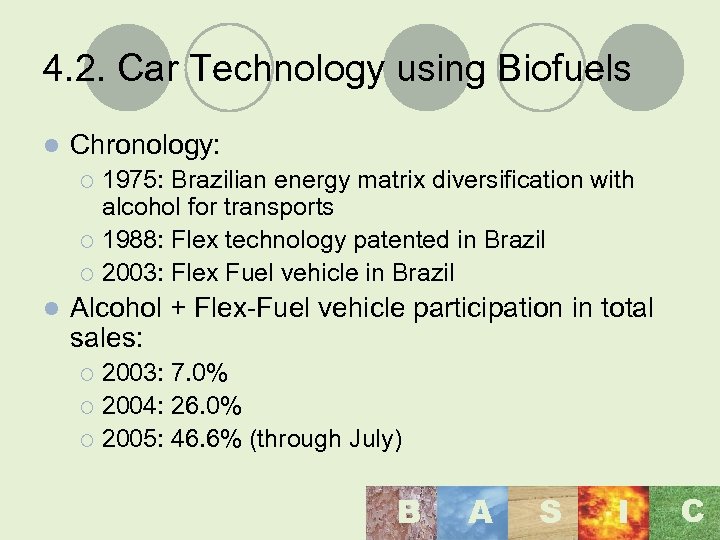

4. 2. Car Technology using Biofuels l Chronology: 1975: Brazilian energy matrix diversification with alcohol for transports ¡ 1988: Flex technology patented in Brazil ¡ 2003: Flex Fuel vehicle in Brazil ¡ l Alcohol + Flex-Fuel vehicle participation in total sales: 2003: 7. 0% ¡ 2004: 26. 0% ¡ 2005: 46. 6% (through July) ¡ B A S I C

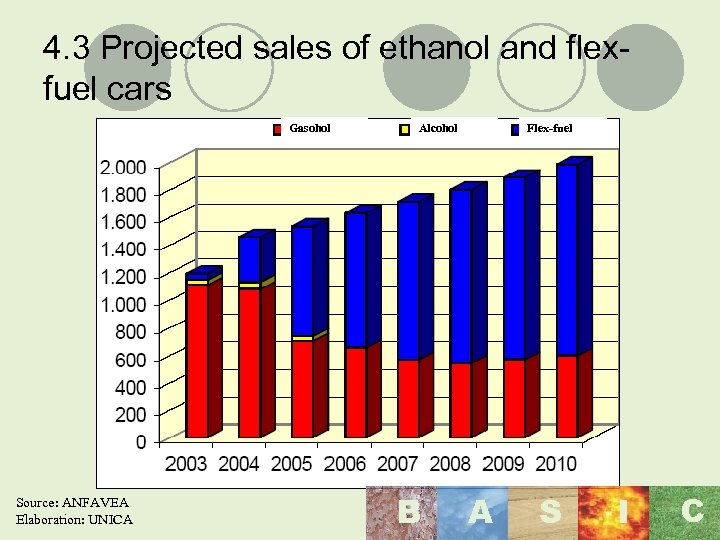

4. 3 Projected sales of ethanol and flexfuel cars Gasohol Source: ANFAVEA Elaboration: UNICA Alcohol B Flex-fuel A S I C

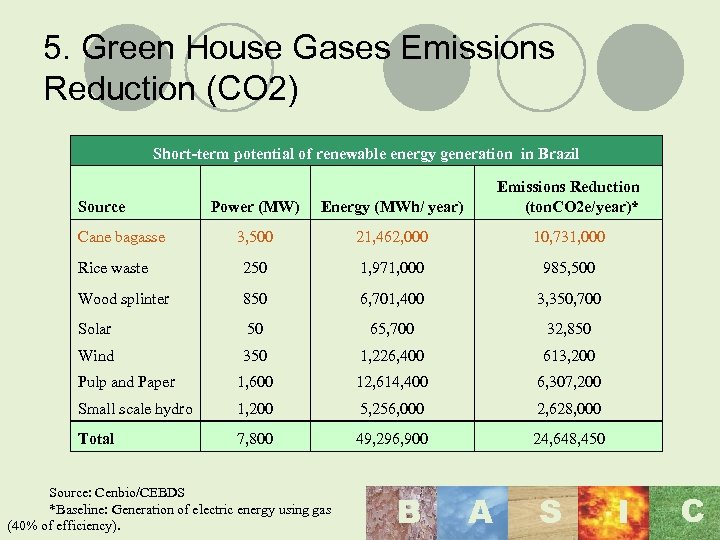

5. Green House Gases Emissions Reduction (CO 2) Short-term potential of renewable energy generation in Brazil Power (MW) Energy (MWh/ year) Emissions Reduction (ton. CO 2 e/year)* 3, 500 21, 462, 000 10, 731, 000 Rice waste 250 1, 971, 000 985, 500 Wood splinter 850 6, 701, 400 3, 350, 700 Solar 50 65, 700 32, 850 Wind 350 1, 226, 400 613, 200 Pulp and Paper 1, 600 12, 614, 400 6, 307, 200 Small scale hydro 1, 200 5, 256, 000 2, 628, 000 Total 7, 800 49, 296, 900 24, 648, 450 Source Cane bagasse Source: Cenbio/CEBDS *Baseline: Generation of electric energy using gas (40% of efficiency). B A S I C

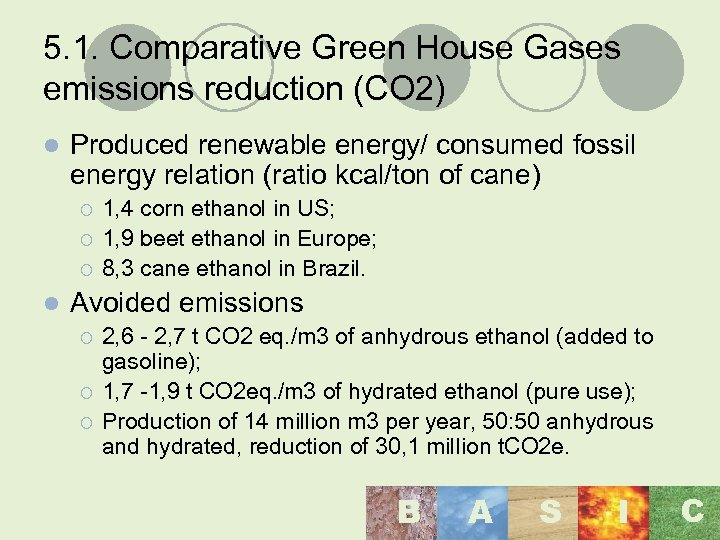

5. 1. Comparative Green House Gases emissions reduction (CO 2) l Produced renewable energy/ consumed fossil energy relation (ratio kcal/ton of cane) ¡ ¡ ¡ l 1, 4 corn ethanol in US; 1, 9 beet ethanol in Europe; 8, 3 cane ethanol in Brazil. Avoided emissions ¡ ¡ ¡ 2, 6 - 2, 7 t CO 2 eq. /m 3 of anhydrous ethanol (added to gasoline); 1, 7 -1, 9 t CO 2 eq. /m 3 of hydrated ethanol (pure use); Production of 14 million m 3 per year, 50: 50 anhydrous and hydrated, reduction of 30, 1 million t. CO 2 e. B A S I C

6. Technology innovation and the South cooperation l Ethanol production technology: ¡ ¡ l Main countries : India, Thailand etc…. . Caribbean countries: reduction of taxes for access to US market South-South technology co-operation ¡ ¡ Sharing of information regarding the performance of ESTs in developing countries; Joint R&D and demonstration programs; Promoting the development of human resources. Opening markets for ESTs from other developing countries. B A S I C

7. Sugar Cane Agriculture in Brazil North-Northeast (20% area) Crop season: sept/march Mid-South (80% area) crop season: april/ november

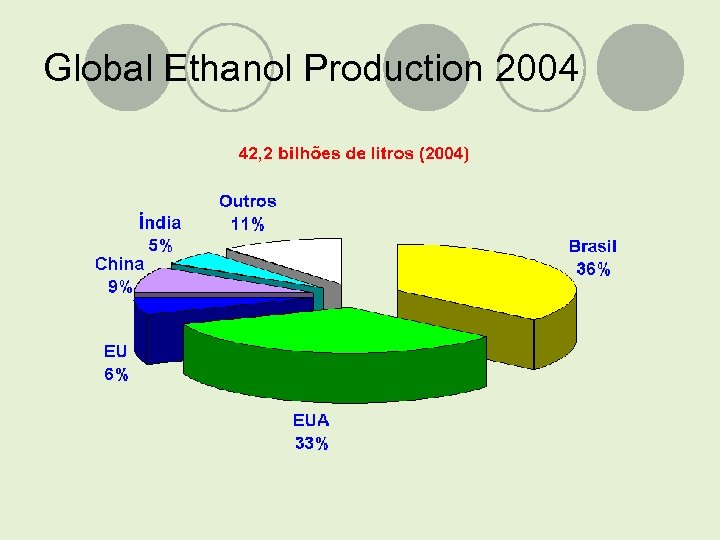

Global Ethanol Production 2004

Thank you! Prof. Jacques Marcovitch Universidade de São Paulo E-mail: jmarcovi@usp. br B A S I C

75cbbcbc1754658999f421cc5bf4df07.ppt