943305a2b73f4a0b903477238b959c52.ppt

- Количество слайдов: 51

Autonomously Controlled Front Loader By: Steve Koopman and Jerred Peterson Advisor: Dr. Schertz

Presentation Outline n n n n Project Introduction Hardware Design Software Design Final Progress Future Work Conclusion Questions

Presentation Outline n n n n Project Introduction Hardware Design Software Design Final Progress Future Work Conclusion Questions

Project Introduction n Project Motivation Work towards a fully automated system, such as a gravel yard n Investigate small-scale operation of autonomous vehicle n n Can model several interacting robots cheaply, without risk of damage n Allows work to be done towards full-scale operation n Starting point for additional small autonomous vehicles

Project Introduction n Specific Project Goals n Modify toy vehicle to do simple tasks n Load a bucket with material n Dump material into truck n Repeat until the truck is full Vehicle operates autonomously n Low cost vehicle design n Flexible design for future expansion n

Project Introduction n Project Goals for Tasks Rotate vehicle until loading bin located n Line up with bin, drive to it n Lower bucket and load material n Raise bucket and leave bin n Rotate until truck located, line up with the truck n Drive to truck, dump material into it n Repeat process until truck full n

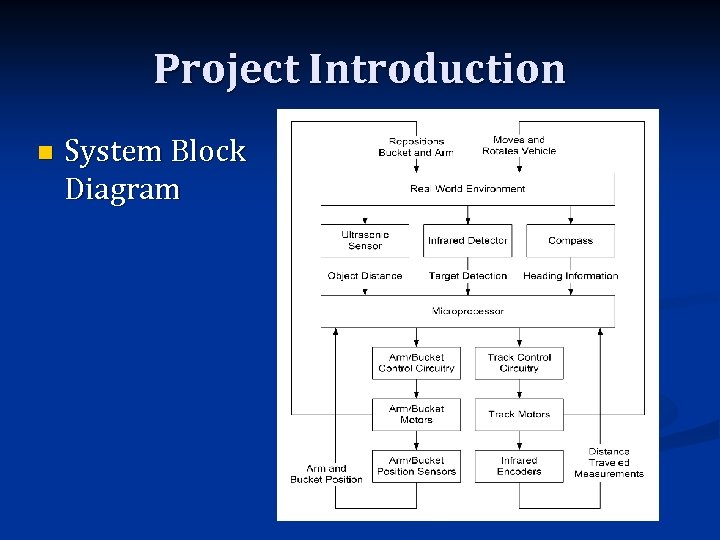

Project Introduction n System Block Diagram

Presentation Outline n n n n Project Introduction Hardware Design Software Design Final Progress Future Work Conclusion Questions

Hardware Design n Design Steps Vehicle Choice n Sensor Choice n Circuitry Design n Circuit Board Construction n Microcontroller Interfacing n

Hardware Design n Vehicle Choice n Hobby Kit Vehicle (Tamiya hobby kit) n n Bobcat RC Vehicle (Bobcat T 190) n n 2 drive motors, arm raise motor Easier to expand Weak lifting capacity 2 drive motors, arm raise motor, bucket dump motor Internal limit switches Harder to modify Continued with Bobcat Vehicle

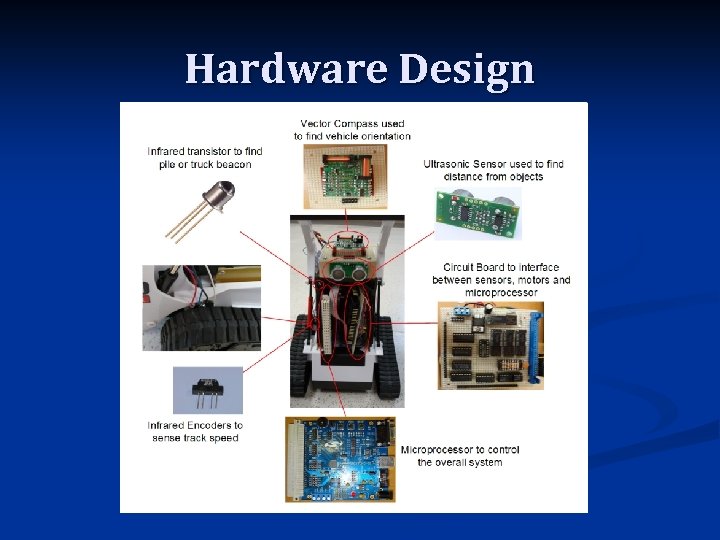

Hardware Design n Sensor Choice n SRF 05 Ultrasonic Sensor for Distance Measurement n Can operate down to ~1 inch n Used in previous projects n PNZ 109 L-ND Infrared (IR) Transistor for Object Detector n Detects IR LED at ~5 feet away n Little issue with stray IR interference

Hardware Design n Sensor Choice n Vector V 2 x Compass for Heading Information n ~1 degree resolution n Serial output n 10 Hz update rate n Continuous sample mode

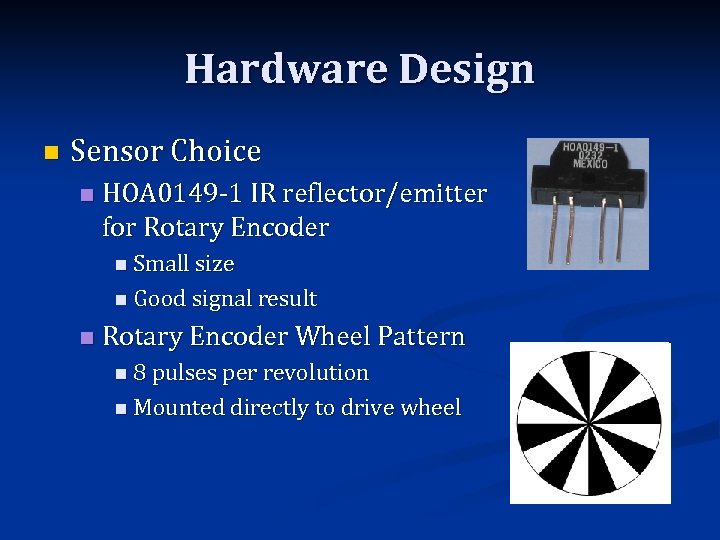

Hardware Design n Sensor Choice n HOA 0149 -1 IR reflector/emitter for Rotary Encoder n Small size n Good signal result n Rotary Encoder Wheel Pattern n 8 pulses per revolution n Mounted directly to drive wheel

Hardware Design

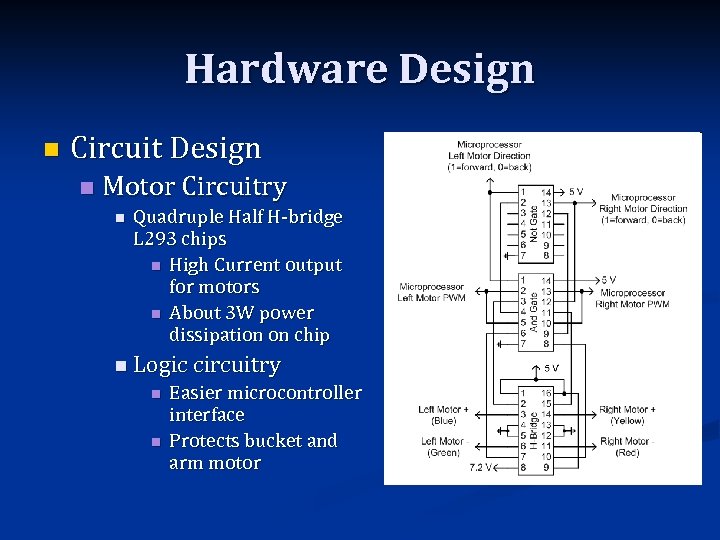

Hardware Design n Circuit Design n Motor Circuitry n Quadruple Half H-bridge L 293 chips n High Current output for motors n About 3 W power dissipation on chip n Logic circuitry n n Easier microcontroller interface Protects bucket and arm motor

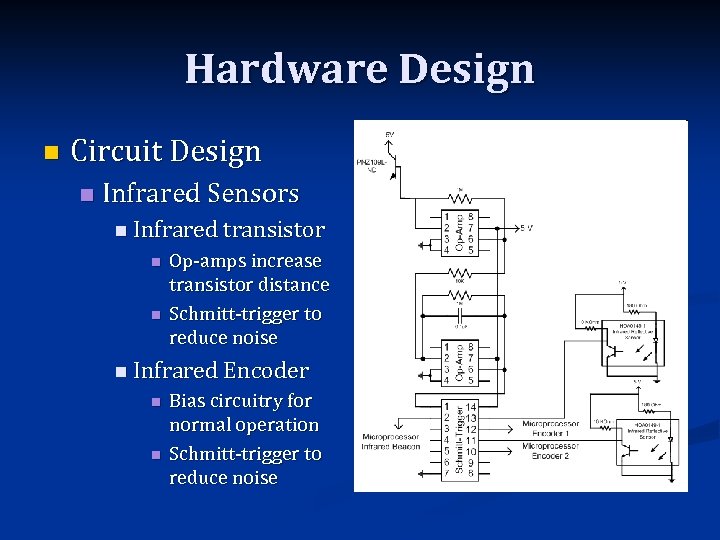

Hardware Design n Circuit Design n Infrared Sensors n Infrared transistor n n Op-amps increase transistor distance Schmitt-trigger to reduce noise n Infrared Encoder n n Bias circuitry for normal operation Schmitt-trigger to reduce noise

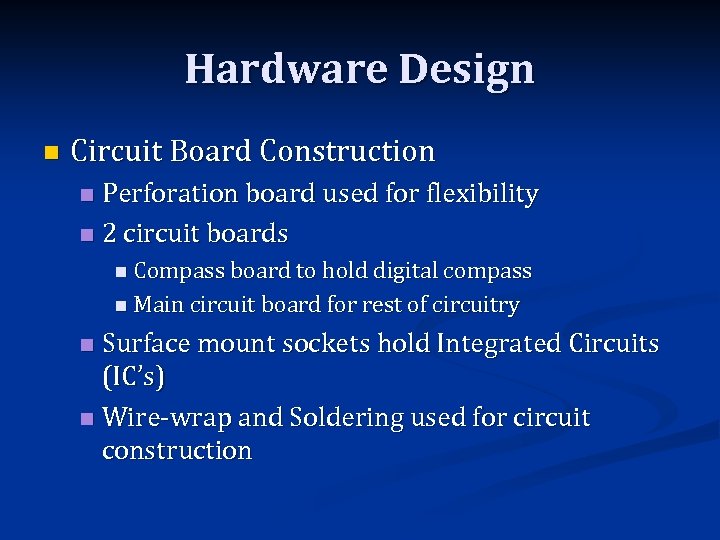

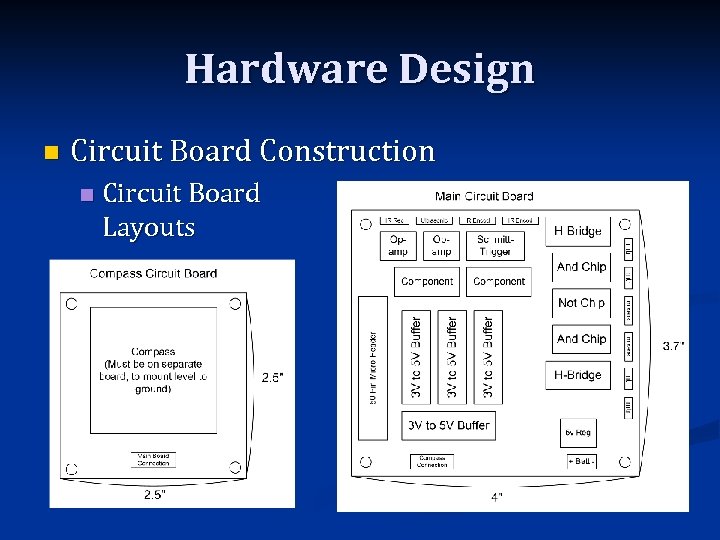

Hardware Design n Circuit Board Construction Perforation board used for flexibility n 2 circuit boards n n Compass board to hold digital compass n Main circuit board for rest of circuitry Surface mount sockets hold Integrated Circuits (IC’s) n Wire-wrap and Soldering used for circuit construction n

Hardware Design n Circuit Board Construction Terminal Strip used for power connection n Single and Double Pin Headers for external connections n n Single pin headers connect to motors and sensors n Double pin header connects to microcontroller and compass board to main circuit board

Hardware Design n Circuit Board Construction n Circuit Board Layouts

Presentation Outline n n n n Project Introduction Hardware Design Software Design Final Progress Future Work Conclusion Questions

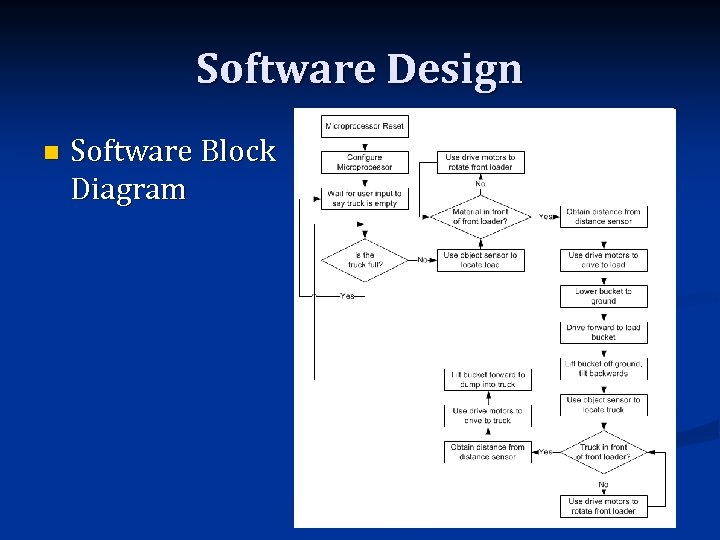

Software Design Software Block Diagram n Microcontroller Features n Software Setup n Low Level Task Breakdown n

Software Design n Software Block Diagram

Software Design n Microcontroller: n 8051 F 340 Development Kit n Similar Operation as EMAC board n Features: n n n 48 million instructions per second (MIPS) Four independent timers (T 0 through T 3) Five Programmable Counter Arrays (PCA 0 through PCA 4) One Serial Peripheral Interface (SPI 0) Two external Interrupts (EX 0 and EX 1) Etc.

Software Design n Software Setup: Handle sensor reading in interrupts n Write low level functions for basic operations n Make functions to do complicated tasks n n i. e. locate IR beacon, load bucket, dump bucket

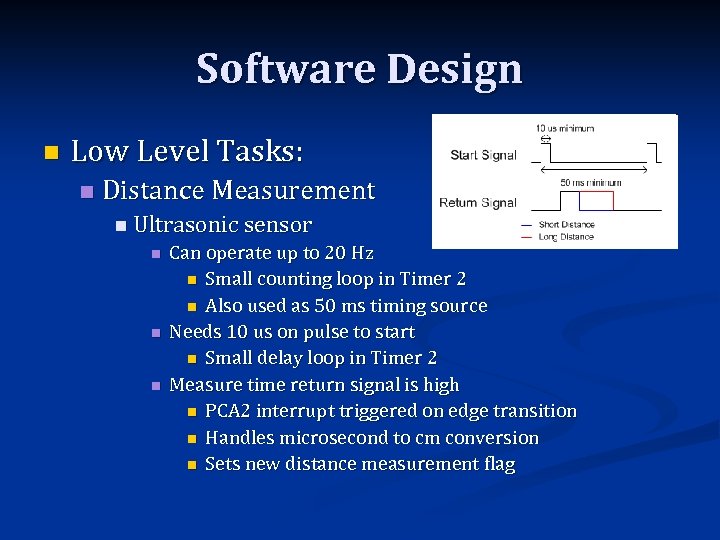

Software Design n Low Level Tasks: n Distance Measurement n Ultrasonic sensor n n n Can operate up to 20 Hz n Small counting loop in Timer 2 n Also used as 50 ms timing source Needs 10 us on pulse to start n Small delay loop in Timer 2 Measure time return signal is high n PCA 2 interrupt triggered on edge transition n Handles microsecond to cm conversion n Sets new distance measurement flag

Software Design n Low Level Tasks: n Rotary Encoders n Uses EX 0 and EX 1 for interrupts n Encoder period calculated based off Timer 2 n Velocity Controller n n n Variable period update rates Simple proportional controller used Proportional-Integral (PI) controller did not work n Low resolution encoder n Possible initial condition problems n Oscillations noticed with small gain

Software Design n Low Level Tasks: n Infrared Beacon n n External Reset Button: n n n Manually read in software Use PCA 3 as interrupt Interrupt triggers software reset Compass n n n Function to control enable/disable of compass SPI 0 handles data reception Code reconstructs information, sets new compass reading flag

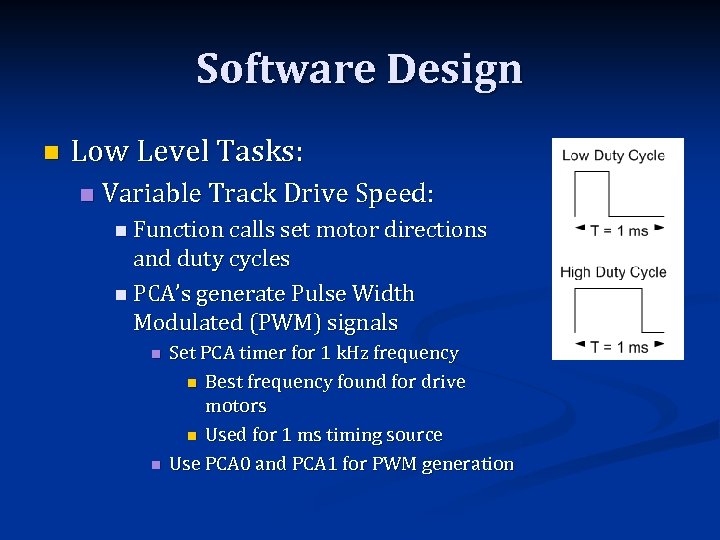

Software Design n Low Level Tasks: n Variable Track Drive Speed: n Function calls set motor directions and duty cycles n PCA’s generate Pulse Width Modulated (PWM) signals n n Set PCA timer for 1 k. Hz frequency n Best frequency found for drive motors n Used for 1 ms timing source Use PCA 0 and PCA 1 for PWM generation

Software Design n Low Level Tasks: n Arm and Bucket control: n n n Rotate vehicle to heading n n n Function sets motors to move correct direction Reads corresponding sensor until pressed Rotate fastest direction to reach the desired heading Turn slightly when near desired heading until facing the right way Remaining tasks: n Make routines using these basic functions plus sensor information

Presentation Outline n n n n Project Introduction Hardware Design Software Design Final Progress Future Work Conclusion Questions

Final Progress n Sensors testing completed n n n All sensors interface to microcontroller Sensors work as desired Exceptions: n n n Ultrasonic and IR transistor when blocked by bucket Compass when arm is near fully raised Motor drive electronics work n n Microcontroller successfully controls speed and direction Heat sink added to drive circuitry to prevent overheating

Final Progress n Vehicle operates mostly autonomously Can navigate between truck and load n Loads bucket and dumps properly usually n n Small bug in location routine that causes long delay when IR beacon too far away n Lining up with truck is difficult due to IR beacon spread n Vehicle repeats task until stopped

Final Progress n Small project difficulties IR beacons not easy to differentiate at long ranges n IR beacon gives wide detection angle, and not easy to track n Compass/software sometimes gives wrong orientation n n Causes alignment with bin and truck to be off n Unknown reason for this problem n Vehicle operation becomes somewhat random with low batteries

Presentation Outline n n n n Project Introduction Hardware Design Software Design Final Progress Future Work Conclusion Questions

Future Work n Add camera and computer interface Image processing system next step in system n Necessary for full scale operation n n Create additional autonomous vehicles Allow cooperative interactions between vehicles n Could do tasks like operate truck, fill bin, etc. n

Future Work n Replace/Upgrade Infrared Transistors n n n Work on Compass/Microcontroller interface n n n Difficulty tracking infrared beacons Infrared beacon period varies with distance Determine why compass gives wrong direction readings Replace compass with newer model if necessary Better Battery and Charger n n n Improve operation time of vehicle Increase linear range of drive motors Decrease chance of overcharging battery

Future Work n Improve Rotary Encoder Resolution n n Model Track motor and Gear Train n n Allows better velocity controller routine Minor hardware changes n n Better measurement of linear/rotational velocity Active low drive signals, change ultrasonic and IR beacon, make secure board mount in vehicle, etc. Create testing station with interface n Battery-free operation, receive debug

Presentation Outline n n n n Project Introduction Hardware Design Software Design Final Progress Future Work Conclusion Questions

Conclusions n Small scale autonomous robot works n n Bucket can be loaded without special sensors n n n Need changes to system if full scale implementation desired Detect full bucket by period of rotary encoders increasing past threshold Detect nearing wall by consecutive equal distance readings More work to be done with project n n Full scale implementation would need image processing More robots needed for automating an entire system

Conclusions n Vehicle Testing Area

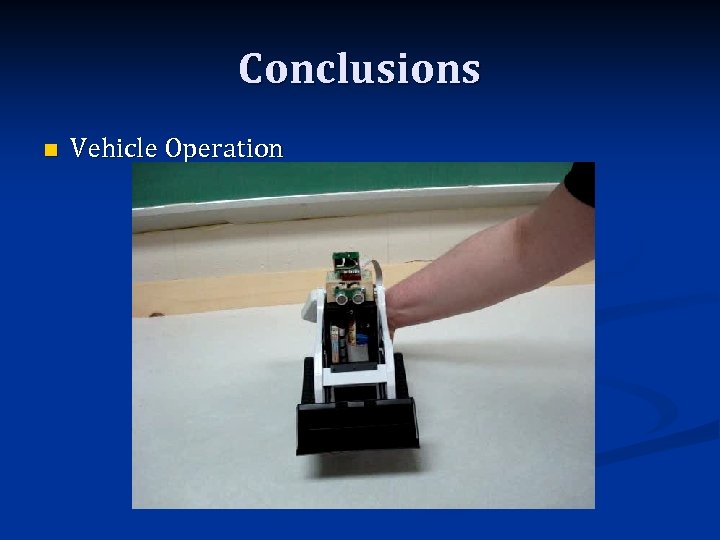

Conclusions n Vehicle Operation

Conclusions n Special Thanks To: n n n Nick Schmidt for help with hardware construction and modification Dr. Donald Schertz for project advising, and help with microcontroller problems Dr. Malinowski for help with using microcontroller Chris Mattus for ordering parts, and printing poster board The rest of the EE faculty for feedback about our project

Presentation Outline n n n n Project Introduction Hardware Design Software Design Final Progress Future Work Conclusion Questions

Questions n Any Questions? ? ?

Backup Material

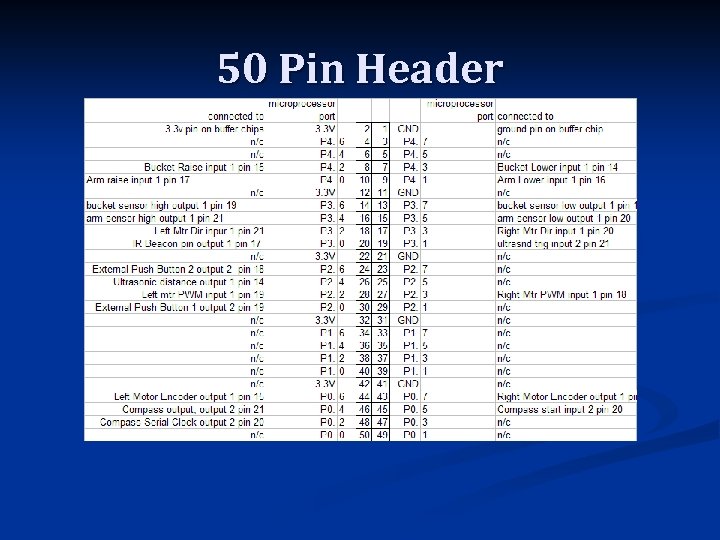

50 Pin Header

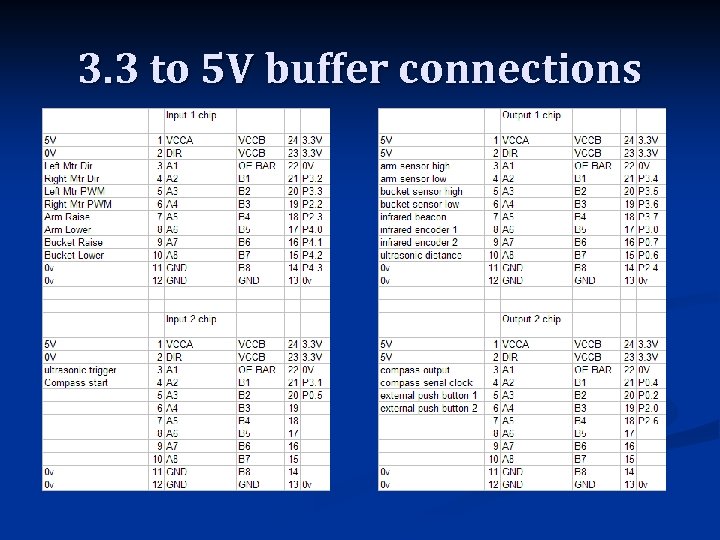

3. 3 to 5 V buffer connections

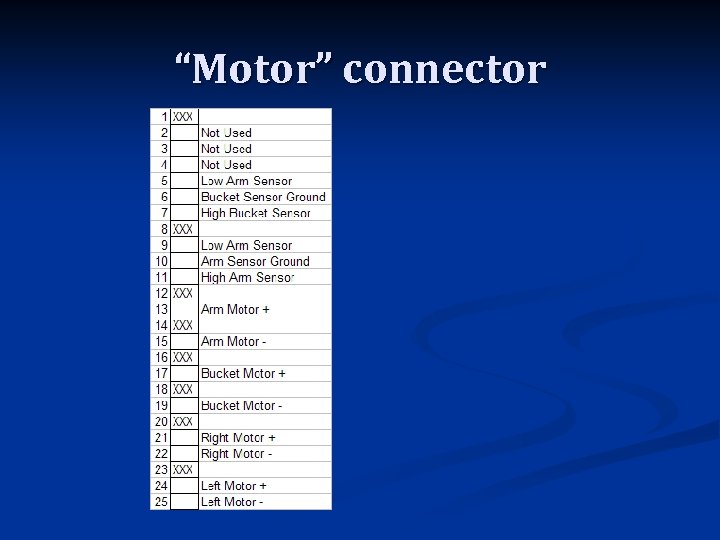

“Motor” connector

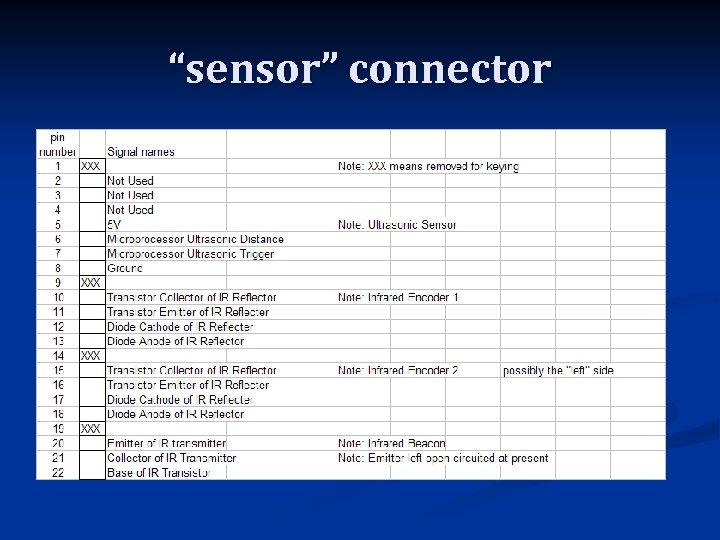

“sensor” connector

943305a2b73f4a0b903477238b959c52.ppt