2d45561047c68a82ddd6df78231c14b0.ppt

- Количество слайдов: 27

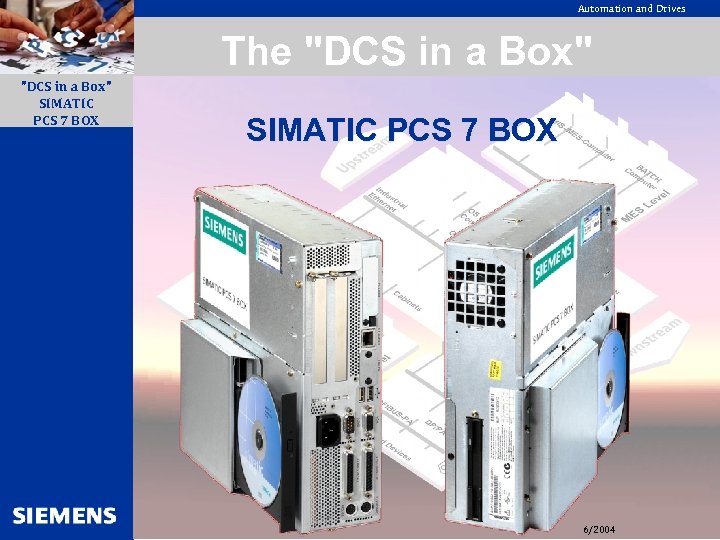

Automation and Drives The "DCS in a Box" SIMATIC PCS 7 BOX 6/2004 1

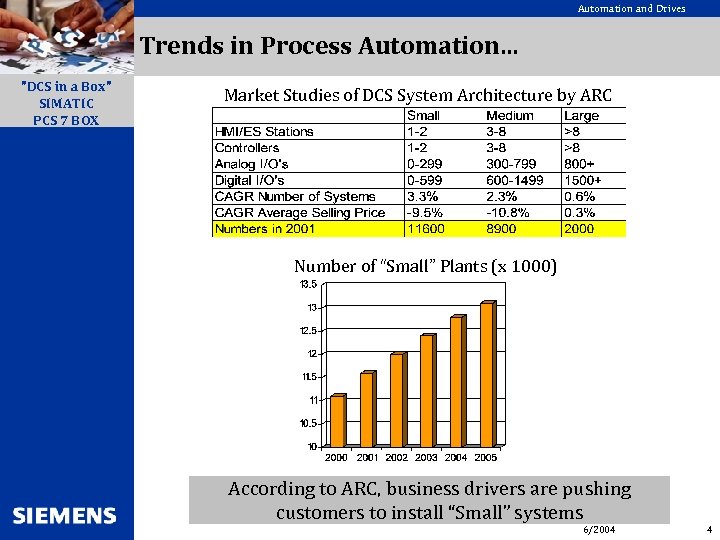

Automation and Drives Trends in Process Automation. . . "DCS in a Box" SIMATIC PCS 7 BOX Market Studies of DCS System Architecture by ARC Number of “Small” Plants (x 1000) According to ARC, business drivers are pushing customers to install “Small” systems 6/2004 4

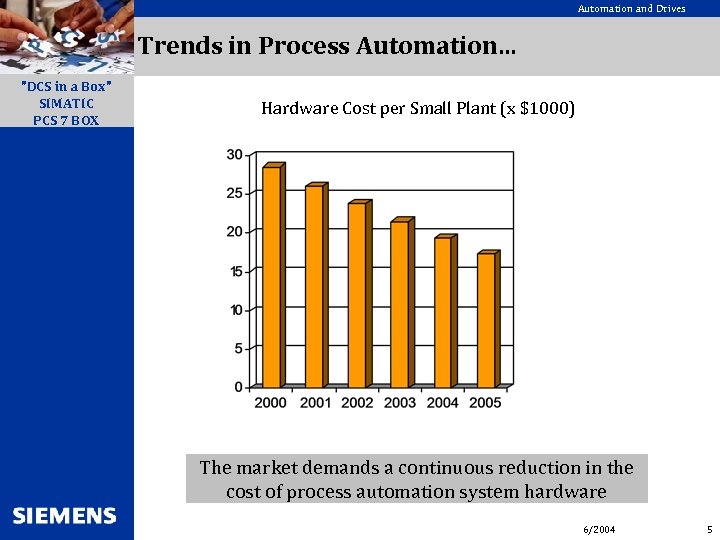

Automation and Drives Trends in Process Automation. . . "DCS in a Box" SIMATIC PCS 7 BOX Hardware Cost per Small Plant (x $1000) The market demands a continuous reduction in the cost of process automation system hardware 6/2004 5

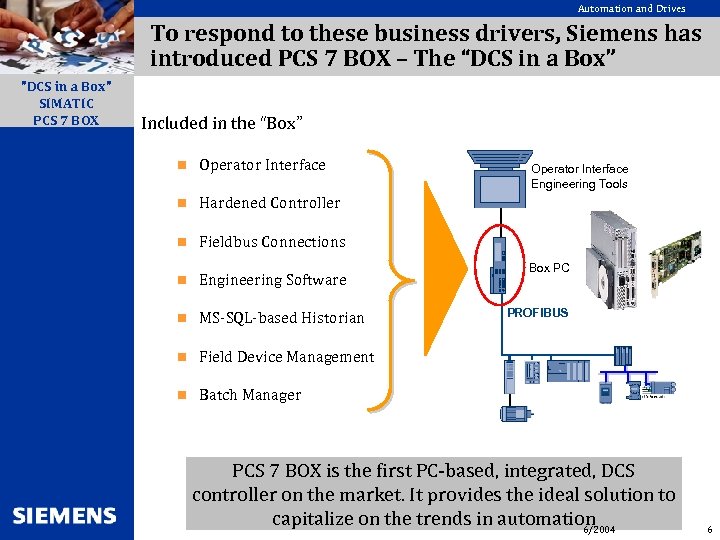

Automation and Drives To respond to these business drivers, Siemens has introduced PCS 7 BOX – The “DCS in a Box” "DCS in a Box" SIMATIC PCS 7 BOX Included in the “Box” n Operator Interface n Hardened Controller n Fieldbus Connections n Engineering Software n MS-SQL-based Historian n Box PC Field Device Management n Operator Interface Engineering Tools Batch Manager PROFIBUS PCS 7 BOX is the first PC-based, integrated, DCS controller on the market. It provides the ideal solution to capitalize on the trends in automation 6/2004 6

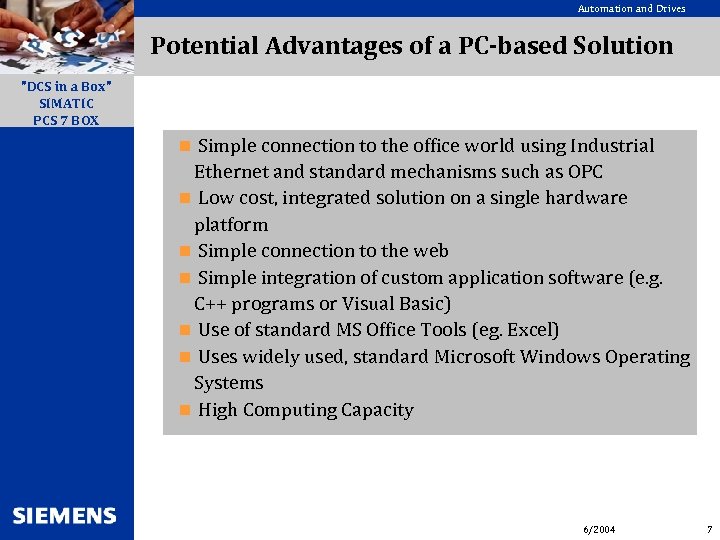

Automation and Drives Potential Advantages of a PC-based Solution "DCS in a Box" SIMATIC PCS 7 BOX Simple connection to the office world using Industrial Ethernet and standard mechanisms such as OPC n Low cost, integrated solution on a single hardware platform n Simple connection to the web n Simple integration of custom application software (e. g. C++ programs or Visual Basic) n Use of standard MS Office Tools (eg. Excel) n Uses widely used, standard Microsoft Windows Operating Systems n High Computing Capacity n 6/2004 7

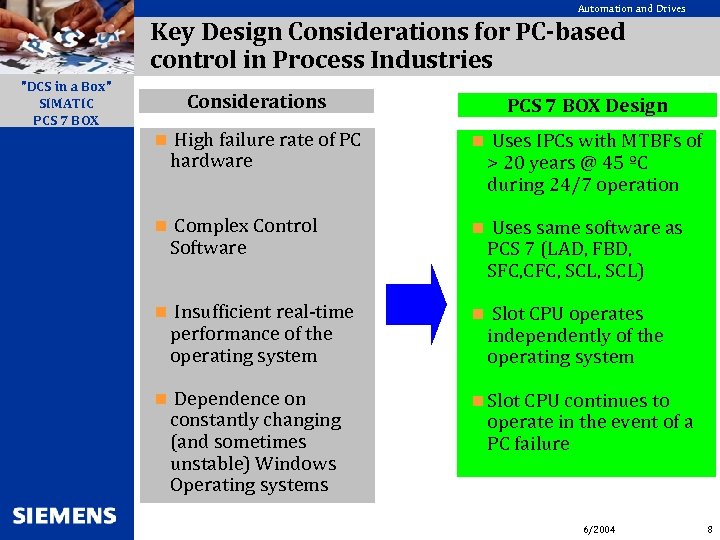

Automation and Drives Key Design Considerations for PC-based control in Process Industries "DCS in a Box" SIMATIC PCS 7 BOX Considerations PCS 7 BOX Design n High failure rate of PC hardware n Uses IPCs with MTBFs of > 20 years @ 45 ºC during 24/7 operation n Complex Control Software n Uses same software as PCS 7 (LAD, FBD, SFC, CFC, SCL) n Insufficient real-time performance of the operating system n Slot CPU operates independently of the operating system n Dependence on constantly changing (and sometimes unstable) Windows Operating systems n Slot CPU continues to operate in the event of a PC failure 6/2004 8

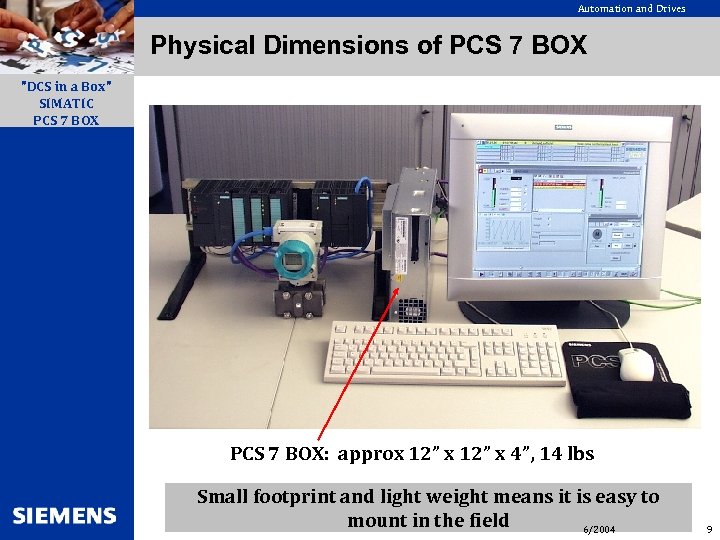

Automation and Drives Physical Dimensions of PCS 7 BOX "DCS in a Box" SIMATIC PCS 7 BOX: approx 12” x 4”, 14 lbs Small footprint and light weight means it is easy to mount in the field 6/2004 9

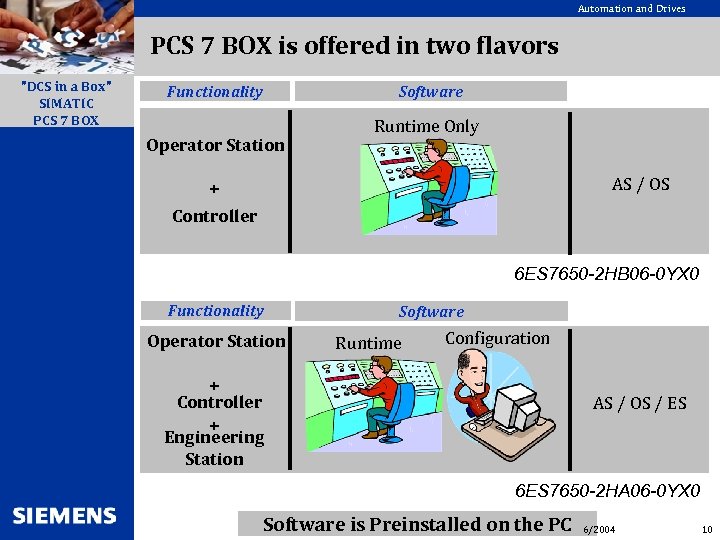

Automation and Drives PCS 7 BOX is offered in two flavors "DCS in a Box" SIMATIC PCS 7 BOX Functionality Software Operator Station Runtime Only AS / OS + Controller 6 ES 7650 -2 HB 06 -0 YX 0 Functionality Operator Station Software Runtime Configuration + Controller + Engineering Station AS / OS / ES 6 ES 7650 -2 HA 06 -0 YX 0 Software is Preinstalled on the PC 6/2004 10

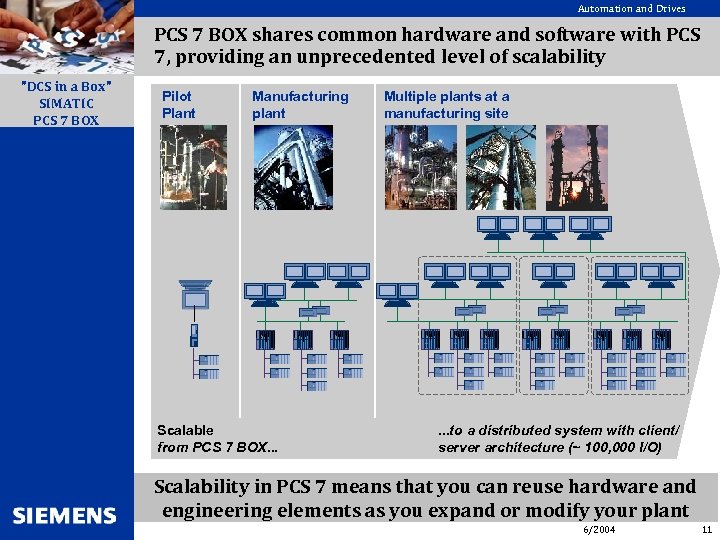

Automation and Drives PCS 7 BOX shares common hardware and software with PCS 7, providing an unprecedented level of scalability "DCS in a Box" SIMATIC PCS 7 BOX Pilot Plant Manufacturing plant Scalable from PCS 7 BOX. . . Multiple plants at a manufacturing site . . . to a distributed system with client/ server architecture (~ 100, 000 I/O) Scalability in PCS 7 means that you can reuse hardware and engineering elements as you expand or modify your plant 6/2004 11

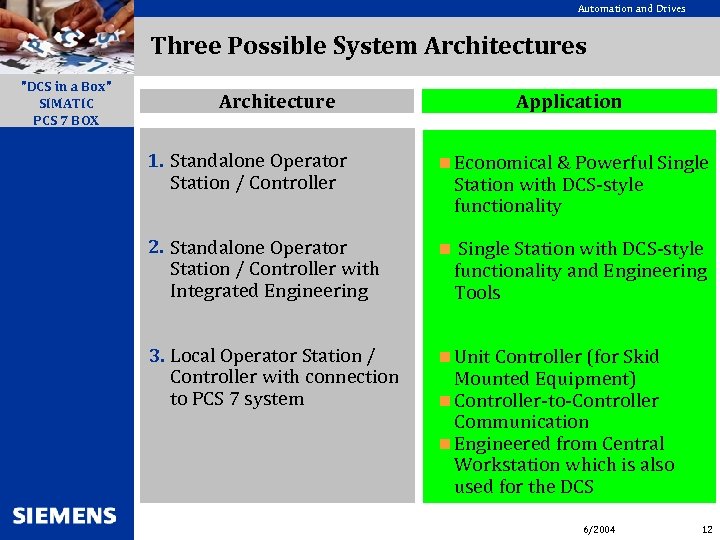

Automation and Drives Three Possible System Architectures "DCS in a Box" SIMATIC PCS 7 BOX Architecture Application 1. Standalone Operator Station / Controller n Economical & Powerful Single 2. Standalone Operator Station / Controller with Integrated Engineering n 3. Local Operator Station / Controller with connection to PCS 7 system n Unit Controller (for Skid Station with DCS-style functionality Single Station with DCS-style functionality and Engineering Tools Mounted Equipment) n Controller-to-Controller Communication n Engineered from Central Workstation which is also used for the DCS 6/2004 12

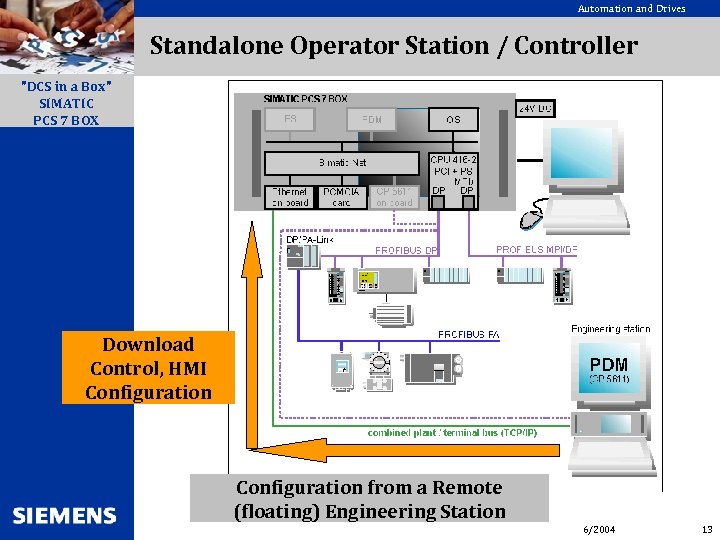

Automation and Drives Standalone Operator Station / Controller "DCS in a Box" SIMATIC PCS 7 BOX Download Control, HMI Configuration from a Remote (floating) Engineering Station 6/2004 13

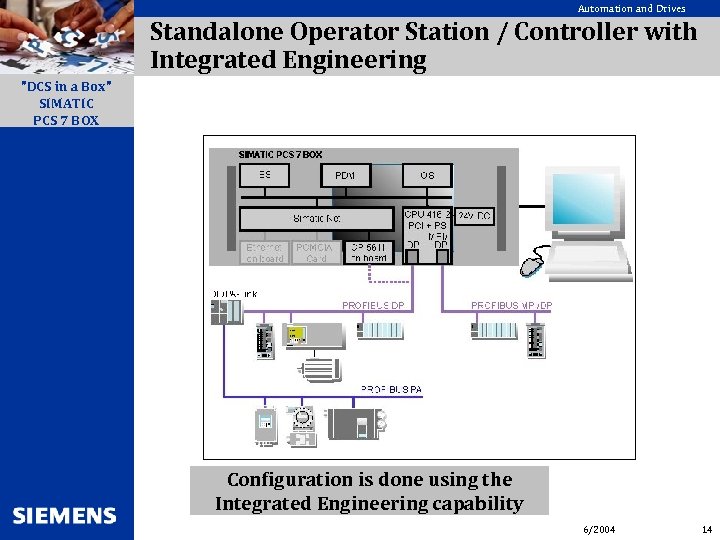

Automation and Drives Standalone Operator Station / Controller with Integrated Engineering "DCS in a Box" SIMATIC PCS 7 BOX Configuration is done using the Integrated Engineering capability 6/2004 14

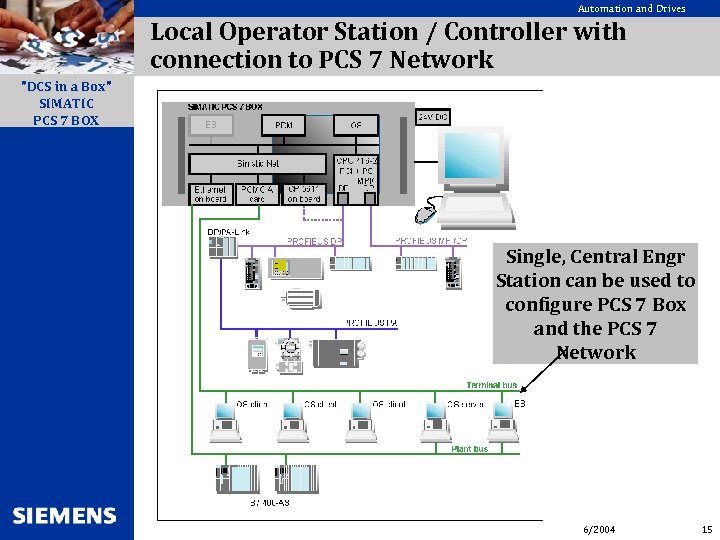

Automation and Drives Local Operator Station / Controller with connection to PCS 7 Network "DCS in a Box" SIMATIC PCS 7 BOX Single, Central Engr Station can be used to configure PCS 7 Box and the PCS 7 Network 6/2004 15

Automation and Drives More Details on the PC "DCS in a Box" SIMATIC PCS 7 BOX 6/2004 16

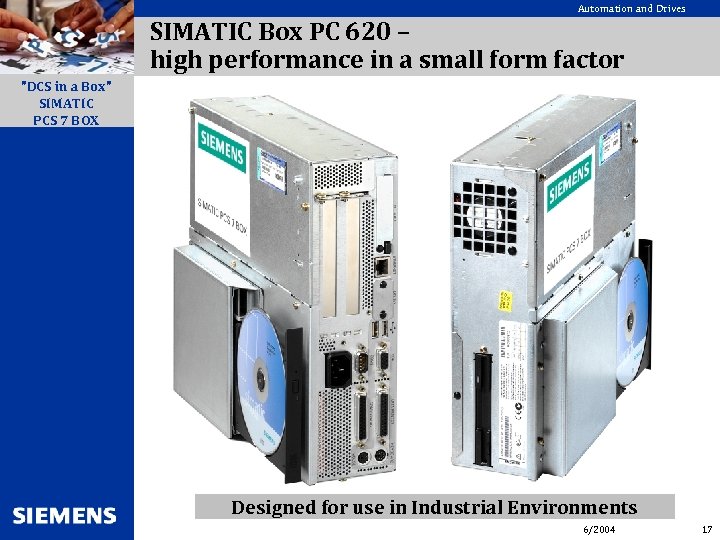

Automation and Drives SIMATIC Box PC 620 – high performance in a small form factor "DCS in a Box" SIMATIC PCS 7 BOX Designed for use in Industrial Environments 6/2004 17

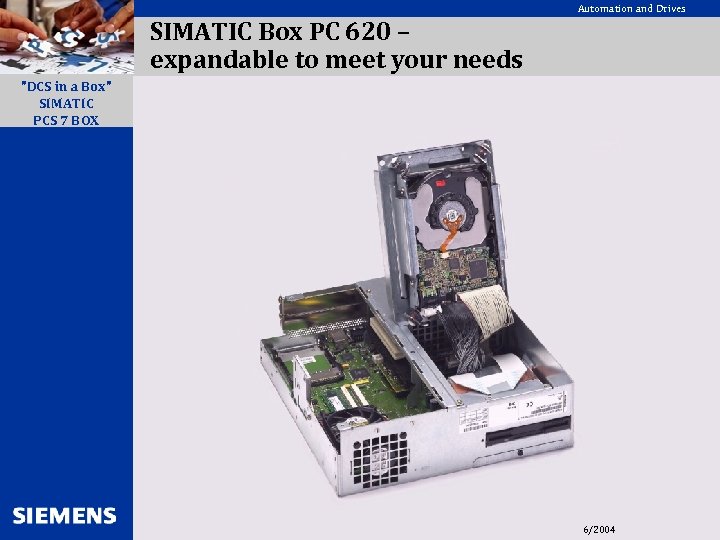

Automation and Drives SIMATIC Box PC 620 – expandable to meet your needs "DCS in a Box" SIMATIC PCS 7 BOX 6/2004 18

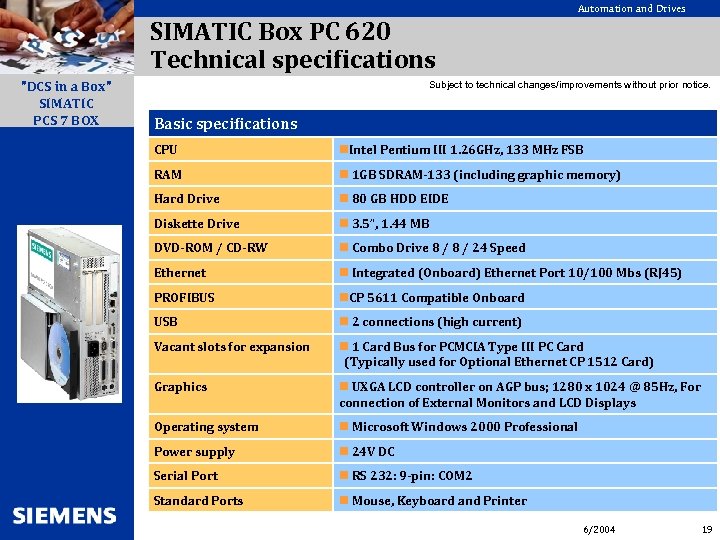

Automation and Drives SIMATIC Box PC 620 Technical specifications "DCS in a Box" SIMATIC PCS 7 BOX Subject to technical changes/improvements without prior notice. Basic specifications CPU n. Intel Pentium III 1. 26 GHz, 133 MHz FSB RAM n 1 GB SDRAM-133 (including graphic memory) Hard Drive n 80 GB HDD EIDE Diskette Drive n 3. 5”, 1. 44 MB DVD-ROM / CD-RW n Combo Drive 8 / 24 Speed Ethernet n Integrated (Onboard) Ethernet Port 10/100 Mbs (RJ 45) PROFIBUS n. CP 5611 Compatible Onboard USB n 2 connections (high current) Vacant slots for expansion n 1 Card Bus for PCMCIA Type III PC Card (Typically used for Optional Ethernet CP 1512 Card) Graphics n UXGA LCD controller on AGP bus; 1280 x 1024 @ 85 Hz, For connection of External Monitors and LCD Displays Operating system n Microsoft Windows 2000 Professional Power supply n 24 V DC Serial Port n RS 232: 9 -pin: COM 2 Standard Ports n Mouse, Keyboard and Printer 6/2004 19

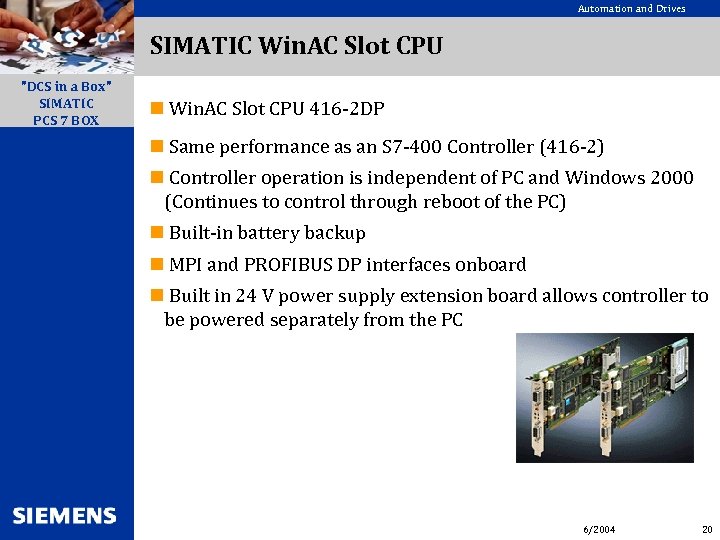

Automation and Drives SIMATIC Win. AC Slot CPU "DCS in a Box" SIMATIC PCS 7 BOX n Win. AC Slot CPU 416 -2 DP n Same performance as an S 7 -400 Controller (416 -2) n Controller operation is independent of PC and Windows 2000 (Continues to control through reboot of the PC) n Built-in battery backup n MPI and PROFIBUS DP interfaces onboard n Built in 24 V power supply extension board allows controller to be powered separately from the PC 6/2004 20

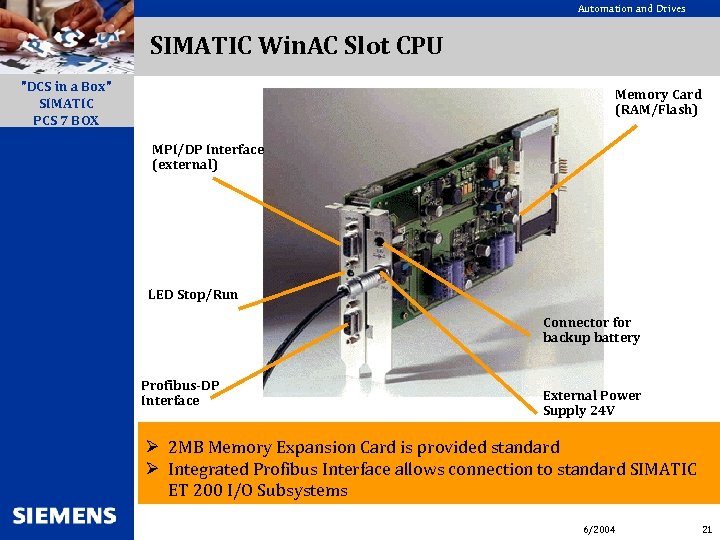

Automation and Drives SIMATIC Win. AC Slot CPU "DCS in a Box" SIMATIC PCS 7 BOX Memory Card (RAM/Flash) MPI/DP Interface (external) LED Stop/Run Connector for backup battery Profibus-DP Interface External Power Supply 24 V Ø 2 MB Memory Expansion Card is provided standard Ø Integrated Profibus Interface allows connection to standard SIMATIC ET 200 I/O Subsystems 6/2004 21

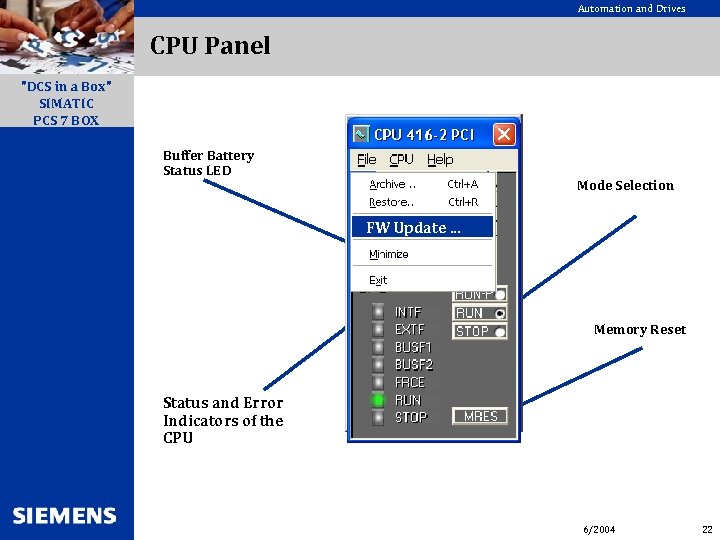

Automation and Drives CPU Panel "DCS in a Box" SIMATIC PCS 7 BOX Buffer Battery Status LED Mode Selection FW Update. . . Memory Reset Status and Error Indicators of the CPU 6/2004 22

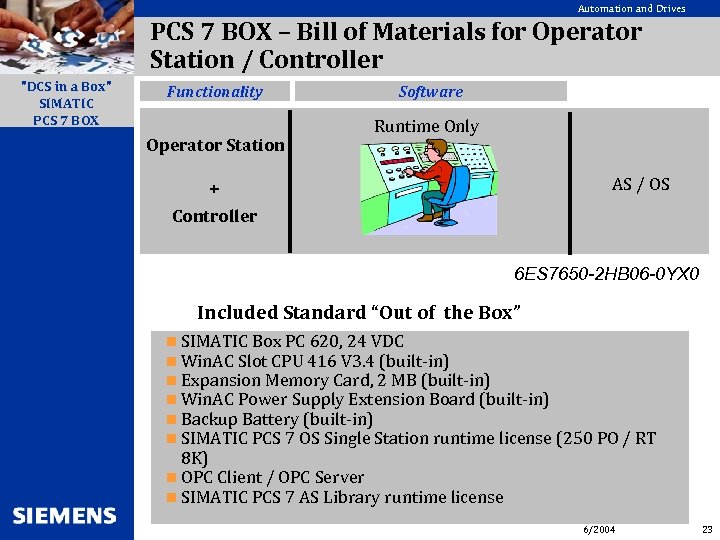

Automation and Drives PCS 7 BOX – Bill of Materials for Operator Station / Controller "DCS in a Box" SIMATIC PCS 7 BOX Functionality Operator Station Software Runtime Only AS / OS + Controller 6 ES 7650 -2 HB 06 -0 YX 0 Included Standard “Out of the Box” n SIMATIC Box PC 620, 24 VDC n Win. AC Slot CPU 416 V 3. 4 (built-in) n Expansion Memory Card, 2 MB (built-in) n Win. AC Power Supply Extension Board (built-in) n Backup Battery (built-in) n SIMATIC PCS 7 OS Single Station runtime license (250 PO / RT 8 K) n OPC Client / OPC Server n SIMATIC PCS 7 AS Library runtime license 6/2004 23

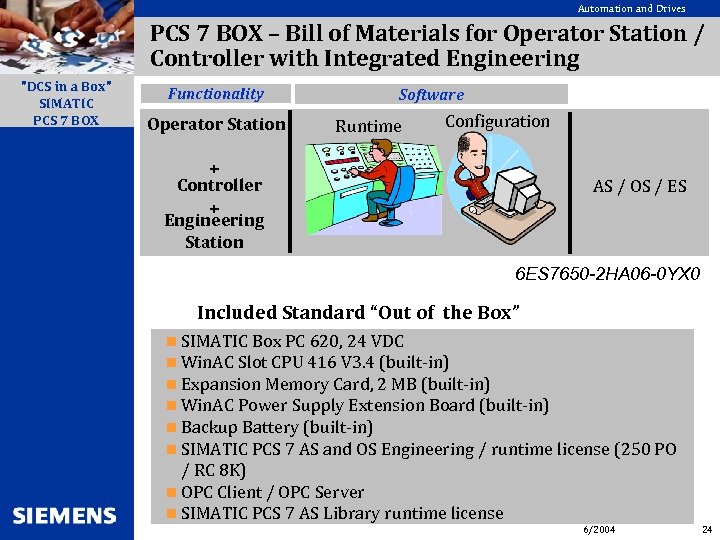

Automation and Drives PCS 7 BOX – Bill of Materials for Operator Station / Controller with Integrated Engineering "DCS in a Box" SIMATIC PCS 7 BOX Functionality Operator Station Software Runtime Configuration + Controller + Engineering Station AS / OS / ES 6 ES 7650 -2 HA 06 -0 YX 0 Included Standard “Out of the Box” n SIMATIC Box PC 620, 24 VDC n Win. AC Slot CPU 416 V 3. 4 (built-in) n Expansion Memory Card, 2 MB (built-in) n Win. AC Power Supply Extension Board (built-in) n Backup Battery (built-in) n SIMATIC PCS 7 AS and OS Engineering / runtime license (250 PO / RC 8 K) n OPC Client / OPC Server n SIMATIC PCS 7 AS Library runtime license 6/2004 24

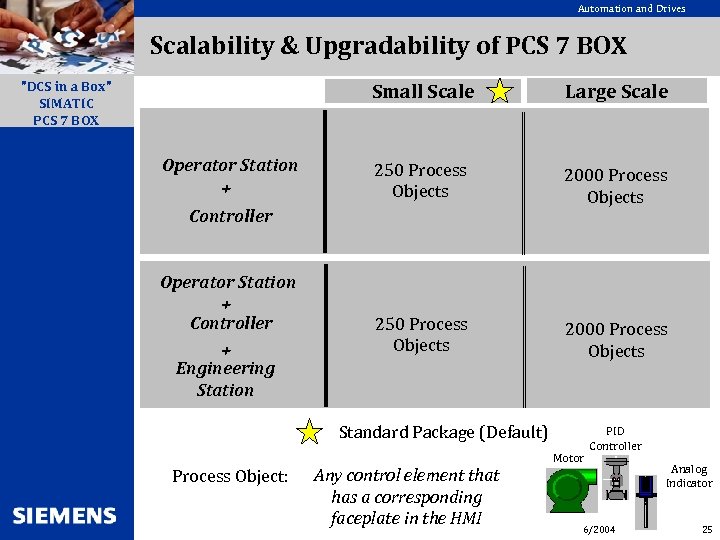

Automation and Drives Scalability & Upgradability of PCS 7 BOX "DCS in a Box" SIMATIC PCS 7 BOX Small Scale Operator Station + Large Scale 250 Process Objects 2000 Process Objects Controller Operator Station + Controller + Engineering Station Standard Package (Default) Process Object: Any control element that has a corresponding faceplate in the HMI Motor PID Controller 6/2004 Analog Indicator 25

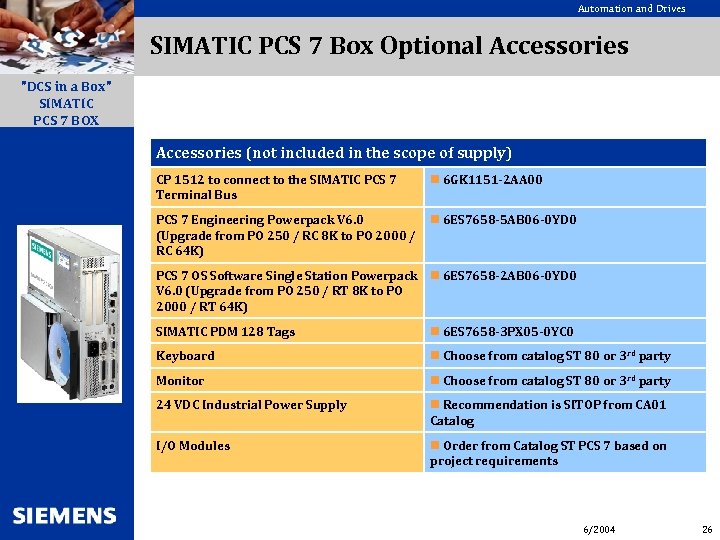

Automation and Drives SIMATIC PCS 7 Box Optional Accessories "DCS in a Box" SIMATIC PCS 7 BOX Accessories (not included in the scope of supply) CP 1512 to connect to the SIMATIC PCS 7 Terminal Bus n 6 GK 1151 -2 AA 00 PCS 7 Engineering Powerpack V 6. 0 (Upgrade from PO 250 / RC 8 K to PO 2000 / RC 64 K) n 6 ES 7658 -5 AB 06 -0 YD 0 PCS 7 OS Software Single Station Powerpack n 6 ES 7658 -2 AB 06 -0 YD 0 V 6. 0 (Upgrade from PO 250 / RT 8 K to PO 2000 / RT 64 K) SIMATIC PDM 128 Tags n 6 ES 7658 -3 PX 05 -0 YC 0 Keyboard n Choose from catalog ST 80 or 3 rd party Monitor n Choose from catalog ST 80 or 3 rd party 24 VDC Industrial Power Supply n Recommendation is SITOP from CA 01 Catalog I/O Modules n Order from Catalog ST PCS 7 based on project requirements 6/2004 26

Automation and Drives PCS 7 Box “Going Where No DCS Has Gone Before” "DCS in a Box" SIMATIC PCS 7 BOX Benefits n Provides DCS functionality in applications where it was previously too expensive or too large n Reduces Integration Costs – by making it easier to integrate secondary processes and DCS applications n Compact Footprint n Supports applications requiring FDA Validation n Scalable and Expandable n Allows standardization of Control & HMI Elements between Skids and DCS 6/2004 27

Automation and Drives PCS 7 Box “Going Where No DCS Has Gone Before” "DCS in a Box" SIMATIC PCS 7 BOX Applications n OEMs to the Process Industry n Skid Vendors (“Smart Skids) n Secondary Processing n Pilot Plant Applications n Stand-Alone or Networked Architectures 6/2004 28

Automation and Drives "DCS in a Box" SIMATIC PCS 7 BOX Questions ? Thanks for Listening ! 6/2004 29

2d45561047c68a82ddd6df78231c14b0.ppt