72352799d6834d55481dc8fad8ba076f.ppt

- Количество слайдов: 5

Automation and Drives About the project About the Project the project Process Flow Sheet Automation System Architecture Customer: Penoplex Town Kirishi Process / plant name “Process control system for the foam polystyrene granule production plant” Automation object properties I/O signals – 900 Control loops – 35 (including complex cascade control loops) Notes Automation system properties Redundant controllers Simatic S 7 -417 H-F Decentralized periphery Simatic ET-200 M, safety system modules – F-modules, Add. FEM modules Redundant operator stations SCADA Win. CC (PCS 7) Network equipment – Simatic Net Industrial Ethernet Adjacent systems Peletizer – protocol Profibus ( Y-Link – module) BONO (Italy) - protocol Modbus Seminar Partner SIEMENS A&D 26 -30 Мая 2003

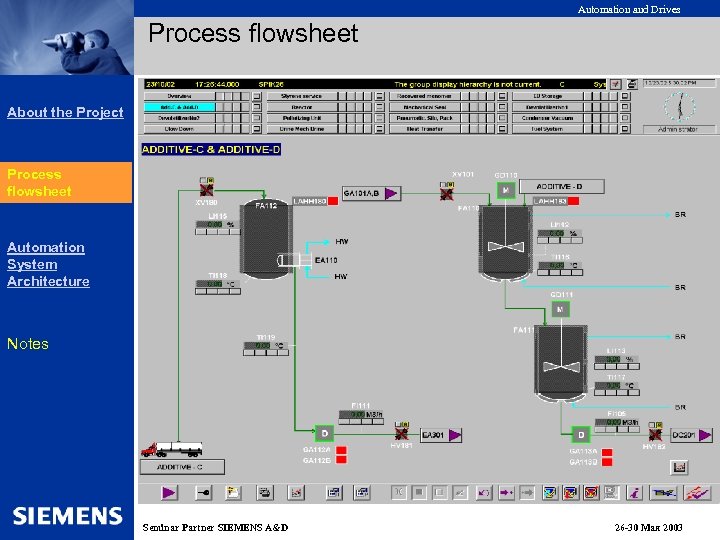

Automation and Drives Process flowsheet About the Project Process Flow flowsheet Sheet Automation System Architecture Notes Seminar Partner SIEMENS A&D 26 -30 Мая 2003

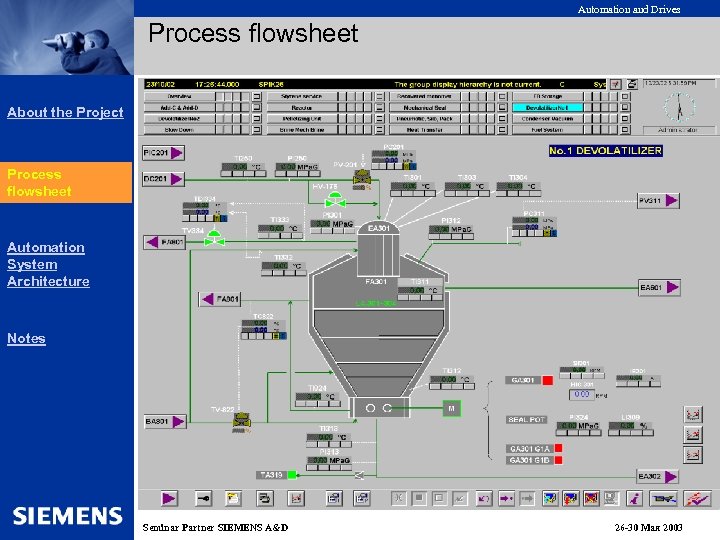

Automation and Drives Process flowsheet About the Project Process Flow flowsheet Sheet Automation System Architecture Notes Seminar Partner SIEMENS A&D 26 -30 Мая 2003

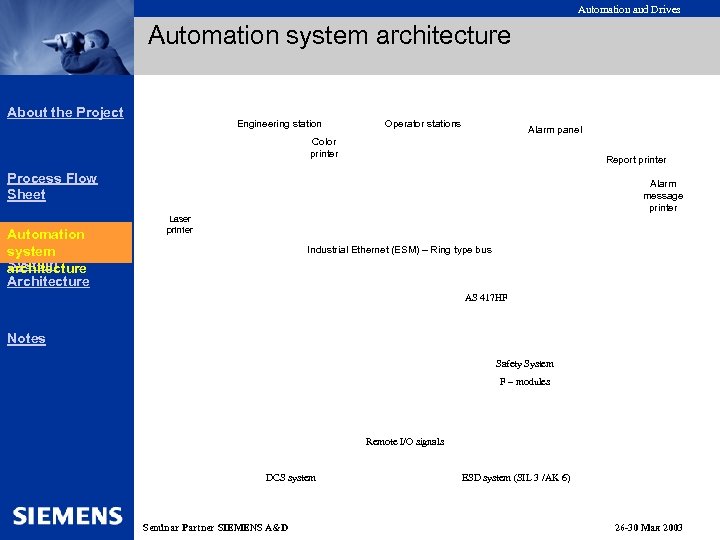

Automation and Drives Automation system architecture About the Project Engineering station Operator stations Alarm panel Color printer Report printer Process Flow Sheet Automation system System architecture Alarm message printer Laser printer Industrial Ethernet (ESM) – Ring type bus AS 417 HF Notes Safety System F – modules Remote I/O signals DCS system Seminar Partner SIEMENS A&D ESD system (SIL 3 /AK 6) 26 -30 Мая 2003

Automation and Drives Notes • Polystyrene production plant was developed by Toyo Engineering Corporation (Japan) The project – initial data was prepared in Japan • Software and PCS 7 equipment were supplied by SIEMENS AG (Germany) • Partner – SPIK SZMA, Saint-Petersburg, Russia About the Project Process Flow Sheet Automation System Architecture Notes Features • SIMBA software and PCI module were used to debug and validate the DCS and ESD programs. The same tools were then used to demonstrate the working applications to the customer during FAT. . • Implementation of H-F system • Redundant PID Control Loops were implemented using redundant Add. FEM modules • Specific requirements to the alarm massage protocol and emergency alarm algorithm (first out alarm): alarm source detection, alarm grouping by priorities. Notes Seminar Partner SIEMENS A&D 26 -30 Мая 2003

72352799d6834d55481dc8fad8ba076f.ppt