bc15f0707c822accad8654783b07ef2a.ppt

- Количество слайдов: 28

Automatic Success Adept Business and Product update Keith Bailey 513 -702 -6561 Keith. bailey@adept. com July 2005

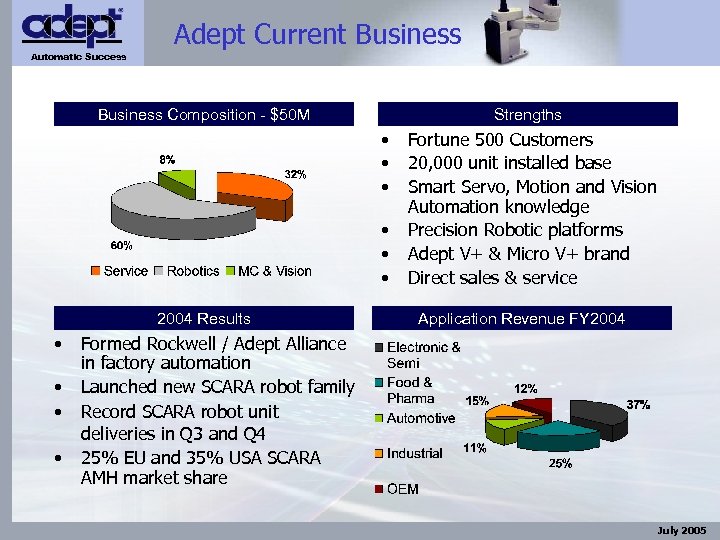

Adept Current Business Automatic Success Business Composition - $50 M Strengths • • • 2004 Results • • Fortune 500 Customers 20, 000 unit installed base Smart Servo, Motion and Vision Automation knowledge Precision Robotic platforms Adept V+ & Micro V+ brand Direct sales & service Application Revenue FY 2004 Formed Rockwell / Adept Alliance in factory automation Launched new SCARA robot family Record SCARA robot unit deliveries in Q 3 and Q 4 25% EU and 35% USA SCARA AMH market share July 2005

New Management Team Automatic Success Robert Bucher, CEO COO & VP Operations Honeywell Industrial Automation, 25 years in Automation Robert Strickland, CFO Trend Technologies, 20+ years with manufacturing companies Matt Murphy, VP Operations & Engineering ADAC & Lockheed Martin, 20 years in Engineering & Marketing Janine Roth; VP Marketing & Corporate Development VP Bus Dev Juniper Networks, 20 years in Marketing & Strategy Joachim Melis, VP Adept Europe Adept Sales & Service, 20 years in Industrial Robotics Barry Dale, VP of Worldwide Sales VP of sales for Honeywell, 30 years experience in sales mgt. Markets John Dulchinos, VP & GM of Vertical 20 years experience with Adept Service years in Industrial Automation Asia/Pacific Lee Blake, VP & GM Adept Newport & GE Robot Service, 15 Tim Coogan, VP July 2005

2005 Product Portfolio Automatic Success Software Applications Software PC Active. X Software Rockwell PLC Software Motion Control & Vision Robotics New Linear Modules SCARA “COBRA” Cartesian 6 -Axis Floor Mount July 2005

New Product Developments Automatic Success Application Accessories I-Sight Vision Systems Motion. BLOX Robot Controllers I-COBRA, COBRA-PLC Pendant & Adept Desk Top Adept L Series Linear Modules Adept VIPER Flex Robots July 2005

Automatic Success Adept 350 mm SCARA Product Preview July 2005

Adept 350 mm SCARA Automatic Success Product Preview • Preliminary Specs – – – 5 KG paylaod Repeatibility +/-. 015 mm Adept cycle. 35 sec or better Max. inertia. 1 Kgm*2 Standard and clean room versions • New Motion. Blox 44 controller – S Series introduction first • Introduction in October 2005 July 2005

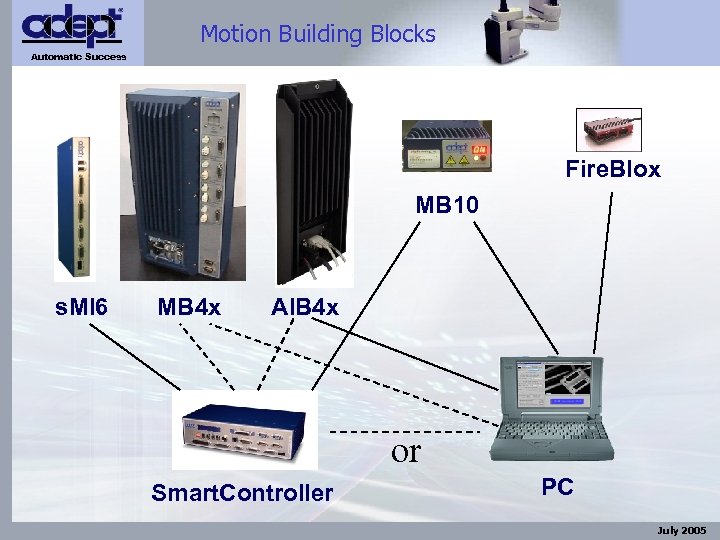

Motion Building Blocks Automatic Success Fire. Blox MB 10 s. MI 6 MB 4 x AIB 4 x or Smart. Controller PC July 2005

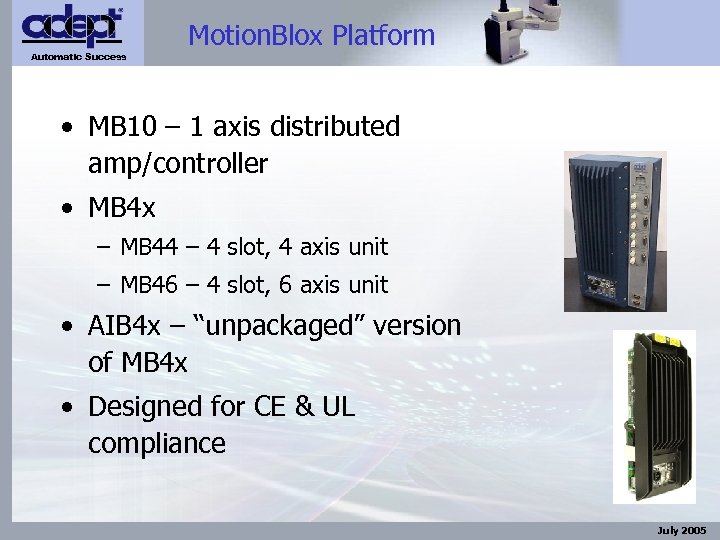

Automatic Success Motion. Blox Platform • MB 10 – 1 axis distributed amp/controller • MB 4 x – MB 44 – 4 slot, 4 axis unit – MB 46 – 4 slot, 6 axis unit • AIB 4 x – “unpackaged” version of MB 4 x • Designed for CE & UL compliance July 2005

Automatic Success MB 4 x - Robot Controller • Complete multi-axis robot control system – Power amplifiers, Power control board – Micro. V+ servo controller (200 MHz Power. PC) – 8 KHz servo rate – Inverse kinematics – Coordinated motion and path interpolation – Diagnostic display – Absolute encoder interface • Interface to outside world – – 220 VAC, 24 VDC Front panel with E-Stop RS-232 for PC and MCP Digital I/O – 12 inputs (2 fast) and 8 outputs July 2005

Automatic Success L-Series Modules July 2005

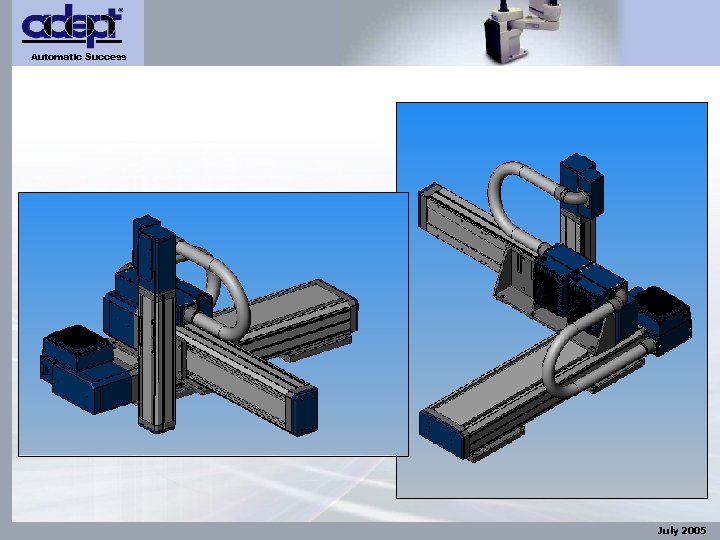

Automatic Success July 2005

Automatic Success L-series Module Introduction L 12 Series L 18 Series • Three new module series: L 18, L 12, L 08 • Designed as a ‘family‘ – similar construcion, similar appearance L 08 Series July 2005

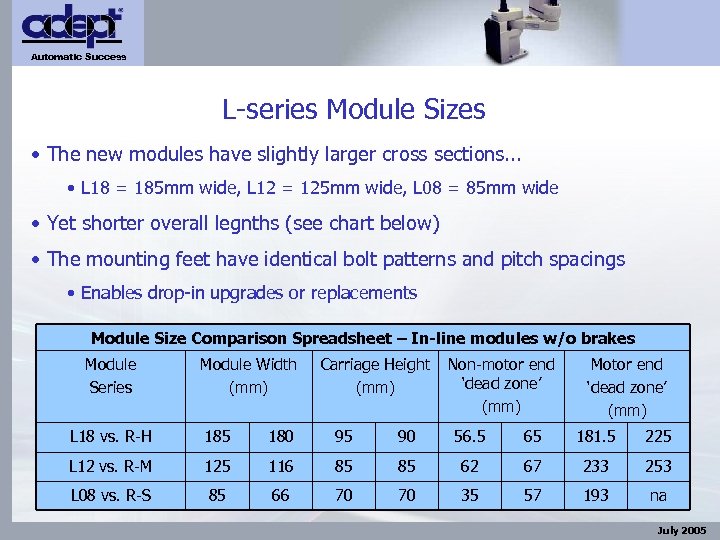

Automatic Success L-series Module Sizes • The new modules have slightly larger cross sections. . . • L 18 = 185 mm wide, L 12 = 125 mm wide, L 08 = 85 mm wide • Yet shorter overall legnths (see chart below) • The mounting feet have identical bolt patterns and pitch spacings • Enables drop-in upgrades or replacements Module Size Comparison Spreadsheet – In-line modules w/o brakes Module Series Module Width (mm) Carriage Height (mm) Non-motor end ‘dead zone’ (mm) Motor end ‘dead zone’ (mm) L 18 vs. R-H 185 180 95 90 56. 5 65 181. 5 225 L 12 vs. R-M 125 116 85 85 62 67 233 253 L 08 vs. R-S 85 66 70 70 35 57 193 na July 2005

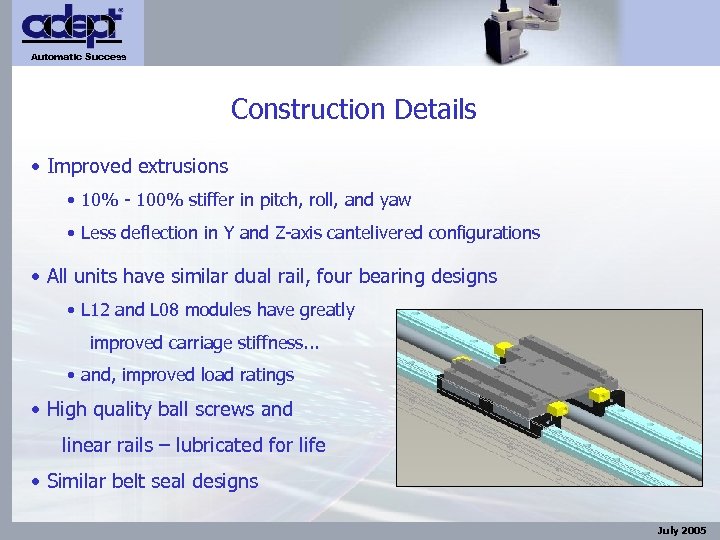

Automatic Success Construction Details • Improved extrusions • 10% - 100% stiffer in pitch, roll, and yaw • Less deflection in Y and Z-axis cantelivered configurations • All units have similar dual rail, four bearing designs • L 12 and L 08 modules have greatly improved carriage stiffness. . . • and, improved load ratings • High quality ball screws and linear rails – lubricated for life • Similar belt seal designs July 2005

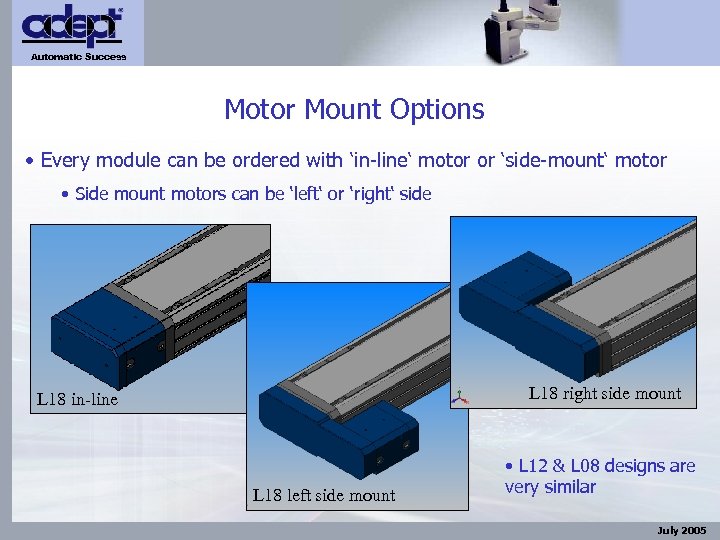

Automatic Success Motor Mount Options • Every module can be ordered with ‘in-line‘ motor or ‘side-mount‘ motor • Side mount motors can be ‘left‘ or ‘right‘ side L 18 right side mount L 18 in-line L 18 left side mount • L 12 & L 08 designs are very similar July 2005

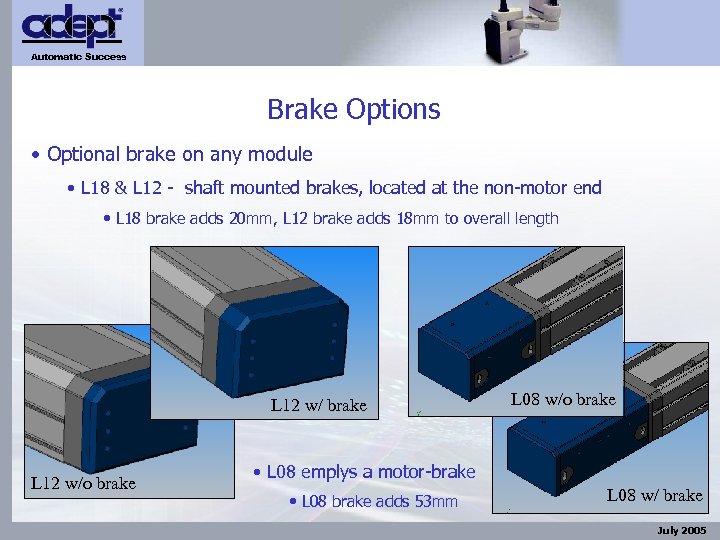

Automatic Success Brake Options • Optional brake on any module • L 18 & L 12 - shaft mounted brakes, located at the non-motor end • L 18 brake adds 20 mm, L 12 brake adds 18 mm to overall length L 12 w/ brake L 12 w/o brake L 08 w/o brake • L 08 emplys a motor-brake • L 08 brake adds 53 mm L 08 w/ brake July 2005

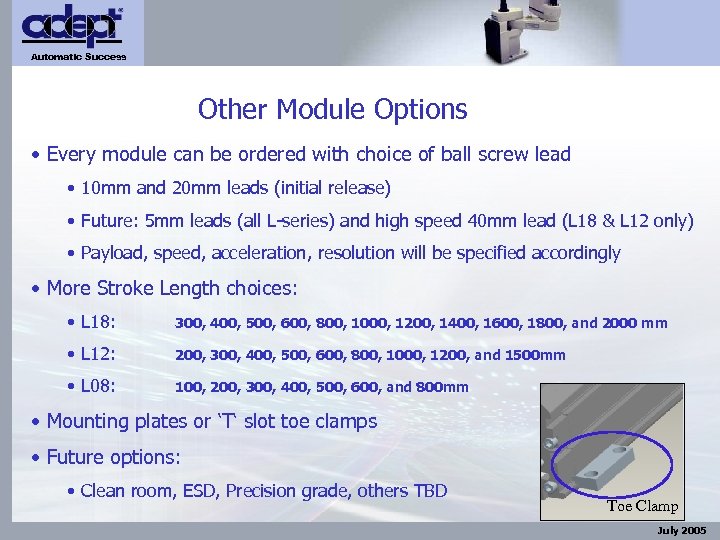

Automatic Success Other Module Options • Every module can be ordered with choice of ball screw lead • 10 mm and 20 mm leads (initial release) • Future: 5 mm leads (all L-series) and high speed 40 mm lead (L 18 & L 12 only) • Payload, speed, acceleration, resolution will be specified accordingly • More Stroke Length choices: • L 18: 300, 400, 500, 600, 800, 1000, 1200, 1400, 1600, 1800, and 2000 mm • L 12: 200, 300, 400, 500, 600, 800, 1000, 1200, and 1500 mm • L 08: 100, 200, 300, 400, 500, 600, and 800 mm • Mounting plates or ‘T‘ slot toe clamps • Future options: • Clean room, ESD, Precision grade, others TBD Toe Clamp July 2005

Automatic Success New L-Series Gantry Support • Smaller yet stiffer than existing Gantry Support • Clean room option (future) LG 6 Gantry Support Module • More options for mounting: • Attach to the end cap of the Y-axis (4 screws) Or LG 6 Mount Bracket Assy • Attach to the Y-axis main body extrusion (2 screws) July 2005

Automatic Success New Manufacturing Partner • Parker Hannifin – Daedal Division, Pittsburgh Pa, USA • L-series modules have been jointly developed by Adept and Parker • Parker is vertically integrated: • All machining is done in-house • Critical components are Kan. Ban‘d • 2 week deliveries on standard product • 4 -6 week deliveries on customs • Possible manufacturing in Germany in 2006 July 2005

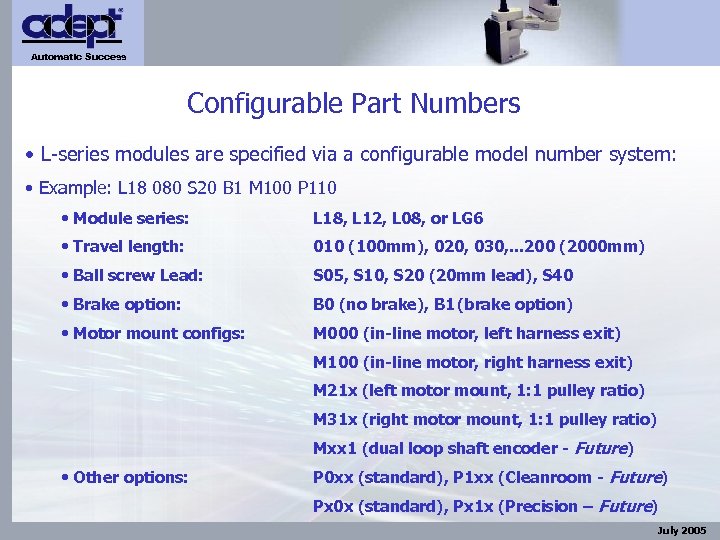

Automatic Success Configurable Part Numbers • L-series modules are specified via a configurable model number system: • Example: L 18 080 S 20 B 1 M 100 P 110 • Module series: L 18, L 12, L 08, or LG 6 • Travel length: 010 (100 mm), 020, 030, . . . 200 (2000 mm) • Ball screw Lead: S 05, S 10, S 20 (20 mm lead), S 40 • Brake option: B 0 (no brake), B 1 (brake option) • Motor mount configs: M 000 (in-line motor, left harness exit) M 100 (in-line motor, right harness exit) M 21 x (left motor mount, 1: 1 pulley ratio) M 31 x (right motor mount, 1: 1 pulley ratio) Mxx 1 (dual loop shaft encoder - Future) • Other options: P 0 xx (standard), P 1 xx (Cleanroom - Future) Px 0 x (standard), Px 1 x (Precision – Future) July 2005

Automatic Success Configured Systems • Adept will build & ship pre-configured systems with Motion. Blox-10 amps • Single Axis, two axis, three axis, and four axis Cartesian systems S 1000 System July 2005

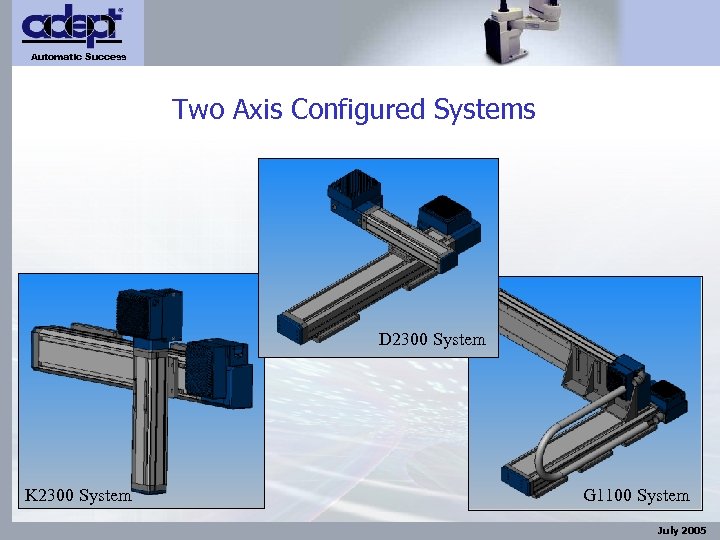

Automatic Success Two Axis Configured Systems D 2300 System K 2300 System G 1100 System July 2005

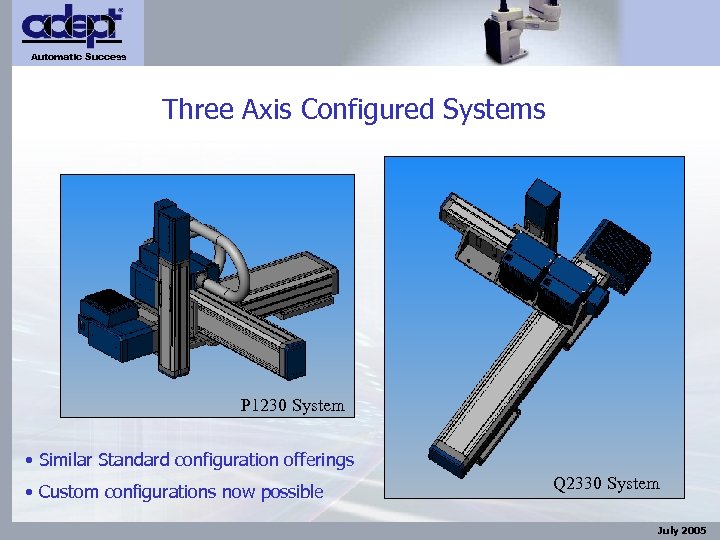

Automatic Success Three Axis Configured Systems P 1230 System • Similar Standard configuration offerings • Custom configurations now possible Q 2330 System July 2005

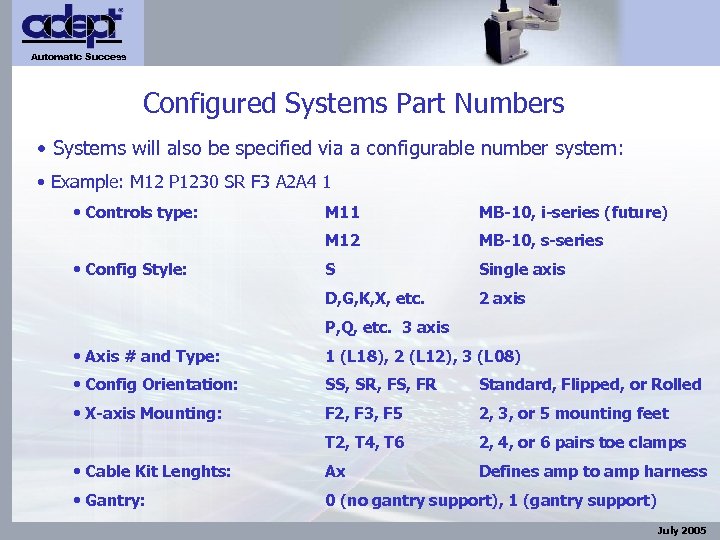

Automatic Success Configured Systems Part Numbers • Systems will also be specified via a configurable number system: • Example: M 12 P 1230 SR F 3 A 2 A 4 1 • Controls type: MB-10, i-series (future) M 12 MB-10, s-series S Single axis D, G, K, X, etc. • Config Style: M 11 2 axis P, Q, etc. 3 axis • Axis # and Type: 1 (L 18), 2 (L 12), 3 (L 08) • Config Orientation: SS, SR, FS, FR Standard, Flipped, or Rolled • X-axis Mounting: F 2, F 3, F 5 2, 3, or 5 mounting feet T 2, T 4, T 6 2, 4, or 6 pairs toe clamps • Cable Kit Lenghts: Ax Defines amp to amp harness • Gantry: 0 (no gantry support), 1 (gantry support) July 2005

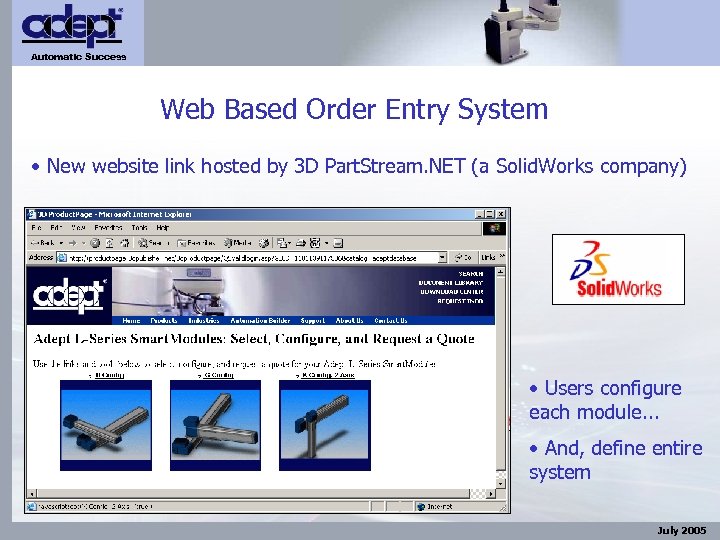

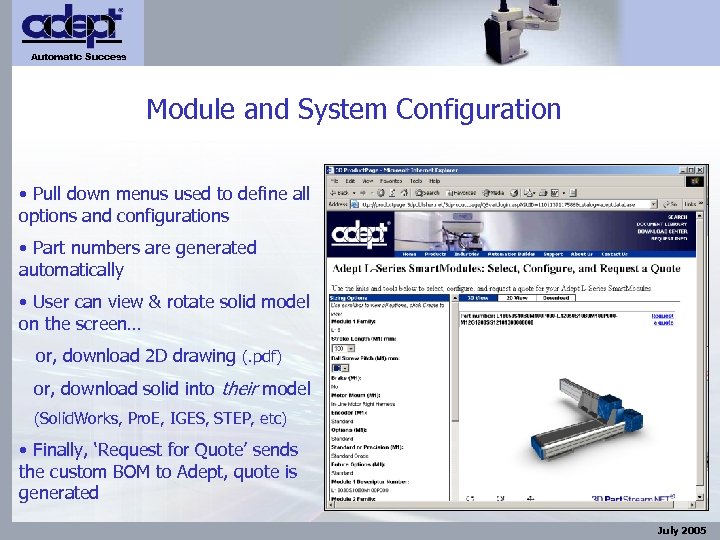

Automatic Success Web Based Order Entry System • New website link hosted by 3 D Part. Stream. NET (a Solid. Works company) • Users configure each module. . . • And, define entire system July 2005

Automatic Success Module and System Configuration • Pull down menus used to define all options and configurations • Part numbers are generated automatically • User can view & rotate solid model on the screen… or, download 2 D drawing (. pdf) or, download solid into their model (Solid. Works, Pro. E, IGES, STEP, etc) • Finally, ‘Request for Quote’ sends the custom BOM to Adept, quote is generated July 2005

Automatic Success Shipment Status • • Adept evaluate 1 st prototypes of each series: Design verification testing – modules: 1 st orders accepted (8 -10 week lead time): Design verification testing – systems: New Website live (initial 3 systems): 1 st customer shipments: Lead time for standard systems reduced to 4 weeks: May ‘ 05 June ’ 05 July ’ 05 Aug ‘ 05 Aug ’ 05 Jan ‘ 06 Future Developments • • Additional standard options: Cleanroom, ESD Protection, High Precision Z/Theta Cartesian Systems Theta Modules Custom systems for OEM or large volume opportunities July 2005

bc15f0707c822accad8654783b07ef2a.ppt