43dae07dcb3175db00a65566e456aa74.ppt

- Количество слайдов: 15

Automated Surface Observing System Sustainment Project January 2009 Jim Mc. Nitt and Joe Facundo NOAA NWS Office of Operational Systems James. mcnitt@noaa. gov 301 -713 -2093 Ext 102

ASOS Overview n n ASOS provides surface observations for aviation operations, weather forecasts and warnings, and climate services ASOS is a modular system, designed to automatically collect, process, and transmit surface weather observations Access to this data is available to a variety of users at local and remote locations on a 24 -hour basis The ASOS Operations and Monitoring Center (AOMC) can access the entire system at all levels for remote maintenance and diagnostics

Automated Surface Observing System Sites n At 1001 airports, worldwide u 312 NWS sponsored sites u 571 FAA sponsored sites u 47 Air Force sponsored sites u 71 Navy sponsored sites

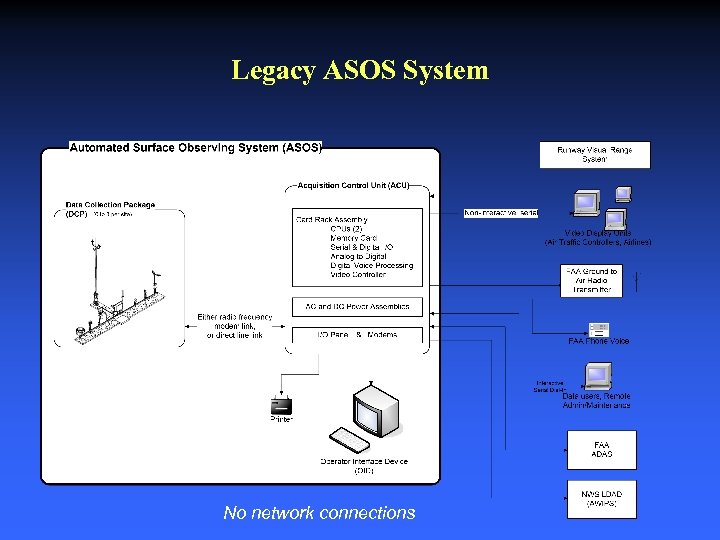

Legacy ASOS System No network connections

Reason for ASOS Sustainment n n A number of factors have changed since ASOS was developed and in order to sustain it into the year 2020, the participating Federal agencies agreed to start planning a technology refresh of the ASOS IT infrastructure Improvements are required to meet user requirements, comply with federal information technology security policy and procedures, and continue to perform within the ASOS reliability, availability, and maintainability specifications

ASOS Service Levels n n Service Level D -- "stand-alone" sites and have no observer interface. ASOS provides an automated report Service Level C -- airports staffed when the federal government facility is open. During hours that the facility is closed, the airport reverts to stand-alone ASOS or service level D operations. The observer can augment the automated observation with weather phenomena Service Level B -- airports staffed with observers or air traffic control specialists who can augment ASOS obs Service Level A -- airports staffed with observers or air traffic control specialists who can augment ASOS generated obs. Observations from these airports can include all of the elements of service level B, C, and D, plus 10 -minute long-line RVR or additional visibility increments; sector visibility; variable sky condition; cloud layers above 12, 000 feet and cloud types; volcanic eruptions; and dust, sand, and other obscurations

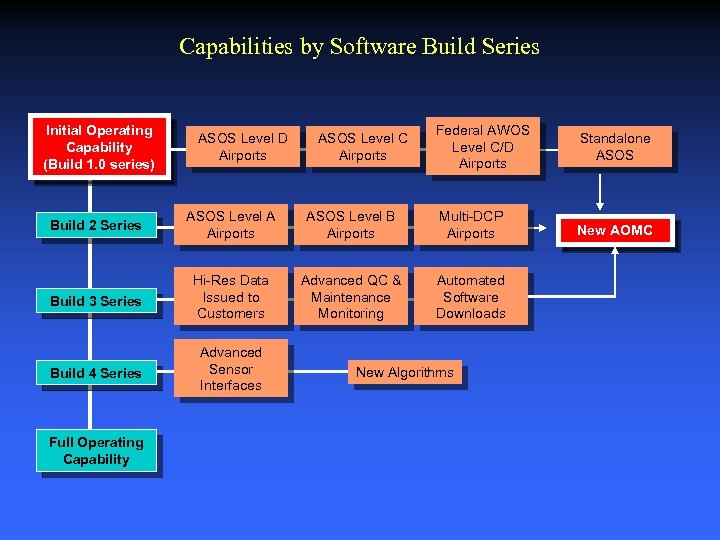

Capabilities by Software Build Series Initial Operating Capability (Build 1. 0 series) ASOS Level D Airports ASOS Level C Airports Federal AWOS Level C/D Airports Standalone ASOS New AOMC Build 2 Series ASOS Level A Airports ASOS Level B Airports Multi-DCP Airports Build 3 Series Hi-Res Data Issued to Customers Advanced QC & Maintenance Monitoring Automated Software Downloads Build 4 Series Advanced Sensor Interfaces Full Operating Capability New Algorithms

Assumptions n n The ACU and DCP hardware configuration will be standardized across the entire ASOS network in order to maintain a costeffective and efficient logistics process The same software will be running on both ASOS and AWOS. Interface differences between AWOS and ASOS will be managed within the software’s configurability features A single development team would release one version of software supporting both the AWOS and ASOS systems, versus having development teams for both, thus reducing software support costs. Remote monitoring and maintenance will reduce the amount of time technicians spend on the road

Assumptions n n n The communications architecture ultimately selected will require changes to the ASOS software, and perhaps also to the ACU hardware. Dial-in connections will not be required when ASOS is connected to an IP network ASOS will be able to conduct time checks to synchronize its clock and will store data on its hard drive. The AOMC will no longer have to provide time synchronization and short term data storage. AOMC will backup system files Combining the full testing resources of the FAA and NWS for the software going into both AWOS and ASOS will bring together a fuller and more diverse set of capabilities, resulting in improved quality of the software releases.

Constraints n n n The Engineering Development Model (EDM) design will incorporate strategies to deal with parts obsolescence and alternative sources, operating system upgrades and replacement, and sustainability through year 2020 IT security policies and procedures of DOC NOAA, DOT FAA, and DOD Air Force and Navy are a constraint. ASOS is required to undergo Certification and Accreditation (C&A), Security Content Automation Protocol (SCAP), and Department of Defense Information Technology Security Certification and Accreditation Process (DITSCAP) The design will modularize the ACU and DCP subsystems so that maintenance staff can replace the lowest repairable units efficiently

Constraints n n n Design considerations include the automatic downloading of software and remote diagnosing of hardware/software problems reducing field visits Network connectivity will have to account for agency architectures and system constraints and system boundaries System configuration checklists will be developed, reviewed, and used to certify all ASOSs before they are connected to the network

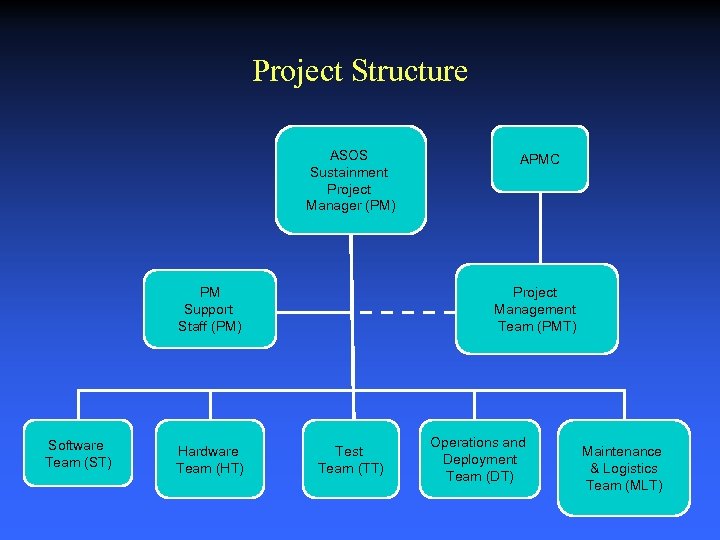

Project Structure ASOS Sustainment Project Manager (PM) PM Support Staff (PM) Software Team (ST) Hardware Team (HT) APMC Project Management Team (PMT) Test Team (TT) Operations and Deployment Team (DT) Maintenance & Logistics Team (MLT)

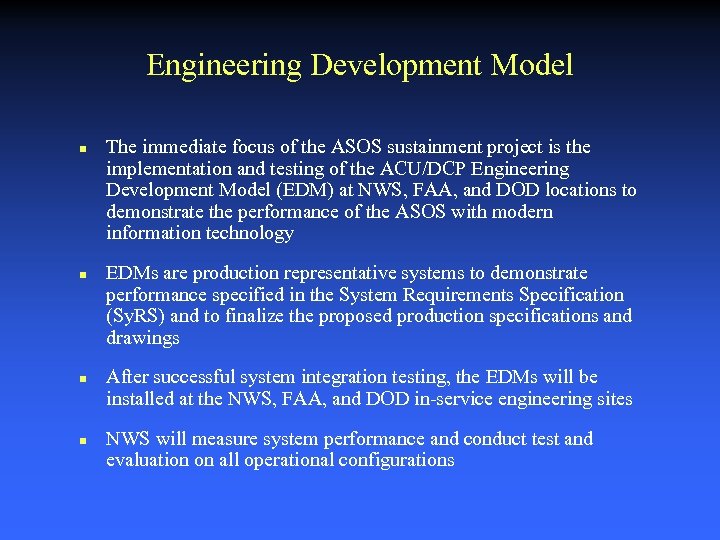

Engineering Development Model n n The immediate focus of the ASOS sustainment project is the implementation and testing of the ACU/DCP Engineering Development Model (EDM) at NWS, FAA, and DOD locations to demonstrate the performance of the ASOS with modern information technology EDMs are production representative systems to demonstrate performance specified in the System Requirements Specification (Sy. RS) and to finalize the proposed production specifications and drawings After successful system integration testing, the EDMs will be installed at the NWS, FAA, and DOD in-service engineering sites NWS will measure system performance and conduct test and evaluation on all operational configurations

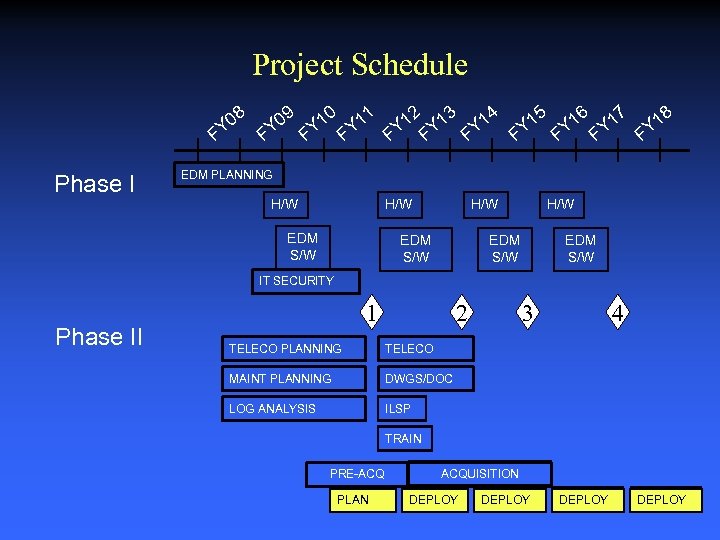

Project Schedule 08 Y F Phase I 09 Y 10 Y 11 Y 12 Y 13 Y 14 Y 15 Y 16 Y 17 Y 18 F FY F F F F EDM PLANNING H/W EDM S/W IT SECURITY Phase II 1 2 TELECO PLANNING DWGS/DOC LOG ANALYSIS 4 TELECO MAINT PLANNING 3 ILSP TRAIN PRE-ACQ PLAN ACQUISITION DEPLOY

43dae07dcb3175db00a65566e456aa74.ppt