85e073df54e5b49bee2424c458eb47f1.ppt

- Количество слайдов: 23

Automated Spray Patternator Team 14 Kevin M. Agnew Greg Barber David Rubin

Automated Spray Patternator Team 14 Kevin M. Agnew Greg Barber David Rubin

Design Concept Review • • • Background Mission Statement Customers: – wants, constraints • Benchmarking: – system – functional • • Metrics / Target Values Generated Concepts Concept Selection Schedule – expected vs. actual • Budget

Design Concept Review • • • Background Mission Statement Customers: – wants, constraints • Benchmarking: – system – functional • • Metrics / Target Values Generated Concepts Concept Selection Schedule – expected vs. actual • Budget

Background • Function of a Spray Patternator • Problems with current Du. Pont Patternator: – Low Accuracy – Human Error – Insufficient Resolution – High Reset Times – Limited To One Nozzle

Background • Function of a Spray Patternator • Problems with current Du. Pont Patternator: – Low Accuracy – Human Error – Insufficient Resolution – High Reset Times – Limited To One Nozzle

Mission Statement To develop and test an automatic spray patternator with high accuracy, improved resolution, a minimal amount of human error, test reset time, and allowing superior flexibility.

Mission Statement To develop and test an automatic spray patternator with high accuracy, improved resolution, a minimal amount of human error, test reset time, and allowing superior flexibility.

Prioritized Customer List • Dupont Agricultural Research Team – Larry Gaultney – Ted Lang – James Davis • George Wicks • Dr. Leonard Schwartz • Dan Coppens (Anholt Technologies Inc. ) • Joseph Buckley (Cherry Hill Mercedes)

Prioritized Customer List • Dupont Agricultural Research Team – Larry Gaultney – Ted Lang – James Davis • George Wicks • Dr. Leonard Schwartz • Dan Coppens (Anholt Technologies Inc. ) • Joseph Buckley (Cherry Hill Mercedes)

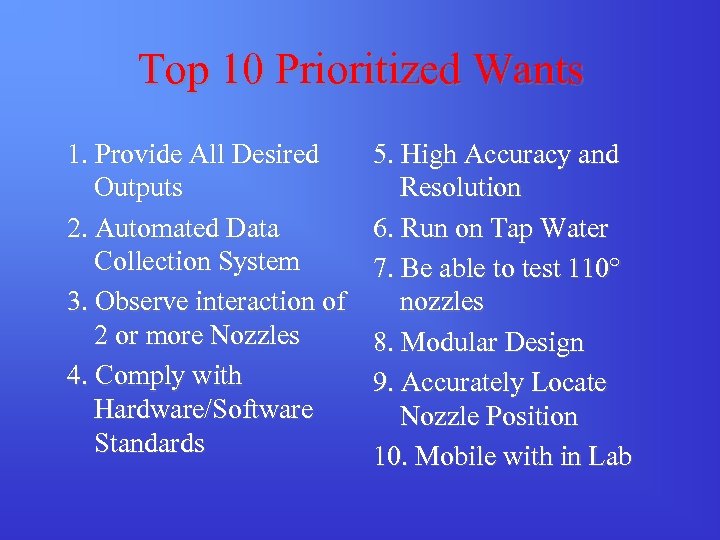

Top 10 Prioritized Wants 1. Provide All Desired Outputs 2. Automated Data Collection System 3. Observe interaction of 2 or more Nozzles 4. Comply with Hardware/Software Standards 5. High Accuracy and Resolution 6. Run on Tap Water 7. Be able to test 110° nozzles 8. Modular Design 9. Accurately Locate Nozzle Position 10. Mobile with in Lab

Top 10 Prioritized Wants 1. Provide All Desired Outputs 2. Automated Data Collection System 3. Observe interaction of 2 or more Nozzles 4. Comply with Hardware/Software Standards 5. High Accuracy and Resolution 6. Run on Tap Water 7. Be able to test 110° nozzles 8. Modular Design 9. Accurately Locate Nozzle Position 10. Mobile with in Lab

Constraints • 54” Door Width • Safety Guidelines (OSHA, DOSH) • Senior Design Project Schedule

Constraints • 54” Door Width • Safety Guidelines (OSHA, DOSH) • Senior Design Project Schedule

Quality Metrics / Target Values

Quality Metrics / Target Values

Quality Metrics / Target Values

Quality Metrics / Target Values

System Benchmarks • Current Du. Pont Spray Patternator • Hardi Inc. – Field Patternator – Laboratory Patternator • Transportable Spray Patternator – (Patent) • Spray Systems Co. – Laboratory Patternator Hardi Field Patternator

System Benchmarks • Current Du. Pont Spray Patternator • Hardi Inc. – Field Patternator – Laboratory Patternator • Transportable Spray Patternator – (Patent) • Spray Systems Co. – Laboratory Patternator Hardi Field Patternator

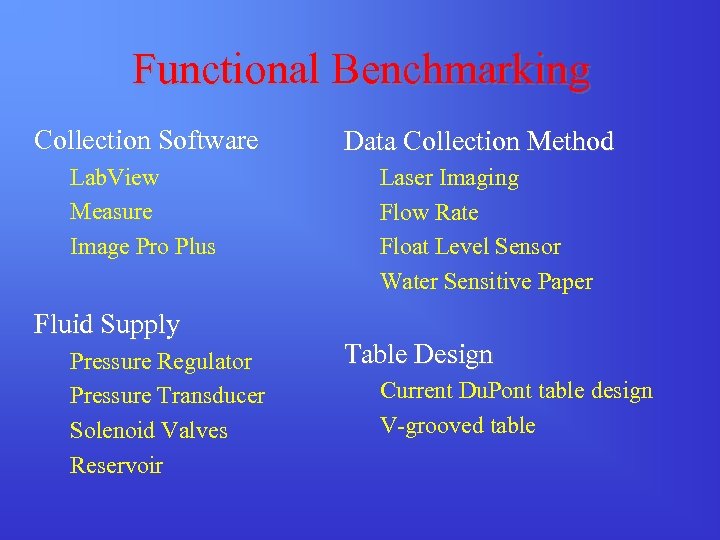

Functional Benchmarking Collection Software Data Collection Method Lab. View Measure Image Pro Plus Laser Imaging Flow Rate Float Level Sensor Water Sensitive Paper Fluid Supply Pressure Regulator Pressure Transducer Solenoid Valves Reservoir Table Design Current Du. Pont table design V-grooved table

Functional Benchmarking Collection Software Data Collection Method Lab. View Measure Image Pro Plus Laser Imaging Flow Rate Float Level Sensor Water Sensitive Paper Fluid Supply Pressure Regulator Pressure Transducer Solenoid Valves Reservoir Table Design Current Du. Pont table design V-grooved table

Initial Design Concepts Data Collection Design Function: To measure water distribution • Level Detection (Using graduated cylinders) – Manual Reading – Pressure Sensors – Laser Imaging • Flow Detection – In-Line Flow Meters • Image Acquisition – Filter Paper Flow Meter

Initial Design Concepts Data Collection Design Function: To measure water distribution • Level Detection (Using graduated cylinders) – Manual Reading – Pressure Sensors – Laser Imaging • Flow Detection – In-Line Flow Meters • Image Acquisition – Filter Paper Flow Meter

Initial Design Concepts Table and Water Collection Design Function: To capture water being sprayed from nozzle and separate into measurable quantities • 2 -Dimensional Design – V-Grooved Table Top – Square Channels (dividing walls) • 3 -Dimensional Design – Flat Table (Filter Paper design) – Honeycomb

Initial Design Concepts Table and Water Collection Design Function: To capture water being sprayed from nozzle and separate into measurable quantities • 2 -Dimensional Design – V-Grooved Table Top – Square Channels (dividing walls) • 3 -Dimensional Design – Flat Table (Filter Paper design) – Honeycomb

Initial Design Concepts Water Supply System Function: To supply pressurized water to the nozzles • Reservoir – Water Tank – Tap • Test Stop System – Solenoid Valves – Cylinder Covers • Pressure System – Water Pump – Air Pressure Source with Regulator

Initial Design Concepts Water Supply System Function: To supply pressurized water to the nozzles • Reservoir – Water Tank – Tap • Test Stop System – Solenoid Valves – Cylinder Covers • Pressure System – Water Pump – Air Pressure Source with Regulator

Comparison of Conceptual Designs

Comparison of Conceptual Designs

Concept Selection • Data Acquisition System – Pressure Sensors • high accuracy ( 0. 5 m. L) • relatively inexpensive (~$27. 00) • allows for simpler design of water supply system • Collection Software – Lab. View • compliant with Du. Pont software/hardware standards – Measure • allows direct input of data into Microsoft Excel

Concept Selection • Data Acquisition System – Pressure Sensors • high accuracy ( 0. 5 m. L) • relatively inexpensive (~$27. 00) • allows for simpler design of water supply system • Collection Software – Lab. View • compliant with Du. Pont software/hardware standards – Measure • allows direct input of data into Microsoft Excel

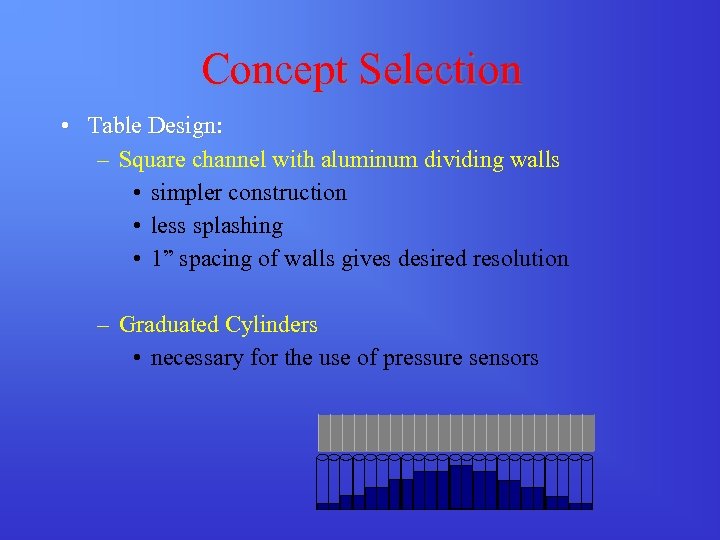

Concept Selection • Table Design: – Square channel with aluminum dividing walls • simpler construction • less splashing • 1” spacing of walls gives desired resolution – Graduated Cylinders • necessary for the use of pressure sensors

Concept Selection • Table Design: – Square channel with aluminum dividing walls • simpler construction • less splashing • 1” spacing of walls gives desired resolution – Graduated Cylinders • necessary for the use of pressure sensors

Concept Selection • Water Pressure System – Pressure Pot • air readily available • pressure can be regulated – Solenoid Valves • acts as automatic shut-off • eliminates residual spray – Pressure Gauge • inexpensive • simplifies design

Concept Selection • Water Pressure System – Pressure Pot • air readily available • pressure can be regulated – Solenoid Valves • acts as automatic shut-off • eliminates residual spray – Pressure Gauge • inexpensive • simplifies design

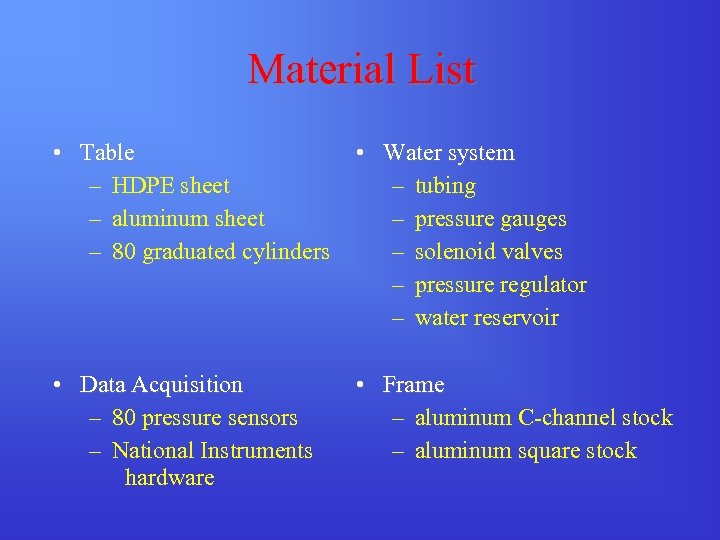

Material List • Table – HDPE sheet – aluminum sheet – 80 graduated cylinders • Water system – tubing – pressure gauges – solenoid valves – pressure regulator – water reservoir • Data Acquisition – 80 pressure sensors – National Instruments hardware • Frame – aluminum C-channel stock – aluminum square stock

Material List • Table – HDPE sheet – aluminum sheet – 80 graduated cylinders • Water system – tubing – pressure gauges – solenoid valves – pressure regulator – water reservoir • Data Acquisition – 80 pressure sensors – National Instruments hardware • Frame – aluminum C-channel stock – aluminum square stock

Budget • Estimated Shop Hours: 100 – 100 hours X $30/hr • Data Acquisition System – National Instruments hardware and software – Pressure Sensors • Structural Materials – aluminum C-channel/square stock – HDPE sheet • Water System – Reservoir – Regulator/Gauges – Solenoids Valves – Tubing $3000. 00 $9980. 00 $607. 71 $816. 45 Total = $14, 404. 16

Budget • Estimated Shop Hours: 100 – 100 hours X $30/hr • Data Acquisition System – National Instruments hardware and software – Pressure Sensors • Structural Materials – aluminum C-channel/square stock – HDPE sheet • Water System – Reservoir – Regulator/Gauges – Solenoids Valves – Tubing $3000. 00 $9980. 00 $607. 71 $816. 45 Total = $14, 404. 16

Schedule

Schedule

Tentative Spring Schedule – Winter • Order parts and materials – Spring • February – get final approval from Du. Pont – finish ordering materials/parts • March - April – wait for parts to arrive – machine parts for assembly • April - May – assemble prototype and test – modify design (if necessary)

Tentative Spring Schedule – Winter • Order parts and materials – Spring • February – get final approval from Du. Pont – finish ordering materials/parts • March - April – wait for parts to arrive – machine parts for assembly • April - May – assemble prototype and test – modify design (if necessary)

Summary • Final Design – – 80 graduated cylinders w/pressure sensors Square collection channels Pressure pot water supply w/solenoid valves Lab. View and Measure for data acquisition • Total Cost – ~$15, 000 • Expected Completion Date – April 1999

Summary • Final Design – – 80 graduated cylinders w/pressure sensors Square collection channels Pressure pot water supply w/solenoid valves Lab. View and Measure for data acquisition • Total Cost – ~$15, 000 • Expected Completion Date – April 1999