85bf3029acdd2023d41011690bda7690.ppt

- Количество слайдов: 37

Automated Precision Machines Team 2 Nicholas Neumann Ralph Prewett Jonathan Brouker Li Tian Felix Adisaputra November 5 th, 2010

Automated Precision Machines Team 2 Nicholas Neumann Ralph Prewett Jonathan Brouker Li Tian Felix Adisaputra November 5 th, 2010

Contents § § § Servo Motor Stepper Motor Sensors for Precision Control Robotic Programming Languages Automated Machines

Contents § § § Servo Motor Stepper Motor Sensors for Precision Control Robotic Programming Languages Automated Machines

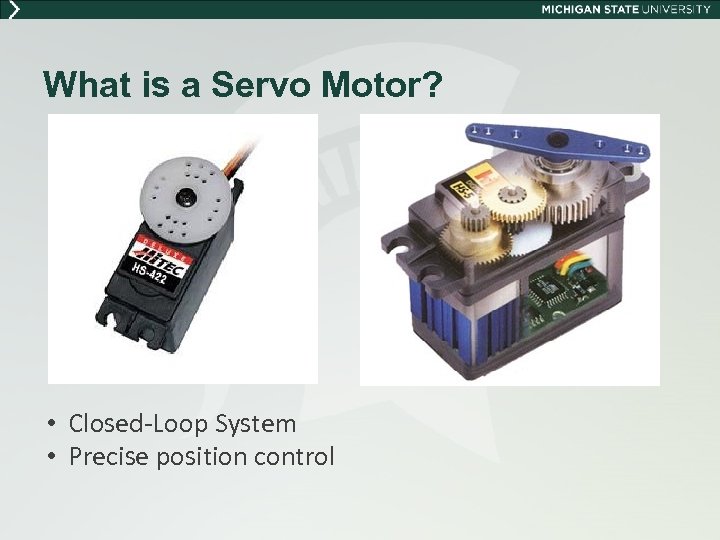

What is a Servo Motor? • Closed-Loop System • Precise position control

What is a Servo Motor? • Closed-Loop System • Precise position control

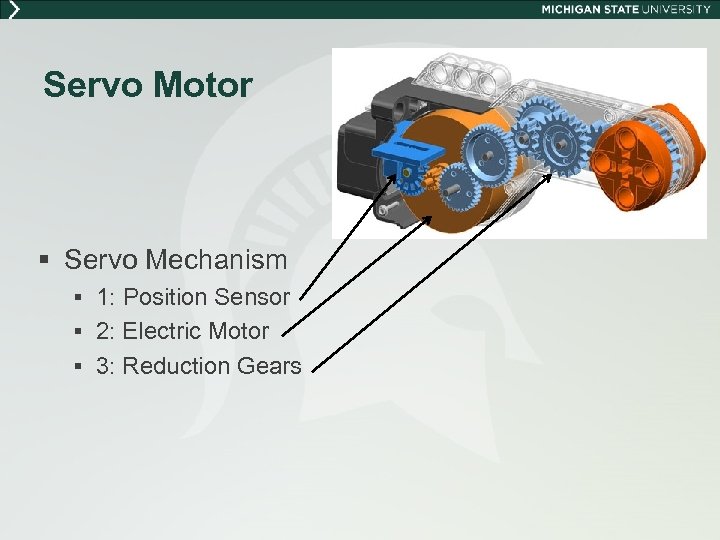

Servo Motor § Servo Mechanism § 1: Position Sensor § 2: Electric Motor § 3: Reduction Gears

Servo Motor § Servo Mechanism § 1: Position Sensor § 2: Electric Motor § 3: Reduction Gears

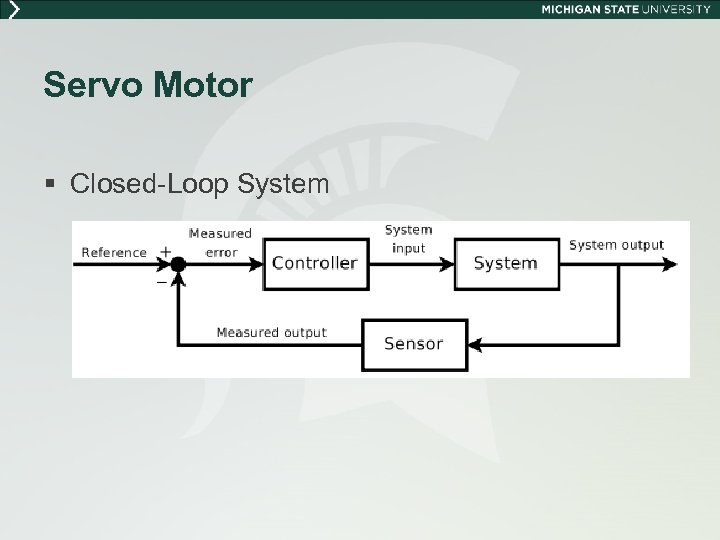

Servo Motor § Closed-Loop System

Servo Motor § Closed-Loop System

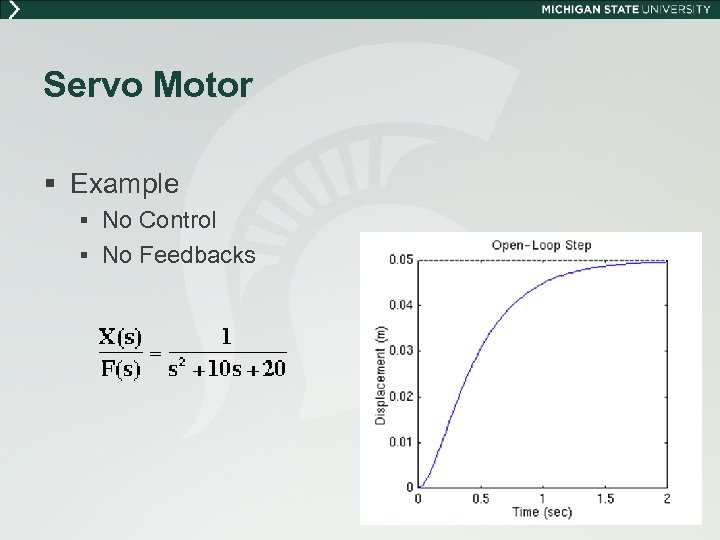

Servo Motor § Example § No Control § No Feedbacks

Servo Motor § Example § No Control § No Feedbacks

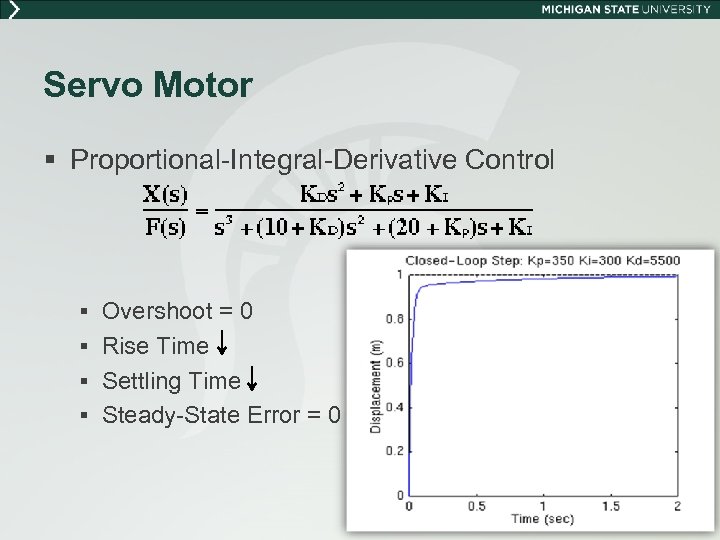

Servo Motor § Proportional-Integral-Derivative Control § Overshoot = 0 § Rise Time § Settling Time § Steady-State Error = 0

Servo Motor § Proportional-Integral-Derivative Control § Overshoot = 0 § Rise Time § Settling Time § Steady-State Error = 0

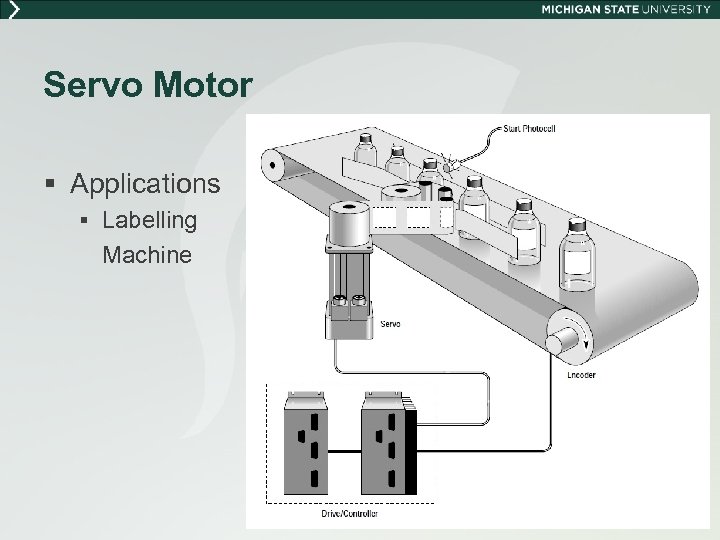

Servo Motor § Applications § Labelling Machine

Servo Motor § Applications § Labelling Machine

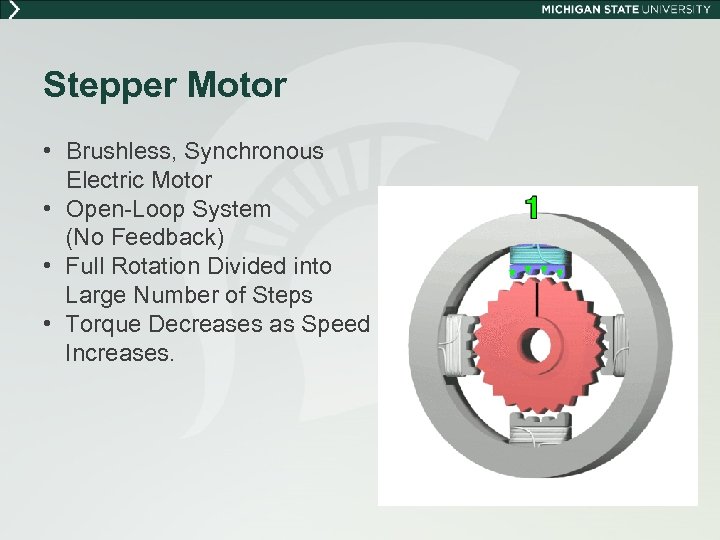

Stepper Motor • Brushless, Synchronous Electric Motor • Open-Loop System (No Feedback) • Full Rotation Divided into Large Number of Steps • Torque Decreases as Speed Increases.

Stepper Motor • Brushless, Synchronous Electric Motor • Open-Loop System (No Feedback) • Full Rotation Divided into Large Number of Steps • Torque Decreases as Speed Increases.

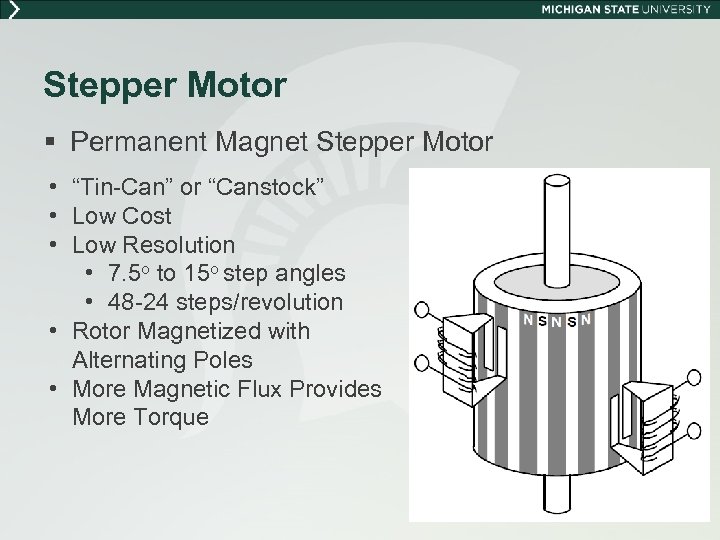

Stepper Motor § Permanent Magnet Stepper Motor • “Tin-Can” or “Canstock” • Low Cost • Low Resolution • 7. 5 o to 15 o step angles • 48 -24 steps/revolution • Rotor Magnetized with Alternating Poles • More Magnetic Flux Provides More Torque

Stepper Motor § Permanent Magnet Stepper Motor • “Tin-Can” or “Canstock” • Low Cost • Low Resolution • 7. 5 o to 15 o step angles • 48 -24 steps/revolution • Rotor Magnetized with Alternating Poles • More Magnetic Flux Provides More Torque

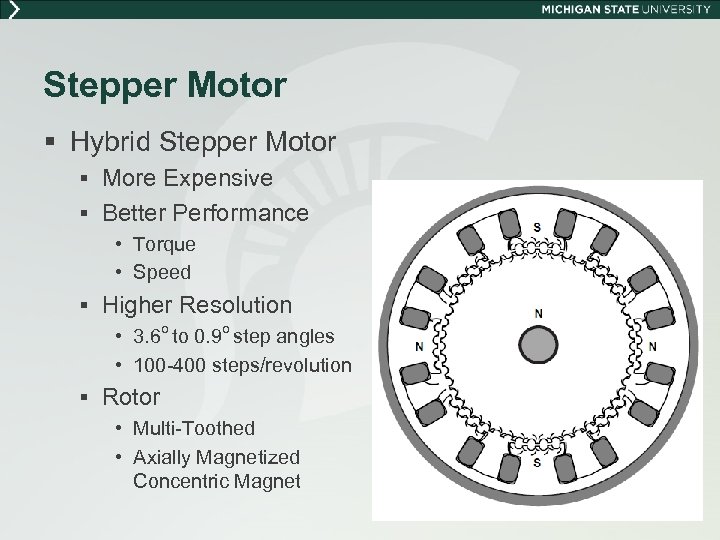

Stepper Motor § Hybrid Stepper Motor § More Expensive § Better Performance • Torque • Speed § Higher Resolution • 3. 6 o to 0. 9 o step angles • 100 -400 steps/revolution § Rotor • Multi-Toothed • Axially Magnetized Concentric Magnet

Stepper Motor § Hybrid Stepper Motor § More Expensive § Better Performance • Torque • Speed § Higher Resolution • 3. 6 o to 0. 9 o step angles • 100 -400 steps/revolution § Rotor • Multi-Toothed • Axially Magnetized Concentric Magnet

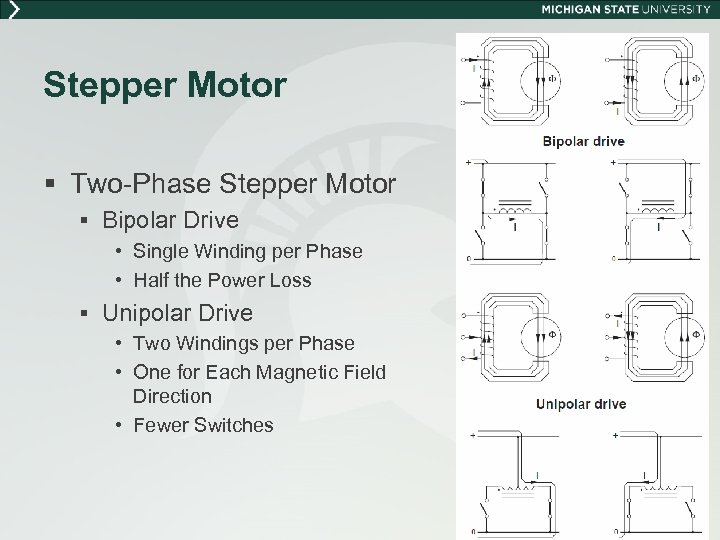

Stepper Motor § Two-Phase Stepper Motor § Bipolar Drive • Single Winding per Phase • Half the Power Loss § Unipolar Drive • Two Windings per Phase • One for Each Magnetic Field Direction • Fewer Switches

Stepper Motor § Two-Phase Stepper Motor § Bipolar Drive • Single Winding per Phase • Half the Power Loss § Unipolar Drive • Two Windings per Phase • One for Each Magnetic Field Direction • Fewer Switches

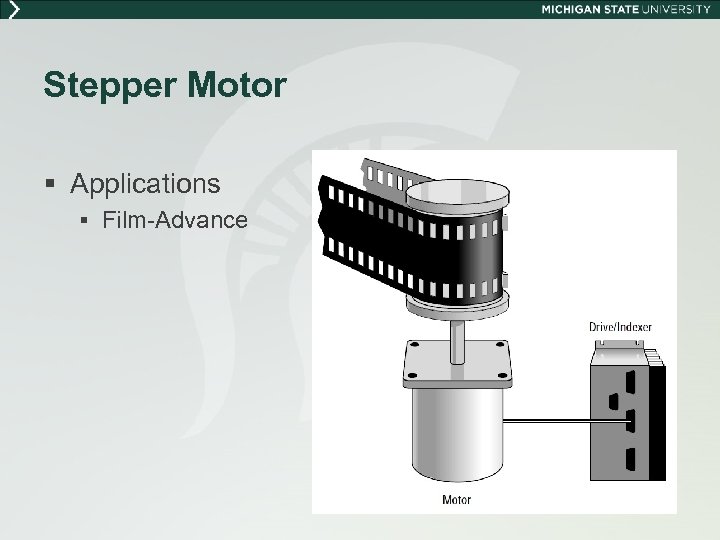

Stepper Motor § Applications § Film-Advance

Stepper Motor § Applications § Film-Advance

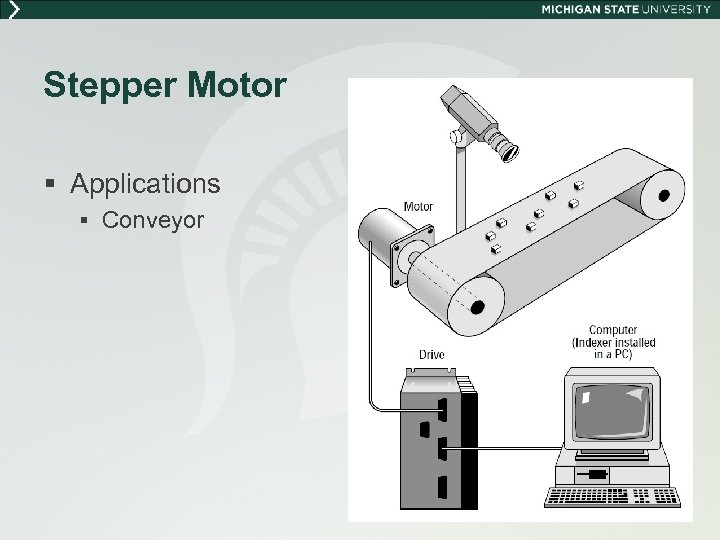

Stepper Motor § Applications § Conveyor

Stepper Motor § Applications § Conveyor

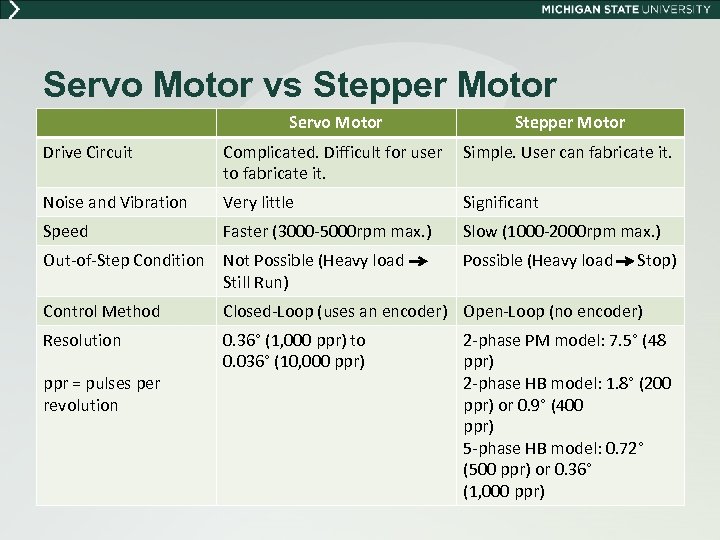

Servo Motor vs Stepper Motor Servo Motor Stepper Motor Drive Circuit Complicated. Difficult for user to fabricate it. Simple. User can fabricate it. Noise and Vibration Very little Significant Speed Faster (3000 -5000 rpm max. ) Slow (1000 -2000 rpm max. ) Out-of-Step Condition Not Possible (Heavy load Still Run) Possible (Heavy load Control Method Closed-Loop (uses an encoder) Open-Loop (no encoder) Resolution 0. 36° (1, 000 ppr) to 0. 036° (10, 000 ppr) ppr = pulses per revolution Stop) 2 -phase PM model: 7. 5° (48 ppr) 2 -phase HB model: 1. 8° (200 ppr) or 0. 9° (400 ppr) 5 -phase HB model: 0. 72° (500 ppr) or 0. 36° (1, 000 ppr)

Servo Motor vs Stepper Motor Servo Motor Stepper Motor Drive Circuit Complicated. Difficult for user to fabricate it. Simple. User can fabricate it. Noise and Vibration Very little Significant Speed Faster (3000 -5000 rpm max. ) Slow (1000 -2000 rpm max. ) Out-of-Step Condition Not Possible (Heavy load Still Run) Possible (Heavy load Control Method Closed-Loop (uses an encoder) Open-Loop (no encoder) Resolution 0. 36° (1, 000 ppr) to 0. 036° (10, 000 ppr) ppr = pulses per revolution Stop) 2 -phase PM model: 7. 5° (48 ppr) 2 -phase HB model: 1. 8° (200 ppr) or 0. 9° (400 ppr) 5 -phase HB model: 0. 72° (500 ppr) or 0. 36° (1, 000 ppr)

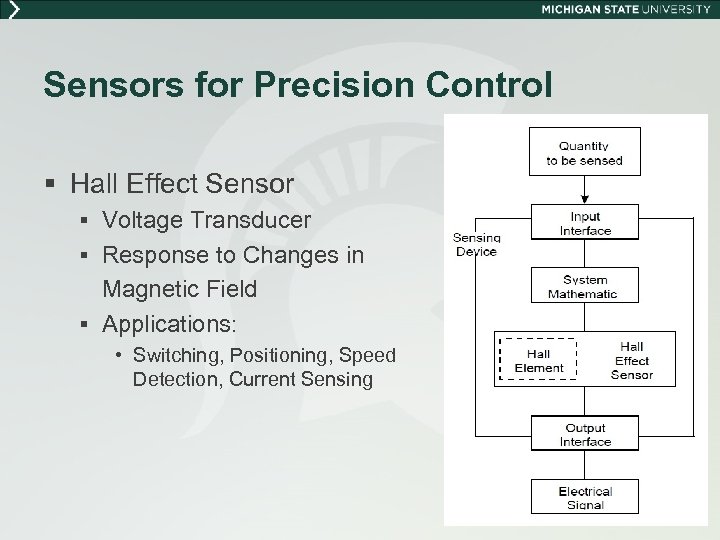

Sensors for Precision Control § Hall Effect Sensor § Voltage Transducer § Response to Changes in Magnetic Field § Applications: • Switching, Positioning, Speed Detection, Current Sensing

Sensors for Precision Control § Hall Effect Sensor § Voltage Transducer § Response to Changes in Magnetic Field § Applications: • Switching, Positioning, Speed Detection, Current Sensing

Sensors for Precision Control Advantage: § They are immune to dirt, dust and water, § They are capable of switching at high frequencies. § They can be used for a wide variety of applications.

Sensors for Precision Control Advantage: § They are immune to dirt, dust and water, § They are capable of switching at high frequencies. § They can be used for a wide variety of applications.

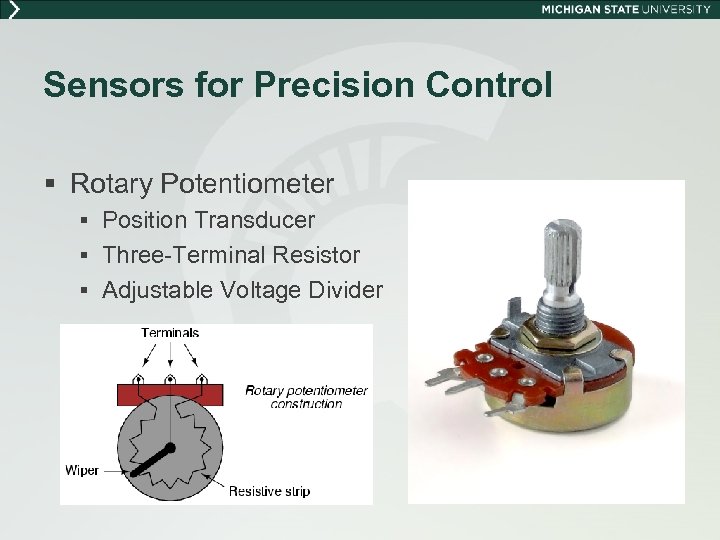

Sensors for Precision Control § Rotary Potentiometer § Position Transducer § Three-Terminal Resistor § Adjustable Voltage Divider

Sensors for Precision Control § Rotary Potentiometer § Position Transducer § Three-Terminal Resistor § Adjustable Voltage Divider

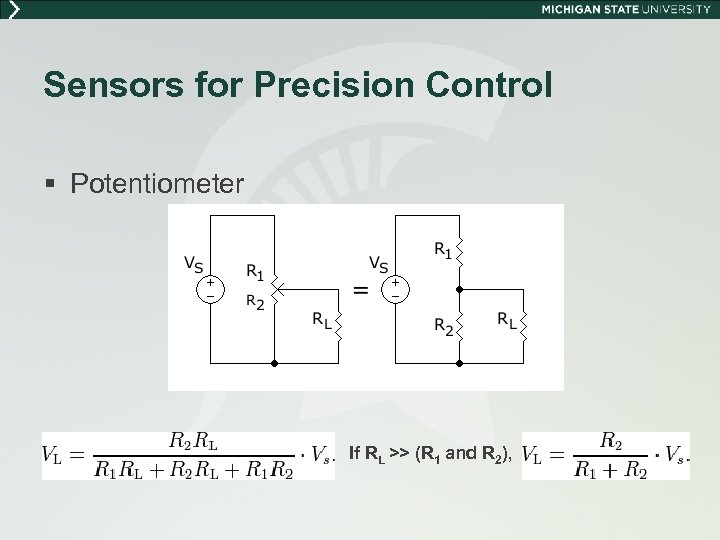

Sensors for Precision Control § Potentiometer If RL >> (R 1 and R 2),

Sensors for Precision Control § Potentiometer If RL >> (R 1 and R 2),

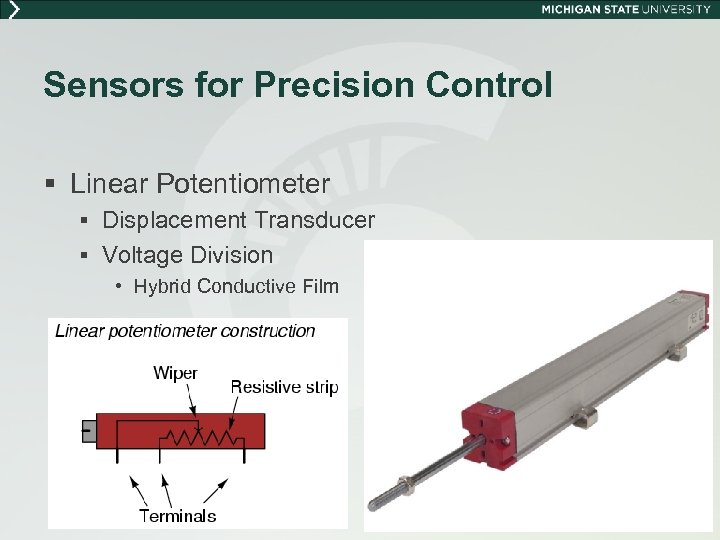

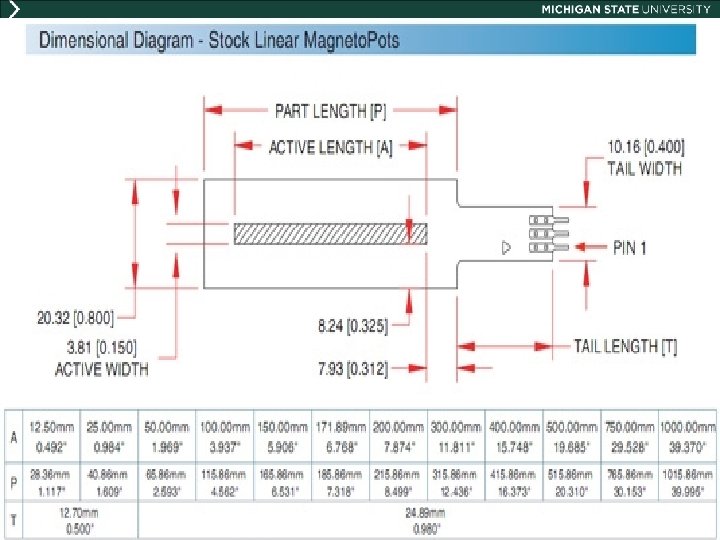

Sensors for Precision Control § Linear Potentiometer § Displacement Transducer § Voltage Division • Hybrid Conductive Film

Sensors for Precision Control § Linear Potentiometer § Displacement Transducer § Voltage Division • Hybrid Conductive Film

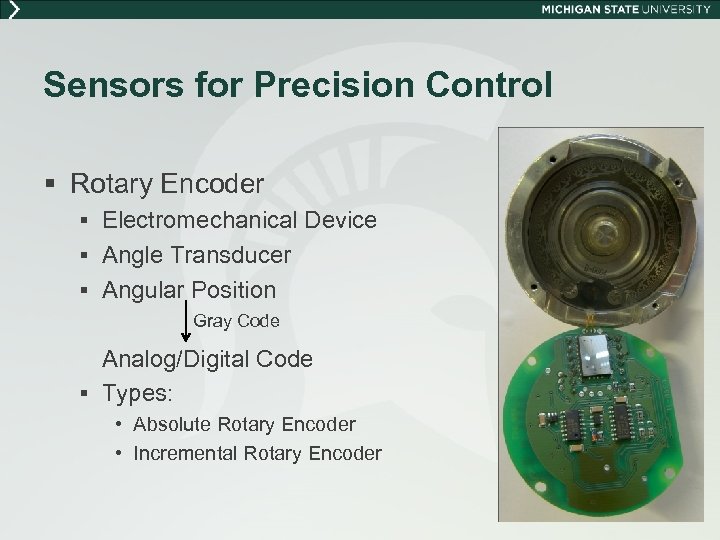

Sensors for Precision Control § Rotary Encoder § Electromechanical Device § Angle Transducer § Angular Position Gray Code Analog/Digital Code § Types: • Absolute Rotary Encoder • Incremental Rotary Encoder

Sensors for Precision Control § Rotary Encoder § Electromechanical Device § Angle Transducer § Angular Position Gray Code Analog/Digital Code § Types: • Absolute Rotary Encoder • Incremental Rotary Encoder

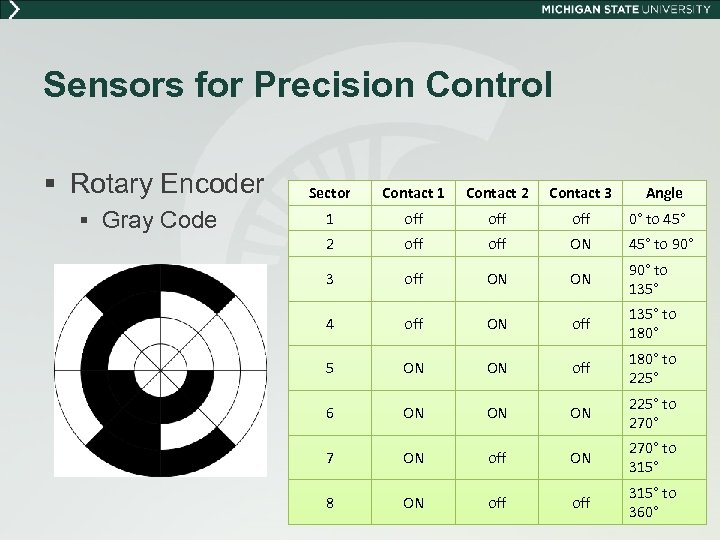

Sensors for Precision Control § Rotary Encoder § Gray Code Sector Contact 1 Contact 2 Contact 3 Angle 1 off off 0° to 45° 2 off ON 45° to 90° 3 off ON ON 90° to 135° 4 off ON off 135° to 180° 5 ON ON off 180° to 225° 6 ON ON ON 225° to 270° 7 ON off ON 270° to 315° 8 ON off 315° to 360°

Sensors for Precision Control § Rotary Encoder § Gray Code Sector Contact 1 Contact 2 Contact 3 Angle 1 off off 0° to 45° 2 off ON 45° to 90° 3 off ON ON 90° to 135° 4 off ON off 135° to 180° 5 ON ON off 180° to 225° 6 ON ON ON 225° to 270° 7 ON off ON 270° to 315° 8 ON off 315° to 360°

Robotic Programming Languages § C Language § Pros: • Speed of Resulting Application • Application in Firmware Programming • Compatible with Many Other Languages • Code is Compacted into Executable Instruction § Cons: • No Runtime Checking • No Strict Type Checking – Can Pass Integer Value for Floating Data Type • Very Difficult to Fix Bugs as Program Extends

Robotic Programming Languages § C Language § Pros: • Speed of Resulting Application • Application in Firmware Programming • Compatible with Many Other Languages • Code is Compacted into Executable Instruction § Cons: • No Runtime Checking • No Strict Type Checking – Can Pass Integer Value for Floating Data Type • Very Difficult to Fix Bugs as Program Extends

Robotic Programming Languages § Robot. C Language § Pros: • More Functions than Regular Graphical Language • Easy to Navigate Through Program • Suitable for More Complicated Programs § Cons: • Text-Based Language – Hard for Beginners • Must be Bought Separately from Kit

Robotic Programming Languages § Robot. C Language § Pros: • More Functions than Regular Graphical Language • Easy to Navigate Through Program • Suitable for More Complicated Programs § Cons: • Text-Based Language – Hard for Beginners • Must be Bought Separately from Kit

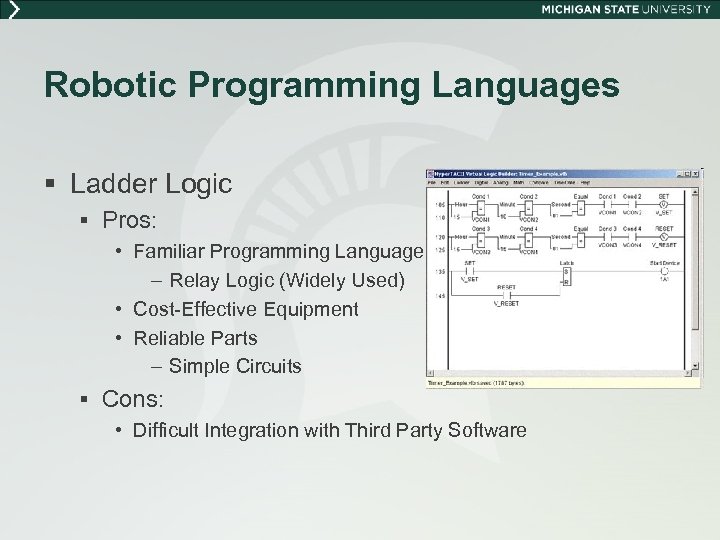

Robotic Programming Languages § Ladder Logic § Pros: • Familiar Programming Language – Relay Logic (Widely Used) • Cost-Effective Equipment • Reliable Parts – Simple Circuits § Cons: • Difficult Integration with Third Party Software

Robotic Programming Languages § Ladder Logic § Pros: • Familiar Programming Language – Relay Logic (Widely Used) • Cost-Effective Equipment • Reliable Parts – Simple Circuits § Cons: • Difficult Integration with Third Party Software

Robotic Programming Languages § BASIC § Pros: • User Friendly and Interactive • Simple and Easy • Rapid Development • Powerful Front-End Tool • Multiple Vendor Support § Cons: • Memory Leakage • Passing Value by Reference • Only for Windows • Sluggish Performance

Robotic Programming Languages § BASIC § Pros: • User Friendly and Interactive • Simple and Easy • Rapid Development • Powerful Front-End Tool • Multiple Vendor Support § Cons: • Memory Leakage • Passing Value by Reference • Only for Windows • Sluggish Performance

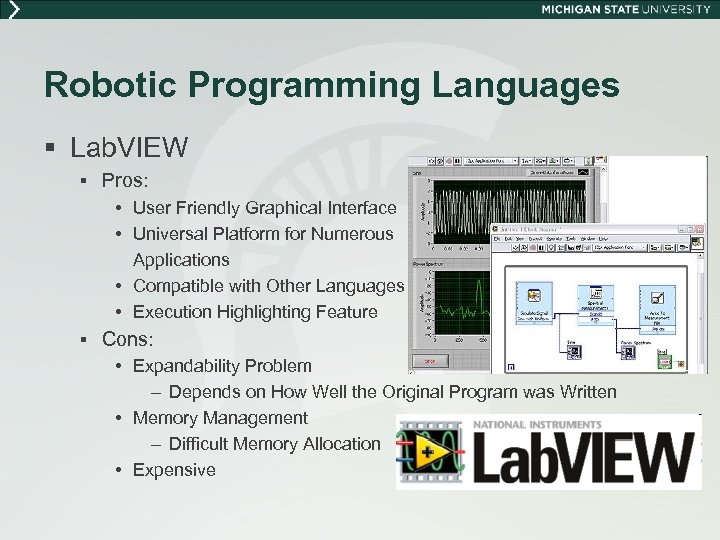

Robotic Programming Languages § Lab. VIEW § Pros: • User Friendly Graphical Interface • Universal Platform for Numerous Applications • Compatible with Other Languages • Execution Highlighting Feature § Cons: • Expandability Problem – Depends on How Well the Original Program was Written • Memory Management – Difficult Memory Allocation • Expensive

Robotic Programming Languages § Lab. VIEW § Pros: • User Friendly Graphical Interface • Universal Platform for Numerous Applications • Compatible with Other Languages • Execution Highlighting Feature § Cons: • Expandability Problem – Depends on How Well the Original Program was Written • Memory Management – Difficult Memory Allocation • Expensive

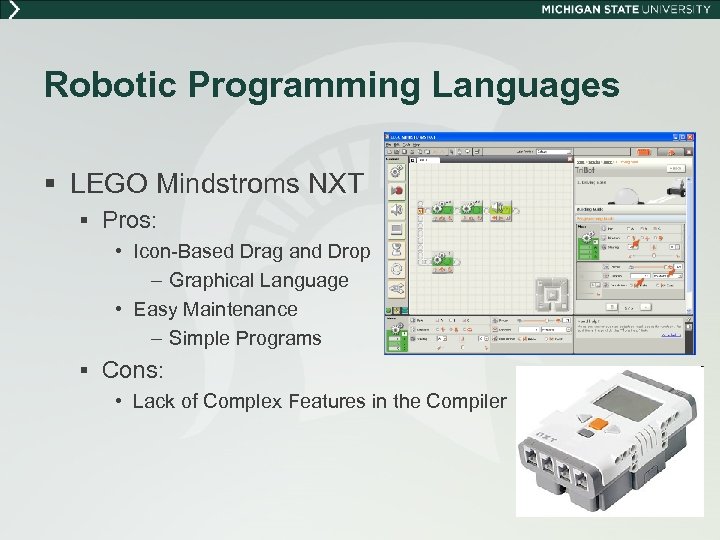

Robotic Programming Languages § LEGO Mindstroms NXT § Pros: • Icon-Based Drag and Drop – Graphical Language • Easy Maintenance – Simple Programs § Cons: • Lack of Complex Features in the Compiler

Robotic Programming Languages § LEGO Mindstroms NXT § Pros: • Icon-Based Drag and Drop – Graphical Language • Easy Maintenance – Simple Programs § Cons: • Lack of Complex Features in the Compiler

Robotic Programming Languages § Which Language to pick? § Previous Experience § How much time and effort you intend to invest § Your goals § Availability

Robotic Programming Languages § Which Language to pick? § Previous Experience § How much time and effort you intend to invest § Your goals § Availability

Automated Machines § Control Systems § Information Technologies § Reduce Human Work

Automated Machines § Control Systems § Information Technologies § Reduce Human Work

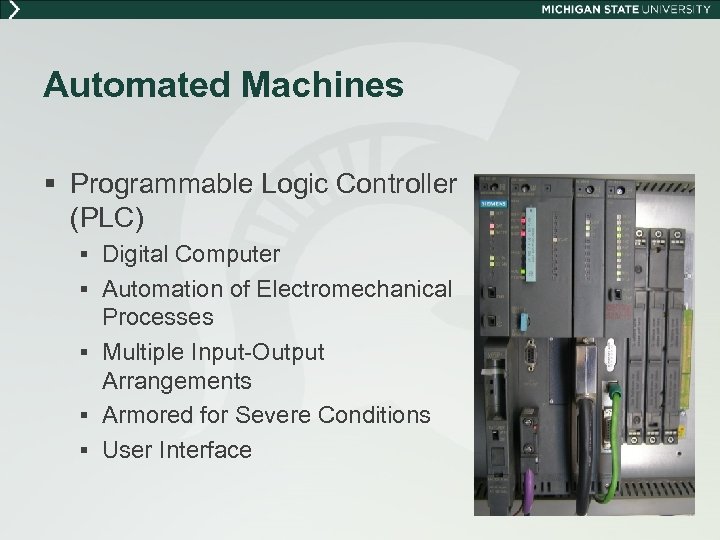

Automated Machines § Programmable Logic Controller (PLC) § Digital Computer § Automation of Electromechanical Processes § Multiple Input-Output Arrangements § Armored for Severe Conditions § User Interface

Automated Machines § Programmable Logic Controller (PLC) § Digital Computer § Automation of Electromechanical Processes § Multiple Input-Output Arrangements § Armored for Severe Conditions § User Interface

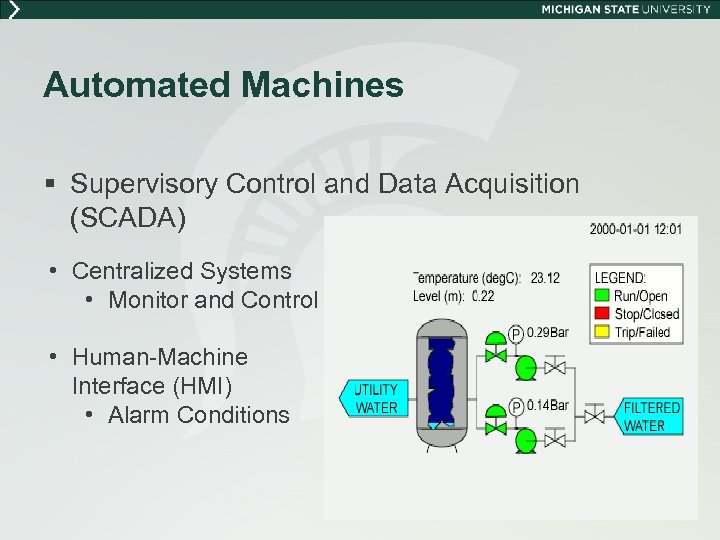

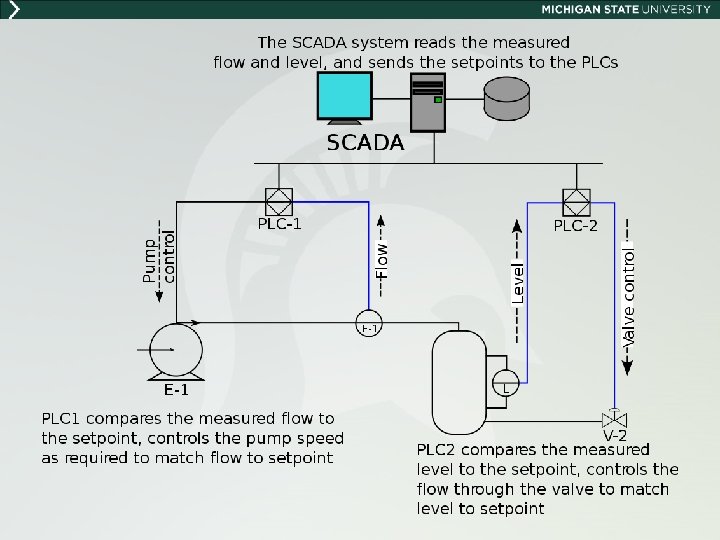

Automated Machines § Supervisory Control and Data Acquisition (SCADA) • Centralized Systems • Monitor and Control • Human-Machine Interface (HMI) • Alarm Conditions

Automated Machines § Supervisory Control and Data Acquisition (SCADA) • Centralized Systems • Monitor and Control • Human-Machine Interface (HMI) • Alarm Conditions

Automated Machines § Main Advantages § Replacing Human Operators in Monotonous Work § Performing Tasks that are Beyond Human Capabilities • Size, Weight, Speed § Dangerous Environment • Space, Underwater, Nuclear Facilities § Economy Improvement

Automated Machines § Main Advantages § Replacing Human Operators in Monotonous Work § Performing Tasks that are Beyond Human Capabilities • Size, Weight, Speed § Dangerous Environment • Space, Underwater, Nuclear Facilities § Economy Improvement

Automated Machines § Main Disadvantages § Technology Limits • Unable to Automate All Desired Tasks § High Initial Cost § Unpredictable Development Costs

Automated Machines § Main Disadvantages § Technology Limits • Unable to Automate All Desired Tasks § High Initial Cost § Unpredictable Development Costs

Questions

Questions