c9658049063e4951d2757f308f31e0d0.ppt

- Количество слайдов: 1

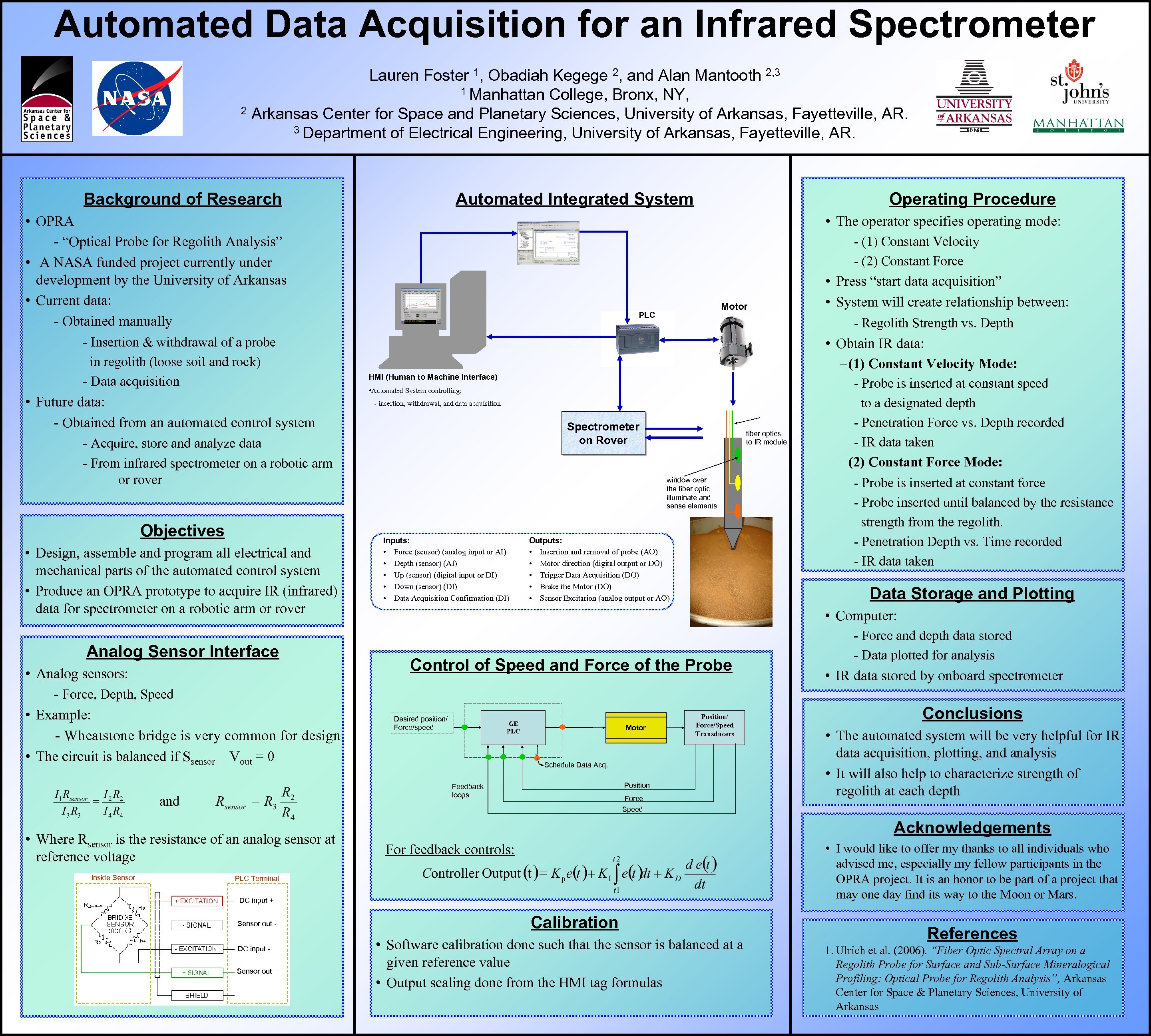

Automated Data Acquisition for an Infrared Spectrometer Lauren Foster 1, Obadiah Kegege 2, and Alan Mantooth 2, 3 1 Manhattan College, Bronx, NY, 2 Arkansas Center for Space and Planetary Sciences, University of Arkansas, Fayetteville, AR. 3 Department of Electrical Engineering, University of Arkansas, Fayetteville, AR. Background of Research Automated Integrated System • OPRA - “Optical Probe for Regolith Analysis” • A NASA funded project currently under development by the University of Arkansas • Current data: - Obtained manually - Insertion & withdrawal of a probe in regolith (loose soil and rock) - Data acquisition • Future data: - Obtained from an automated control system • The operator specifies operating mode: - (1) Constant Velocity - (2) Constant Force • Design, assemble and program all electrical and mechanical parts of the automated control system • Produce an OPRA prototype to acquire IR (infrared) data for spectrometer on a robotic arm or rover Analog Sensor Interface • Analog sensors: - Force, Depth, Speed • Example: - Wheatstone bridge is very common for design • The circuit is balanced if Ssensor _ Vout = 0 • Where Rsensor is the resistance of an analog sensor at reference voltage Inside Sensor R_sensor - Regolith Strength vs. Depth HMI (Human to Machine Interface) • Automated System controlling: - insertion, withdrawal, and data acquisition Spectrometer on Rover fiber optics to IR module window over the fiber optic illuminate and sense elements Inputs: • Force (sensor) (analog input or AI) • Depth (sensor) (AI) • Up (sensor) (digital input or DI) • Down (sensor) (DI) • Data Acquisition Confirmation (DI) Outputs: • Insertion and removal of probe (AO) • Motor direction (digital output or DO) • Trigger Data Acquisition (DO) • Brake the Motor (DO) • Sensor Excitation (analog output or AO) - Probe is inserted at constant speed to a designated depth - Penetration Force vs. Depth recorded - IR data taken – (2) Constant Force Mode: - Probe is inserted at constant force - Probe inserted until balanced by the resistance strength from the regolith. - Penetration Depth vs. Time recorded - IR data taken Data Storage and Plotting • Computer: Control of Speed and Force of the Probe Desired position/ Force/speed GE PLC Motor Position/ Force/Speed Transducers Schedule Data Acq. Position Force Speed - Force and depth data stored - Data plotted for analysis • IR data stored by onboard spectrometer Conclusions • The automated system will be very helpful for IR data acquisition, plotting, and analysis • It will also help to characterize strength of regolith at each depth Acknowledgements • I would like to offer my thanks to all individuals who advised me, especially my fellow participants in the OPRA project. It is an honor to be part of a project that may one day find its way to the Moon or Mars. For feedback controls: PLC Terminal DC input + R 3 Sensor out R 2 • Press “start data acquisition” • System will create relationship between: • Obtain IR data: – (1) Constant Velocity Mode: Feedback loops and Motor PLC - Acquire, store and analyze data - From infrared spectrometer on a robotic arm or rover Objectives Operating Procedure R 4 DC input Sensor out + Calibration • Software calibration done such that the sensor is balanced at a given reference value • Output scaling done from the HMI tag formulas References 1. Ulrich et al. (2006). “Fiber Optic Spectral Array on a Regolith Probe for Surface and Sub-Surface Mineralogical Profiling: Optical Probe for Regolith Analysis”, Arkansas Center for Space & Planetary Sciences, University of Arkansas

Automated Data Acquisition for an Infrared Spectrometer Lauren Foster 1, Obadiah Kegege 2, and Alan Mantooth 2, 3 1 Manhattan College, Bronx, NY, 2 Arkansas Center for Space and Planetary Sciences, University of Arkansas, Fayetteville, AR. 3 Department of Electrical Engineering, University of Arkansas, Fayetteville, AR. Background of Research Automated Integrated System • OPRA - “Optical Probe for Regolith Analysis” • A NASA funded project currently under development by the University of Arkansas • Current data: - Obtained manually - Insertion & withdrawal of a probe in regolith (loose soil and rock) - Data acquisition • Future data: - Obtained from an automated control system • The operator specifies operating mode: - (1) Constant Velocity - (2) Constant Force • Design, assemble and program all electrical and mechanical parts of the automated control system • Produce an OPRA prototype to acquire IR (infrared) data for spectrometer on a robotic arm or rover Analog Sensor Interface • Analog sensors: - Force, Depth, Speed • Example: - Wheatstone bridge is very common for design • The circuit is balanced if Ssensor _ Vout = 0 • Where Rsensor is the resistance of an analog sensor at reference voltage Inside Sensor R_sensor - Regolith Strength vs. Depth HMI (Human to Machine Interface) • Automated System controlling: - insertion, withdrawal, and data acquisition Spectrometer on Rover fiber optics to IR module window over the fiber optic illuminate and sense elements Inputs: • Force (sensor) (analog input or AI) • Depth (sensor) (AI) • Up (sensor) (digital input or DI) • Down (sensor) (DI) • Data Acquisition Confirmation (DI) Outputs: • Insertion and removal of probe (AO) • Motor direction (digital output or DO) • Trigger Data Acquisition (DO) • Brake the Motor (DO) • Sensor Excitation (analog output or AO) - Probe is inserted at constant speed to a designated depth - Penetration Force vs. Depth recorded - IR data taken – (2) Constant Force Mode: - Probe is inserted at constant force - Probe inserted until balanced by the resistance strength from the regolith. - Penetration Depth vs. Time recorded - IR data taken Data Storage and Plotting • Computer: Control of Speed and Force of the Probe Desired position/ Force/speed GE PLC Motor Position/ Force/Speed Transducers Schedule Data Acq. Position Force Speed - Force and depth data stored - Data plotted for analysis • IR data stored by onboard spectrometer Conclusions • The automated system will be very helpful for IR data acquisition, plotting, and analysis • It will also help to characterize strength of regolith at each depth Acknowledgements • I would like to offer my thanks to all individuals who advised me, especially my fellow participants in the OPRA project. It is an honor to be part of a project that may one day find its way to the Moon or Mars. For feedback controls: PLC Terminal DC input + R 3 Sensor out R 2 • Press “start data acquisition” • System will create relationship between: • Obtain IR data: – (1) Constant Velocity Mode: Feedback loops and Motor PLC - Acquire, store and analyze data - From infrared spectrometer on a robotic arm or rover Objectives Operating Procedure R 4 DC input Sensor out + Calibration • Software calibration done such that the sensor is balanced at a given reference value • Output scaling done from the HMI tag formulas References 1. Ulrich et al. (2006). “Fiber Optic Spectral Array on a Regolith Probe for Surface and Sub-Surface Mineralogical Profiling: Optical Probe for Regolith Analysis”, Arkansas Center for Space & Planetary Sciences, University of Arkansas