7c50d4aeef32679b05739bc7b007256d.ppt

- Количество слайдов: 16

Automated Collimation Operation LHC-MAC 2007 06 15 M. Jonker On behalf of the collimation project (as the controls coordinator)

Automated Collimation Operation LHC-MAC 2007 06 15 M. Jonker On behalf of the collimation project (as the controls coordinator)

Collimation Controls • Collimation Controls Steering team (Cocost) – – – Stefano Redaelli Maciej Sobczak Roberto Losito Alessandro Masi Ralph Assmann Michel Jonker (high level control applications) (css, middle level) (low level control) (project leader) (controls coordinator) Invited – Philippe Gayet (plc’s) – Rudiger Schmidt (machine protection) – Bernd Dehning (beam loss monitors)

Collimation Controls • Collimation Controls Steering team (Cocost) – – – Stefano Redaelli Maciej Sobczak Roberto Losito Alessandro Masi Ralph Assmann Michel Jonker (high level control applications) (css, middle level) (low level control) (project leader) (controls coordinator) Invited – Philippe Gayet (plc’s) – Rudiger Schmidt (machine protection) – Bernd Dehning (beam loss monitors)

Outline • 94 (up to 160 in final upgrade) collimators, to protect against machine damage and magnet quenches. • The collimation process is a multi-staged process that require precise (0. 1 ) setting of the jaws with respect to the beam envelope. Goal for positioning accuracy is 20 m (0. 1 at 7 Te. V). beam • Actual beam envelope (position and size) may change (from fill to fill ? , by how much? )

Outline • 94 (up to 160 in final upgrade) collimators, to protect against machine damage and magnet quenches. • The collimation process is a multi-staged process that require precise (0. 1 ) setting of the jaws with respect to the beam envelope. Goal for positioning accuracy is 20 m (0. 1 at 7 Te. V). beam • Actual beam envelope (position and size) may change (from fill to fill ? , by how much? )

Collimation Optimisation • Adapt to changing beam parameters to guarantee machine protection and to keep good cleaning efficiency • There are 376 degrees of freedom (4 motors per collimator) (188 if not considering the angle of the jaws) 30 seconds per degree of freedom (a very efficient operator) still requires about 3 hours. We need automated tools and procedures

Collimation Optimisation • Adapt to changing beam parameters to guarantee machine protection and to keep good cleaning efficiency • There are 376 degrees of freedom (4 motors per collimator) (188 if not considering the angle of the jaws) 30 seconds per degree of freedom (a very efficient operator) still requires about 3 hours. We need automated tools and procedures

Setup Procedures • Beam probing – Determine beam positions and size at every collimator by touching the beam. – Required for initial setup of a machine optics (injection and top energies ), or after substantial changes in beam parameters. – Setup at with a low intensity beam 5 nominal LHC bunches (equivalent to the Tevatron Beam in stored energy). Extrapolation from 5 to 3000 bunches…(bunch train effects? ) • Fast beam based setup – Position collimators based on loss patterns, not on measured beam positions and sizes – Further systematic optimisation with nominal intensity beam • Response matrix corrections – Correct collimator positions guided by loss patterns.

Setup Procedures • Beam probing – Determine beam positions and size at every collimator by touching the beam. – Required for initial setup of a machine optics (injection and top energies ), or after substantial changes in beam parameters. – Setup at with a low intensity beam 5 nominal LHC bunches (equivalent to the Tevatron Beam in stored energy). Extrapolation from 5 to 3000 bunches…(bunch train effects? ) • Fast beam based setup – Position collimators based on loss patterns, not on measured beam positions and sizes – Further systematic optimisation with nominal intensity beam • Response matrix corrections – Correct collimator positions guided by loss patterns.

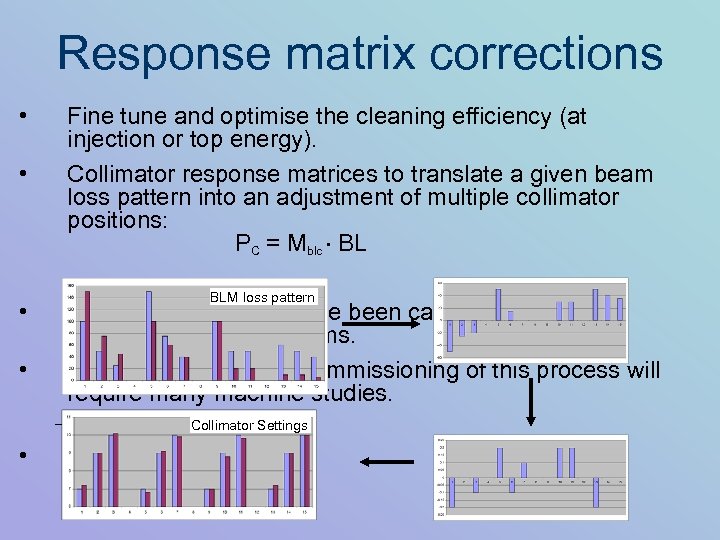

Response matrix corrections • Fine tune and optimise the cleaning efficiency (at injection or top energy). Collimator response matrices to translate a given beam loss pattern into an adjustment of multiple collimator positions: PC = Mblc BL • BLM loss pattern • Theoretical matrices have been calculated based on Fluka and Struct programs. Ambitious procedure, commissioning of this process will require many machine studies. • – • Not for the. Collimator Settings beginning Not discussed here

Response matrix corrections • Fine tune and optimise the cleaning efficiency (at injection or top energy). Collimator response matrices to translate a given beam loss pattern into an adjustment of multiple collimator positions: PC = Mblc BL • BLM loss pattern • Theoretical matrices have been calculated based on Fluka and Struct programs. Ambitious procedure, commissioning of this process will require many machine studies. • – • Not for the. Collimator Settings beginning Not discussed here

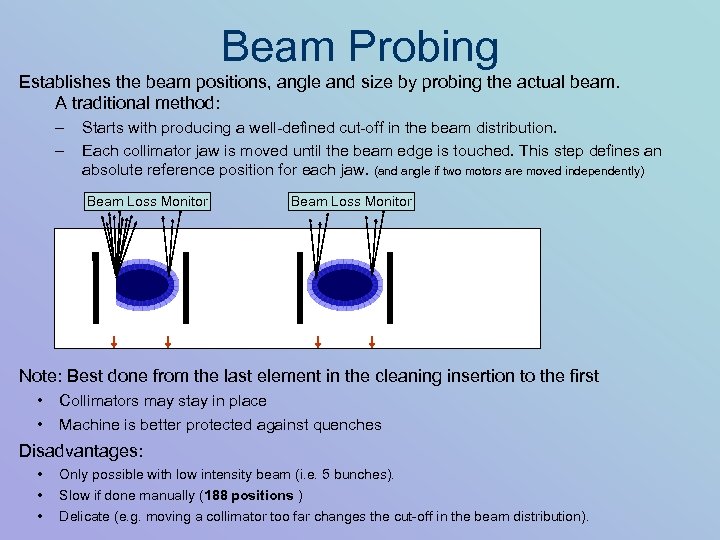

Beam Probing Establishes the beam positions, angle and size by probing the actual beam. A traditional method: – – Starts with producing a well-defined cut-off in the beam distribution. Each collimator jaw is moved until the beam edge is touched. This step defines an absolute reference position for each jaw. (and angle if two motors are moved independently) Beam Loss Monitor Note: Best done from the last element in the cleaning insertion to the first • Collimators may stay in place • Machine is better protected against quenches Disadvantages: • • • Only possible with low intensity beam (i. e. 5 bunches). Slow if done manually (188 positions ) Delicate (e. g. moving a collimator too far changes the cut-off in the beam distribution).

Beam Probing Establishes the beam positions, angle and size by probing the actual beam. A traditional method: – – Starts with producing a well-defined cut-off in the beam distribution. Each collimator jaw is moved until the beam edge is touched. This step defines an absolute reference position for each jaw. (and angle if two motors are moved independently) Beam Loss Monitor Note: Best done from the last element in the cleaning insertion to the first • Collimators may stay in place • Machine is better protected against quenches Disadvantages: • • • Only possible with low intensity beam (i. e. 5 bunches). Slow if done manually (188 positions ) Delicate (e. g. moving a collimator too far changes the cut-off in the beam distribution).

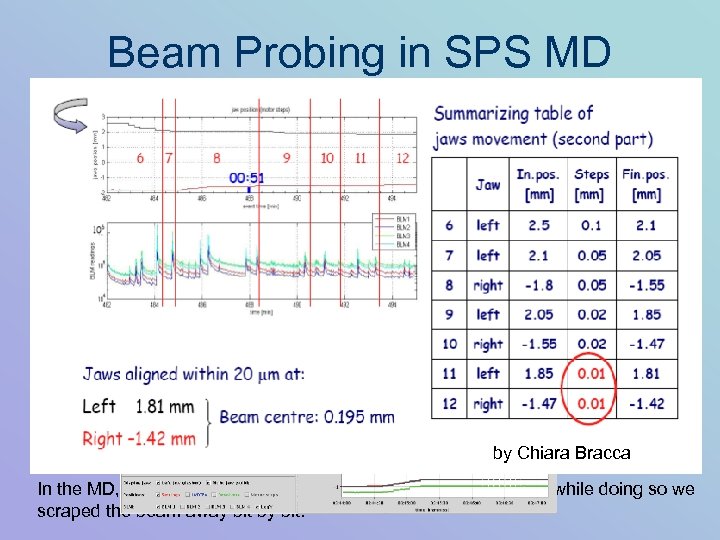

Beam Probing in SPS MD Beam probing was tested in the collimation MD at the SPS in 2006 with the collimation control system. • The jaws were driven in by the control application either manually or in repetitive steps. • The control application simultaneously displays jaw position and Beam Loss Data by Chiara Bracca In the MD, to speed up we used successively smaller steps, and while doing so we scraped the beam away bit by bit.

Beam Probing in SPS MD Beam probing was tested in the collimation MD at the SPS in 2006 with the collimation control system. • The jaws were driven in by the control application either manually or in repetitive steps. • The control application simultaneously displays jaw position and Beam Loss Data by Chiara Bracca In the MD, to speed up we used successively smaller steps, and while doing so we scraped the beam away bit by bit.

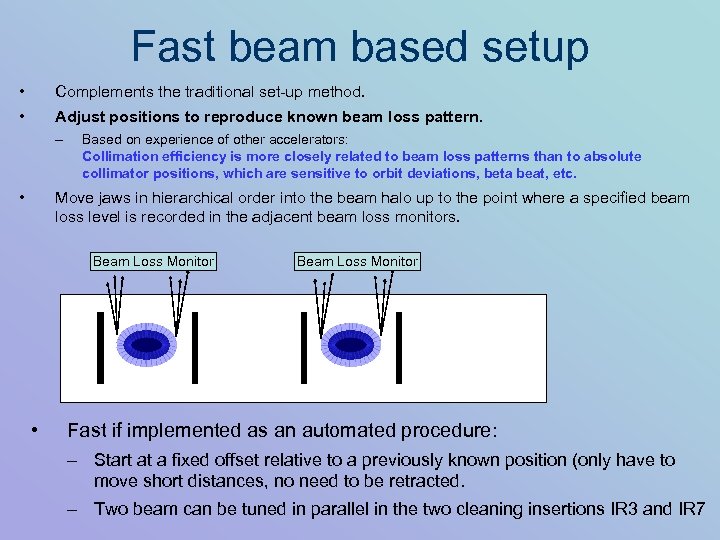

Fast beam based setup • Complements the traditional set-up method. • Adjust positions to reproduce known beam loss pattern. – • Based on experience of other accelerators: Collimation efficiency is more closely related to beam loss patterns than to absolute collimator positions, which are sensitive to orbit deviations, beta beat, etc. Move jaws in hierarchical order into the beam halo up to the point where a specified beam loss level is recorded in the adjacent beam loss monitors. Beam Loss Monitor • Beam Loss Monitor Fast if implemented as an automated procedure: – Start at a fixed offset relative to a previously known position (only have to move short distances, no need to be retracted. – Two beam can be tuned in parallel in the two cleaning insertions IR 3 and IR 7

Fast beam based setup • Complements the traditional set-up method. • Adjust positions to reproduce known beam loss pattern. – • Based on experience of other accelerators: Collimation efficiency is more closely related to beam loss patterns than to absolute collimator positions, which are sensitive to orbit deviations, beta beat, etc. Move jaws in hierarchical order into the beam halo up to the point where a specified beam loss level is recorded in the adjacent beam loss monitors. Beam Loss Monitor • Beam Loss Monitor Fast if implemented as an automated procedure: – Start at a fixed offset relative to a previously known position (only have to move short distances, no need to be retracted. – Two beam can be tuned in parallel in the two cleaning insertions IR 3 and IR 7

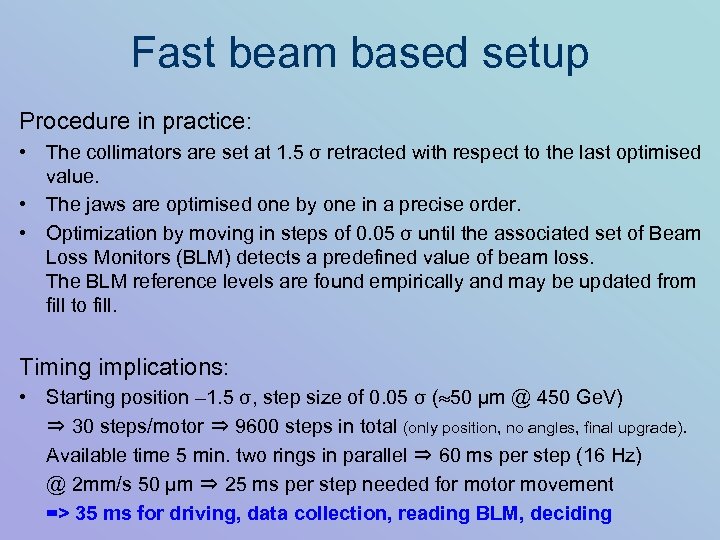

Fast beam based setup Procedure in practice: • The collimators are set at 1. 5 σ retracted with respect to the last optimised value. • The jaws are optimised one by one in a precise order. • Optimization by moving in steps of 0. 05 σ until the associated set of Beam Loss Monitors (BLM) detects a predefined value of beam loss. The BLM reference levels are found empirically and may be updated from fill to fill. Timing implications: • Starting position – 1. 5 σ, step size of 0. 05 σ ( 50 μm @ 450 Ge. V) ⇒ 30 steps/motor ⇒ 9600 steps in total (only position, no angles, final upgrade). Available time 5 min. two rings in parallel ⇒ 60 ms per step (16 Hz) @ 2 mm/s 50 μm ⇒ 25 ms per step needed for motor movement => 35 ms for driving, data collection, reading BLM, deciding

Fast beam based setup Procedure in practice: • The collimators are set at 1. 5 σ retracted with respect to the last optimised value. • The jaws are optimised one by one in a precise order. • Optimization by moving in steps of 0. 05 σ until the associated set of Beam Loss Monitors (BLM) detects a predefined value of beam loss. The BLM reference levels are found empirically and may be updated from fill to fill. Timing implications: • Starting position – 1. 5 σ, step size of 0. 05 σ ( 50 μm @ 450 Ge. V) ⇒ 30 steps/motor ⇒ 9600 steps in total (only position, no angles, final upgrade). Available time 5 min. two rings in parallel ⇒ 60 ms per step (16 Hz) @ 2 mm/s 50 μm ⇒ 25 ms per step needed for motor movement => 35 ms for driving, data collection, reading BLM, deciding

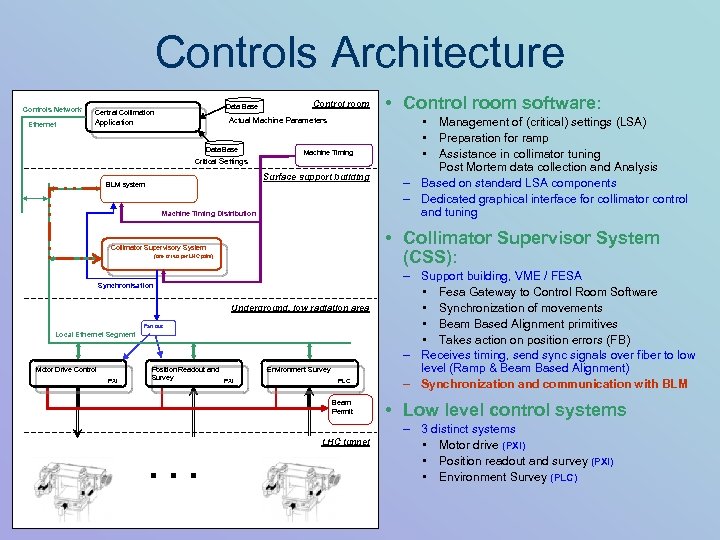

Controls Architecture Controls Network Ethernet Data Base Central Collimation Control room Actual Machine Parameters Application Data Base Machine Timing Critical Settings Surface support building BLM system Machine Timing Distribution (one or two per LHC point) Synchronisation Underground, low radiation area Fan out Local Ethernet Segment PXI Position Readout and Survey PXI Environment Survey PLC Beam Permit . . . • • • Management of (critical) settings (LSA) Preparation for ramp Assistance in collimator tuning Post Mortem data collection and Analysis – Based on standard LSA components – Dedicated graphical interface for collimator control and tuning • Collimator Supervisor System (CSS): Collimator Supervisory System Motor Drive Control • Control room software: LHC tunnel – Support building, VME / FESA • Fesa Gateway to Control Room Software • Synchronization of movements • Beam Based Alignment primitives • Takes action on position errors (FB) – Receives timing, send sync signals over fiber to low level (Ramp & Beam Based Alignment) – Synchronization and communication with BLM • Low level control systems – 3 distinct systems • Motor drive (PXI) • Position readout and survey (PXI) • Environment Survey (PLC)

Controls Architecture Controls Network Ethernet Data Base Central Collimation Control room Actual Machine Parameters Application Data Base Machine Timing Critical Settings Surface support building BLM system Machine Timing Distribution (one or two per LHC point) Synchronisation Underground, low radiation area Fan out Local Ethernet Segment PXI Position Readout and Survey PXI Environment Survey PLC Beam Permit . . . • • • Management of (critical) settings (LSA) Preparation for ramp Assistance in collimator tuning Post Mortem data collection and Analysis – Based on standard LSA components – Dedicated graphical interface for collimator control and tuning • Collimator Supervisor System (CSS): Collimator Supervisory System Motor Drive Control • Control room software: LHC tunnel – Support building, VME / FESA • Fesa Gateway to Control Room Software • Synchronization of movements • Beam Based Alignment primitives • Takes action on position errors (FB) – Receives timing, send sync signals over fiber to low level (Ramp & Beam Based Alignment) – Synchronization and communication with BLM • Low level control systems – 3 distinct systems • Motor drive (PXI) • Position readout and survey (PXI) • Environment Survey (PLC)

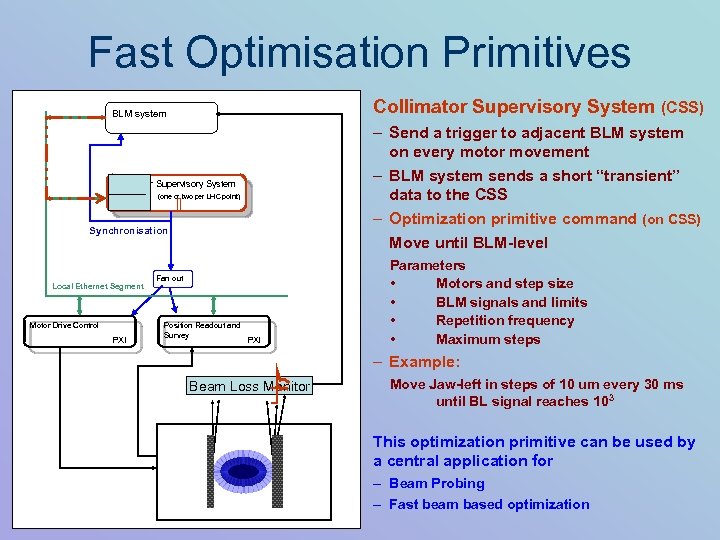

Fast Optimisation Primitives Collimator Supervisory System (CSS) BLM system – Send a trigger to adjacent BLM system on every motor movement – BLM system sends a short “transient” data to the CSS – Optimization primitive command (on CSS) Move until BLM-level Collimator Supervisory System (one or two per LHC point) Synchronisation Local Ethernet Segment Motor Drive Control PXI Fan out Position Readout and Survey PXI Parameters • Motors and step size • BLM signals and limits • Repetition frequency • Maximum steps – Example: Beam Loss Monitor Move Jaw-left in steps of 10 um every 30 ms until BL signal reaches 103 This optimization primitive can be used by a central application for – Beam Probing – Fast beam based optimization

Fast Optimisation Primitives Collimator Supervisory System (CSS) BLM system – Send a trigger to adjacent BLM system on every motor movement – BLM system sends a short “transient” data to the CSS – Optimization primitive command (on CSS) Move until BLM-level Collimator Supervisory System (one or two per LHC point) Synchronisation Local Ethernet Segment Motor Drive Control PXI Fan out Position Readout and Survey PXI Parameters • Motors and step size • BLM signals and limits • Repetition frequency • Maximum steps – Example: Beam Loss Monitor Move Jaw-left in steps of 10 um every 30 ms until BL signal reaches 103 This optimization primitive can be used by a central application for – Beam Probing – Fast beam based optimization

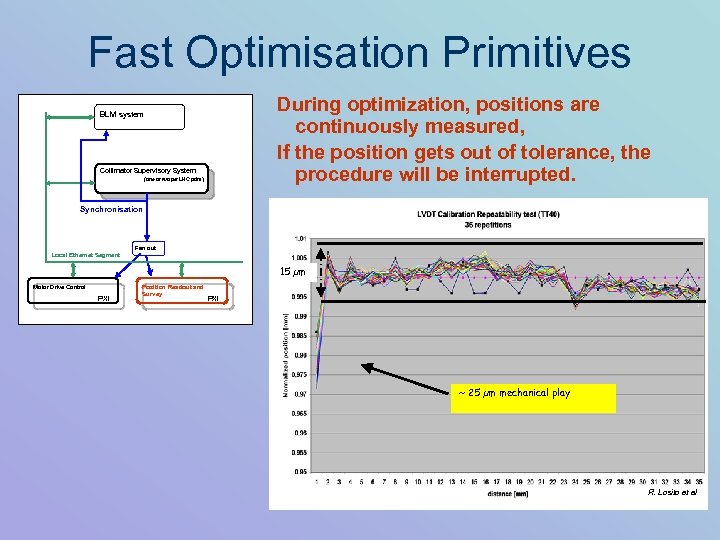

Fast Optimisation Primitives During optimization, positions are continuously measured, If the position gets out of tolerance, the procedure will be interrupted. BLM system Collimator Supervisory System (one or two per LHC point) Synchronisation Fan out Local Ethernet Segment 15 µm Motor Drive Control PXI Position Readout and Survey PXI ~ 25 µm mechanical play R. Losito et al

Fast Optimisation Primitives During optimization, positions are continuously measured, If the position gets out of tolerance, the procedure will be interrupted. BLM system Collimator Supervisory System (one or two per LHC point) Synchronisation Fan out Local Ethernet Segment 15 µm Motor Drive Control PXI Position Readout and Survey PXI ~ 25 µm mechanical play R. Losito et al

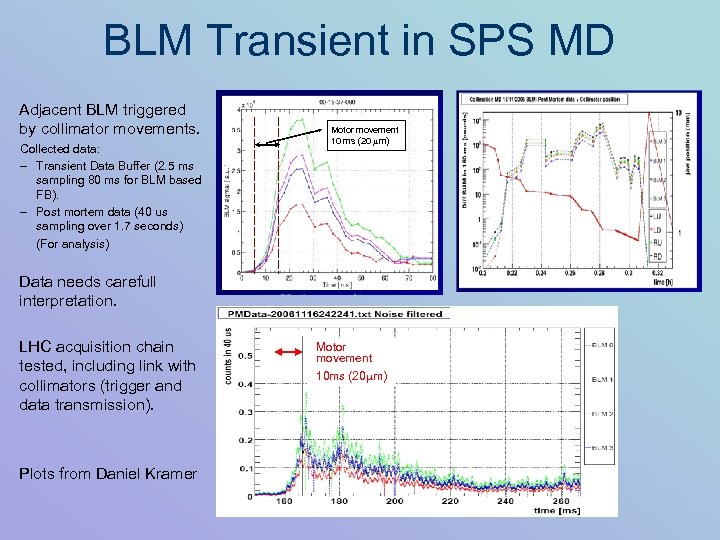

BLM Transient in SPS MD Adjacent BLM triggered by collimator movements. Collected data: – Transient Data Buffer (2. 5 ms sampling 80 ms for BLM based FB). – Post mortem data (40 us sampling over 1. 7 seconds) (For analysis) Motor movement 10 ms (20 m) Data needs carefull interpretation. LHC acquisition chain tested, including link with collimators (trigger and data transmission). Plots from Daniel Kramer Motor movement 10 ms (20 m)

BLM Transient in SPS MD Adjacent BLM triggered by collimator movements. Collected data: – Transient Data Buffer (2. 5 ms sampling 80 ms for BLM based FB). – Post mortem data (40 us sampling over 1. 7 seconds) (For analysis) Motor movement 10 ms (20 m) Data needs carefull interpretation. LHC acquisition chain tested, including link with collimators (trigger and data transmission). Plots from Daniel Kramer Motor movement 10 ms (20 m)

Conclusion • Fast collimator optimisation is technically possible. • The controls architecture contains the necessary elements to deal with these requirement (synchronisation lines, BLM data acquisition and connection) • The principles have been tested during an SPS MD in 2006 • Fully automated steering application and procedures to be developed and tested (2008) • However, the real challenge… – beam dynamics… – SPS md: BLM responds to collimator movement over time scales of 100 th of ms

Conclusion • Fast collimator optimisation is technically possible. • The controls architecture contains the necessary elements to deal with these requirement (synchronisation lines, BLM data acquisition and connection) • The principles have been tested during an SPS MD in 2006 • Fully automated steering application and procedures to be developed and tested (2008) • However, the real challenge… – beam dynamics… – SPS md: BLM responds to collimator movement over time scales of 100 th of ms

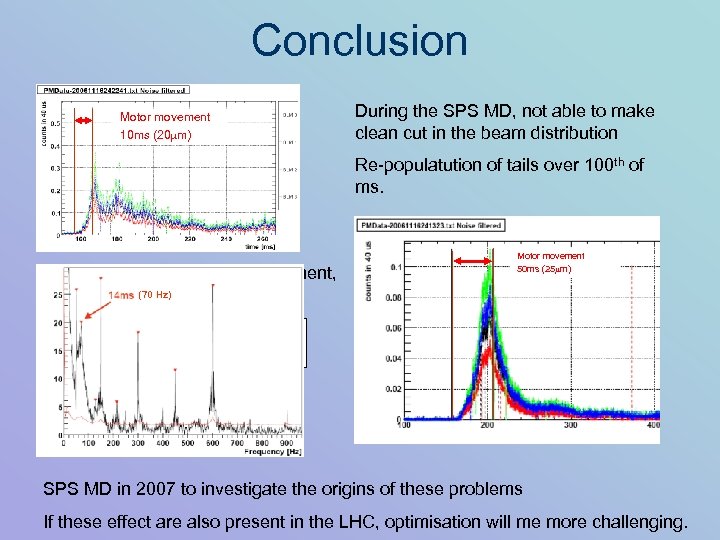

Conclusion Motor movement 10 ms (20 m) During the SPS MD, not able to make clean cut in the beam distribution Re-populatution of tails over 100 th of ms. Motor movement Long tails after collimator movement, 50 ms (25 m) (70 Hz) Large noise components 50, 150, 300, 450 & 600 Hz noise SPS MD in 2007 to investigate the origins of these problems If these effect are also present in the LHC, optimisation will me more challenging.

Conclusion Motor movement 10 ms (20 m) During the SPS MD, not able to make clean cut in the beam distribution Re-populatution of tails over 100 th of ms. Motor movement Long tails after collimator movement, 50 ms (25 m) (70 Hz) Large noise components 50, 150, 300, 450 & 600 Hz noise SPS MD in 2007 to investigate the origins of these problems If these effect are also present in the LHC, optimisation will me more challenging.