f29e265a83d10e523d21ce1826584682.ppt

- Количество слайдов: 33

Auto. Loader. T 3 Trailer Tasking Technology Copyright © 2000

Auto. Loader. T 3 Trailer Tasking Technology Copyright © 2000

What is Auto. Loader. T 3? l Auto. Loader. T 3 is a truck loading system: èUses expert rule-driven planning engine to load trailers èGoal is to maximize load weight/cube and minimize loader effort l Works in conjunction with WMS (Warehouse Management System) 2

What is Auto. Loader. T 3? l Auto. Loader. T 3 is a truck loading system: èUses expert rule-driven planning engine to load trailers èGoal is to maximize load weight/cube and minimize loader effort l Works in conjunction with WMS (Warehouse Management System) 2

What Can Auto. Loader. T 3 Do For Your Warehouse Operations? Auto. Loader. T 3: • Reduces effort in loading trucks • Supports better cube/weight utilization • Saves money 3

What Can Auto. Loader. T 3 Do For Your Warehouse Operations? Auto. Loader. T 3: • Reduces effort in loading trucks • Supports better cube/weight utilization • Saves money 3

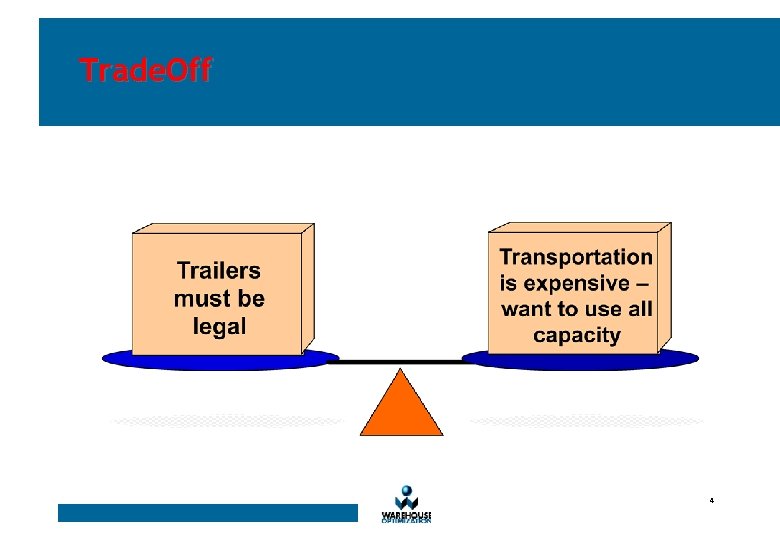

Trade. Off 4

Trade. Off 4

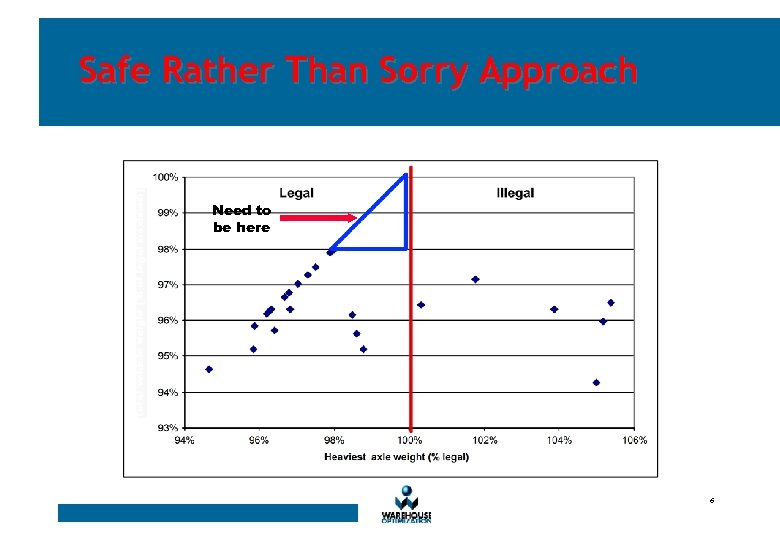

Safe Rather Than Sorry Approach • The complexity of “maxing” out a truck’s capacity has meant a safe rather than sorry approach. • Shipper’s deliberately use “rules of thumb”, such as “a truckload is 44, 000 lbs. ” – Don’t know what tractor/trailer will be used – Loader expertise varies 5

Safe Rather Than Sorry Approach • The complexity of “maxing” out a truck’s capacity has meant a safe rather than sorry approach. • Shipper’s deliberately use “rules of thumb”, such as “a truckload is 44, 000 lbs. ” – Don’t know what tractor/trailer will be used – Loader expertise varies 5

Safe Rather Than Sorry Approach Need to be here 6

Safe Rather Than Sorry Approach Need to be here 6

Loading is Time Intensive 7

Loading is Time Intensive 7

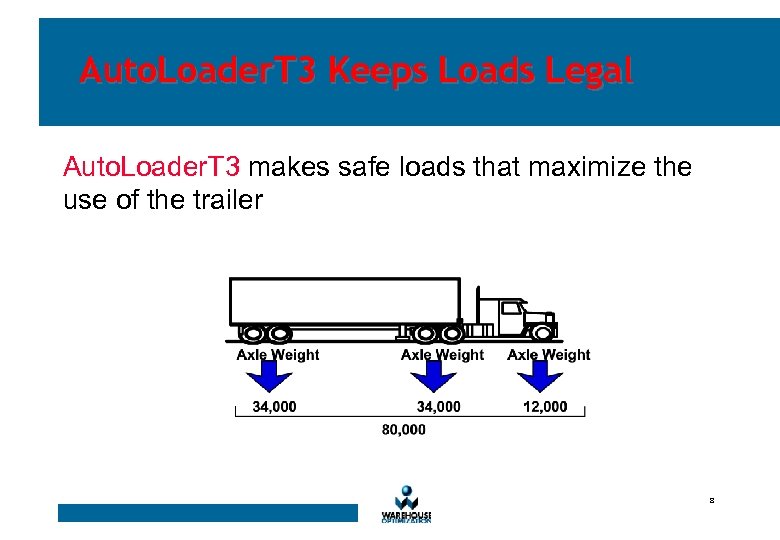

Auto. Loader. T 3 Keeps Loads Legal Auto. Loader. T 3 makes safe loads that maximize the use of the trailer 8

Auto. Loader. T 3 Keeps Loads Legal Auto. Loader. T 3 makes safe loads that maximize the use of the trailer 8

Sample Results. . . 9

Sample Results. . . 9

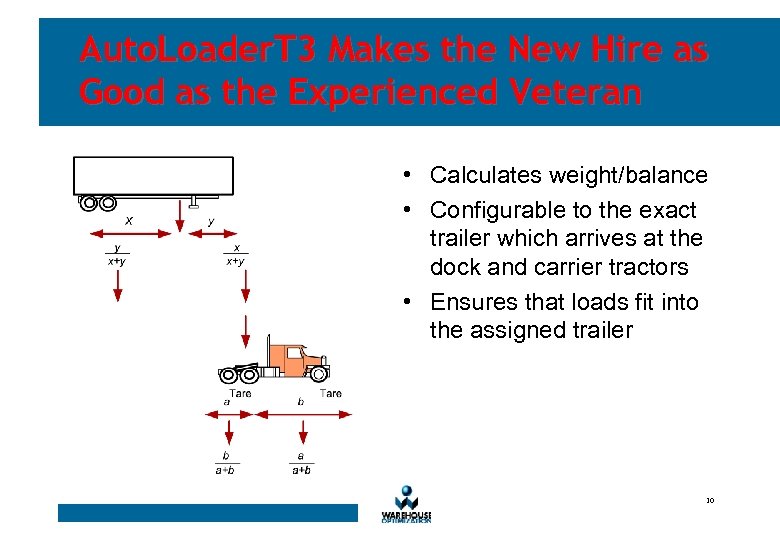

Auto. Loader. T 3 Makes the New Hire as Good as the Experienced Veteran • Calculates weight/balance • Configurable to the exact trailer which arrives at the dock and carrier tractors • Ensures that loads fit into the assigned trailer 10

Auto. Loader. T 3 Makes the New Hire as Good as the Experienced Veteran • Calculates weight/balance • Configurable to the exact trailer which arrives at the dock and carrier tractors • Ensures that loads fit into the assigned trailer 10

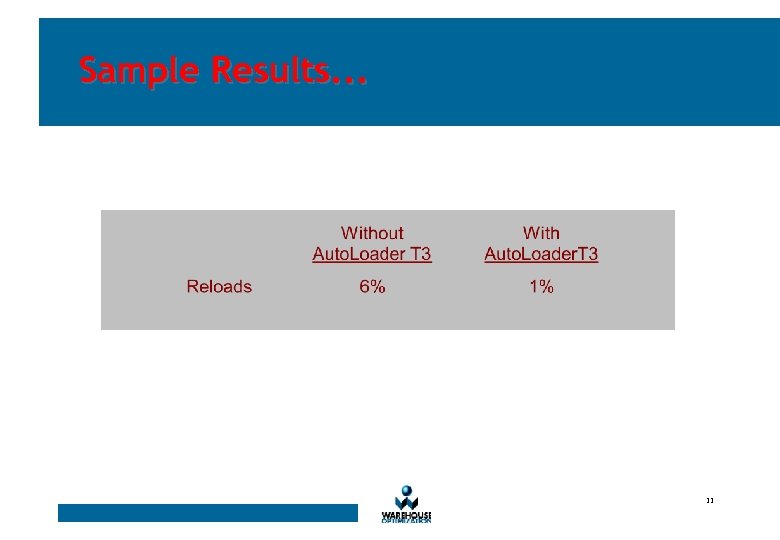

Sample Results. . . 11

Sample Results. . . 11

Auto. Loader. T 3 Increases Productivity • Reduces planning time by eliminating thinking time • Eliminates double handling by sequencing staging and retrieval • Tries to have loaders pick up two items at once 12

Auto. Loader. T 3 Increases Productivity • Reduces planning time by eliminating thinking time • Eliminates double handling by sequencing staging and retrieval • Tries to have loaders pick up two items at once 12

Auto. Loader. T 3 Increases Productivity • Groups items to minimize number of trips to staging and storage 13

Auto. Loader. T 3 Increases Productivity • Groups items to minimize number of trips to staging and storage 13

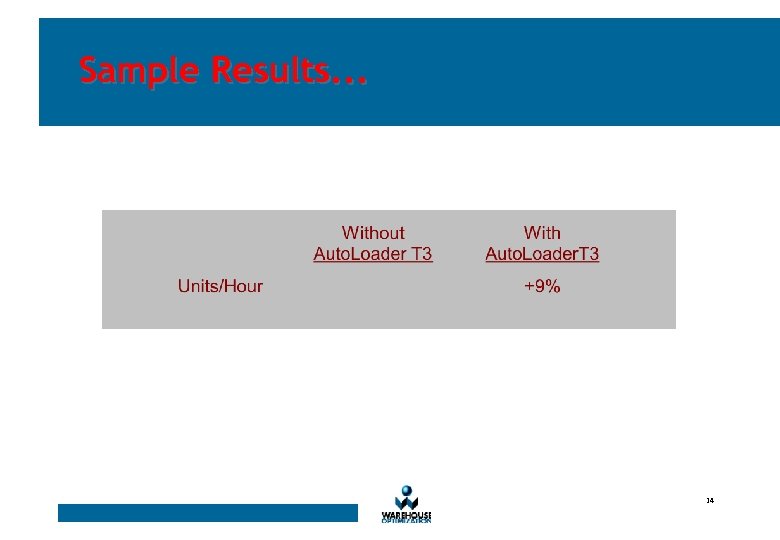

Sample Results. . . 14

Sample Results. . . 14

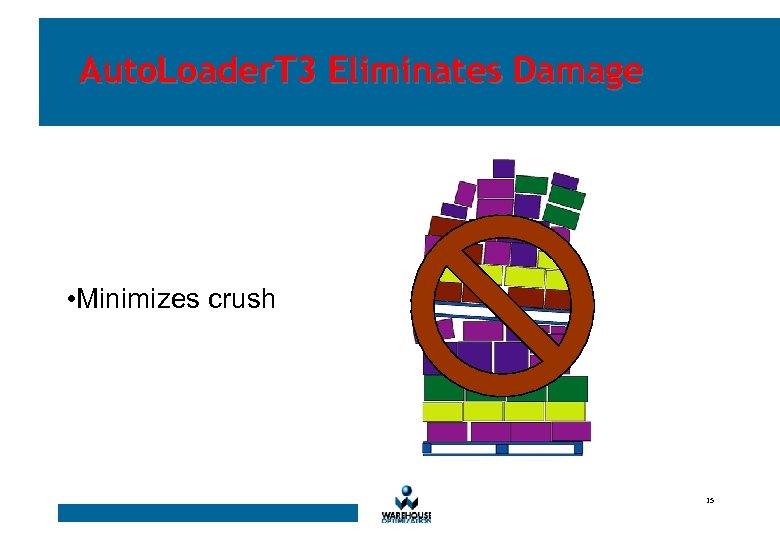

Auto. Loader. T 3 Eliminates Damage • Minimizes crush 15

Auto. Loader. T 3 Eliminates Damage • Minimizes crush 15

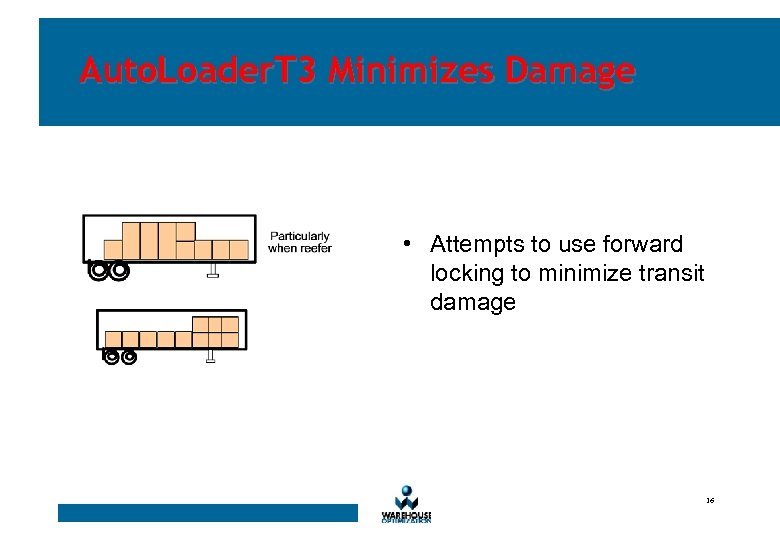

Auto. Loader. T 3 Minimizes Damage • Attempts to use forward locking to minimize transit damage 16

Auto. Loader. T 3 Minimizes Damage • Attempts to use forward locking to minimize transit damage 16

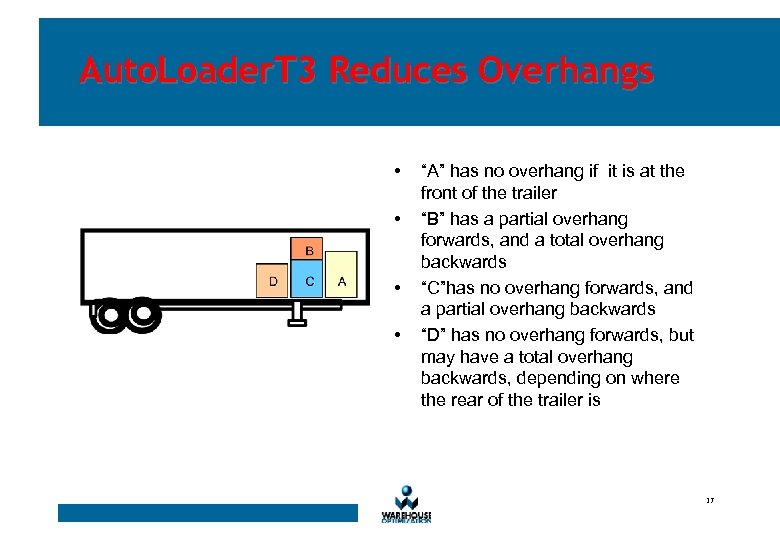

Auto. Loader. T 3 Reduces Overhangs • • “A” has no overhang if it is at the front of the trailer “B” has a partial overhang forwards, and a total overhang backwards “C”has no overhang forwards, and a partial overhang backwards “D” has no overhang forwards, but may have a total overhang backwards, depending on where the rear of the trailer is 17

Auto. Loader. T 3 Reduces Overhangs • • “A” has no overhang if it is at the front of the trailer “B” has a partial overhang forwards, and a total overhang backwards “C”has no overhang forwards, and a partial overhang backwards “D” has no overhang forwards, but may have a total overhang backwards, depending on where the rear of the trailer is 17

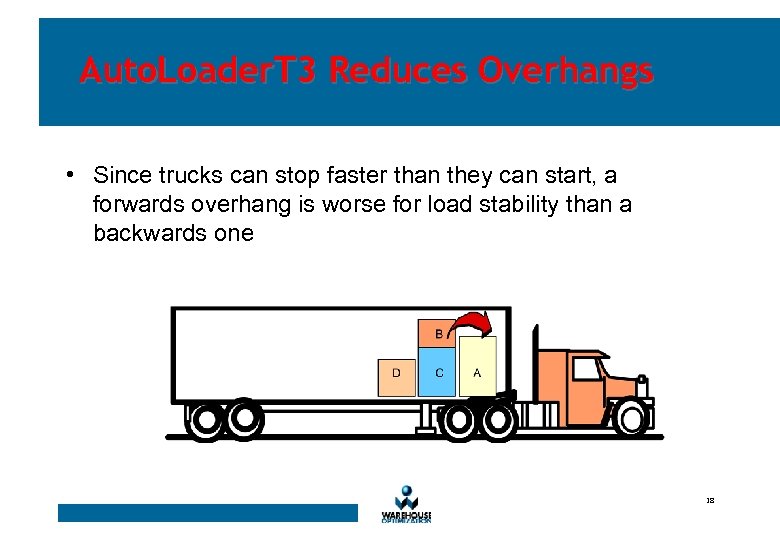

Auto. Loader. T 3 Reduces Overhangs • Since trucks can stop faster than they can start, a forwards overhang is worse for load stability than a backwards one 18

Auto. Loader. T 3 Reduces Overhangs • Since trucks can stop faster than they can start, a forwards overhang is worse for load stability than a backwards one 18

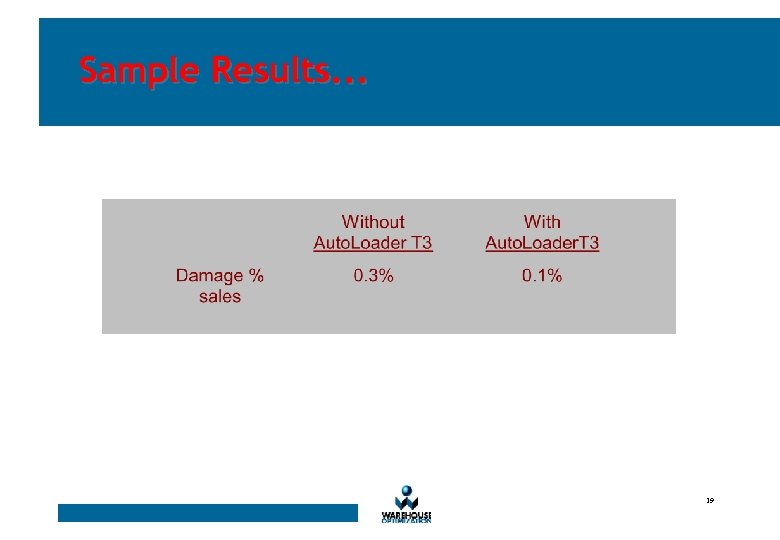

Sample Results. . . 19

Sample Results. . . 19

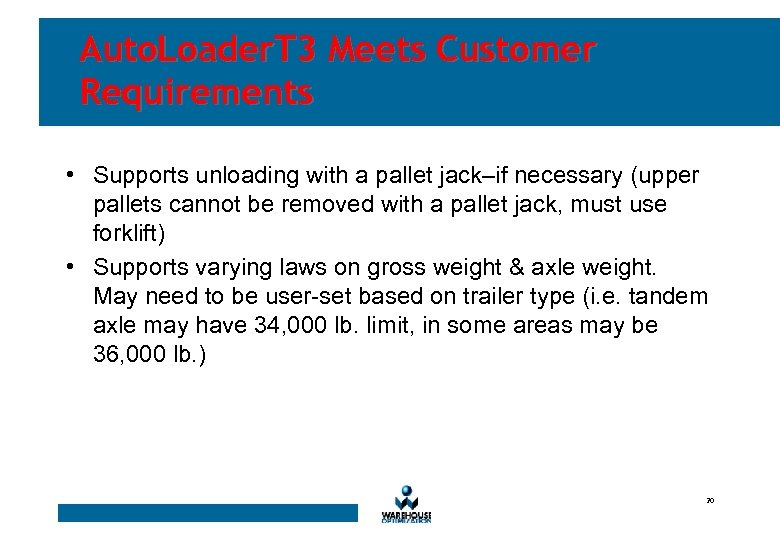

Auto. Loader. T 3 Meets Customer Requirements • Supports unloading with a pallet jack–if necessary (upper pallets cannot be removed with a pallet jack, must use forklift) • Supports varying laws on gross weight & axle weight. May need to be user-set based on trailer type (i. e. tandem axle may have 34, 000 lb. limit, in some areas may be 36, 000 lb. ) 20

Auto. Loader. T 3 Meets Customer Requirements • Supports unloading with a pallet jack–if necessary (upper pallets cannot be removed with a pallet jack, must use forklift) • Supports varying laws on gross weight & axle weight. May need to be user-set based on trailer type (i. e. tandem axle may have 34, 000 lb. limit, in some areas may be 36, 000 lb. ) 20

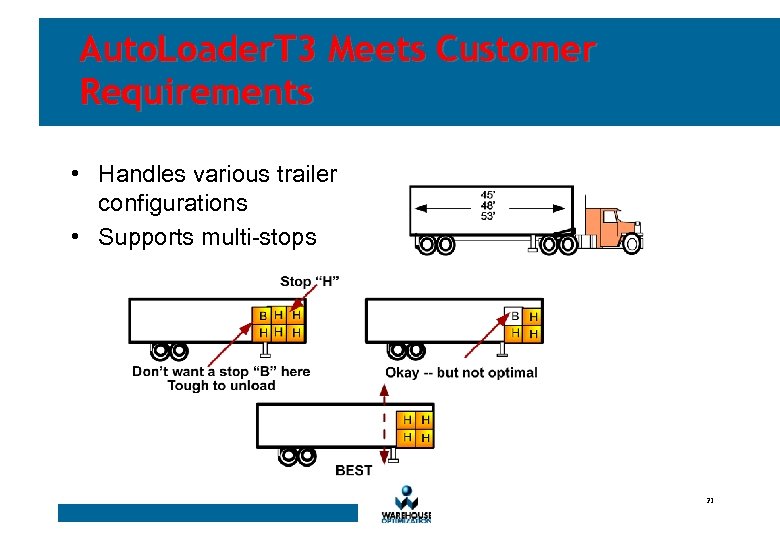

Auto. Loader. T 3 Meets Customer Requirements • Handles various trailer configurations • Supports multi-stops 21

Auto. Loader. T 3 Meets Customer Requirements • Handles various trailer configurations • Supports multi-stops 21

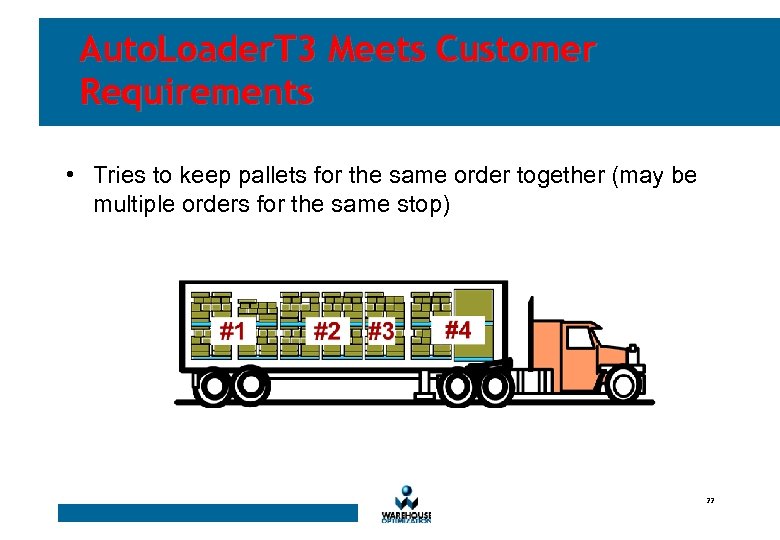

Auto. Loader. T 3 Meets Customer Requirements • Tries to keep pallets for the same order together (may be multiple orders for the same stop) 22

Auto. Loader. T 3 Meets Customer Requirements • Tries to keep pallets for the same order together (may be multiple orders for the same stop) 22

Auto. Loader. T 3 Allows Loads To Be Maximized Auto. Loader. T 3 supports maximizing the utilization of expensive trailer capacity at 3 levels: • Generic truck • Carrier specific vehicle using carrier specific database of tractors and trailers (i. e. J. B. Hunt) • Tractor/trailer specific Detailer setting, if desired, can be to the pin setting. 23

Auto. Loader. T 3 Allows Loads To Be Maximized Auto. Loader. T 3 supports maximizing the utilization of expensive trailer capacity at 3 levels: • Generic truck • Carrier specific vehicle using carrier specific database of tractors and trailers (i. e. J. B. Hunt) • Tractor/trailer specific Detailer setting, if desired, can be to the pin setting. 23

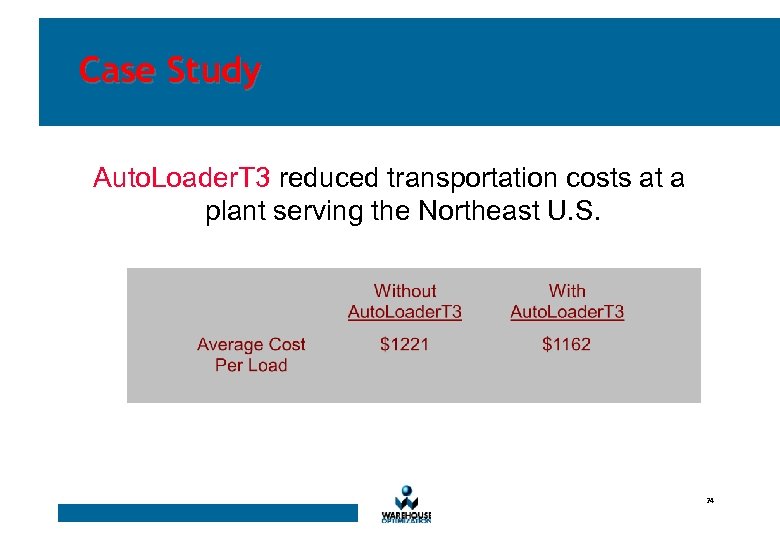

Case Study Auto. Loader. T 3 reduced transportation costs at a plant serving the Northeast U. S. 24

Case Study Auto. Loader. T 3 reduced transportation costs at a plant serving the Northeast U. S. 24

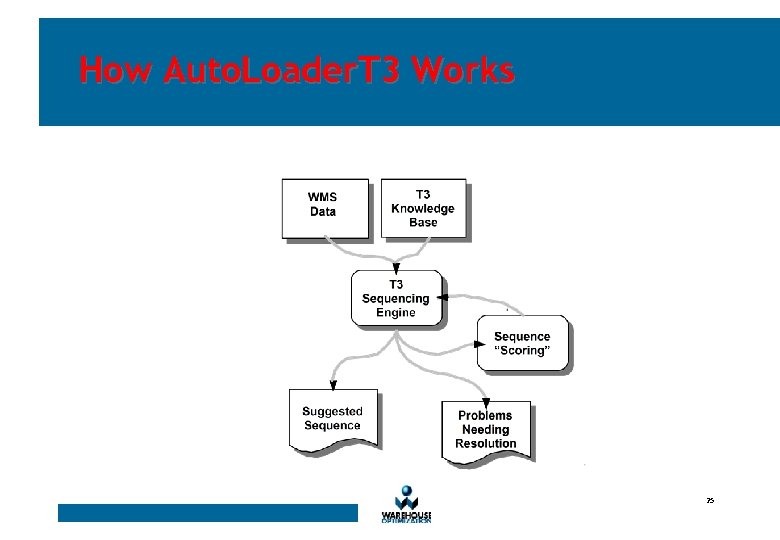

How Auto. Loader. T 3 Works 25

How Auto. Loader. T 3 Works 25

Running Auto. Loader. T 3 26

Running Auto. Loader. T 3 26

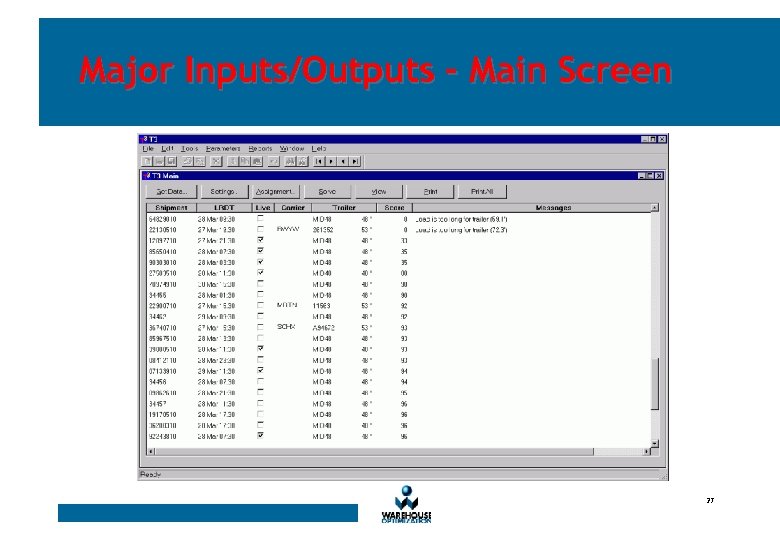

Major Inputs/Outputs – Main Screen 27

Major Inputs/Outputs – Main Screen 27

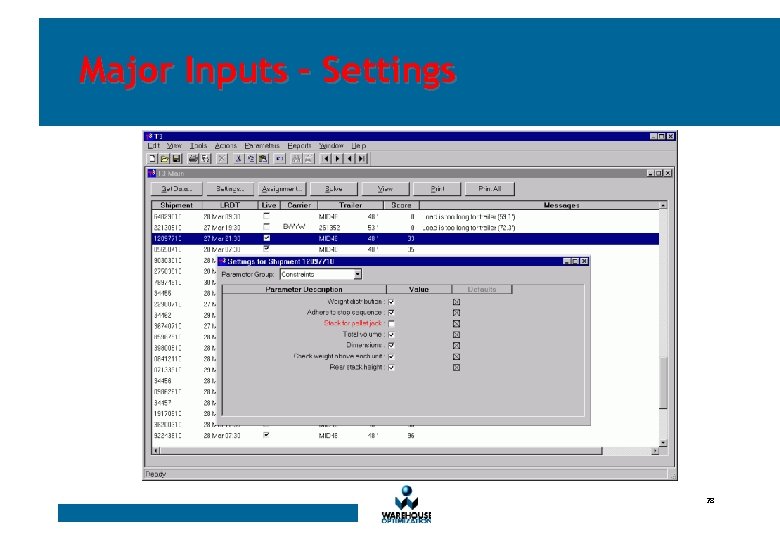

Major Inputs – Settings 28

Major Inputs – Settings 28

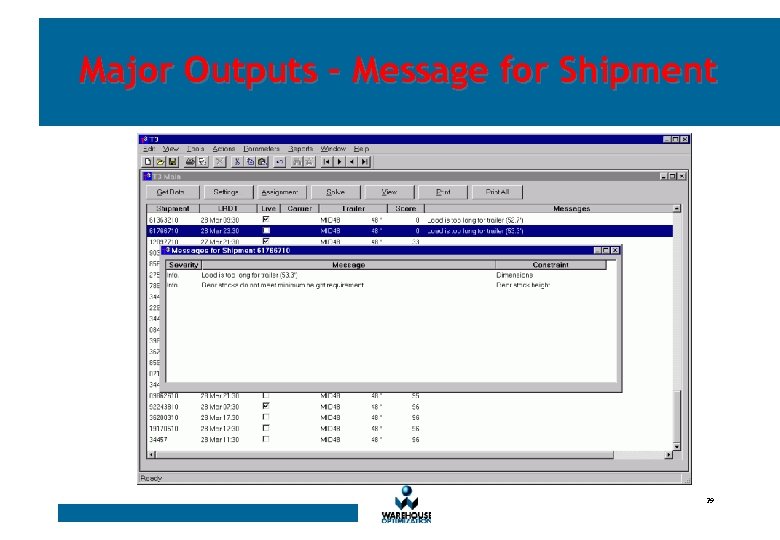

Major Outputs – Message for Shipment 29

Major Outputs – Message for Shipment 29

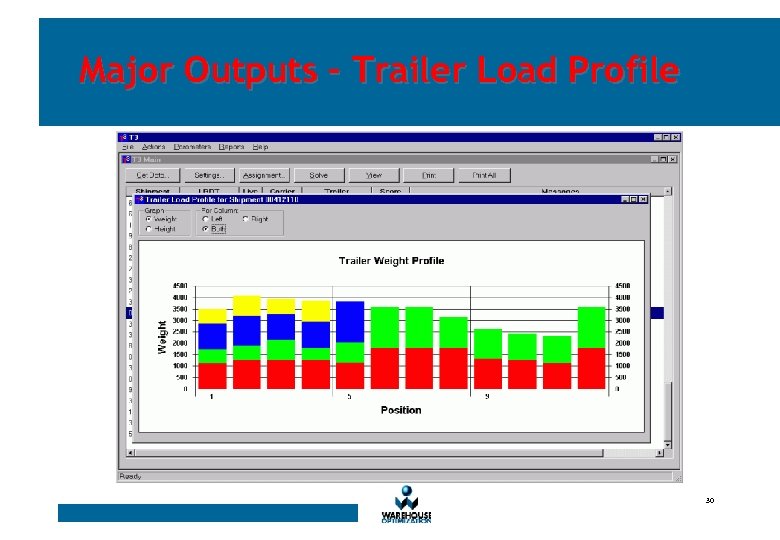

Major Outputs – Trailer Load Profile 30

Major Outputs – Trailer Load Profile 30

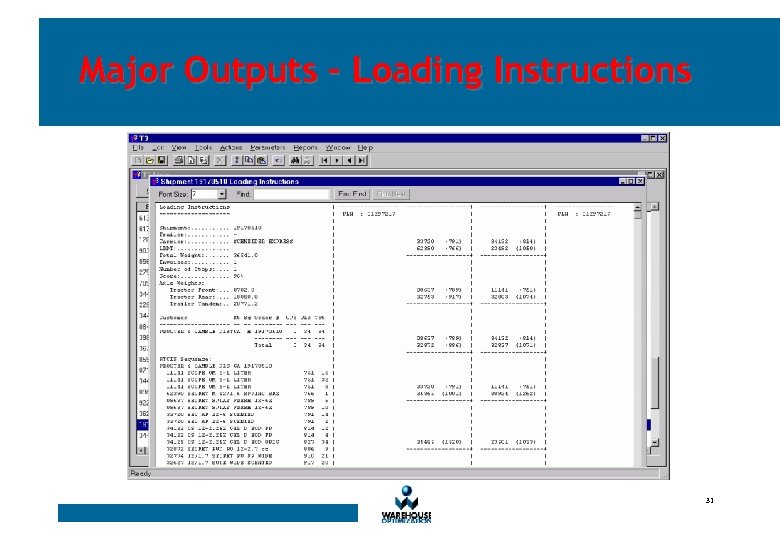

Major Outputs – Loading Instructions 31

Major Outputs – Loading Instructions 31

Major Benefits • No overload fines • More product on each trailer • Less damage • Increased productivity 32

Major Benefits • No overload fines • More product on each trailer • Less damage • Increased productivity 32

Contact Us For More Information Warehouse Optimization, LLC Phone (615) 791 -8000 Email: info@warehouseoptimization. com 33

Contact Us For More Information Warehouse Optimization, LLC Phone (615) 791 -8000 Email: info@warehouseoptimization. com 33