89bb7d82854bdf944615ba1cdaf0e545.ppt

- Количество слайдов: 25

Atmospheric Plasma Alternative for Metal Degreasing

Atmospheric Plasma Alternative for Metal Degreasing

What is Plasma? Ø Fourth state of matter l l Gas-like Consists of neutral atoms/molecules, ions, and electrons Ø High energy, highly reactive substance l l Electrons have 10, 000 K worth of energy Activates surfaces Image: http: //discovery. nasa. gov/genesis. html

What is Plasma? Ø Fourth state of matter l l Gas-like Consists of neutral atoms/molecules, ions, and electrons Ø High energy, highly reactive substance l l Electrons have 10, 000 K worth of energy Activates surfaces Image: http: //discovery. nasa. gov/genesis. html

Plasma for Metal Treatment High Temperature Arc Plasma (up to 16000ºC) Ceramic Deposition Ø Ø Radio Frequency Induction Coupled Plasmas (5000ºC) Surface treatments for semiconductors Electrodeless Atmospheric Microwave Plasmas EAMP Ø

Plasma for Metal Treatment High Temperature Arc Plasma (up to 16000ºC) Ceramic Deposition Ø Ø Radio Frequency Induction Coupled Plasmas (5000ºC) Surface treatments for semiconductors Electrodeless Atmospheric Microwave Plasmas EAMP Ø

Atmospheric ≠ The Sun Plasma Ø Non-equilibrium plasma l l Electrons at 10 -20, 000 ºC Ions, molecules at 60 -80 ºC Ø Relatively uniform energy distribution Ø Does not require special vacuum chambers like low pressure plasma Image: http: //www. seas. ucla. edu/prosurf/plasmapro. htm

Atmospheric ≠ The Sun Plasma Ø Non-equilibrium plasma l l Electrons at 10 -20, 000 ºC Ions, molecules at 60 -80 ºC Ø Relatively uniform energy distribution Ø Does not require special vacuum chambers like low pressure plasma Image: http: //www. seas. ucla. edu/prosurf/plasmapro. htm

Atmospheric Plasma Ø Use microwave energy to create gas plasma streams at atmospheric pressure and moderate temperature (70 -200ºC) Ø 10 -20% conversion to active ion and radical species Ø Flow gas through an orifice to create a plasma jet or through into an application chamber

Atmospheric Plasma Ø Use microwave energy to create gas plasma streams at atmospheric pressure and moderate temperature (70 -200ºC) Ø 10 -20% conversion to active ion and radical species Ø Flow gas through an orifice to create a plasma jet or through into an application chamber

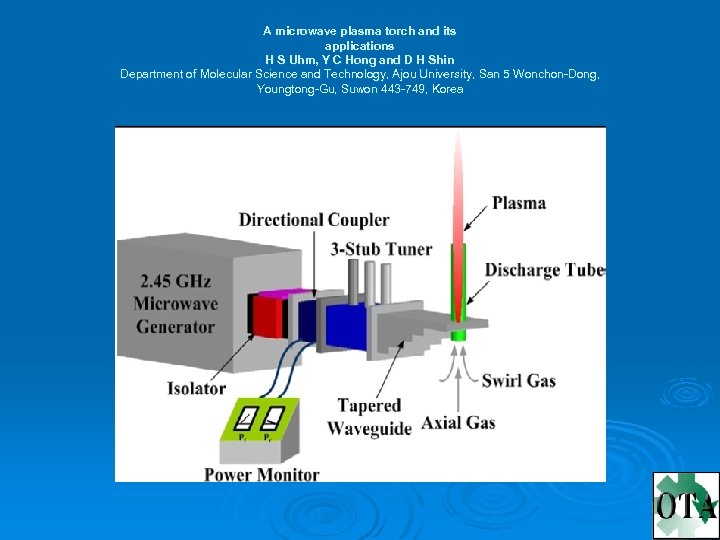

A microwave plasma torch and its applications H S Uhm, Y C Hong and D H Shin Department of Molecular Science and Technology, Ajou University, San 5 Wonchon-Dong, Youngtong-Gu, Suwon 443 -749, Korea

A microwave plasma torch and its applications H S Uhm, Y C Hong and D H Shin Department of Molecular Science and Technology, Ajou University, San 5 Wonchon-Dong, Youngtong-Gu, Suwon 443 -749, Korea

Plasma Jet

Plasma Jet

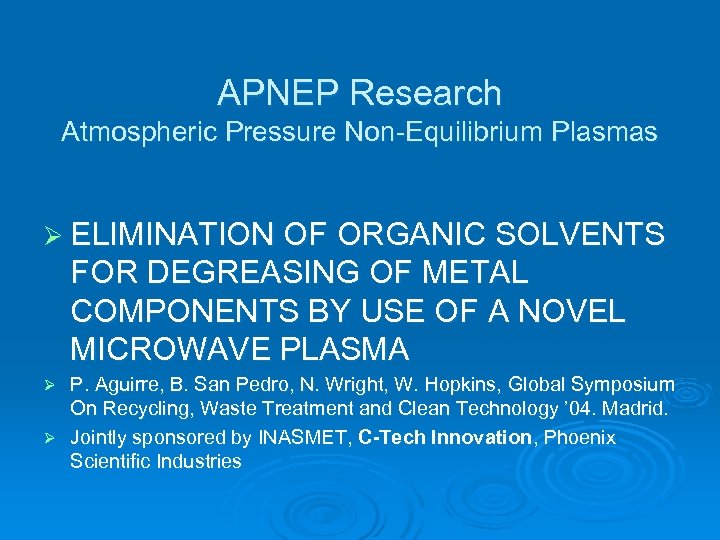

APNEP Research Atmospheric Pressure Non-Equilibrium Plasmas Ø ELIMINATION OF ORGANIC SOLVENTS FOR DEGREASING OF METAL COMPONENTS BY USE OF A NOVEL MICROWAVE PLASMA P. Aguirre, B. San Pedro, N. Wright, W. Hopkins, Global Symposium On Recycling, Waste Treatment and Clean Technology ’ 04. Madrid. Ø Jointly sponsored by INASMET, C-Tech Innovation, Phoenix Scientific Industries Ø

APNEP Research Atmospheric Pressure Non-Equilibrium Plasmas Ø ELIMINATION OF ORGANIC SOLVENTS FOR DEGREASING OF METAL COMPONENTS BY USE OF A NOVEL MICROWAVE PLASMA P. Aguirre, B. San Pedro, N. Wright, W. Hopkins, Global Symposium On Recycling, Waste Treatment and Clean Technology ’ 04. Madrid. Ø Jointly sponsored by INASMET, C-Tech Innovation, Phoenix Scientific Industries Ø

APNEP Research Ø Examined the effects of Atmospheric Non Equilibrium Plasmas of Oxygen, Nitrogen, Argon, and Mixtures. Ø Treated standard industrial components contaminated with commercial oils and lubricants at loadings of 1 -5 g/m 2

APNEP Research Ø Examined the effects of Atmospheric Non Equilibrium Plasmas of Oxygen, Nitrogen, Argon, and Mixtures. Ø Treated standard industrial components contaminated with commercial oils and lubricants at loadings of 1 -5 g/m 2

APNEP Research Varied plasma flow rate, microwave output power, and exposure duration. Plasma jet temperatures averaged 200ºC. Ø Achieved cleanliness equivalent to TCE vapor degreasing with an emission profile that met EU Industrial limits. Ø Claimed 98 -100% removal of oils. Ø Paper left out key detail to determine exact operation costs. Ø Nitrogen plasmas produce NOX, leading the focus to oxygen Ø

APNEP Research Varied plasma flow rate, microwave output power, and exposure duration. Plasma jet temperatures averaged 200ºC. Ø Achieved cleanliness equivalent to TCE vapor degreasing with an emission profile that met EU Industrial limits. Ø Claimed 98 -100% removal of oils. Ø Paper left out key detail to determine exact operation costs. Ø Nitrogen plasmas produce NOX, leading the focus to oxygen Ø

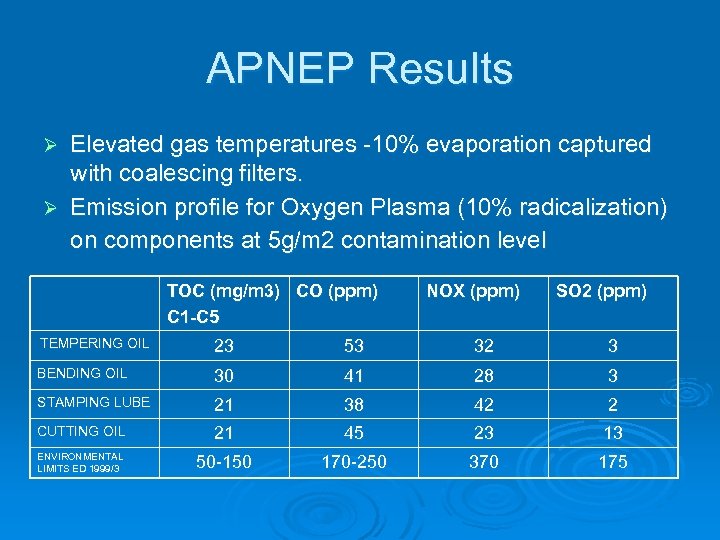

APNEP Results Elevated gas temperatures -10% evaporation captured with coalescing filters. Ø Emission profile for Oxygen Plasma (10% radicalization) on components at 5 g/m 2 contamination level Ø TOC (mg/m 3) CO (ppm) C 1 -C 5 NOX (ppm) SO 2 (ppm) TEMPERING OIL 23 53 32 3 BENDING OIL 30 41 28 3 STAMPING LUBE 21 38 42 2 CUTTING OIL 21 45 23 13 ENVIRONMENTAL LIMITS ED 1999/3 50 -150 170 -250 370 175

APNEP Results Elevated gas temperatures -10% evaporation captured with coalescing filters. Ø Emission profile for Oxygen Plasma (10% radicalization) on components at 5 g/m 2 contamination level Ø TOC (mg/m 3) CO (ppm) C 1 -C 5 NOX (ppm) SO 2 (ppm) TEMPERING OIL 23 53 32 3 BENDING OIL 30 41 28 3 STAMPING LUBE 21 38 42 2 CUTTING OIL 21 45 23 13 ENVIRONMENTAL LIMITS ED 1999/3 50 -150 170 -250 370 175

For immediate release - 10 November 2004 C-Tech Lands DTI Grant for APNEP Plasma Development C-Tech Innovation Limited has successfully obtained funding from the DTI to further develop its unique, Atmospheric Pressure, Non. Equilibrium Plasma (APNEP), which has enormous potential in a wide variety of industrial and environmental applications. C-Tech has been awarded a Research and Development grant (formerly SMART award) for the ongoing development of the APNEP plasma. The DTI grants are provided to help small and medium-sized businesses research and develop technologically innovative products and processes, to generate new scientific or technical knowledge that will be…

For immediate release - 10 November 2004 C-Tech Lands DTI Grant for APNEP Plasma Development C-Tech Innovation Limited has successfully obtained funding from the DTI to further develop its unique, Atmospheric Pressure, Non. Equilibrium Plasma (APNEP), which has enormous potential in a wide variety of industrial and environmental applications. C-Tech has been awarded a Research and Development grant (formerly SMART award) for the ongoing development of the APNEP plasma. The DTI grants are provided to help small and medium-sized businesses research and develop technologically innovative products and processes, to generate new scientific or technical knowledge that will be…

Commercialization 06/07 Ø Several commercial lab systems Ø One (? ) industrial system supplier in US

Commercialization 06/07 Ø Several commercial lab systems Ø One (? ) industrial system supplier in US

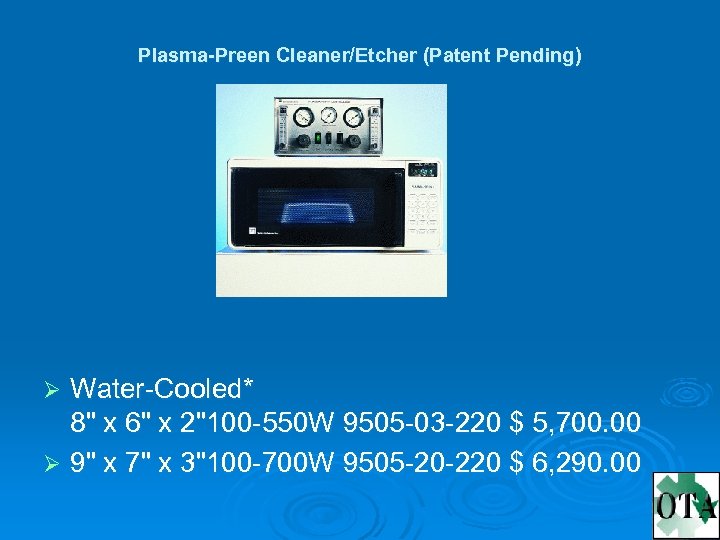

Plasma-Preen Cleaner/Etcher (Patent Pending) Water-Cooled* 8" x 6" x 2"100 -550 W 9505 -03 -220 $ 5, 700. 00 Ø 9" x 7" x 3"100 -700 W 9505 -20 -220 $ 6, 290. 00 Ø

Plasma-Preen Cleaner/Etcher (Patent Pending) Water-Cooled* 8" x 6" x 2"100 -550 W 9505 -03 -220 $ 5, 700. 00 Ø 9" x 7" x 3"100 -700 W 9505 -20 -220 $ 6, 290. 00 Ø

Sold for: US $189. 50 Ended: Nov-02 -06 06: 40: 11 PST Shipping costs: US $19. 70 UPS Ground Service to 02067, United States (more services)Calcul ate Ships to: Worldwide Item location: Niagara Falls, USA or Canada, United States History: 1 bid Buyer: bcnu 2 293 ) Auction ended early with Buy It Now. (

Sold for: US $189. 50 Ended: Nov-02 -06 06: 40: 11 PST Shipping costs: US $19. 70 UPS Ground Service to 02067, United States (more services)Calcul ate Ships to: Worldwide Item location: Niagara Falls, USA or Canada, United States History: 1 bid Buyer: bcnu 2 293 ) Auction ended early with Buy It Now. (

Diener Electronics Ø German concern with sales office in Reading, PA Ø Offers standard and custom systems for RF and Microwave plasma treatment systems Ø Utilize 40 KHz generators to minimize emissions. Ø Established marketing, several industrial placements in US at present.

Diener Electronics Ø German concern with sales office in Reading, PA Ø Offers standard and custom systems for RF and Microwave plasma treatment systems Ø Utilize 40 KHz generators to minimize emissions. Ø Established marketing, several industrial placements in US at present.

Diener Economic Example Ø 22 liter chamber turn-key system- $27, 250 Ø 40 KHz/300 W generator Ø One hour treatment with oxygen plasma Ø Operation cost on “small industrial parts” of “ 3 -5 cents per piece”.

Diener Economic Example Ø 22 liter chamber turn-key system- $27, 250 Ø 40 KHz/300 W generator Ø One hour treatment with oxygen plasma Ø Operation cost on “small industrial parts” of “ 3 -5 cents per piece”.

Technical and Economic Hurdles l l l Technology acceptance System capital cost Equipment compatibility with current processing lines Throughput limitations; chamber volume, exposure duration. QC and MIL-SPEC requirements Batch consistency

Technical and Economic Hurdles l l l Technology acceptance System capital cost Equipment compatibility with current processing lines Throughput limitations; chamber volume, exposure duration. QC and MIL-SPEC requirements Batch consistency

OPPORTUNITIES for IMPLEMENTATION Ø Combination cleaning/degreasing and sterilization; medical devices. Ø Displacing infrequently used vapor degreasers. Relieve regulatory burdens. Ø Low throughput/high finish parts; aviation. Ø Energy conservation Ø Solvent use reduction

OPPORTUNITIES for IMPLEMENTATION Ø Combination cleaning/degreasing and sterilization; medical devices. Ø Displacing infrequently used vapor degreasers. Relieve regulatory burdens. Ø Low throughput/high finish parts; aviation. Ø Energy conservation Ø Solvent use reduction

What Can It Do for Textiles and Adhesives ? Ø Surface modification and functionality l l Ø Hydrophobicity Stain resistance Oleophobicity Hydrophilicity Flame retardants Antimicrobials Printability of polypropylene/polyester Pollution prevention l l Uses significantly lower quantities of chemicals Plasma treatments can enable conversion from solvents to aqueous coatings http: //enerconind. com/treating/e. Library/multimedia/plasma. Only. swf

What Can It Do for Textiles and Adhesives ? Ø Surface modification and functionality l l Ø Hydrophobicity Stain resistance Oleophobicity Hydrophilicity Flame retardants Antimicrobials Printability of polypropylene/polyester Pollution prevention l l Uses significantly lower quantities of chemicals Plasma treatments can enable conversion from solvents to aqueous coatings http: //enerconind. com/treating/e. Library/multimedia/plasma. Only. swf

Can Plasma Be Used to Make a Light Saber ?

Can Plasma Be Used to Make a Light Saber ?

At this point maybe a Light Dagger

At this point maybe a Light Dagger

Gerry Podlisny Process Engineer/Environmental Analyst Mass OTA Gerald. Podlisny@state. ma. us

Gerry Podlisny Process Engineer/Environmental Analyst Mass OTA Gerald. Podlisny@state. ma. us