749a2a6c59da029b70b49189666c4744.ppt

- Количество слайдов: 17

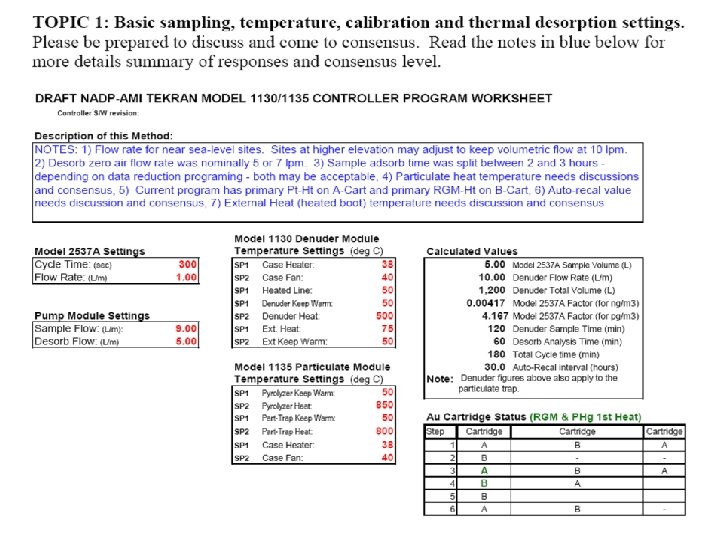

ATMOSPHERIC MERCURY BEST PRACTICES AND SOP WORKSHOP Topics and questions for discussion that require consensus NADP, MDN, Tekran, Academia, NPS, USGS, NFS, S&Ls October 3 -4, 2007 NESCAUM MAC Meeting Mystic, CT October 17 -18, 2007 NYS Department of Environmental Conservation

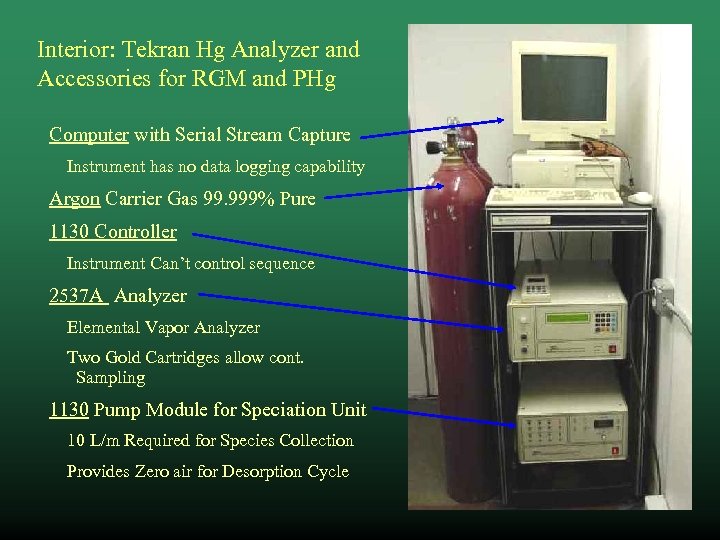

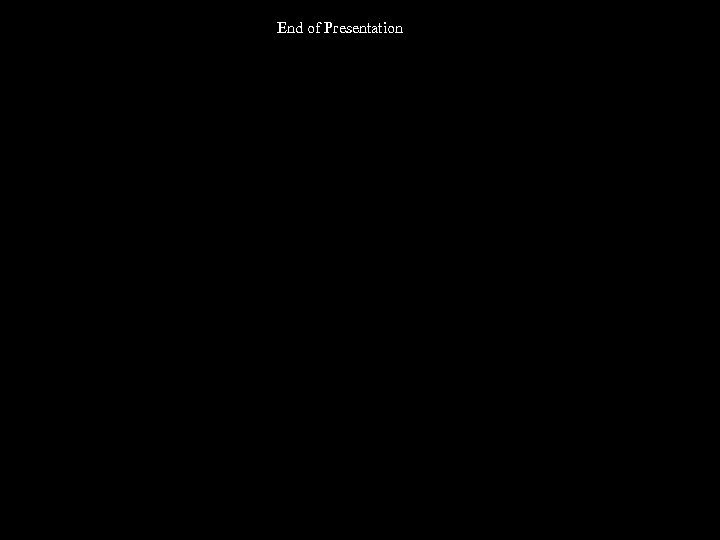

Interior: Tekran Hg Analyzer and Accessories for RGM and PHg Computer with Serial Stream Capture Instrument has no data logging capability Argon Carrier Gas 99. 999% Pure 1130 Controller Instrument Can’t control sequence 2537 A Analyzer Elemental Vapor Analyzer Two Gold Cartridges allow cont. Sampling 1130 Pump Module for Speciation Unit 10 L/m Required for Species Collection Provides Zero air for Desorption Cycle

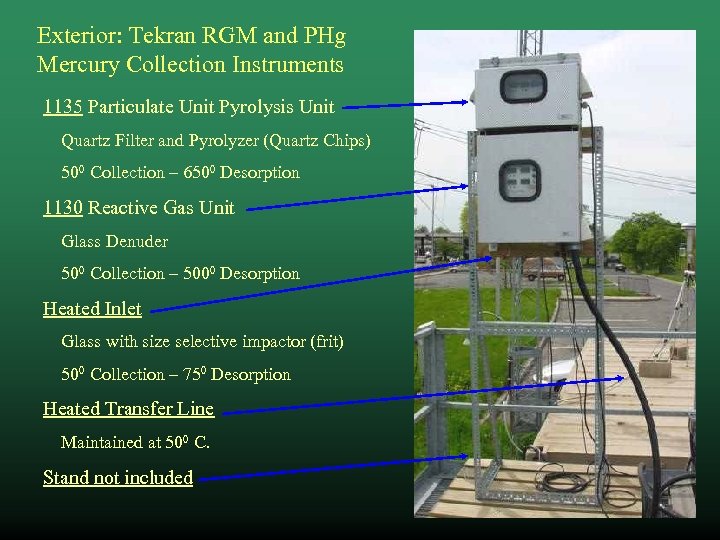

Exterior: Tekran RGM and PHg Mercury Collection Instruments 1135 Particulate Unit Pyrolysis Unit Quartz Filter and Pyrolyzer (Quartz Chips) 500 Collection – 6500 Desorption 1130 Reactive Gas Unit Glass Denuder 500 Collection – 5000 Desorption Heated Inlet Glass with size selective impactor (frit) 500 Collection – 750 Desorption Heated Transfer Line Maintained at 500 C. Stand not included

Goal / Purpose To come to consensus on: Operating method: temps, sequences etc Quality assurance: on-site, external, com option Data interpretation: processing, validating Data: raw, final, publishing interval, sharing agreement Siting: location, fetch, height, for the Tekran 2537 A, 2537 B, 1130 and 1135 in a National network whose motto is: “Build it and they will come”

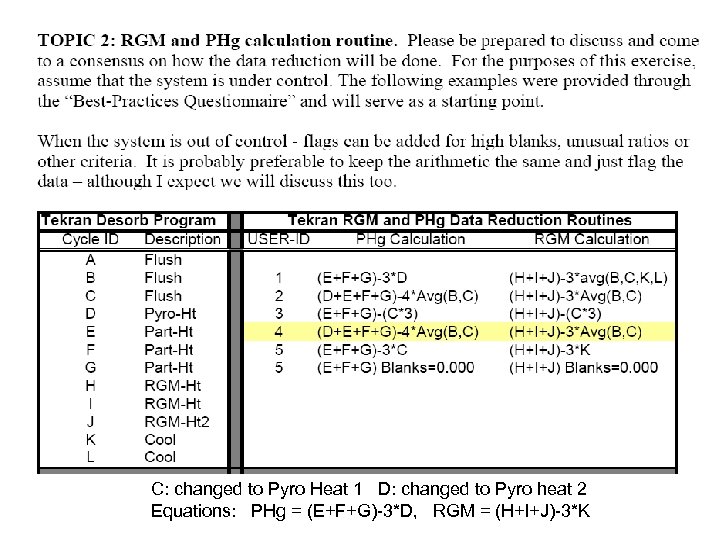

C: changed to Pyro Heat 1 D: changed to Pyro heat 2 Equations: PHg = (E+F+G)-3*D, RGM = (H+I+J)-3*K

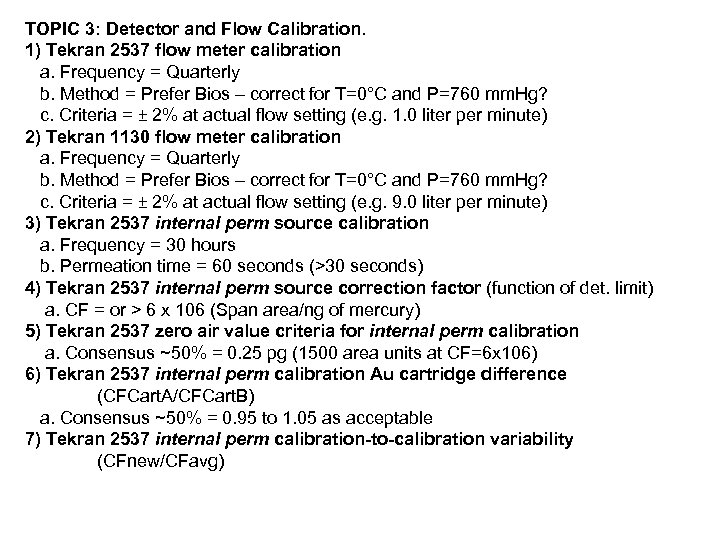

TOPIC 3: Detector and Flow Calibration. 1) Tekran 2537 flow meter calibration a. Frequency = Quarterly b. Method = Prefer Bios – correct for T=0°C and P=760 mm. Hg? c. Criteria = ± 2% at actual flow setting (e. g. 1. 0 liter per minute) 2) Tekran 1130 flow meter calibration a. Frequency = Quarterly b. Method = Prefer Bios – correct for T=0°C and P=760 mm. Hg? c. Criteria = ± 2% at actual flow setting (e. g. 9. 0 liter per minute) 3) Tekran 2537 internal perm source calibration a. Frequency = 30 hours b. Permeation time = 60 seconds (>30 seconds) 4) Tekran 2537 internal perm source correction factor (function of det. limit) a. CF = or > 6 x 106 (Span area/ng of mercury) 5) Tekran 2537 zero air value criteria for internal perm calibration a. Consensus ~50% = 0. 25 pg (1500 area units at CF=6 x 106) 6) Tekran 2537 internal perm calibration Au cartridge difference (CFCart. A/CFCart. B) a. Consensus ~50% = 0. 95 to 1. 05 as acceptable 7) Tekran 2537 internal perm calibration-to-calibration variability (CFnew/CFavg)

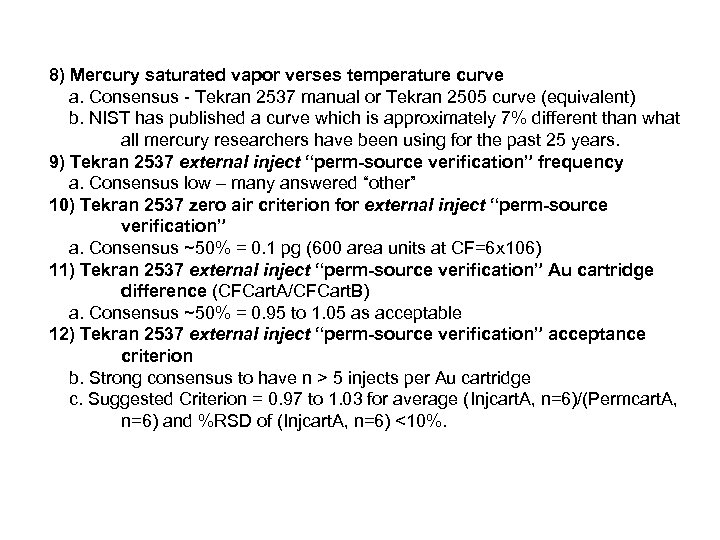

8) Mercury saturated vapor verses temperature curve a. Consensus - Tekran 2537 manual or Tekran 2505 curve (equivalent) b. NIST has published a curve which is approximately 7% different than what all mercury researchers have been using for the past 25 years. 9) Tekran 2537 external inject “perm-source verification” frequency a. Consensus low – many answered “other” 10) Tekran 2537 zero air criterion for external inject “perm-source verification” a. Consensus ~50% = 0. 1 pg (600 area units at CF=6 x 106) 11) Tekran 2537 external inject “perm-source verification” Au cartridge difference (CFCart. A/CFCart. B) a. Consensus ~50% = 0. 95 to 1. 05 as acceptable 12) Tekran 2537 external inject “perm-source verification” acceptance criterion b. Strong consensus to have n > 5 injects per Au cartridge c. Suggested Criterion = 0. 97 to 1. 03 for average (Injcart. A, n=6)/(Permcart. A, n=6) and %RSD of (Injcart. A, n=6) <10%.

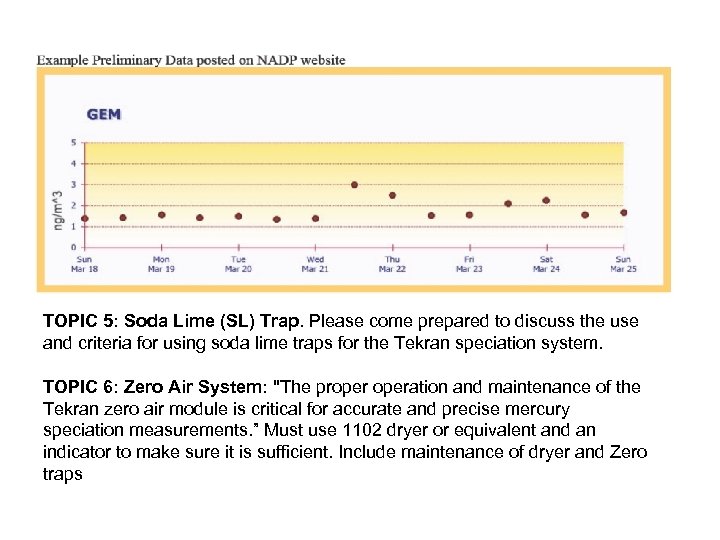

TOPIC 4: Automated and Remote Data Capture and Reduction. 1) Data will be captured by a computer using Tekran “Tekcap” program for windows and a data logger able to capture the serial data stream from the Tekran. An example would be the setup used by Eric Miller at ERG 2) Data from each site will be downloaded automatically every 24 hours by NADP and archived for safe storage. 3) Data will be screen automatically each day for basic performance checks based on logic supplied by a subgroup of users (ad-hoc advisory group) with experience developing such tools. Detailed data plots, ancillary performance data and data flags will be compiled and sent to the site sponsor and site operator daily. An example would be the system used by Edgerton & Hartsell at ARA. 4) Weekly plots of preliminary screened data using low temporal resolution will be posted on the NADP website in picture format, with the proper caveats embedded in the picture (e. g. draft data, data is not final, do not quote, cite or interpret and etc). An example is shown below. 5) Final data flagging and publishing is the subject of another workshop or NADP meeting.

TOPIC 5: Soda Lime (SL) Trap. Please come prepared to discuss the use and criteria for using soda lime traps for the Tekran speciation system. TOPIC 6: Zero Air System: "The properation and maintenance of the Tekran zero air module is critical for accurate and precise mercury speciation measurements. ” Must use 1102 dryer or equivalent and an indicator to make sure it is sufficient. Include maintenance of dryer and Zero traps

TOPIC 7: Field Site and Physical Setup. Because all three mercury fractions, Hg 0, PHg 2. 5 and RGM are know to have surface effects, the location and height of the inlet of the Tekran 1130/1135 should be carefully considered and criteria should be adopted. However, there also constraints, namely cost of installing a tower or similar and length of heated line of 15 meters (power and flow). 1) Inlet height above ground level in meters a. Recommend – all inlet heights should be at least 4 meters above ground level 2) Inlet height above the instrument shelter a. High consensus – all inlets should be at least 2 meters above instrument shelter height. 3) Location a. Only 3 of 13 respondents have their Tekran speciation system at a local high point.

Conclusion There is still no SOP but there was a lot of agreement on many difficult issues. There were 3 -4 other issues that required either a short field study or a detailed explanation from Tekran. Eric Prestbo (formally Frontier Geoscience now Tekran) will release the notes from the meeting and possibly the draft SOP in a few Months. The final SOP will by be a working document to allow for changes due to technology improvements, efficiencies etc. The SOP is going to be a recommended protocol for an acceptable system, it is not designed to prevent research experiments with different goals.

End of Presentation

NYS Department of Environmental Conservation

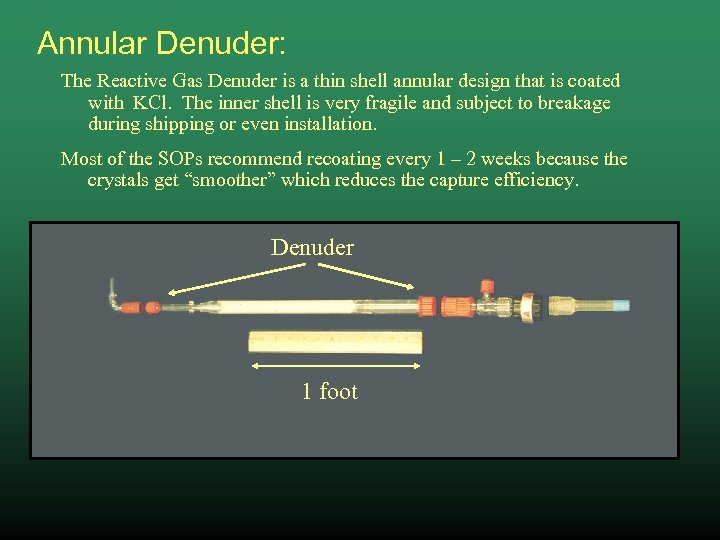

Annular Denuder: The Reactive Gas Denuder is a thin shell annular design that is coated with KCl. The inner shell is very fragile and subject to breakage during shipping or even installation. Most of the SOPs recommend recoating every 1 – 2 weeks because the crystals get “smoother” which reduces the capture efficiency. Denuder 1 foot

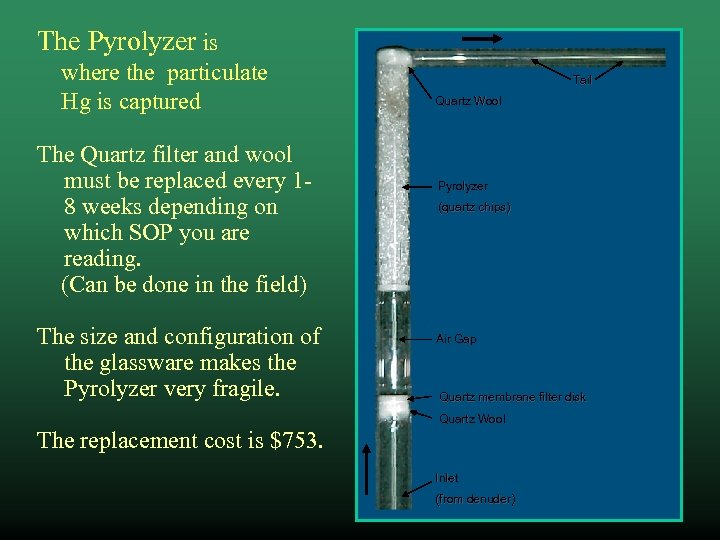

The Pyrolyzer is where the particulate Hg is captured The Quartz filter and wool must be replaced every 18 weeks depending on which SOP you are reading. (Can be done in the field) The size and configuration of the glassware makes the Pyrolyzer very fragile. Tail Quartz Wool Pyrolyzer (quartz chips) Air Gap Quartz membrane filter disk Quartz Wool The replacement cost is $753. Inlet (from denuder)

NYS Department of Environmental Conservation

749a2a6c59da029b70b49189666c4744.ppt