9d37eae5a8b6c9cdd95df0b949fb67b0.ppt

- Количество слайдов: 39

Atlantium Advantage Hydro-Optic Disinfection The “Future” Of Disinfection Atlantium Advantage 2007

Atlantium Advantage Hydro-Optic Disinfection The “Future” Of Disinfection Atlantium Advantage 2007

Who Are We? Worldwide Leader Next Generation Water Disinfection Solutions Revolutionary Disinfection Technology Hydro-Optic Disinfection (HOD): n Environmentally friendly n Simple to use and maintain n At a low cost of ownership n Guaranteed performance… 2

Who Are We? Worldwide Leader Next Generation Water Disinfection Solutions Revolutionary Disinfection Technology Hydro-Optic Disinfection (HOD): n Environmentally friendly n Simple to use and maintain n At a low cost of ownership n Guaranteed performance… 2

Atlantium Advantage… Red Herring’s List: “Companies Driving the Future of Technology” 3

Atlantium Advantage… Red Herring’s List: “Companies Driving the Future of Technology” 3

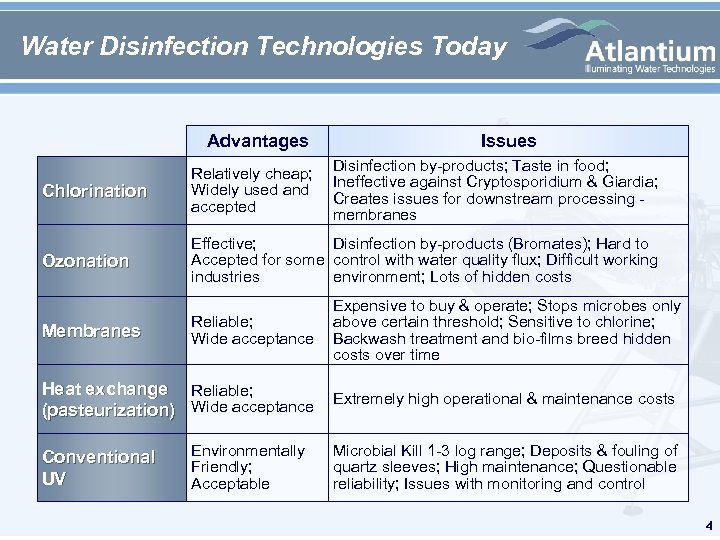

Water Disinfection Technologies Today Advantages Issues Chlorination Disinfection by-products; Taste in food; Relatively cheap; Ineffective against Cryptosporidium & Giardia; Widely used and Creates issues for downstream processing - accepted membranes Ozonation Effective; Disinfection by-products (Bromates); Hard to Accepted for some control with water quality flux; Difficult working industries environment; Lots of hidden costs Membranes Reliable; Wide acceptance Heat exchange Reliable; (pasteurization) Wide acceptance Conventional UV Environmentally Friendly; Acceptable Expensive to buy & operate; Stops microbes only above certain threshold; Sensitive to chlorine; Backwash treatment and bio-films breed hidden costs over time Extremely high operational & maintenance costs Microbial Kill 1 -3 log range; Deposits & fouling of quartz sleeves; High maintenance; Questionable reliability; Issues with monitoring and control 4

Water Disinfection Technologies Today Advantages Issues Chlorination Disinfection by-products; Taste in food; Relatively cheap; Ineffective against Cryptosporidium & Giardia; Widely used and Creates issues for downstream processing - accepted membranes Ozonation Effective; Disinfection by-products (Bromates); Hard to Accepted for some control with water quality flux; Difficult working industries environment; Lots of hidden costs Membranes Reliable; Wide acceptance Heat exchange Reliable; (pasteurization) Wide acceptance Conventional UV Environmentally Friendly; Acceptable Expensive to buy & operate; Stops microbes only above certain threshold; Sensitive to chlorine; Backwash treatment and bio-films breed hidden costs over time Extremely high operational & maintenance costs Microbial Kill 1 -3 log range; Deposits & fouling of quartz sleeves; High maintenance; Questionable reliability; Issues with monitoring and control 4

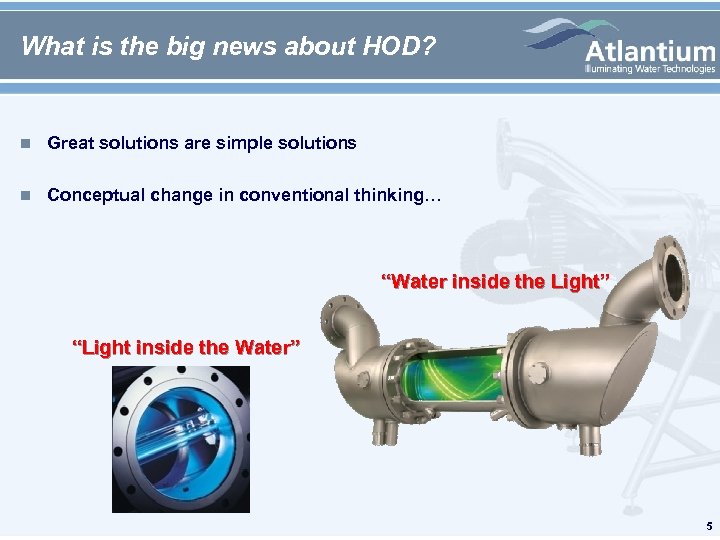

What is the big news about HOD? n Great solutions are simple solutions n Conceptual change in conventional thinking… “Water inside the Light” “Light inside the Water” 5

What is the big news about HOD? n Great solutions are simple solutions n Conceptual change in conventional thinking… “Water inside the Light” “Light inside the Water” 5

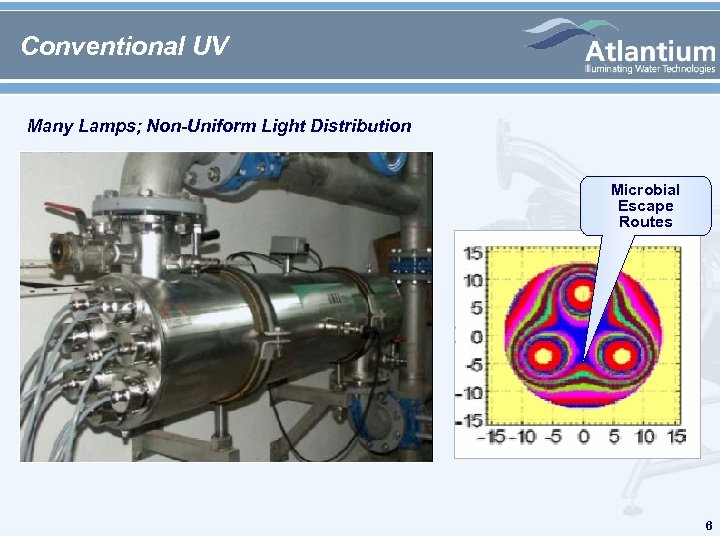

Conventional UV Many Lamps; Non-Uniform Light Distribution Microbial Escape Routes 6

Conventional UV Many Lamps; Non-Uniform Light Distribution Microbial Escape Routes 6

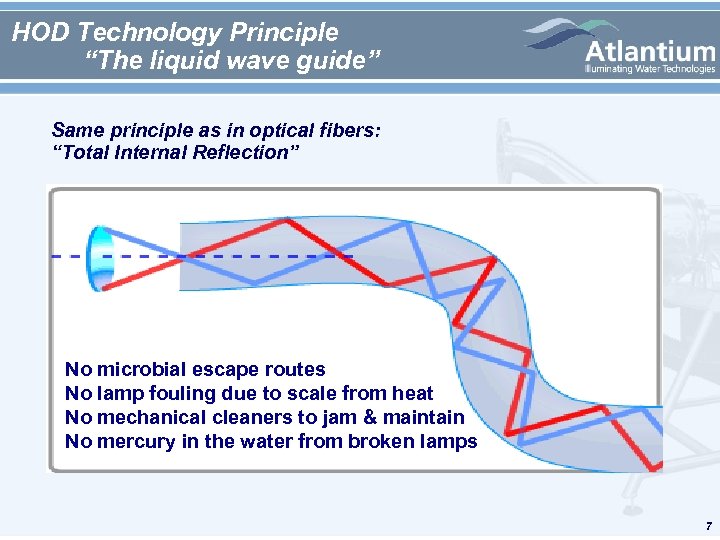

HOD Technology Principle “The liquid wave guide” Same principle as in optical fibers: “Total Internal Reflection” No microbial escape routes No lamp fouling due to scale from heat No mechanical cleaners to jam & maintain No mercury in the water from broken lamps 7

HOD Technology Principle “The liquid wave guide” Same principle as in optical fibers: “Total Internal Reflection” No microbial escape routes No lamp fouling due to scale from heat No mechanical cleaners to jam & maintain No mercury in the water from broken lamps 7

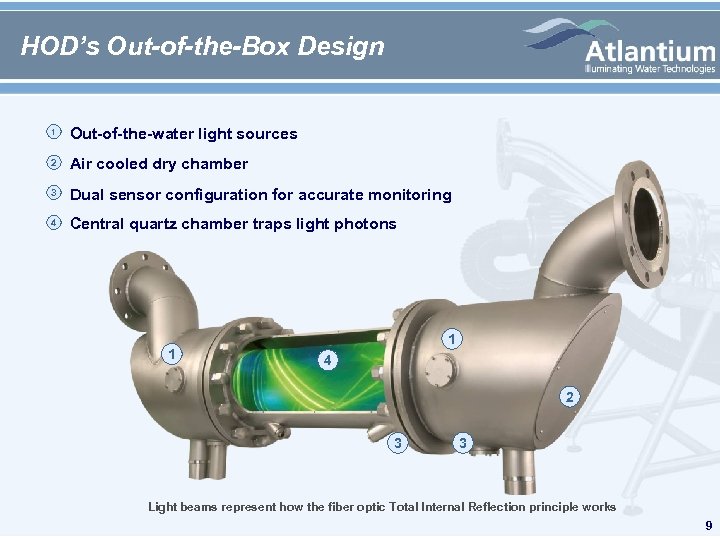

HOD’s Out-of-the-Box Design 1 Out-of-the-water light sources 2 Air cooled dry chamber 3 Dual sensor configuration for accurate monitoring 4 Central quartz chamber traps light photons 1 1 4 2 3 3 Light beams represent how the fiber optic Total Internal Reflection principle works 9

HOD’s Out-of-the-Box Design 1 Out-of-the-water light sources 2 Air cooled dry chamber 3 Dual sensor configuration for accurate monitoring 4 Central quartz chamber traps light photons 1 1 4 2 3 3 Light beams represent how the fiber optic Total Internal Reflection principle works 9

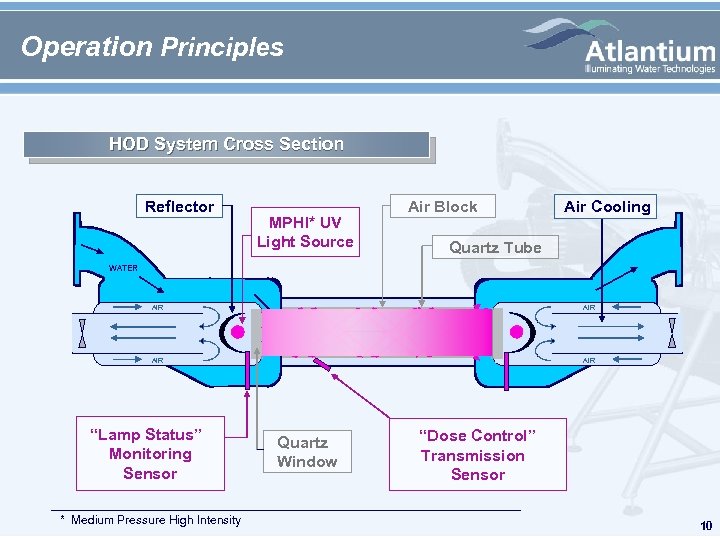

Operation Principles HOD System Cross Section Reflector MPHI* UV Light Source Air Block Air Cooling Quartz Tube WATER AIR AIR “Lamp Status” Monitoring Sensor * Medium Pressure High Intensity Quartz Window “Dose Control” Transmission Sensor 10

Operation Principles HOD System Cross Section Reflector MPHI* UV Light Source Air Block Air Cooling Quartz Tube WATER AIR AIR “Lamp Status” Monitoring Sensor * Medium Pressure High Intensity Quartz Window “Dose Control” Transmission Sensor 10

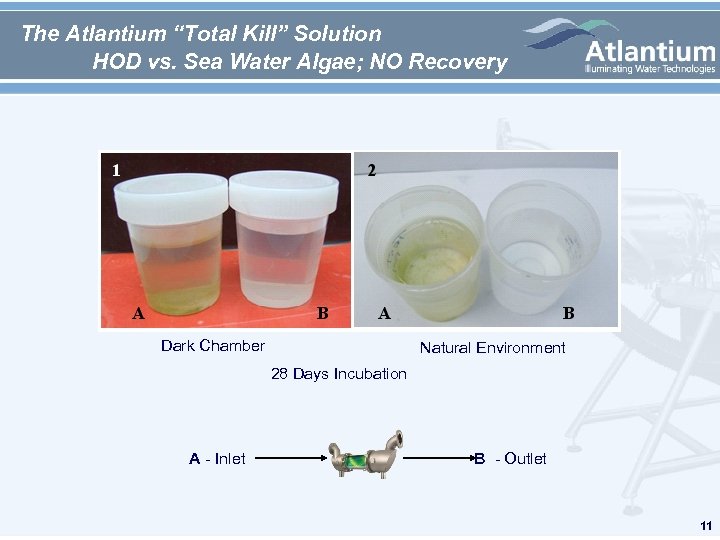

The Atlantium “Total Kill” Solution HOD vs. Sea Water Algae; NO Recovery Dark Chamber Natural Environment 28 Days Incubation A - Inlet B - Outlet 11

The Atlantium “Total Kill” Solution HOD vs. Sea Water Algae; NO Recovery Dark Chamber Natural Environment 28 Days Incubation A - Inlet B - Outlet 11

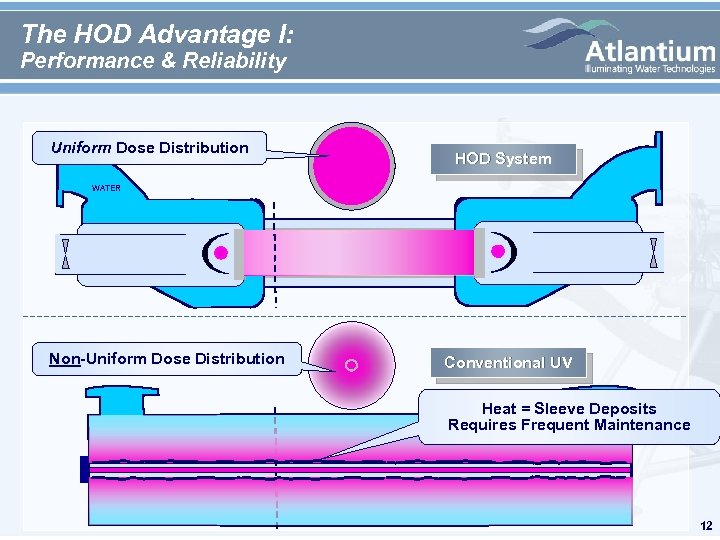

The HOD Advantage I: Performance & Reliability Uniform Dose Distribution HOD System WATER Non-Uniform Dose Distribution Conventional UV Heat = Sleeve Deposits Requires Frequent Maintenance 12

The HOD Advantage I: Performance & Reliability Uniform Dose Distribution HOD System WATER Non-Uniform Dose Distribution Conventional UV Heat = Sleeve Deposits Requires Frequent Maintenance 12

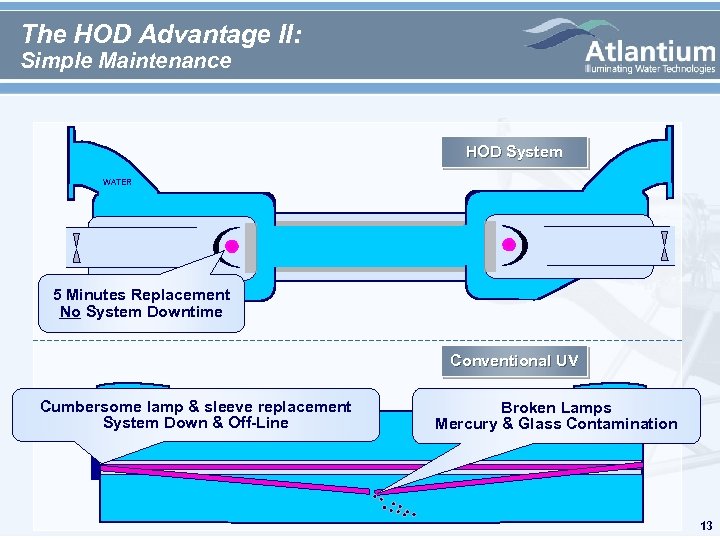

The HOD Advantage II: Simple Maintenance HOD System WATER 5 Minutes Replacement No System Downtime Conventional UV Cumbersome lamp & sleeve replacement System Down & Off-Line Broken Lamps Mercury & Glass Contamination 13

The HOD Advantage II: Simple Maintenance HOD System WATER 5 Minutes Replacement No System Downtime Conventional UV Cumbersome lamp & sleeve replacement System Down & Off-Line Broken Lamps Mercury & Glass Contamination 13

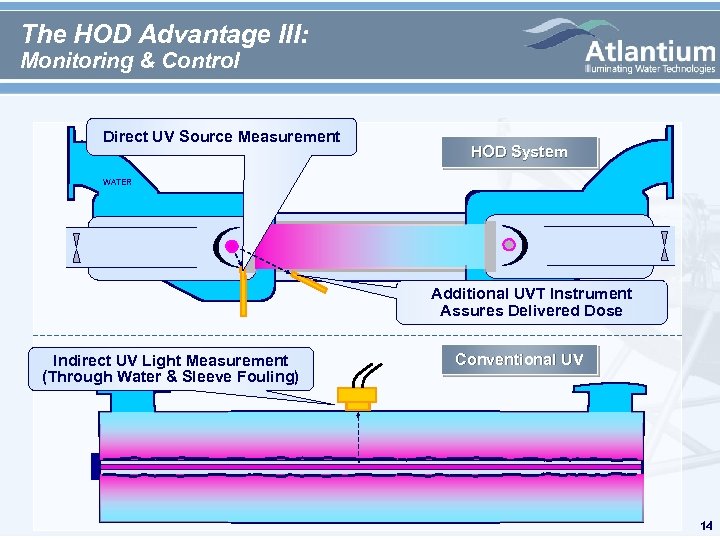

The HOD Advantage III: Monitoring & Control Direct UV Source Measurement HOD System WATER Additional UVT Instrument Assures Delivered Dose Indirect UV Light Measurement (Through Water & Sleeve Fouling) Conventional UV 14

The HOD Advantage III: Monitoring & Control Direct UV Source Measurement HOD System WATER Additional UVT Instrument Assures Delivered Dose Indirect UV Light Measurement (Through Water & Sleeve Fouling) Conventional UV 14

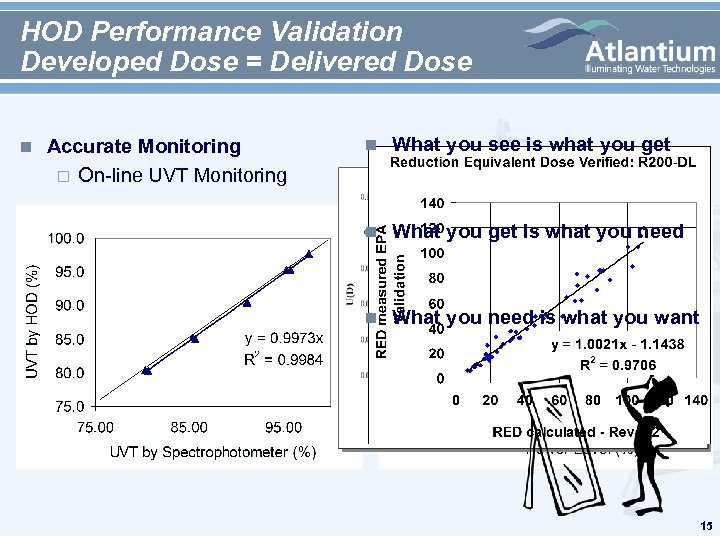

HOD Performance Validation Developed Dose = Delivered Dose n n What you see is what you get On-line Lamp Monitoring Accurate Monitoring On-line UVT Monitoring n Uniform Dose Distribution n Dose Distribution Average Track Minimum Dose What you get is what you need (No “Low Dose” Tracks) n Validated Dose = Displayed Dose n What you need is what you want 15

HOD Performance Validation Developed Dose = Delivered Dose n n What you see is what you get On-line Lamp Monitoring Accurate Monitoring On-line UVT Monitoring n Uniform Dose Distribution n Dose Distribution Average Track Minimum Dose What you get is what you need (No “Low Dose” Tracks) n Validated Dose = Displayed Dose n What you need is what you want 15

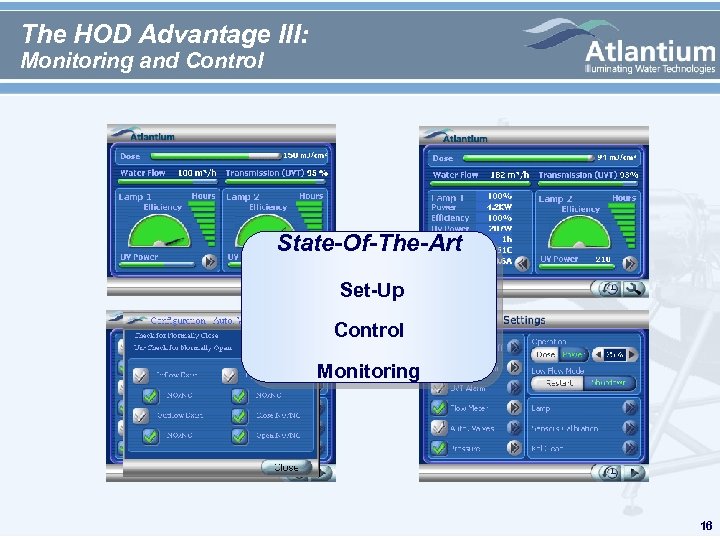

The HOD Advantage III: Monitoring and Control State-Of-The-Art Set-Up Control Monitoring 16

The HOD Advantage III: Monitoring and Control State-Of-The-Art Set-Up Control Monitoring 16

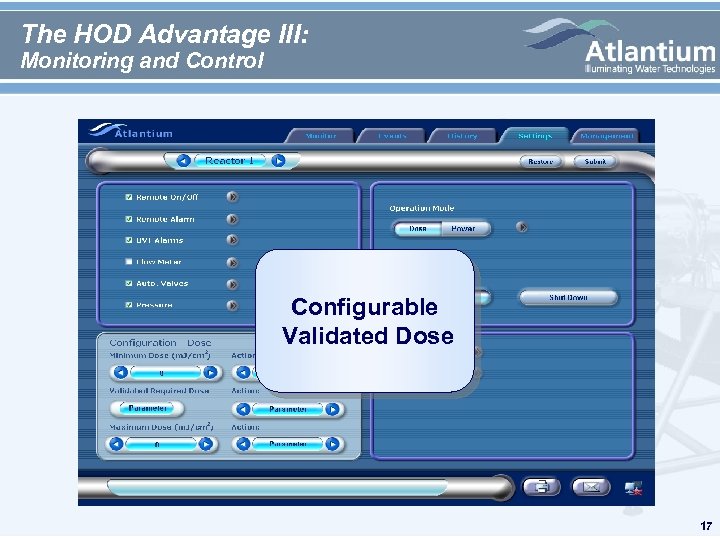

The HOD Advantage III: Monitoring and Control Configurable Validated Dose 17

The HOD Advantage III: Monitoring and Control Configurable Validated Dose 17

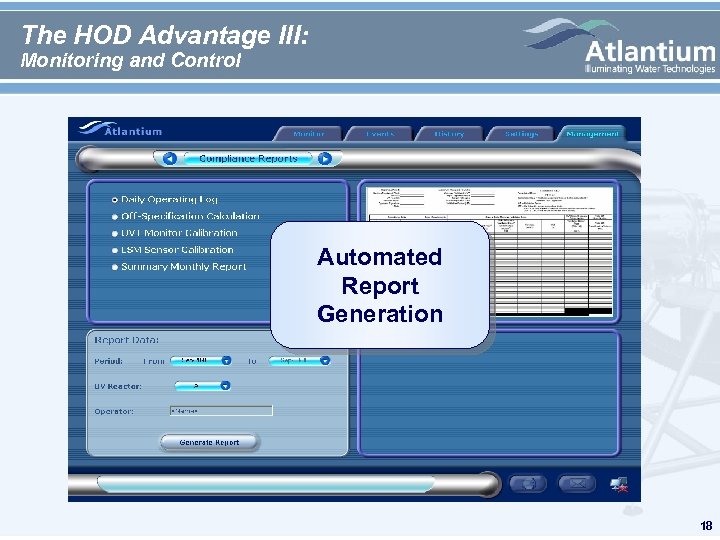

The HOD Advantage III: Monitoring and Control Automated Report Generation 18

The HOD Advantage III: Monitoring and Control Automated Report Generation 18

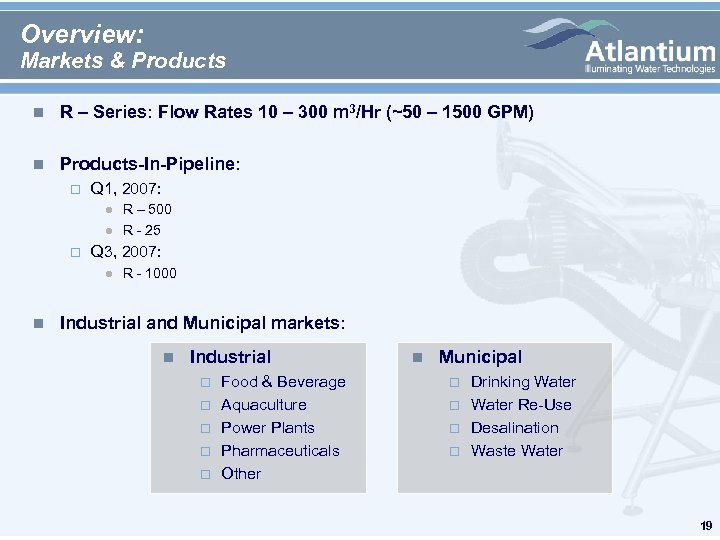

Overview: Markets & Products n R – Series: Flow Rates 10 – 300 m 3/Hr (~50 – 1500 GPM) n Products-In-Pipeline: Q 1, 2007: l l Q 3, 2007: l n R – 500 R - 25 R - 1000 Industrial and Municipal markets: n Industrial Food & Beverage Aquaculture Power Plants Pharmaceuticals Other n Municipal Drinking Water Re-Use Desalination Waste Water 19

Overview: Markets & Products n R – Series: Flow Rates 10 – 300 m 3/Hr (~50 – 1500 GPM) n Products-In-Pipeline: Q 1, 2007: l l Q 3, 2007: l n R – 500 R - 25 R - 1000 Industrial and Municipal markets: n Industrial Food & Beverage Aquaculture Power Plants Pharmaceuticals Other n Municipal Drinking Water Re-Use Desalination Waste Water 19

The Atlantium Advantage Industrial Market Applications Product Water Pasteurization Aquaculture Fire-Wall Process Water Ultra-Pure / AOP 20

The Atlantium Advantage Industrial Market Applications Product Water Pasteurization Aquaculture Fire-Wall Process Water Ultra-Pure / AOP 20

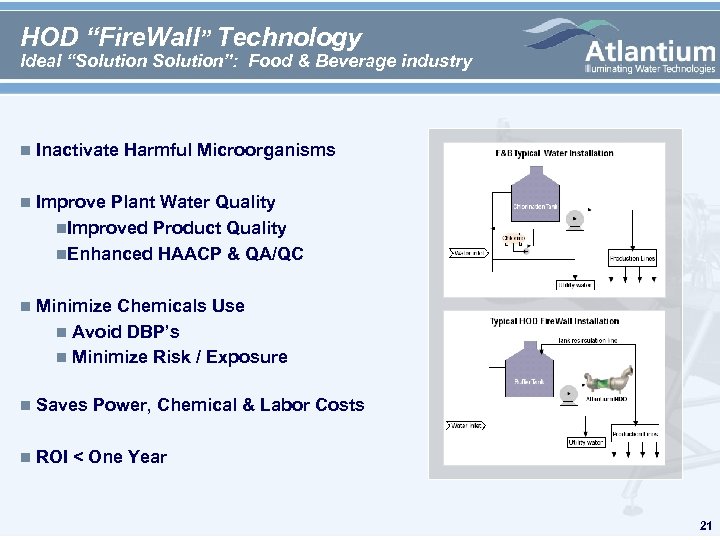

HOD “Fire. Wall” Technology Ideal “Solution”: Food & Beverage industry n Inactivate Harmful Microorganisms n Improve Plant Water Quality n. Improved Product Quality n. Enhanced HAACP & QA/QC n Minimize Chemicals Use n Avoid DBP’s n Minimize Risk / Exposure n Saves Power, Chemical & Labor Costs n ROI < One Year 21

HOD “Fire. Wall” Technology Ideal “Solution”: Food & Beverage industry n Inactivate Harmful Microorganisms n Improve Plant Water Quality n. Improved Product Quality n. Enhanced HAACP & QA/QC n Minimize Chemicals Use n Avoid DBP’s n Minimize Risk / Exposure n Saves Power, Chemical & Labor Costs n ROI < One Year 21

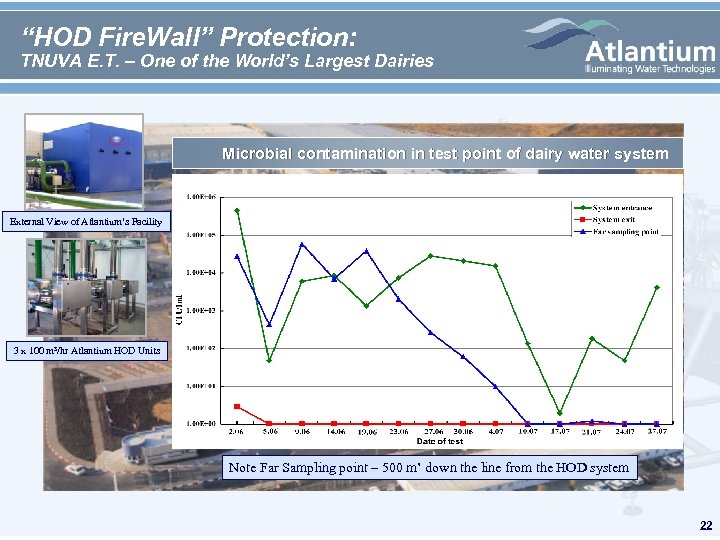

“HOD Fire. Wall” Protection: TNUVA E. T. – One of the World’s Largest Dairies Microbial contamination in test point of dairy water system External View of Atlantium’s Facility 3 x 100 m 3/hr Atlantium HOD Units Note Far Sampling point – 500 m’ down the line from the HOD system 22

“HOD Fire. Wall” Protection: TNUVA E. T. – One of the World’s Largest Dairies Microbial contamination in test point of dairy water system External View of Atlantium’s Facility 3 x 100 m 3/hr Atlantium HOD Units Note Far Sampling point – 500 m’ down the line from the HOD system 22

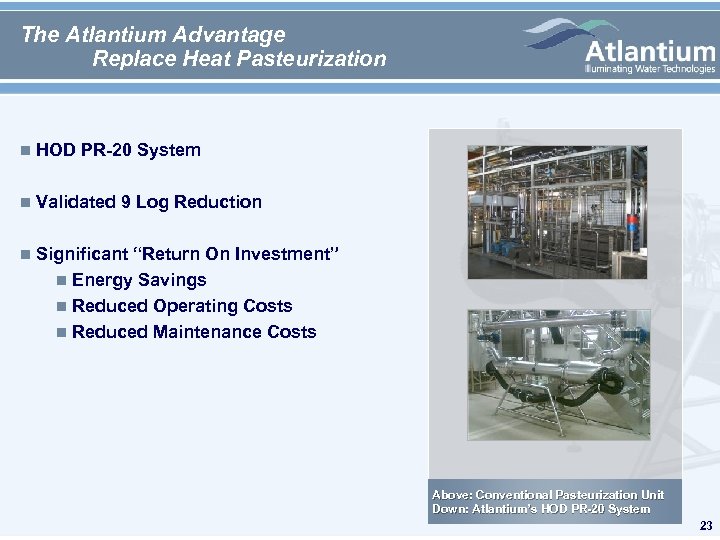

The Atlantium Advantage Replace Heat Pasteurization n HOD PR-20 System n Validated 9 Log Reduction n Significant “Return On Investment” n Energy Savings n Reduced Operating Costs n Reduced Maintenance Costs Above: Conventional Pasteurization Unit Down: Atlantium’s HOD PR-20 System 23

The Atlantium Advantage Replace Heat Pasteurization n HOD PR-20 System n Validated 9 Log Reduction n Significant “Return On Investment” n Energy Savings n Reduced Operating Costs n Reduced Maintenance Costs Above: Conventional Pasteurization Unit Down: Atlantium’s HOD PR-20 System 23

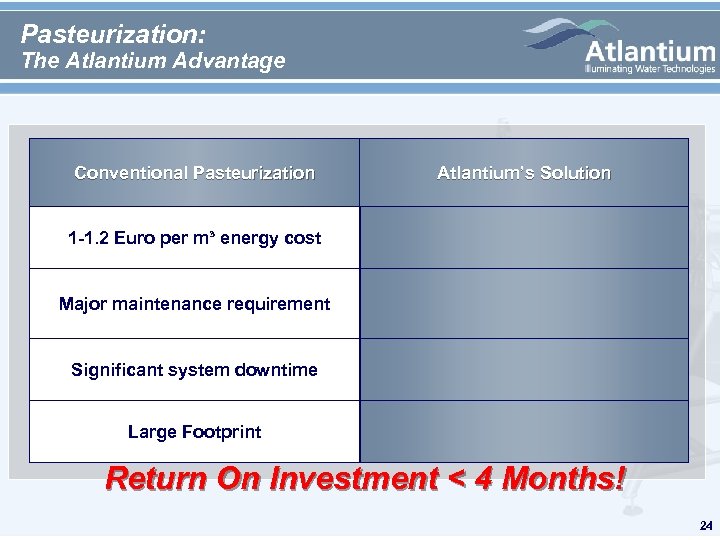

Pasteurization: The Atlantium Advantage Conventional Pasteurization Atlantium’s Solution 1 -1. 2 Euro per m³ energy cost 0. 05 Euro per m³ energy cost Major maintenance requirement Simple & easy maintenance Significant system downtime Almost no system downtime Large Footprint Small Footprint Return On Investment < 4 Months! 24

Pasteurization: The Atlantium Advantage Conventional Pasteurization Atlantium’s Solution 1 -1. 2 Euro per m³ energy cost 0. 05 Euro per m³ energy cost Major maintenance requirement Simple & easy maintenance Significant system downtime Almost no system downtime Large Footprint Small Footprint Return On Investment < 4 Months! 24

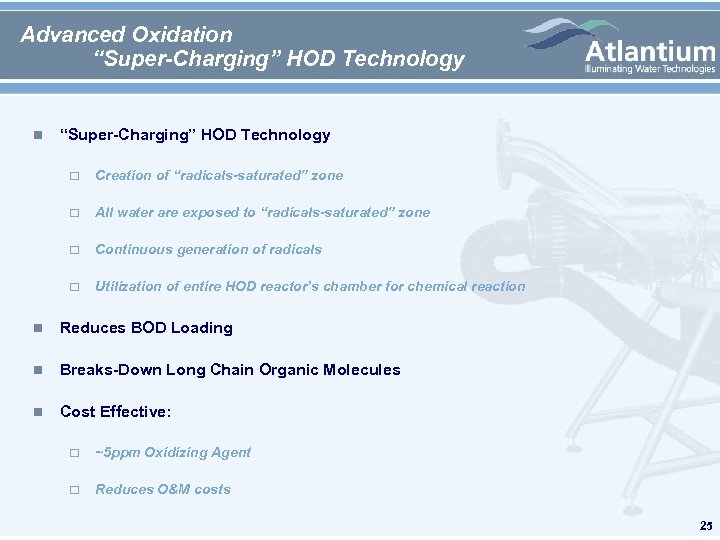

Advanced Oxidation “Super-Charging” HOD Technology Creation of “radicals-saturated” zone All water are exposed to “radicals-saturated” zone Continuous generation of radicals Utilization of entire HOD reactor’s chamber for chemical reaction n Reduces BOD Loading n Breaks-Down Long Chain Organic Molecules n Cost Effective: ~5 ppm Oxidizing Agent Reduces O&M costs 25

Advanced Oxidation “Super-Charging” HOD Technology Creation of “radicals-saturated” zone All water are exposed to “radicals-saturated” zone Continuous generation of radicals Utilization of entire HOD reactor’s chamber for chemical reaction n Reduces BOD Loading n Breaks-Down Long Chain Organic Molecules n Cost Effective: ~5 ppm Oxidizing Agent Reduces O&M costs 25

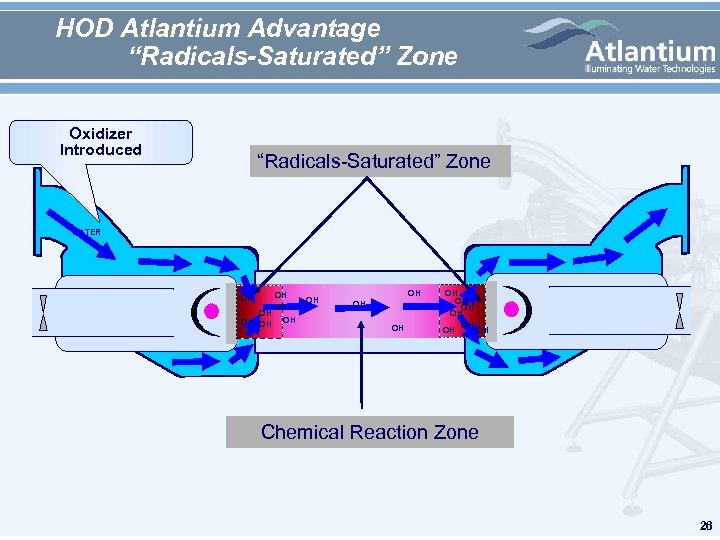

HOD Atlantium Advantage “Radicals-Saturated” Zone Oxidizer Introduced “Radicals-Saturated” Zone WATER OH OH OH OH OH Chemical Reaction Zone 26

HOD Atlantium Advantage “Radicals-Saturated” Zone Oxidizer Introduced “Radicals-Saturated” Zone WATER OH OH OH OH OH Chemical Reaction Zone 26

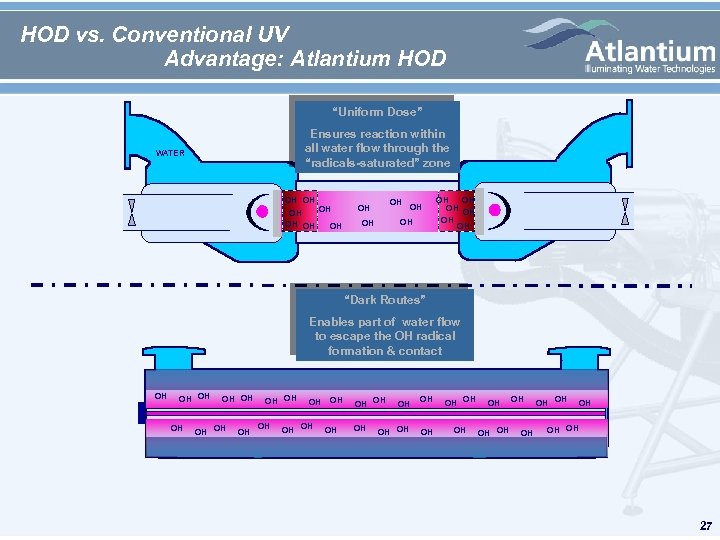

HOD vs. Conventional UV Advantage: Atlantium HOD “Uniform Dose” Ensures reaction within all water flow through the “radicals-saturated” zone WATER OH OH OH OH OH “Dark Routes” Enables part of water flow to escape the OH radical formation & contact OH OH OH OH OH OH OH OH OH OH 27

HOD vs. Conventional UV Advantage: Atlantium HOD “Uniform Dose” Ensures reaction within all water flow through the “radicals-saturated” zone WATER OH OH OH OH OH “Dark Routes” Enables part of water flow to escape the OH radical formation & contact OH OH OH OH OH OH OH OH OH OH 27

The Atlantium Advantage n Unique “Radicals-Saturation Zone” n Total Fluid Exposure To “Radicals-Saturation Zone” n On-Line Lamp Exchange Minimal System Fouling Huge Chemical-Reaction Chamber n No Escape Routes Uniform Dose Continuous Generation of Radicals n High Generation of OH Radicals Assured Water-To-Radical Contact Entire HOD Quartz Chamber No Flow Impediments Applications… 28

The Atlantium Advantage n Unique “Radicals-Saturation Zone” n Total Fluid Exposure To “Radicals-Saturation Zone” n On-Line Lamp Exchange Minimal System Fouling Huge Chemical-Reaction Chamber n No Escape Routes Uniform Dose Continuous Generation of Radicals n High Generation of OH Radicals Assured Water-To-Radical Contact Entire HOD Quartz Chamber No Flow Impediments Applications… 28

Unique AOP Opportunities n TOC / BOD Reductions n Chlorine / THM Reductions n Complex Compounds Break-Down n Odor Control n Disinfection n Waste Waters Re-Use n Waters Disinfection Ballast Waters System Run-Off 29

Unique AOP Opportunities n TOC / BOD Reductions n Chlorine / THM Reductions n Complex Compounds Break-Down n Odor Control n Disinfection n Waste Waters Re-Use n Waters Disinfection Ballast Waters System Run-Off 29

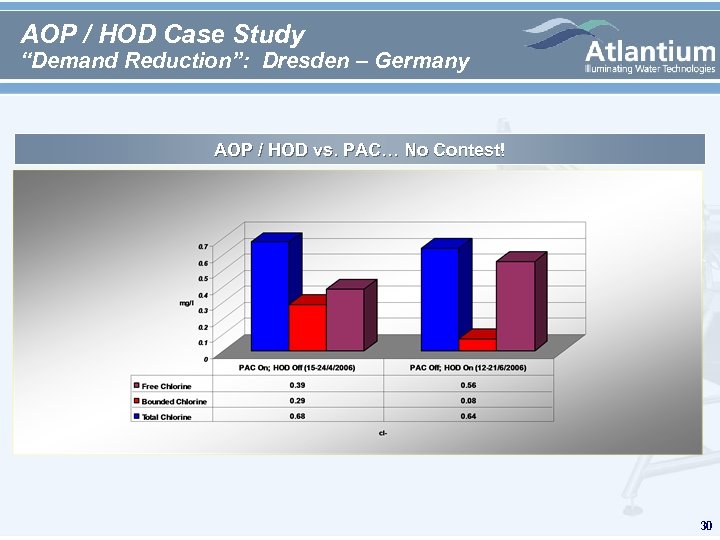

AOP / HOD Case Study “Demand Reduction”: Dresden – Germany AOP / HOD vs. PAC… No Contest! 30

AOP / HOD Case Study “Demand Reduction”: Dresden – Germany AOP / HOD vs. PAC… No Contest! 30

Membrane Pre-Treatment Applications n n n Protect Membranes…. From Bio-Films Chlorine Break-Through Task Separation Biologic Firewall Chemical Firewall Reduce CIP Days Increase Production Decrease Chemical Costs Increase Membrane Lifetime Extended Run-Times Less Cycling Reduce Energy Consumption Return On Investment < One Year 31

Membrane Pre-Treatment Applications n n n Protect Membranes…. From Bio-Films Chlorine Break-Through Task Separation Biologic Firewall Chemical Firewall Reduce CIP Days Increase Production Decrease Chemical Costs Increase Membrane Lifetime Extended Run-Times Less Cycling Reduce Energy Consumption Return On Investment < One Year 31

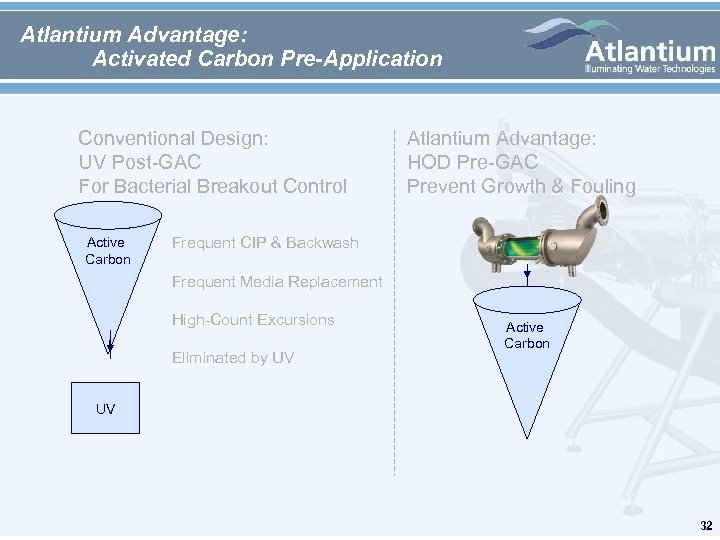

Atlantium Advantage: Activated Carbon Pre-Application Conventional Design: UV Post-GAC For Bacterial Breakout Control Active Carbon Atlantium Advantage: HOD Pre-GAC Prevent Growth & Fouling Frequent CIP & Backwash Frequent Media Replacement High-Count Excursions Eliminated by UV Active Carbon UV 32

Atlantium Advantage: Activated Carbon Pre-Application Conventional Design: UV Post-GAC For Bacterial Breakout Control Active Carbon Atlantium Advantage: HOD Pre-GAC Prevent Growth & Fouling Frequent CIP & Backwash Frequent Media Replacement High-Count Excursions Eliminated by UV Active Carbon UV 32

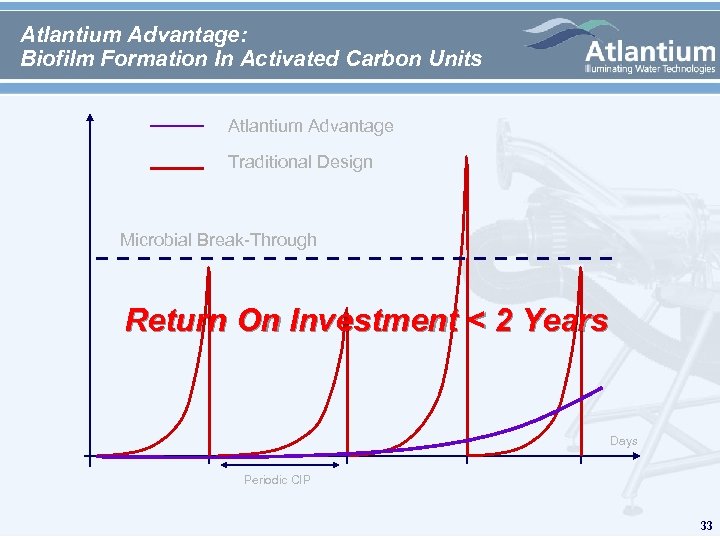

Atlantium Advantage: Biofilm Formation In Activated Carbon Units Atlantium Advantage Traditional Design Microbial Break-Through Return On Investment < 2 Years Days Periodic CIP 33

Atlantium Advantage: Biofilm Formation In Activated Carbon Units Atlantium Advantage Traditional Design Microbial Break-Through Return On Investment < 2 Years Days Periodic CIP 33

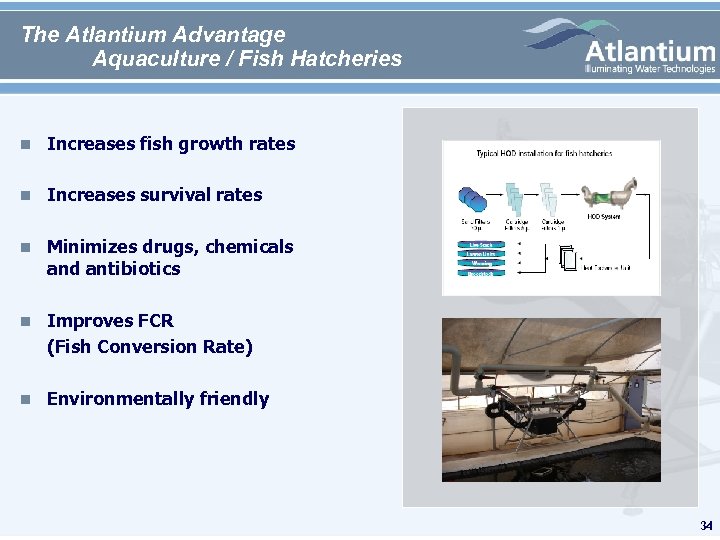

The Atlantium Advantage Aquaculture / Fish Hatcheries n Increases fish growth rates n Increases survival rates n Minimizes drugs, chemicals and antibiotics n Improves FCR (Fish Conversion Rate) n Environmentally friendly 34

The Atlantium Advantage Aquaculture / Fish Hatcheries n Increases fish growth rates n Increases survival rates n Minimizes drugs, chemicals and antibiotics n Improves FCR (Fish Conversion Rate) n Environmentally friendly 34

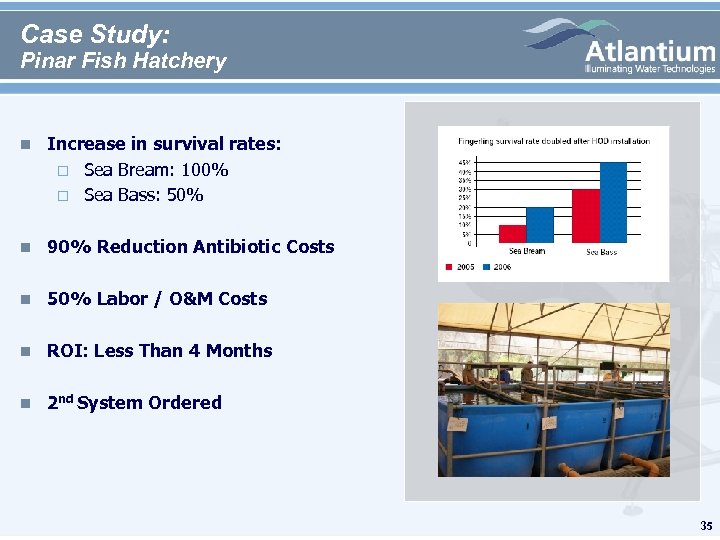

Case Study: Pinar Fish Hatchery n Increase in survival rates: Sea Bream: 100% Sea Bass: 50% n 90% Reduction Antibiotic Costs n 50% Labor / O&M Costs n ROI: Less Than 4 Months n 2 nd System Ordered 35

Case Study: Pinar Fish Hatchery n Increase in survival rates: Sea Bream: 100% Sea Bass: 50% n 90% Reduction Antibiotic Costs n 50% Labor / O&M Costs n ROI: Less Than 4 Months n 2 nd System Ordered 35

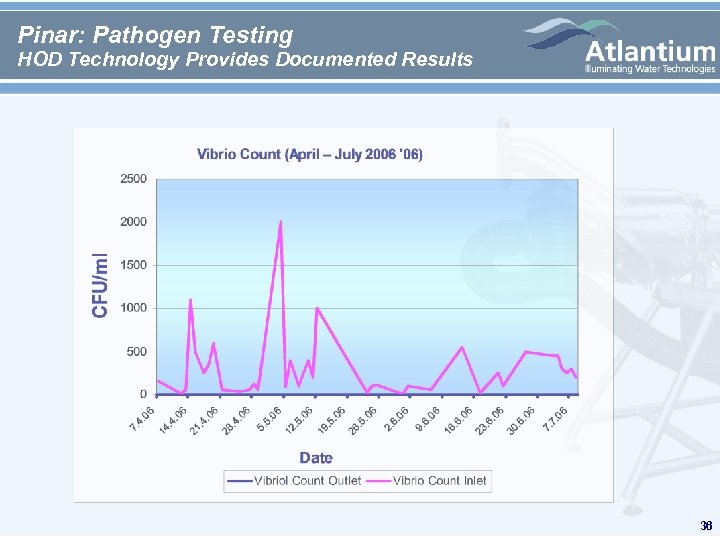

Pinar: Pathogen Testing HOD Technology Provides Documented Results 36

Pinar: Pathogen Testing HOD Technology Provides Documented Results 36

Further Development n Finalizing EPA Validation Process n Developing “Low-UVT” Reactor n Emerging Markets: Municipal Drinking Water / Ground Water Rule Water Re-Use Power Plants Pharmaceutical Industry Semi–Conductor / Electronic Industry n New Applications: Zebra Mussels Activated Carbon Filter Protection 37

Further Development n Finalizing EPA Validation Process n Developing “Low-UVT” Reactor n Emerging Markets: Municipal Drinking Water / Ground Water Rule Water Re-Use Power Plants Pharmaceutical Industry Semi–Conductor / Electronic Industry n New Applications: Zebra Mussels Activated Carbon Filter Protection 37

Summary… Atlantium Advantage n Leader In Innovative Water Disinfection Solutions: Introducing Hydro-Optic Disinfection (HOD) technology A Revolutionary primary disinfection method n Dozens Of Successful Installations & Applications n Comprehensive Intellectual Property (IP) Portfolio Seasoned management, academic and R&D staff Registered and pending patents worldwide n Operations: Europe, US & Asia – 20 Countries Worldwide n Partnering with reps / distributors and “solution” companies for sales, installation, support, distribution and R&D projects 38

Summary… Atlantium Advantage n Leader In Innovative Water Disinfection Solutions: Introducing Hydro-Optic Disinfection (HOD) technology A Revolutionary primary disinfection method n Dozens Of Successful Installations & Applications n Comprehensive Intellectual Property (IP) Portfolio Seasoned management, academic and R&D staff Registered and pending patents worldwide n Operations: Europe, US & Asia – 20 Countries Worldwide n Partnering with reps / distributors and “solution” companies for sales, installation, support, distribution and R&D projects 38

Most important … The Sleep Well At Night (SWAN) Factor 39

Most important … The Sleep Well At Night (SWAN) Factor 39

THANK YOU! Norm Sendler Atlantium Technologies, Ltd. 888. 846. 2464 Norm. S@atlantium. com www. atlantium. com

THANK YOU! Norm Sendler Atlantium Technologies, Ltd. 888. 846. 2464 Norm. S@atlantium. com www. atlantium. com