a6dc4aa0d4ed4df824bbb3d85a7ff10e.ppt

- Количество слайдов: 28

ATGTS: Automated Trace Gas Trapping System Team 7: Sponsored by: Dr. N. Ostrom, Dr. K. Smemo, & Dr. P. Robertson Funded by the Biogeochemistry Environmental Research Initiative

ATGTS: Automated Trace Gas Trapping System Team 7: Sponsored by: Dr. N. Ostrom, Dr. K. Smemo, & Dr. P. Robertson Funded by the Biogeochemistry Environmental Research Initiative

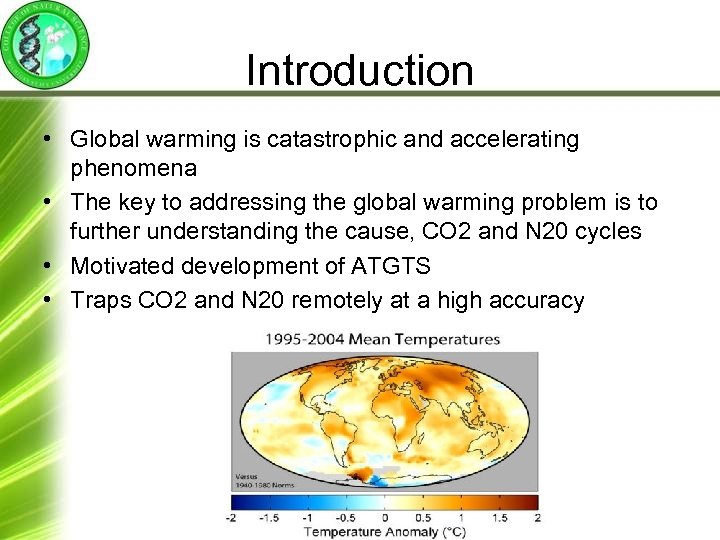

Introduction • Global warming is catastrophic and accelerating phenomena • The key to addressing the global warming problem is to further understanding the cause, CO 2 and N 20 cycles • Motivated development of ATGTS • Traps CO 2 and N 20 remotely at a high accuracy

Introduction • Global warming is catastrophic and accelerating phenomena • The key to addressing the global warming problem is to further understanding the cause, CO 2 and N 20 cycles • Motivated development of ATGTS • Traps CO 2 and N 20 remotely at a high accuracy

Agricultural Practices • The dynamics of CO 2 & N 2 O are heavily influenced by land management practices • System will be used to develop new farming practices and test old ones. • Increase accountability

Agricultural Practices • The dynamics of CO 2 & N 2 O are heavily influenced by land management practices • System will be used to develop new farming practices and test old ones. • Increase accountability

Carbon Crediting • • • ATGTS makes carbon trading possible AAA act Kyoto Protocol Sustainable oversight Nitrogen trading

Carbon Crediting • • • ATGTS makes carbon trading possible AAA act Kyoto Protocol Sustainable oversight Nitrogen trading

Impacts • • • Eliminate slash and burn Regulate crop prices with out waste Sustainable farming No impact on yield or profits Potential to reduce green house gas emissions more than taking 210 million cars of the road (1. 6 billion tons of CO 2) • Up to ¼ reduction in net emissions

Impacts • • • Eliminate slash and burn Regulate crop prices with out waste Sustainable farming No impact on yield or profits Potential to reduce green house gas emissions more than taking 210 million cars of the road (1. 6 billion tons of CO 2) • Up to ¼ reduction in net emissions

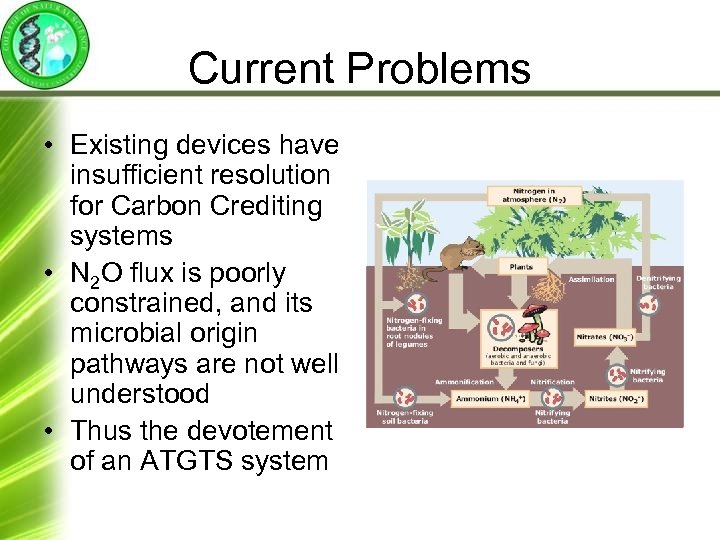

Current Problems • Existing devices have insufficient resolution for Carbon Crediting systems • N 2 O flux is poorly constrained, and its microbial origin pathways are not well understood • Thus the devotement of an ATGTS system

Current Problems • Existing devices have insufficient resolution for Carbon Crediting systems • N 2 O flux is poorly constrained, and its microbial origin pathways are not well understood • Thus the devotement of an ATGTS system

Purpose of the ATGTS • To control greenhouse gas emissions, a method of monitoring their flux from soil is needed • Team 7 charged with designing and constructing a device capable of taking measurements of CO 2 and N 2 O on a local scale • Provide a platform which facilitates analysis techniques to determine microbial origins of gases via isotopic analysis

Purpose of the ATGTS • To control greenhouse gas emissions, a method of monitoring their flux from soil is needed • Team 7 charged with designing and constructing a device capable of taking measurements of CO 2 and N 2 O on a local scale • Provide a platform which facilitates analysis techniques to determine microbial origins of gases via isotopic analysis

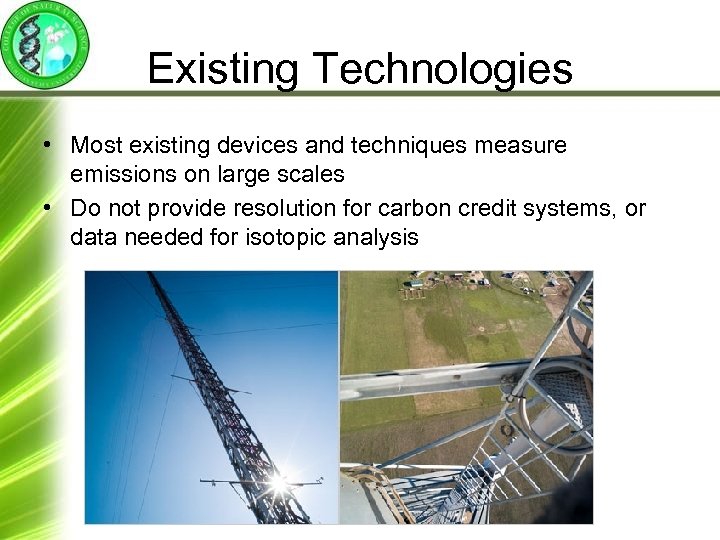

Existing Technologies • Most existing devices and techniques measure emissions on large scales • Do not provide resolution for carbon credit systems, or data needed for isotopic analysis

Existing Technologies • Most existing devices and techniques measure emissions on large scales • Do not provide resolution for carbon credit systems, or data needed for isotopic analysis

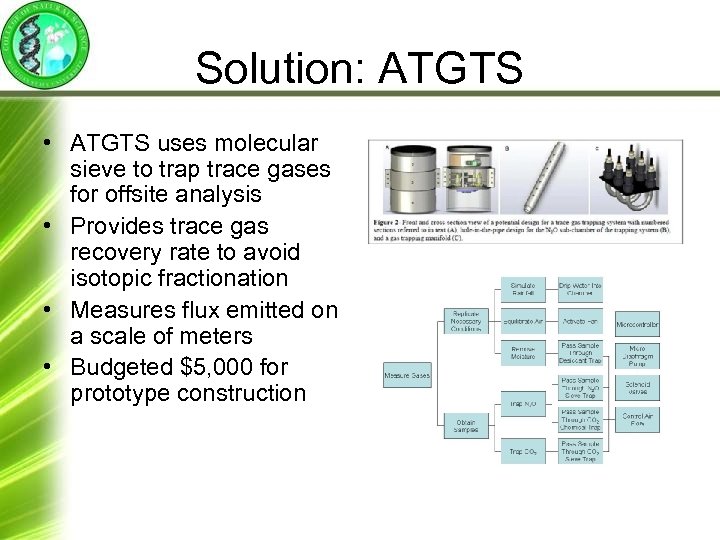

Solution: ATGTS • ATGTS uses molecular sieve to trap trace gases for offsite analysis • Provides trace gas recovery rate to avoid isotopic fractionation • Measures flux emitted on a scale of meters • Budgeted $5, 000 for prototype construction

Solution: ATGTS • ATGTS uses molecular sieve to trap trace gases for offsite analysis • Provides trace gas recovery rate to avoid isotopic fractionation • Measures flux emitted on a scale of meters • Budgeted $5, 000 for prototype construction

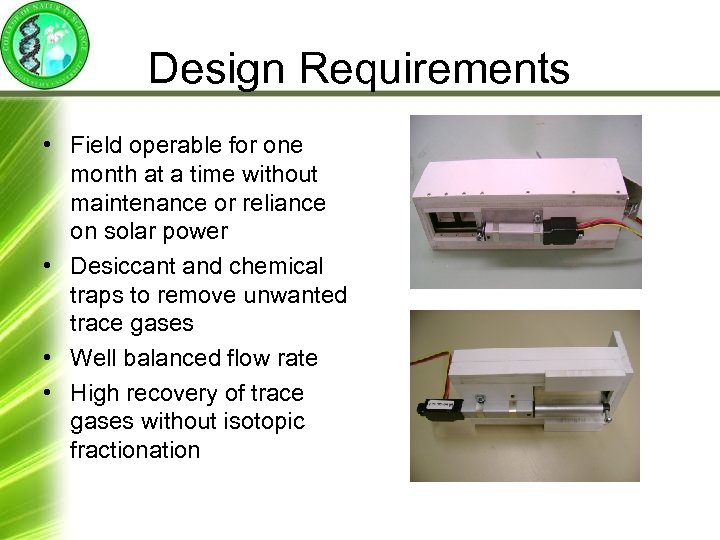

Design Requirements • Field operable for one month at a time without maintenance or reliance on solar power • Desiccant and chemical traps to remove unwanted trace gases • Well balanced flow rate • High recovery of trace gases without isotopic fractionation

Design Requirements • Field operable for one month at a time without maintenance or reliance on solar power • Desiccant and chemical traps to remove unwanted trace gases • Well balanced flow rate • High recovery of trace gases without isotopic fractionation

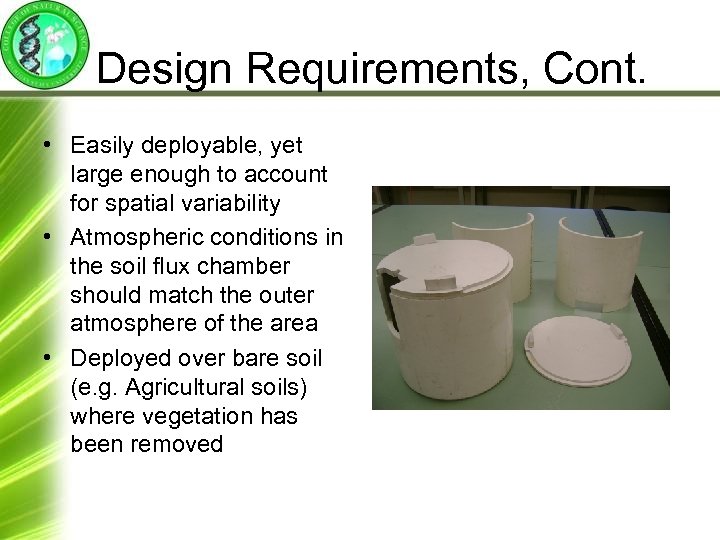

Design Requirements, Cont. • Easily deployable, yet large enough to account for spatial variability • Atmospheric conditions in the soil flux chamber should match the outer atmosphere of the area • Deployed over bare soil (e. g. Agricultural soils) where vegetation has been removed

Design Requirements, Cont. • Easily deployable, yet large enough to account for spatial variability • Atmospheric conditions in the soil flux chamber should match the outer atmosphere of the area • Deployed over bare soil (e. g. Agricultural soils) where vegetation has been removed

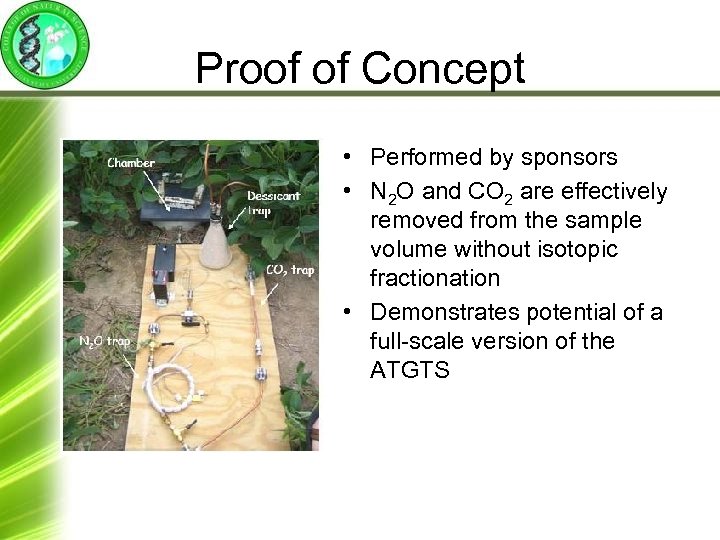

Proof of Concept • Performed by sponsors • N 2 O and CO 2 are effectively removed from the sample volume without isotopic fractionation • Demonstrates potential of a full-scale version of the ATGTS

Proof of Concept • Performed by sponsors • N 2 O and CO 2 are effectively removed from the sample volume without isotopic fractionation • Demonstrates potential of a full-scale version of the ATGTS

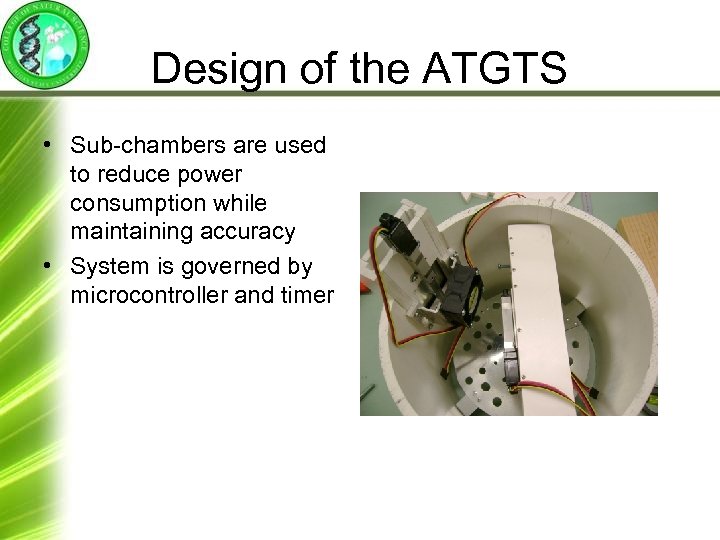

Design of the ATGTS • Sub-chambers are used to reduce power consumption while maintaining accuracy • System is governed by microcontroller and timer

Design of the ATGTS • Sub-chambers are used to reduce power consumption while maintaining accuracy • System is governed by microcontroller and timer

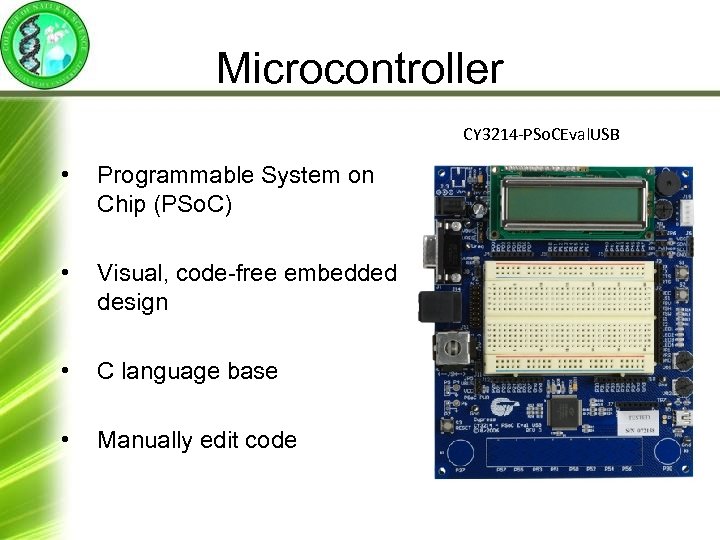

Microcontroller CY 3214 -PSo. CEval. USB • Programmable System on Chip (PSo. C) • Visual, code-free embedded design • C language base • Manually edit code

Microcontroller CY 3214 -PSo. CEval. USB • Programmable System on Chip (PSo. C) • Visual, code-free embedded design • C language base • Manually edit code

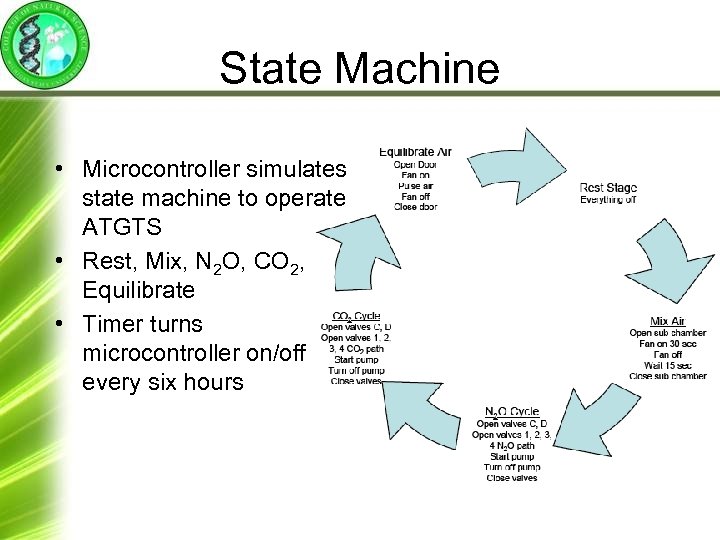

State Machine • Microcontroller simulates state machine to operate ATGTS • Rest, Mix, N 2 O, CO 2, Equilibrate • Timer turns microcontroller on/off every six hours

State Machine • Microcontroller simulates state machine to operate ATGTS • Rest, Mix, N 2 O, CO 2, Equilibrate • Timer turns microcontroller on/off every six hours

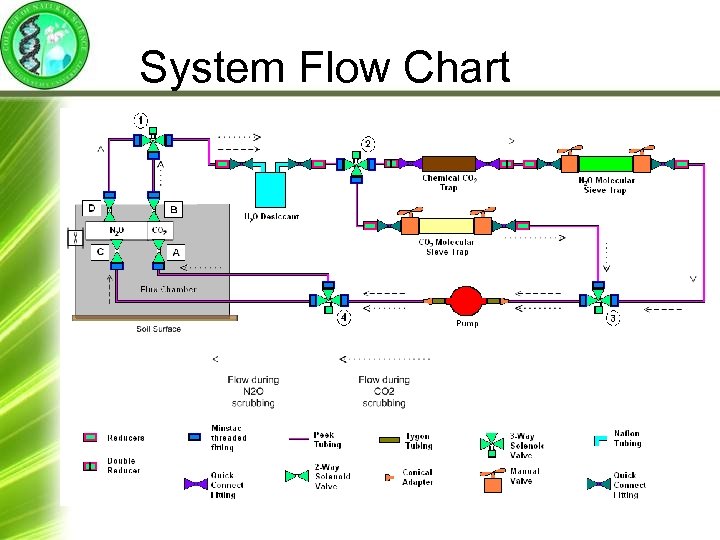

System Flow Chart

System Flow Chart

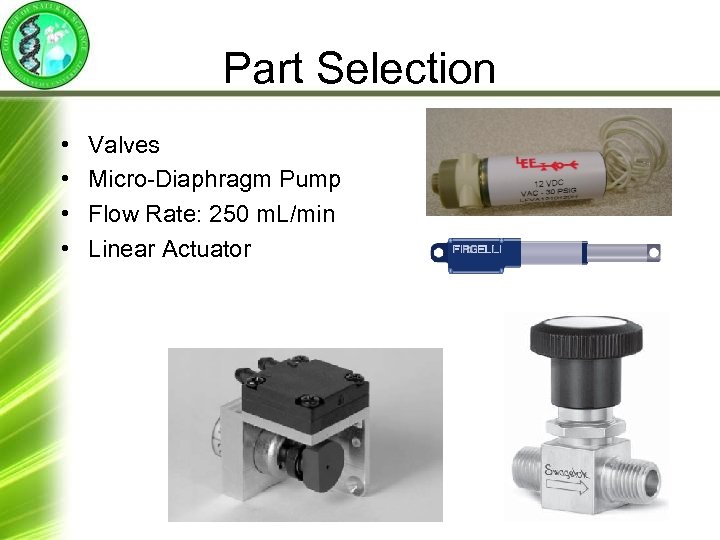

Part Selection • • Valves Micro-Diaphragm Pump Flow Rate: 250 m. L/min Linear Actuator

Part Selection • • Valves Micro-Diaphragm Pump Flow Rate: 250 m. L/min Linear Actuator

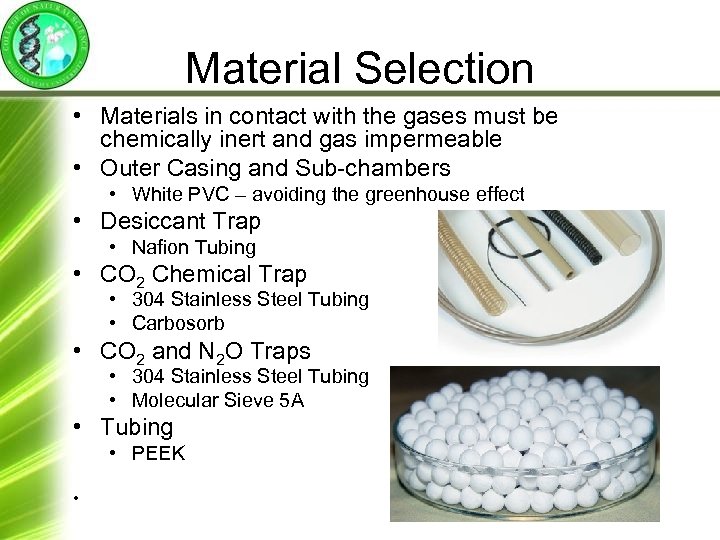

Material Selection • Materials in contact with the gases must be chemically inert and gas impermeable • Outer Casing and Sub-chambers • White PVC – avoiding the greenhouse effect • Desiccant Trap • Nafion Tubing • CO 2 Chemical Trap • 304 Stainless Steel Tubing • Carbosorb • CO 2 and N 2 O Traps • 304 Stainless Steel Tubing • Molecular Sieve 5 A • Tubing • PEEK •

Material Selection • Materials in contact with the gases must be chemically inert and gas impermeable • Outer Casing and Sub-chambers • White PVC – avoiding the greenhouse effect • Desiccant Trap • Nafion Tubing • CO 2 Chemical Trap • 304 Stainless Steel Tubing • Carbosorb • CO 2 and N 2 O Traps • 304 Stainless Steel Tubing • Molecular Sieve 5 A • Tubing • PEEK •

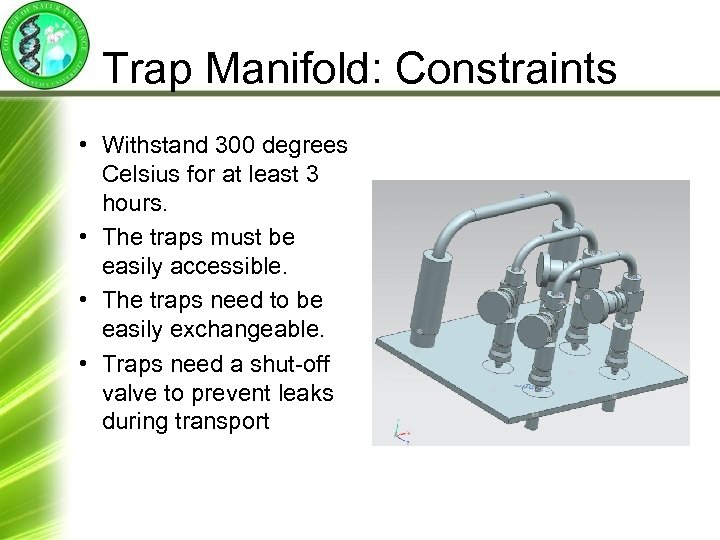

Trap Manifold: Constraints • Withstand 300 degrees Celsius for at least 3 hours. • The traps must be easily accessible. • The traps need to be easily exchangeable. • Traps need a shut-off valve to prevent leaks during transport

Trap Manifold: Constraints • Withstand 300 degrees Celsius for at least 3 hours. • The traps must be easily accessible. • The traps need to be easily exchangeable. • Traps need a shut-off valve to prevent leaks during transport

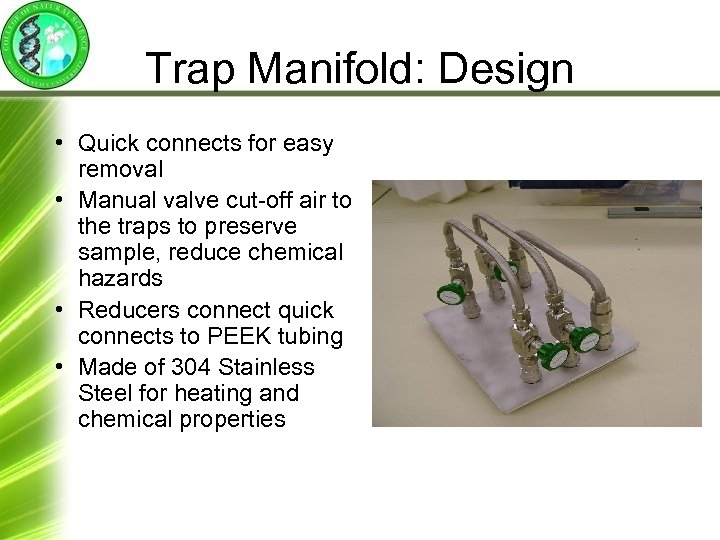

Trap Manifold: Design • Quick connects for easy removal • Manual valve cut-off air to the traps to preserve sample, reduce chemical hazards • Reducers connect quick connects to PEEK tubing • Made of 304 Stainless Steel for heating and chemical properties

Trap Manifold: Design • Quick connects for easy removal • Manual valve cut-off air to the traps to preserve sample, reduce chemical hazards • Reducers connect quick connects to PEEK tubing • Made of 304 Stainless Steel for heating and chemical properties

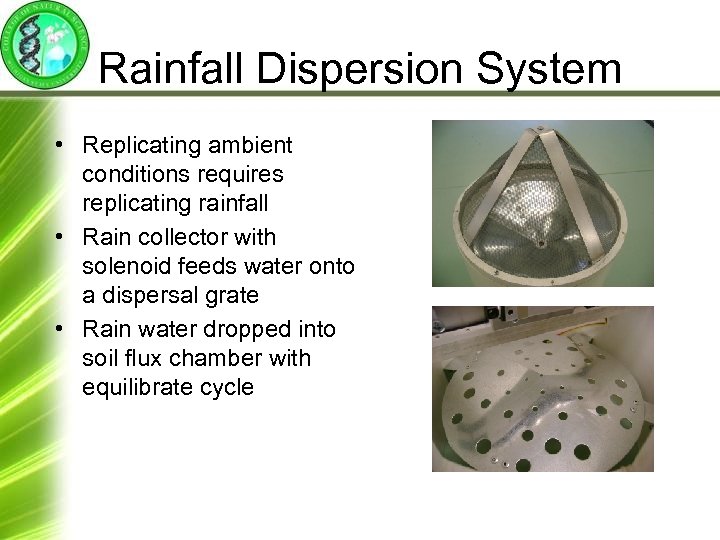

Rainfall Dispersion System • Replicating ambient conditions requires replicating rainfall • Rain collector with solenoid feeds water onto a dispersal grate • Rain water dropped into soil flux chamber with equilibrate cycle

Rainfall Dispersion System • Replicating ambient conditions requires replicating rainfall • Rain collector with solenoid feeds water onto a dispersal grate • Rain water dropped into soil flux chamber with equilibrate cycle

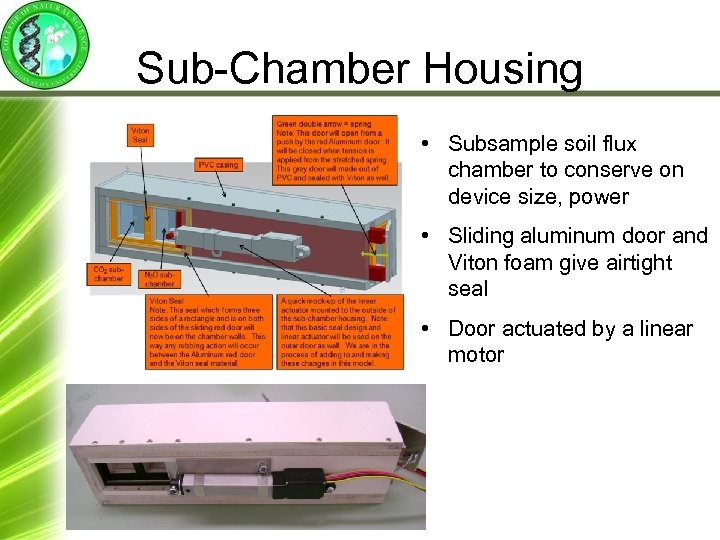

Sub-Chamber Housing • Subsample soil flux chamber to conserve on device size, power • Sliding aluminum door and Viton foam give airtight seal • Door actuated by a linear motor

Sub-Chamber Housing • Subsample soil flux chamber to conserve on device size, power • Sliding aluminum door and Viton foam give airtight seal • Door actuated by a linear motor

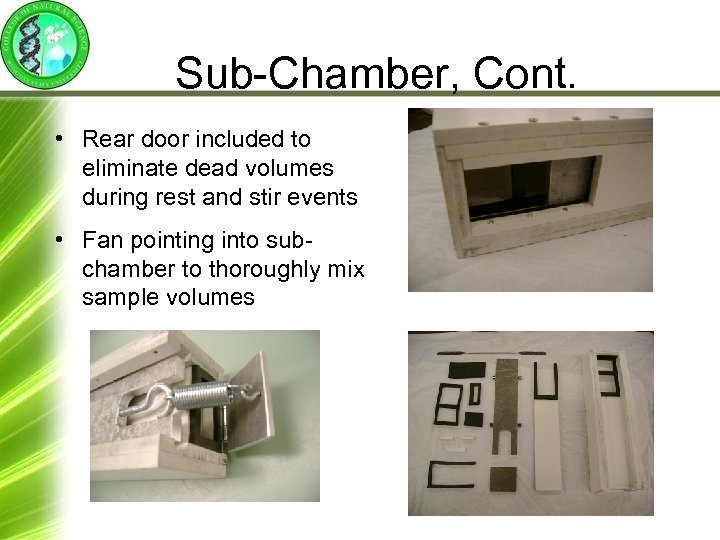

Sub-Chamber, Cont. • Rear door included to eliminate dead volumes during rest and stir events • Fan pointing into subchamber to thoroughly mix sample volumes

Sub-Chamber, Cont. • Rear door included to eliminate dead volumes during rest and stir events • Fan pointing into subchamber to thoroughly mix sample volumes

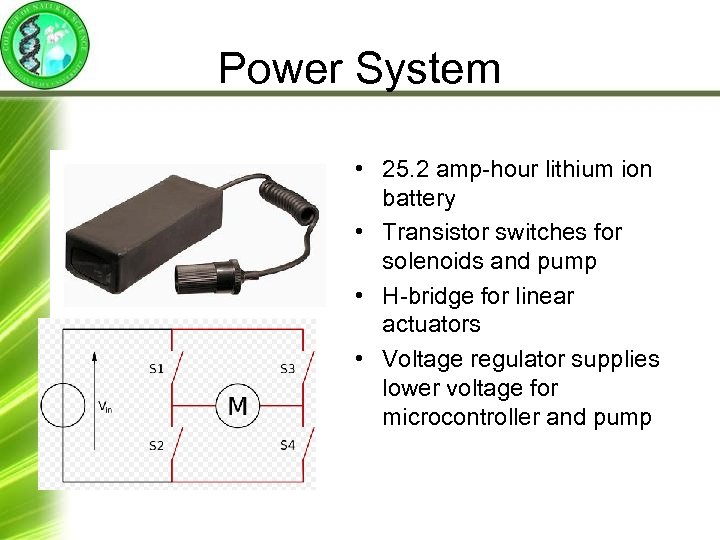

Power System • 25. 2 amp-hour lithium ion battery • Transistor switches for solenoids and pump • H-bridge for linear actuators • Voltage regulator supplies lower voltage for microcontroller and pump

Power System • 25. 2 amp-hour lithium ion battery • Transistor switches for solenoids and pump • H-bridge for linear actuators • Voltage regulator supplies lower voltage for microcontroller and pump

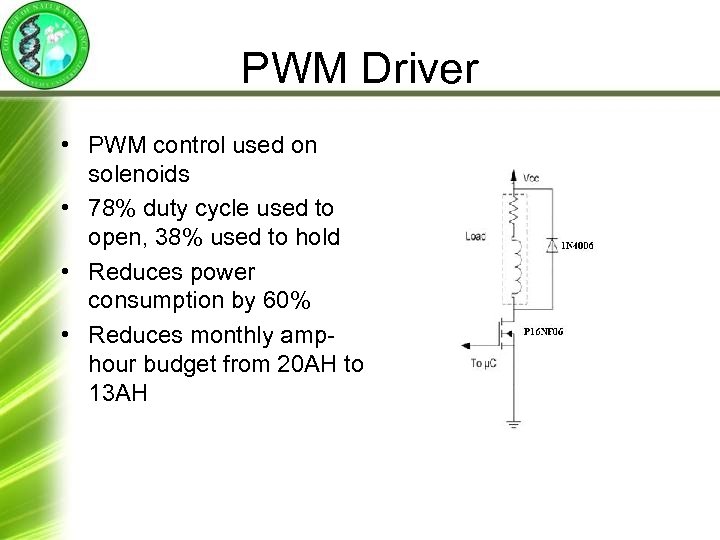

PWM Driver • PWM control used on solenoids • 78% duty cycle used to open, 38% used to hold • Reduces power consumption by 60% • Reduces monthly amphour budget from 20 AH to 13 AH

PWM Driver • PWM control used on solenoids • 78% duty cycle used to open, 38% used to hold • Reduces power consumption by 60% • Reduces monthly amphour budget from 20 AH to 13 AH

Timer • Saves energy by disconnecting the power to all other components when not in use • Activates microcontroller every 6 hours for 10 minutes • Internal relay can output 16 A to system

Timer • Saves energy by disconnecting the power to all other components when not in use • Activates microcontroller every 6 hours for 10 minutes • Internal relay can output 16 A to system

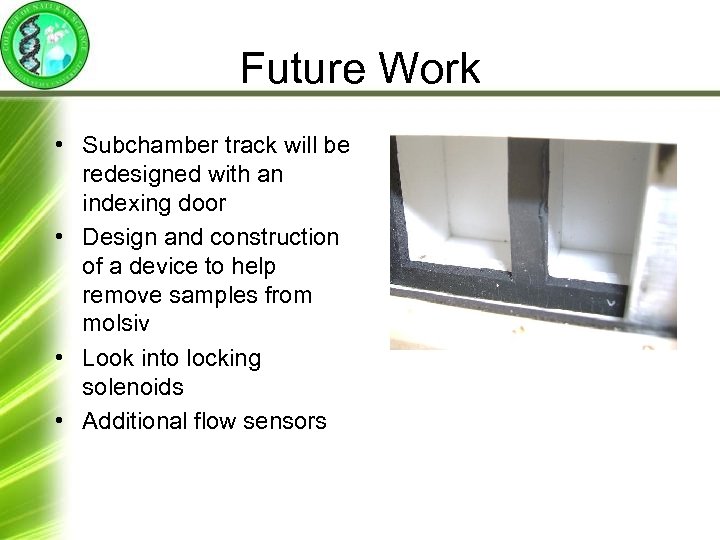

Future Work • Subchamber track will be redesigned with an indexing door • Design and construction of a device to help remove samples from molsiv • Look into locking solenoids • Additional flow sensors

Future Work • Subchamber track will be redesigned with an indexing door • Design and construction of a device to help remove samples from molsiv • Look into locking solenoids • Additional flow sensors

Conclusion • ATGTS will be a useful tool in the development of carbon crediting systems • Will aid future research into the origins of microbial N 2 O

Conclusion • ATGTS will be a useful tool in the development of carbon crediting systems • Will aid future research into the origins of microbial N 2 O