773eac9195a3bbf01f0c4d808beba1b5.ppt

- Количество слайдов: 36

Asset Management Council – WA Chapter & Maintenance Engineering Society of Australia Reliability Modelling for Business Decisions RAM Modelling in the Project Design Phase Friday 30 th April, 2010 Paul Websdane

Asset Management Council – WA Chapter & Maintenance Engineering Society of Australia Reliability Modelling for Business Decisions RAM Modelling in the Project Design Phase Friday 30 th April, 2010 Paul Websdane

RAM Modelling for Business Decisions • Project Design and Execute Phases – Steps in Process. – Examples & Learnings. – Benefits. • RAM in Operations phase – Barriers & Benefits.

RAM Modelling for Business Decisions • Project Design and Execute Phases – Steps in Process. – Examples & Learnings. – Benefits. • RAM in Operations phase – Barriers & Benefits.

Introduction – Snr Reliability Engineer – K 2 Technology. – Experience in Oil and Gas, Alumina, Mining, Condition Monitoring, Pumping. – RAM Tools & Packages; • Many different packages are available. • Each have strengths and weaknesses. – Used RAM for analysis of large new projects, small design changes, tank overhaul scenarios, decisions on redundancy.

Introduction – Snr Reliability Engineer – K 2 Technology. – Experience in Oil and Gas, Alumina, Mining, Condition Monitoring, Pumping. – RAM Tools & Packages; • Many different packages are available. • Each have strengths and weaknesses. – Used RAM for analysis of large new projects, small design changes, tank overhaul scenarios, decisions on redundancy.

RAM Modelling Overview • Tool to analyse and predict the availability / reliability of an asset or facility. • Reliability Block Diagrams (RBD) used. • Use Equipment Capability & Reliability data. • Maintenance Strategies & Schedules (optimise). • Overall production impact - $$$$. • Improved business decisions.

RAM Modelling Overview • Tool to analyse and predict the availability / reliability of an asset or facility. • Reliability Block Diagrams (RBD) used. • Use Equipment Capability & Reliability data. • Maintenance Strategies & Schedules (optimise). • Overall production impact - $$$$. • Improved business decisions.

RAM models in the Design Phase • Evaluate, Validate and Optimize design – Availability & Reliability targets. – Production capability. – Bottlenecks & Big hitters – Critical Equipment. – Redundancy levels. – Sparing. • Can “Design In” Reliability – Focus improvement efforts early in design.

RAM models in the Design Phase • Evaluate, Validate and Optimize design – Availability & Reliability targets. – Production capability. – Bottlenecks & Big hitters – Critical Equipment. – Redundancy levels. – Sparing. • Can “Design In” Reliability – Focus improvement efforts early in design.

Model Basic Steps • Understand system operating context, production • • • impact and cost of downtime. Document assumptions. Build the RBD and Reliability Data Register. Populate with Reliability Data and details of Maintenance Strategy / Shutdowns. Analyse the System. Update and refine over time. Conduct Sensitivity analyses.

Model Basic Steps • Understand system operating context, production • • • impact and cost of downtime. Document assumptions. Build the RBD and Reliability Data Register. Populate with Reliability Data and details of Maintenance Strategy / Shutdowns. Analyse the System. Update and refine over time. Conduct Sensitivity analyses.

Reliability Block Diagrams • Build Reliability Block Diagram from P&ID, system drawings, PFDs; – RBD’s represent the connections between system components from a reliability perspective. – Does not show process flow.

Reliability Block Diagrams • Build Reliability Block Diagram from P&ID, system drawings, PFDs; – RBD’s represent the connections between system components from a reliability perspective. – Does not show process flow.

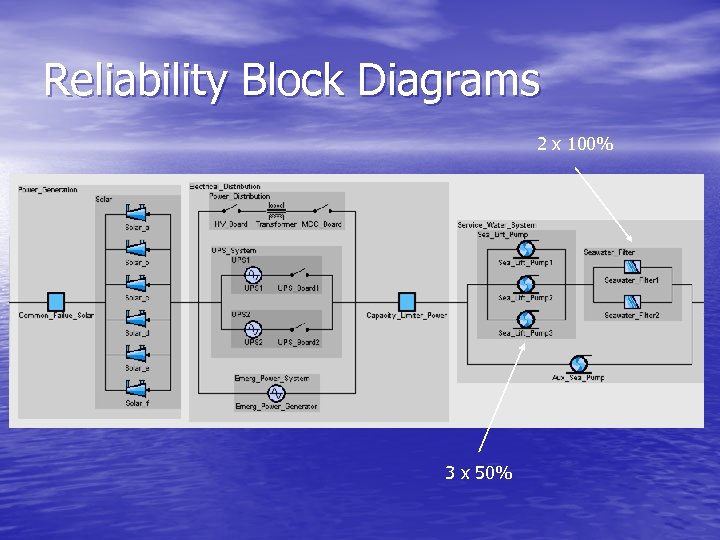

Reliability Block Diagrams 2 x 100% 3 x 50%

Reliability Block Diagrams 2 x 100% 3 x 50%

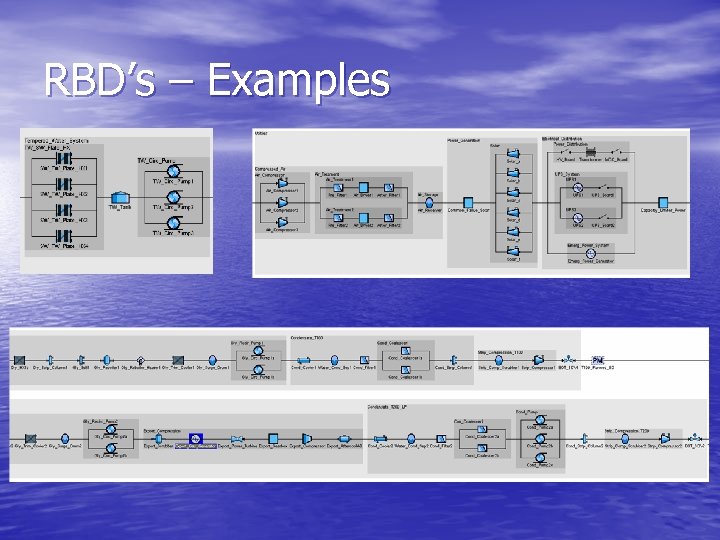

RBD’s – Examples

RBD’s – Examples

Operating Context – what we need • Design Capacity of each block. • Redundancy. • Impact on production – No impact – why in the model? • Single Point Vulnerabilities! – Very important – do not miss these. • Bypass capacity on failure – Inbuilt work arounds that protect production.

Operating Context – what we need • Design Capacity of each block. • Redundancy. • Impact on production – No impact – why in the model? • Single Point Vulnerabilities! – Very important – do not miss these. • Bypass capacity on failure – Inbuilt work arounds that protect production.

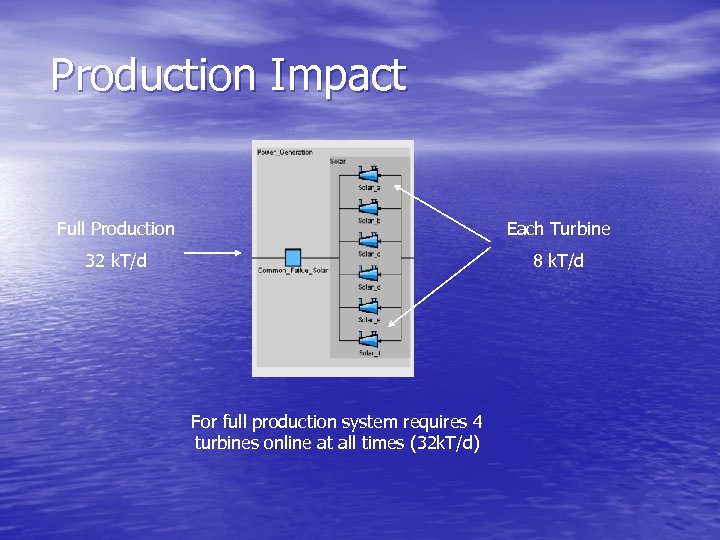

Production Impact Full Production Each Turbine 32 k. T/d 8 k. T/d For full production system requires 4 turbines online at all times (32 k. T/d)

Production Impact Full Production Each Turbine 32 k. T/d 8 k. T/d For full production system requires 4 turbines online at all times (32 k. T/d)

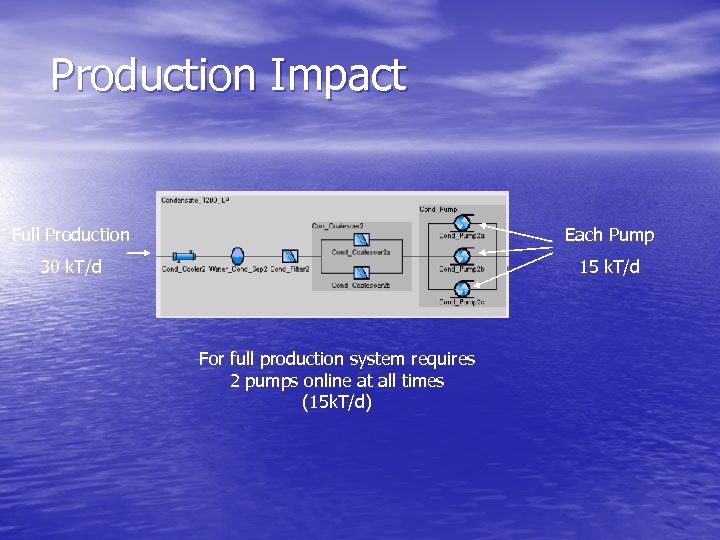

Production Impact Full Production Each Pump 30 k. T/d 15 k. T/d For full production system requires 2 pumps online at all times (15 k. T/d)

Production Impact Full Production Each Pump 30 k. T/d 15 k. T/d For full production system requires 2 pumps online at all times (15 k. T/d)

Production Impact • Bypass capacity – refines model with actual production impact – also helps with buy in from operations. • Must understand the linkages between key elements in the model.

Production Impact • Bypass capacity – refines model with actual production impact – also helps with buy in from operations. • Must understand the linkages between key elements in the model.

Failure Modes / Reliability Data • Understand dominant functional failures. • Reliability data sourced from – CMMS & Facility Operating History. – Experienced operators. – OREDA. – Vendor.

Failure Modes / Reliability Data • Understand dominant functional failures. • Reliability data sourced from – CMMS & Facility Operating History. – Experienced operators. – OREDA. – Vendor.

Reliability Data • CMMS – Maintenance and failure history. – Data accuracy? Job recording? – How accurate is this across industry? – Be careful – garbage in , garbage out. • Facility Operating / Trip history – Often stored outside CMMS. – See your friendly Reliability Engineer.

Reliability Data • CMMS – Maintenance and failure history. – Data accuracy? Job recording? – How accurate is this across industry? – Be careful – garbage in , garbage out. • Facility Operating / Trip history – Often stored outside CMMS. – See your friendly Reliability Engineer.

Reliability Data • Operators & Maintenance Resources – Very valuable information resource. – BUT – difficult to quantify losses without data. – Useful information on Bypass capacity. – Engage operations and maintenance where possible.

Reliability Data • Operators & Maintenance Resources – Very valuable information resource. – BUT – difficult to quantify losses without data. – Useful information on Bypass capacity. – Engage operations and maintenance where possible.

Reliability Data • Vendors and OREDA – Some vendors have good history – check operating context and environment. – OREDA is of use – ensure a reasonable population of equipment is available. • Useful Reliability Data is available – understand limitations and use with care.

Reliability Data • Vendors and OREDA – Some vendors have good history – check operating context and environment. – OREDA is of use – ensure a reasonable population of equipment is available. • Useful Reliability Data is available – understand limitations and use with care.

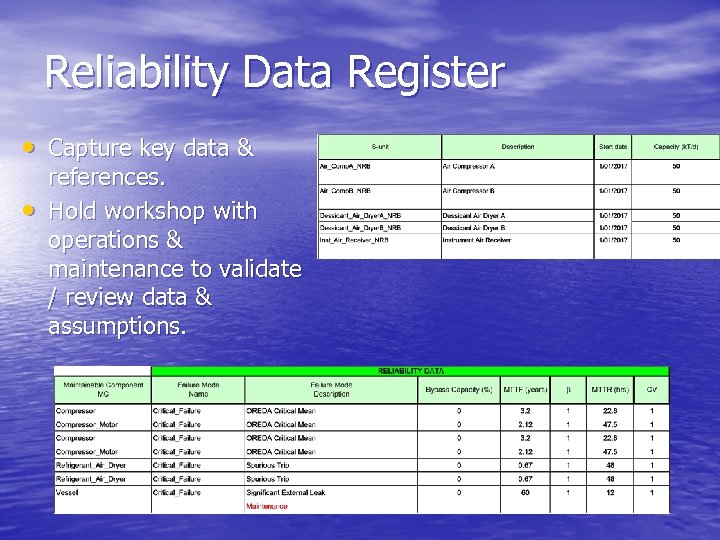

Reliability Data Register • Capture key data & • references. Hold workshop with operations & maintenance to validate / review data & assumptions.

Reliability Data Register • Capture key data & • references. Hold workshop with operations & maintenance to validate / review data & assumptions.

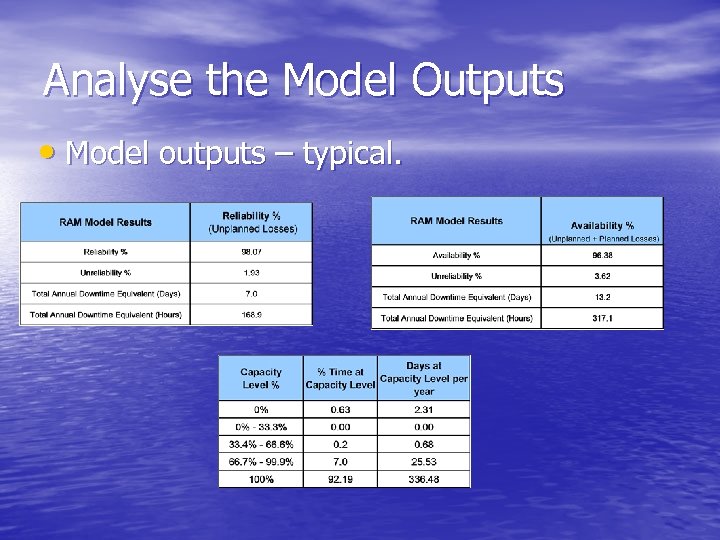

Analyse the Model Outputs • Model outputs – typical.

Analyse the Model Outputs • Model outputs – typical.

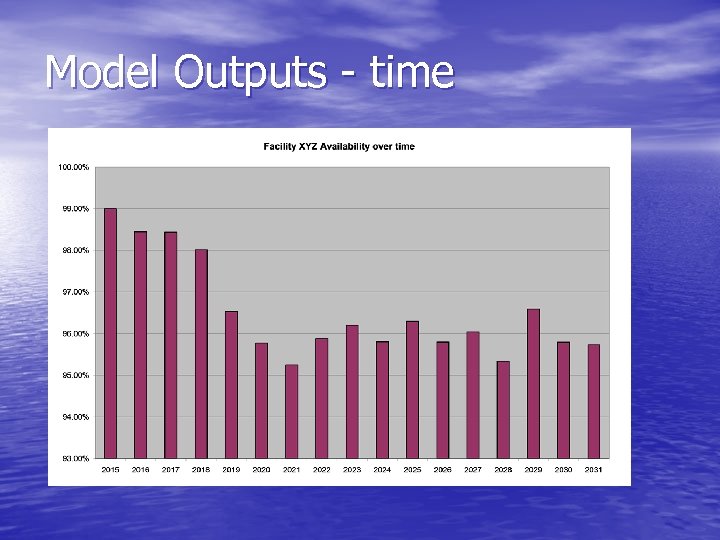

Model Outputs - time

Model Outputs - time

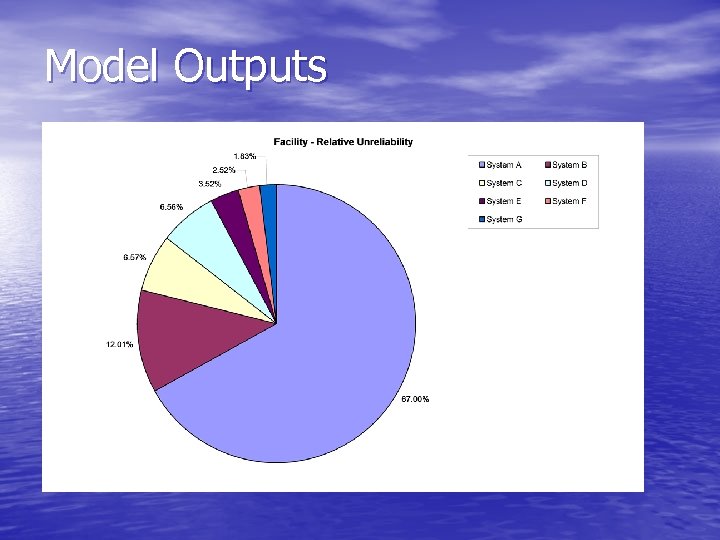

Model Outputs

Model Outputs

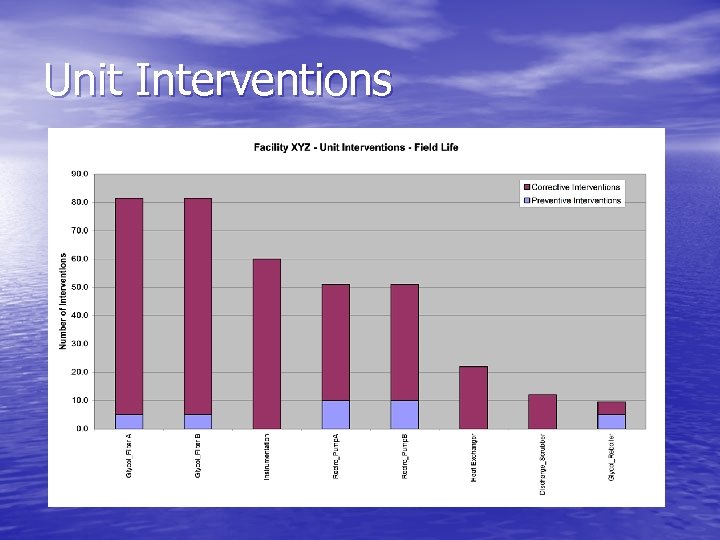

Unit Interventions

Unit Interventions

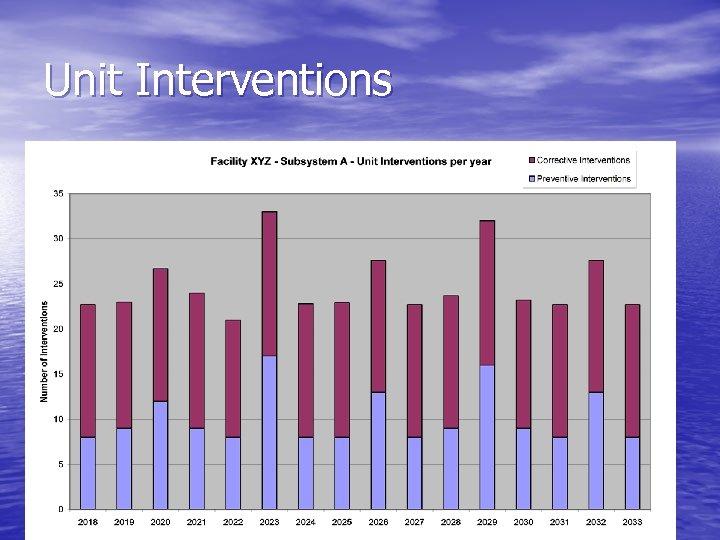

Unit Interventions

Unit Interventions

Update and Refining the Model • Assess Design Changes – Latest updates. – Quantify improvements. – Incorporate maintenance (RCM). • Shutdown analysis. • Sensitivity Studies. • Production Profiles.

Update and Refining the Model • Assess Design Changes – Latest updates. – Quantify improvements. – Incorporate maintenance (RCM). • Shutdown analysis. • Sensitivity Studies. • Production Profiles.

Design Changes • Add newer component (high reliability) – System availability before – 98. 0% – System availability after - 99. 2% • Improvement of 1. 2% or 4. 4 days production @ $1 million per day = $4. 4 m savings

Design Changes • Add newer component (high reliability) – System availability before – 98. 0% – System availability after - 99. 2% • Improvement of 1. 2% or 4. 4 days production @ $1 million per day = $4. 4 m savings

Design Changes • Redesign to save cost! • Reduction in availability 0. 5% or 1. 8 days production @ $1 million per day = $1. 8 m COST to business. • Can demonstrate impact of changes on facility performance – better decisions are made.

Design Changes • Redesign to save cost! • Reduction in availability 0. 5% or 1. 8 days production @ $1 million per day = $1. 8 m COST to business. • Can demonstrate impact of changes on facility performance – better decisions are made.

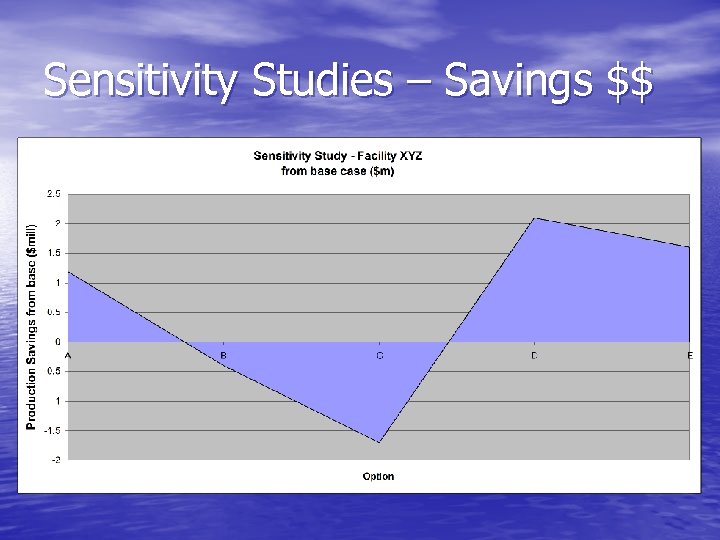

Sensitivity Studies • Critical Equipment improvement options; – water washing frequencies. – more reliable equipment. – maint strategy changes. – Redundancy installed. • Show me the money $$$$! • Shutdown analysis – modify frequency and durations – optimise.

Sensitivity Studies • Critical Equipment improvement options; – water washing frequencies. – more reliable equipment. – maint strategy changes. – Redundancy installed. • Show me the money $$$$! • Shutdown analysis – modify frequency and durations – optimise.

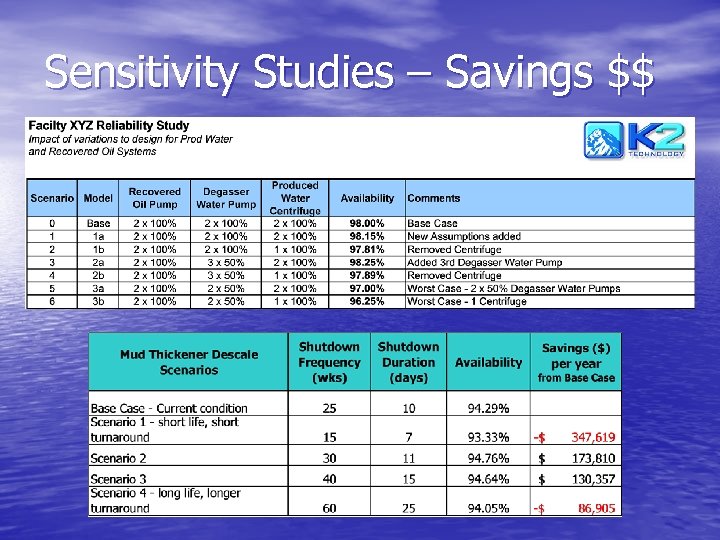

Sensitivity Studies – Savings $$

Sensitivity Studies – Savings $$

Sensitivity Studies – Savings $$

Sensitivity Studies – Savings $$

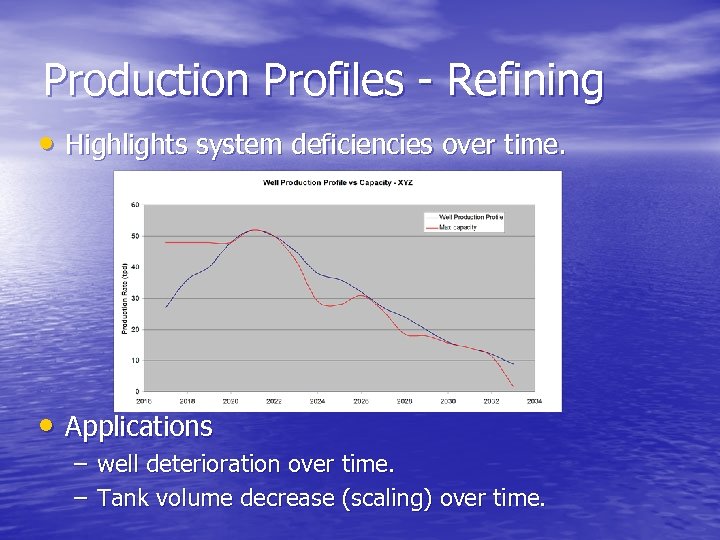

Production Profiles - Refining • Highlights system deficiencies over time. • Applications – well deterioration over time. – Tank volume decrease (scaling) over time.

Production Profiles - Refining • Highlights system deficiencies over time. • Applications – well deterioration over time. – Tank volume decrease (scaling) over time.

Improving Business Decisions • Predict performance over time. • Validate design changes. • Quantify ($) cost and impact of failure. • Identifies Critical Equipment – where to focus improvement efforts. – where to focus training. – where to consider redundancy. – where to hold critical spares (MTTR).

Improving Business Decisions • Predict performance over time. • Validate design changes. • Quantify ($) cost and impact of failure. • Identifies Critical Equipment – where to focus improvement efforts. – where to focus training. – where to consider redundancy. – where to hold critical spares (MTTR).

Asset’s Operations Phase • Traditionally this is done poorly (if at all). • Barriers – Lack of buy in / support from operations & maintenance. – involve O&M in model build and assumptions. – Modelling – inaccuracy, no understanding of operating context. – Rigorous review of data and facility configuration – engage operations.

Asset’s Operations Phase • Traditionally this is done poorly (if at all). • Barriers – Lack of buy in / support from operations & maintenance. – involve O&M in model build and assumptions. – Modelling – inaccuracy, no understanding of operating context. – Rigorous review of data and facility configuration – engage operations.

Asset’s Operations Phase • Barriers – Lack of confidence in model / data. – Use valid data, document assumptions, involve operations & maintenance. • Review actual performance compared to design over time – feedback into model. • Consider the model to be “live” – regularly update to improve accuracy.

Asset’s Operations Phase • Barriers – Lack of confidence in model / data. – Use valid data, document assumptions, involve operations & maintenance. • Review actual performance compared to design over time – feedback into model. • Consider the model to be “live” – regularly update to improve accuracy.

Operations Phase - Benefits • Highlight improvement opportunities. • Justify cost of upgrades. • Quantify BENEFITS of past projects. • Assess effectiveness of maintenance. • Assess risk of shutdowns – optimize shutdown intervals.

Operations Phase - Benefits • Highlight improvement opportunities. • Justify cost of upgrades. • Quantify BENEFITS of past projects. • Assess effectiveness of maintenance. • Assess risk of shutdowns – optimize shutdown intervals.

Summary • RAM modelling is a valuable tool in Reliability Engineering. • Important to use valid data and involve operations & maintenance. • Useful in all industries, for large and small projects. • Can improve business decisions by quantifying loss and benefits in $ terms.

Summary • RAM modelling is a valuable tool in Reliability Engineering. • Important to use valid data and involve operations & maintenance. • Useful in all industries, for large and small projects. • Can improve business decisions by quantifying loss and benefits in $ terms.

Questions?

Questions?