ashing ~ 1100°C • • preheated airflow – to avoid cooling & ensure good uniformity rapid air changes – to provide air/oxygen and carry fumes away heavy duty ceramic material construction - to ensure longevity elements covered by insulation – to ensure no contamination

ashing ~ 1100°C • • preheated airflow – to avoid cooling & ensure good uniformity rapid air changes – to provide air/oxygen and carry fumes away heavy duty ceramic material construction - to ensure longevity elements covered by insulation – to ensure no contamination

ashing ~ 1100°C • preheated airflow – to avoid cooling • rapid air changes – to provide air/oxygen and carry fumes away heavy duty ceramic material construction - to ensure longevity elements covered by insulation – to ensure no contamination • • AAF 11/3 & 7 Design

ashing ~ 1100°C • preheated airflow – to avoid cooling • rapid air changes – to provide air/oxygen and carry fumes away heavy duty ceramic material construction - to ensure longevity elements covered by insulation – to ensure no contamination • • AAF 11/3 & 7 Design

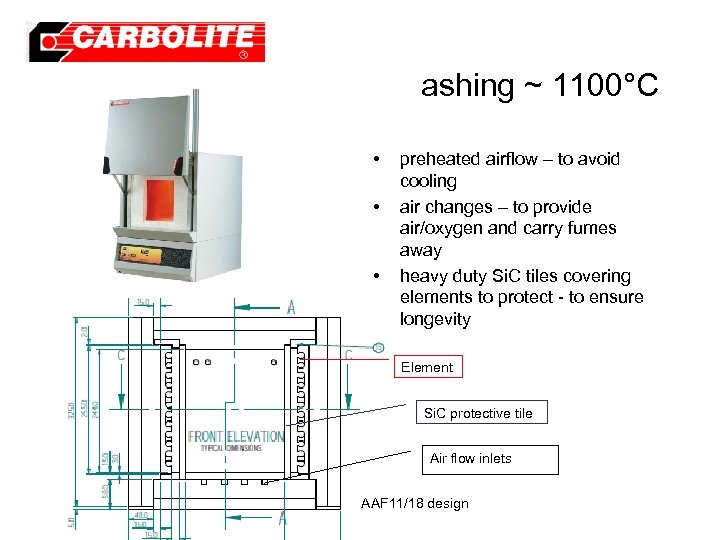

ashing ~ 1100°C • • • preheated airflow – to avoid cooling air changes – to provide air/oxygen and carry fumes away heavy duty Si. C tiles covering elements to protect - to ensure longevity Element Si. C protective tile AAF 11/18 Air flow inlets AAF 11/18 design

ashing ~ 1100°C • • • preheated airflow – to avoid cooling air changes – to provide air/oxygen and carry fumes away heavy duty Si. C tiles covering elements to protect - to ensure longevity Element Si. C protective tile AAF 11/18 Air flow inlets AAF 11/18 design

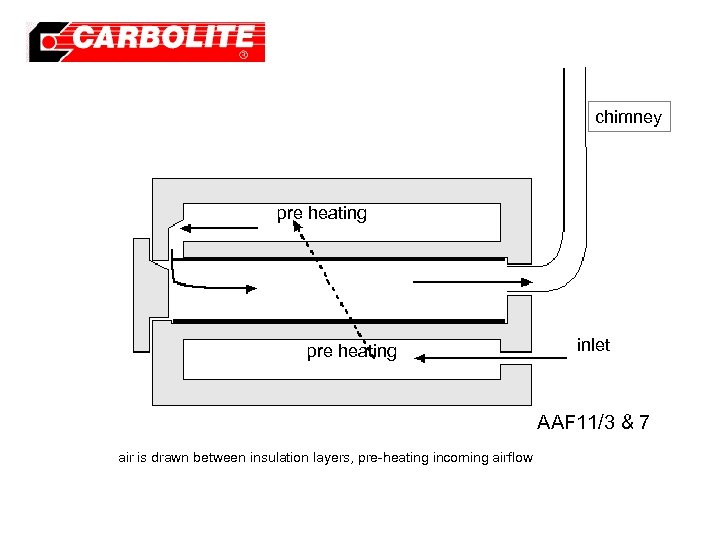

chimney pre heating inlet AAF 11/3 & 7 air is drawn between insulation layers, pre-heating incoming airflow

chimney pre heating inlet AAF 11/3 & 7 air is drawn between insulation layers, pre-heating incoming airflow

uniformity graph The coloured lines indicate temp measurement and therefore show good uniformity from front (left) to rear (right) of chamber

uniformity graph The coloured lines indicate temp measurement and therefore show good uniformity from front (left) to rear (right) of chamber

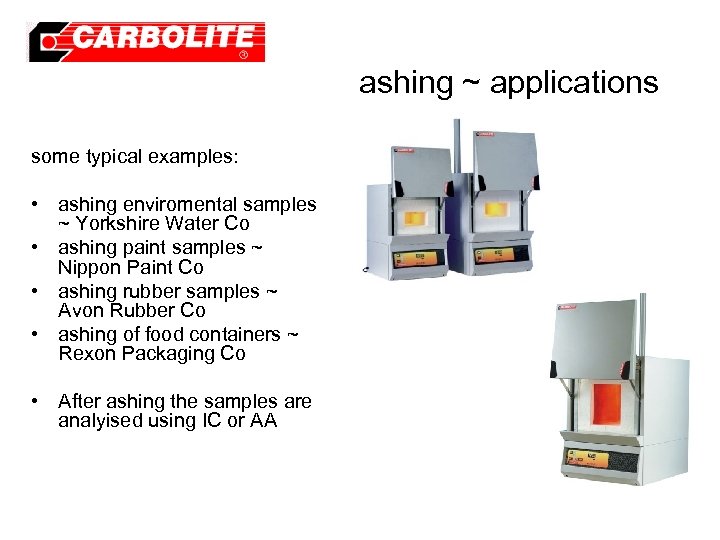

ashing ~ applications some typical examples: • ashing enviromental samples ~ Yorkshire Water Co • ashing paint samples ~ Nippon Paint Co • ashing rubber samples ~ Avon Rubber Co • ashing of food containers ~ Rexon Packaging Co • After ashing the samples are analyised using IC or AA

ashing ~ applications some typical examples: • ashing enviromental samples ~ Yorkshire Water Co • ashing paint samples ~ Nippon Paint Co • ashing rubber samples ~ Avon Rubber Co • ashing of food containers ~ Rexon Packaging Co • After ashing the samples are analyised using IC or AA