eaf180212c1458be135ee19338bfb755.ppt

- Количество слайдов: 30

Arnott’s Biscuits Implementing an Overall Equipment Effectiveness (OEE) Metric March 2006

Today’s Agenda Ø Who we are Ø OEE Theory for Arnotts Ø Implementation Process ØUsing OEE

An overview… Ø 140 years ago, William Arnott opens bakery in Hunter Street, Newcastle Ø Specialised in selling bread, pies and biscuits Ø In 1877, first substantial Arnott’s biscuit factory built Ø Three years later, Arnott’s was employing 50 staff and producing 1. 5 tonnes of biscuits a day Ø In 1882, widespread distribution commenced: Ø wholesalers engaged Ø depot established on Sydney wharves

An overview… Ø Expansion followed throughout SA, WA, Qld, Tasmania, Java, the Pacific Islands, Singapore, India & South Africa Ø 1901 - William Arnott’s five sons take control of the firm after his death Ø 1904 – Arnott’s became a limited liability company Ø Four years later, Homebush factory opens. By 1929, it employed 1800 people, made 150 types of biscuit and had an annual output of 10, 000 tonnes

An overview… Ø To drive expansion, between 1949 -51, Arnott’s gained control of: Ø Morrows of Brisbane, Adelaide’s Motteram’s & Mills Ware of Fremantle Ø 1970 – Arnott’s listed on the ASX Ø 1997 – Arnott’s became a wholly owned subsidiary of Campbell Soup Company Ø 2002 – Arnott’s acquired Snack Foods Limited

Our scope… N Japan China W India Thailand Taiwan Hong Kong E Philippines Malaysia Singapore Papua New Guinea Tahiti Indonesia Australia S New Zealand

An overview… 11 manufacturing sites 4 $1. 3 b sales 8, 500 business units employees

Arnott’s Snackfoods Australia: #2

Campbell’s Australia: #1 New Zealand: #2

Asia PNG: #1 biscuits; #2 snacks Indonesia: #2 biscuits Malaysia: #1 soup Hong Kong: #1 soup & stock

Arnott’s Biscuits Australia: #1 New Zealand: #2

OEE – A Definition 1. OEE – Overall Equipment Effectiveness is a method of measuring how well we use our machines and processes to convert raw materials into finished saleable goods 2. How well do we convert flour, fat and sugar into biscuits 3. 4. 5. 6. 7. Encompasses all loses generated through the process It is zero based It is a benchmarking tool Enables continuous improvement tracking Focus is on productive utilisation of equipment not labour utilisation or product value

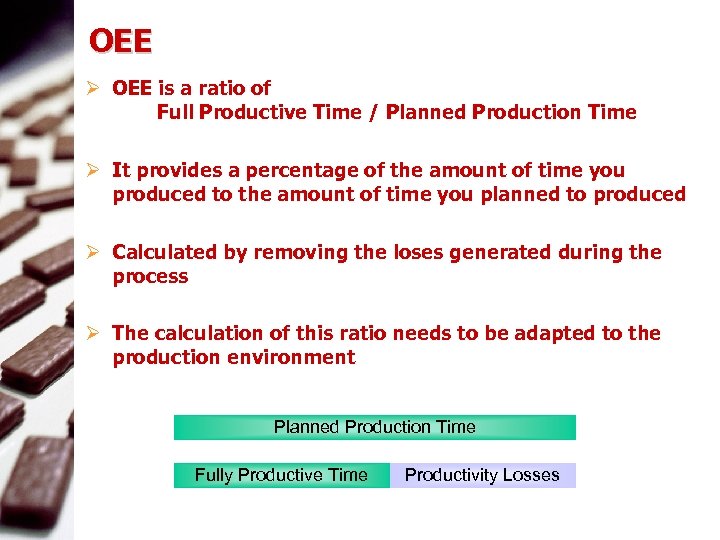

OEE Ø OEE is a ratio of Full Productive Time / Planned Production Time Ø It provides a percentage of the amount of time you produced to the amount of time you planned to produced Ø Calculated by removing the loses generated during the process Ø The calculation of this ratio needs to be adapted to the production environment Planned Production Time Fully Productive Time Productivity Losses

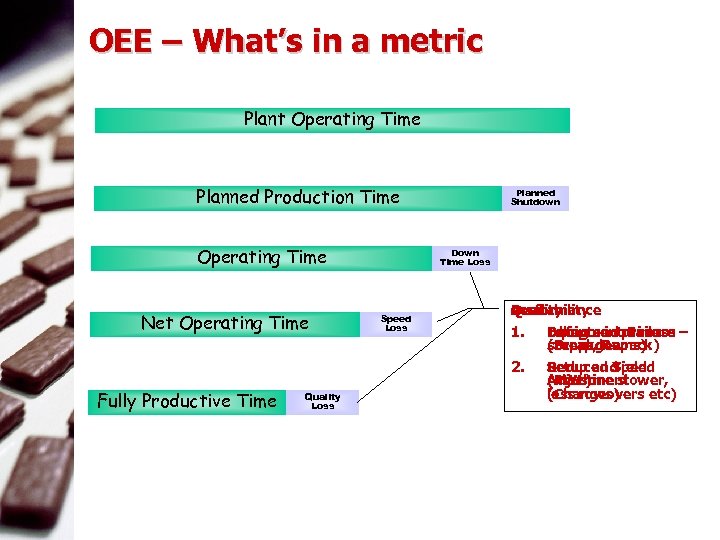

OEE – What’s in a metric Plant Operating Time Planned Production Time Operating Time Net Operating Time Planned Shutdown Down Time Loss Speed Loss Quality Performance Availability Quality Loss Defects in process Idling and minor Equipment Failure – (Scrap, Repack) stoppages (Breakdowns) 2. Fully Productive Time 1. Reduced Yield Reduced Speed Setup and (PWL) (machine slower, Adjustment less rows) (Changeovers etc)

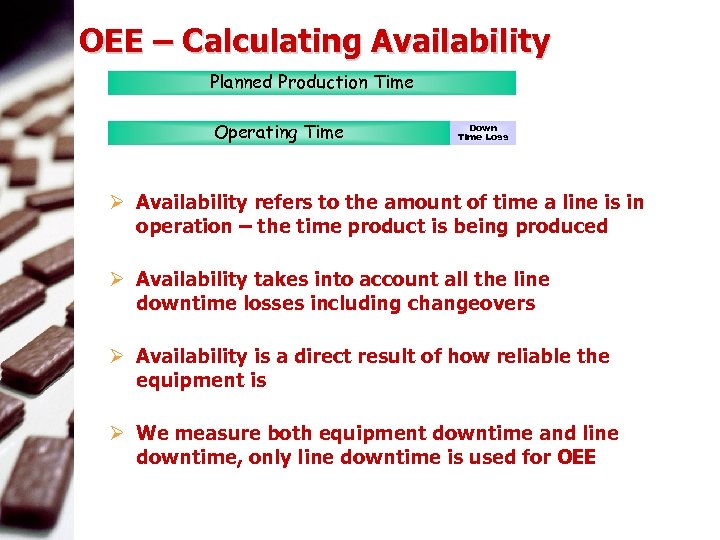

OEE – Calculating Availability Planned Production Time Operating Time Down Time Loss Ø Availability refers to the amount of time a line is in operation – the time product is being produced Ø Availability takes into account all the line downtime losses including changeovers Ø Availability is a direct result of how reliable the equipment is Ø We measure both equipment downtime and line downtime, only line downtime is used for OEE

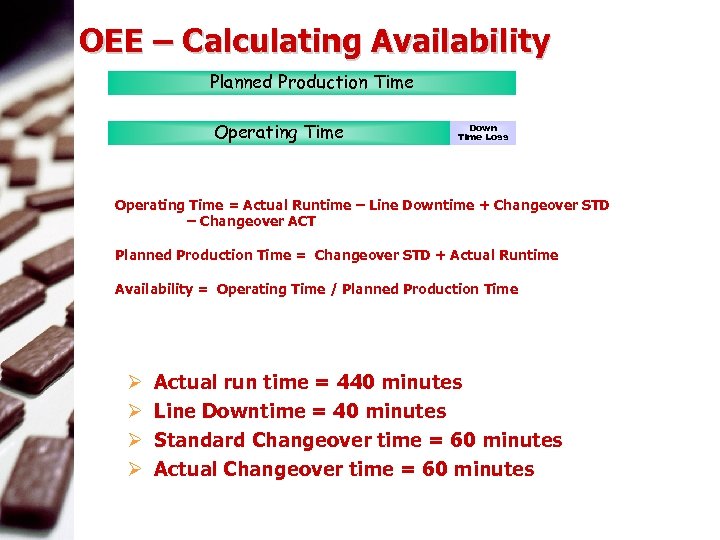

OEE – Calculating Availability Planned Production Time Operating Time Down Time Loss Operating Time = Actual Runtime – Line Downtime + Changeover STD – Changeover ACT Planned Production Time = Changeover STD + Actual Runtime Availability = Operating Time / Planned Production Time Ø Ø Actual run time = 440 minutes Line Downtime = 40 minutes Standard Changeover time = 60 minutes Actual Changeover time = 60 minutes

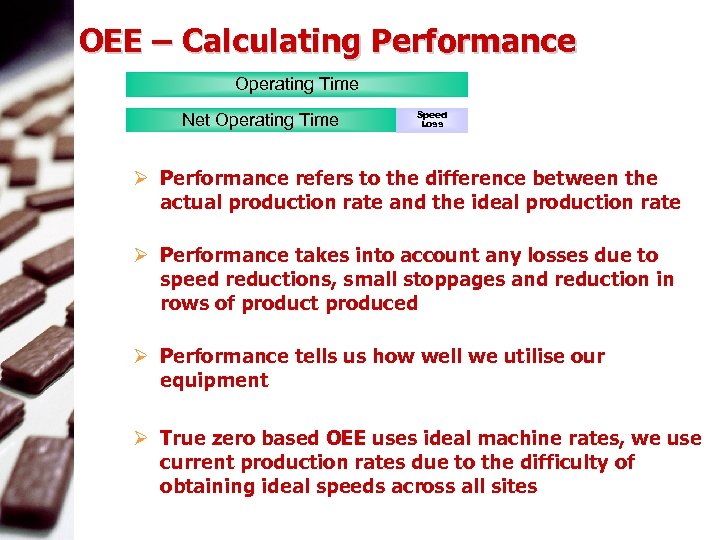

OEE – Calculating Performance Operating Time Net Operating Time Speed Loss Ø Performance refers to the difference between the actual production rate and the ideal production rate Ø Performance takes into account any losses due to speed reductions, small stoppages and reduction in rows of product produced Ø Performance tells us how well we utilise our equipment Ø True zero based OEE uses ideal machine rates, we use current production rates due to the difficulty of obtaining ideal speeds across all sites

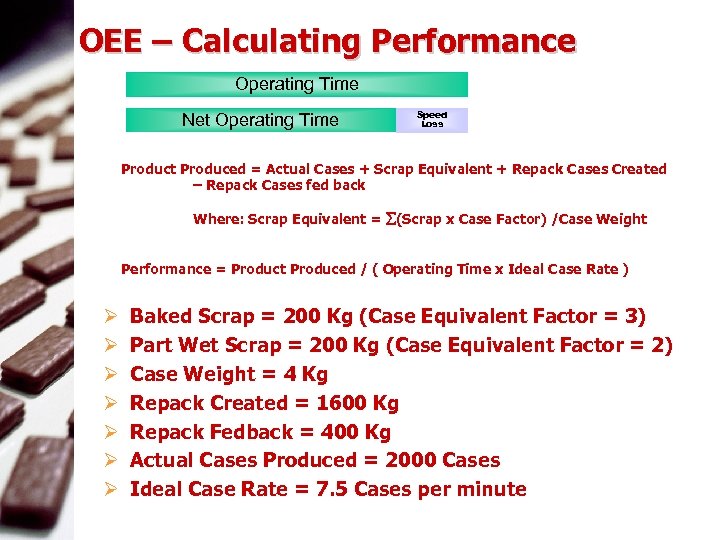

OEE – Calculating Performance Operating Time Net Operating Time Speed Loss Product Produced = Actual Cases + Scrap Equivalent + Repack Cases Created – Repack Cases fed back Where: Scrap Equivalent = (Scrap x Case Factor) /Case Weight Performance = Product Produced / ( Operating Time x Ideal Case Rate ) Ø Ø Ø Ø Baked Scrap = 200 Kg (Case Equivalent Factor = 3) Part Wet Scrap = 200 Kg (Case Equivalent Factor = 2) Case Weight = 4 Kg Repack Created = 1600 Kg Repack Fedback = 400 Kg Actual Cases Produced = 2000 Cases Ideal Case Rate = 7. 5 Cases per minute

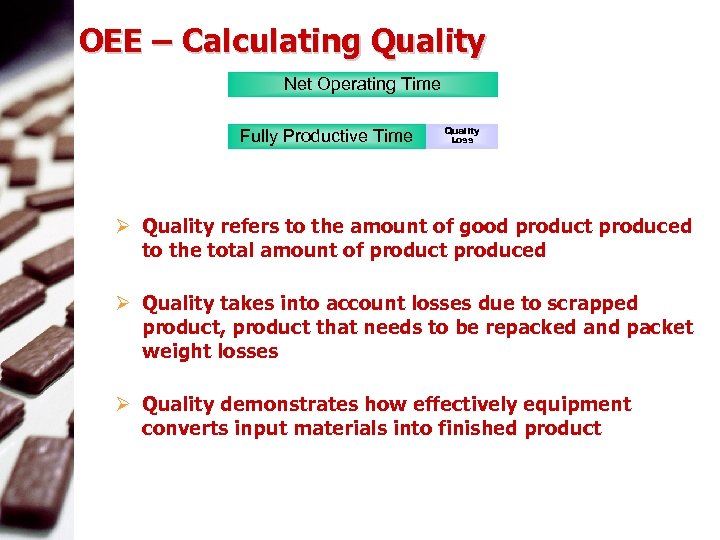

OEE – Calculating Quality Net Operating Time Fully Productive Time Quality Loss Ø Quality refers to the amount of good product produced to the total amount of product produced Ø Quality takes into account losses due to scrapped product, product that needs to be repacked and packet weight losses Ø Quality demonstrates how effectively equipment converts input materials into finished product

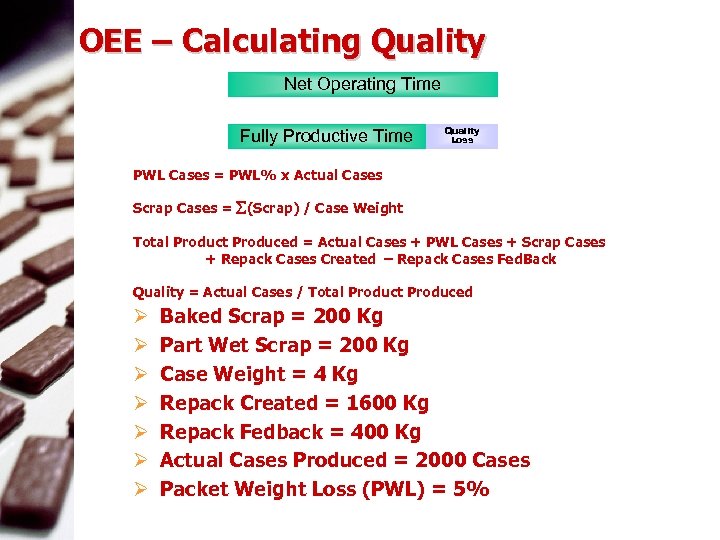

OEE – Calculating Quality Net Operating Time Fully Productive Time Quality Loss PWL Cases = PWL% x Actual Cases Scrap Cases = (Scrap) / Case Weight Total Product Produced = Actual Cases + PWL Cases + Scrap Cases + Repack Cases Created – Repack Cases Fed. Back Quality = Actual Cases / Total Product Produced Ø Ø Ø Ø Baked Scrap = 200 Kg Part Wet Scrap = 200 Kg Case Weight = 4 Kg Repack Created = 1600 Kg Repack Fedback = 400 Kg Actual Cases Produced = 2000 Cases Packet Weight Loss (PWL) = 5%

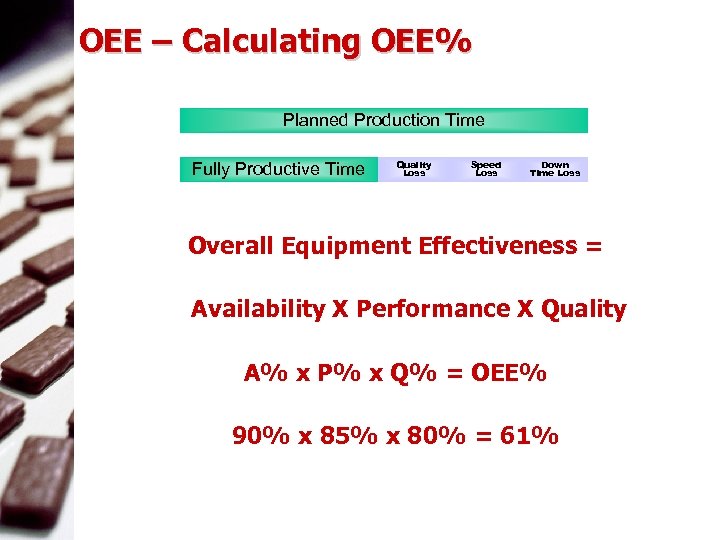

OEE – Calculating OEE% Planned Production Time Fully Productive Time Quality Loss Speed Down Productivity Losses. Loss Time Overall Equipment Effectiveness = Availability X Performance X Quality A% x P% x Q% = OEE% 90% x 85% x 80% = 61%

Implementing OEE Ø Understand your current reality Ø Environment Ø Capabilities Ø Pitfalls Ø Know your vision – where you want to get Ø System scope Ø Purpose of OEE Ø Determine how to get from reality to vision Ø Ø Ø Decide on and build the system Pilot it Communicate Maintain the system Top Level Support

Deciding on the method Ø Obtain the data required to calculate OEE Ø Over 100 machine reports are required every day at each site Ø All sites need to have the same recording methods Ø Data must be collected and processed by operators Ø Need a system that fits in with the business Ø In line production flow processes Ø Complex process paths Ø Factories have different reporting structures Ø Need to utilise existing infrastructure and labour resources Ø Decision was to build it in house Ø Required a database for multiple users Ø Low cost option Ø High level of customisation Ø Able to integrate in with each factory’s existing reporting methods

Understand the Pitfalls Ø Data is collected manually by operators Ø Training is essential Ø Database must be intuitive Ø Daily Feedback/Audit system must be set up Ø OEE score must still be meaningful if data is lacking Ø OEE requires a lot of data about each product Ø Administration and setup must be resourced Ø OEE setup must be part of new product implementation Ø Ideal production rates must be agreed to with production management Ø Reviews of data should be done periodically to validate database Ø OEE calculation is complex Ø Must calculate OEE from first principles to ensure aggregate values each individual results Ø Must calculate OEE each time so historic data uses same information as current to enable comparision

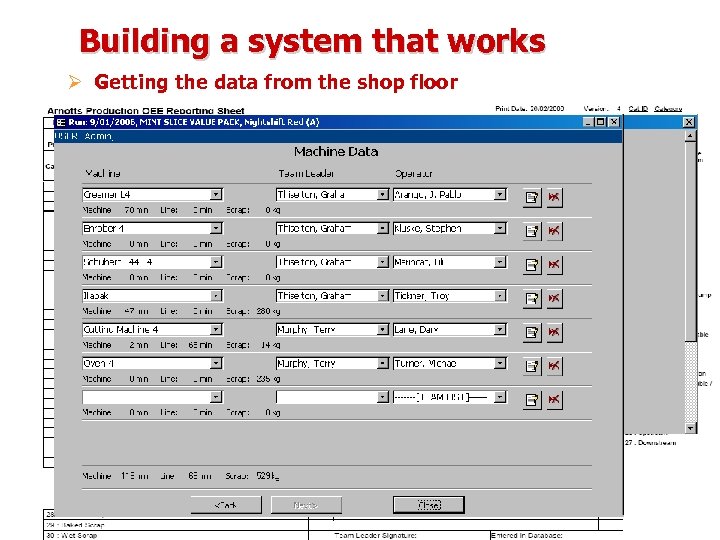

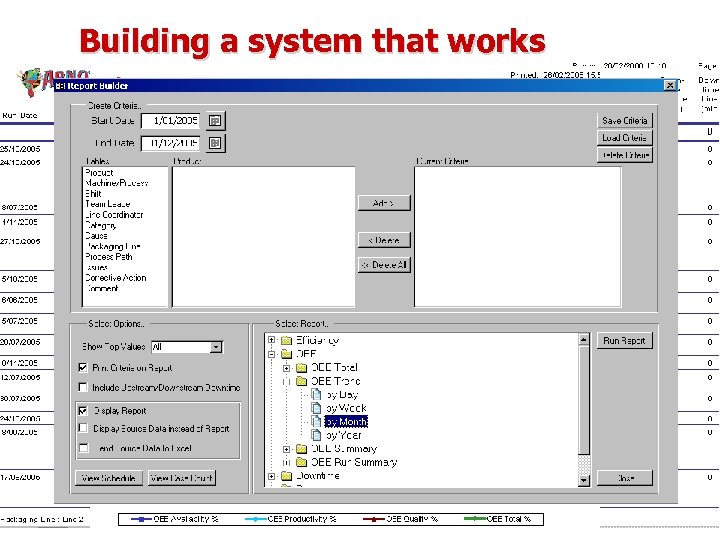

Building a system that works Ø Getting the data from the shop floor

Building a system that works Using the information Ø Daily Decision Making Meeting Ø Production/Engineering meet a 9 am and review the previous 24 hours OEE data Ø OEE is the key metric used to determine performance of run Ø Monthly Reporting Ø All factories include OEE scores for top level reporting Ø OEE needs to be reported both at high level (site) and detailed level (product/line) Ø Analysis Reviews Ø OEE and downtime results have been used as part of equipment analysis Ø Data used for justification of capital upgrades Ø Data used frequently by maintenance to investigate ongoing production issues Ø Covaris currently using data as part of our Engineering Optimisation Strategy creation

Building a system that works

Implementing the System Ø Implementing at Adelaide Ø Training and Communication Ø Small Team involvement Ø Make it easy for the users Ø Develop a daily feedback system Ø Prove it works on one line Ø Roll it out in quick succession Ø Implementing it nationally Ø Nominate a champion from each site Ø Design the database around each site’s structure Ø Set a time-line and milestones Ø Leverage learning's from each sites implementation

Top Level Support Ø OEE was determined to be the manufacturing measure for all sites Ø Manufacturing Director embraced OEE and has included it as a key metric in our National Manufacturing Vision Ø Resources were provided from each site to champion its implementation Ø OEE measures have been embraced and are in use by all manufacturing Ø OEE metrics are included in all manager’s individual performance plans

Where we are now Ø Ø Ø All four biscuits sites are actively calculating OEE has been communicate as a key strategic metric throughout the business People on the shop floor are being trained in the OEE Metric Database has been in use at some sites for over one year Data is accessible on all PC’s throughout each factory to all computer users Continuous Improvement teams are actively using the database to determine root causes to safety, quality and production issues

eaf180212c1458be135ee19338bfb755.ppt