3865cf9fb9a9577669d028a039224cc4.ppt

- Количество слайдов: 27

AQUAREC Project Centre for Water Systems D. Joksimovic

AQUAREC Project Centre for Water Systems D. Joksimovic

Presentation Outline • Background • Integrated Decision Support Systems in Water Reuse • WTRNet Structure and Features • Development of design principles • Conclusions

Presentation Outline • Background • Integrated Decision Support Systems in Water Reuse • WTRNet Structure and Features • Development of design principles • Conclusions

Background • AQUAREC Integrated Concepts for Reuse of Upgraded Wastewater • Objectives – Provision of policy guidelines and water quality standards for municipal wastewater reclamation and reuse – Collection and validation of best management practices – Development of reference manuals and as step by step guides for future end-users – Evaluation, selection and standardization of technological concepts and components for wastewater recycling

Background • AQUAREC Integrated Concepts for Reuse of Upgraded Wastewater • Objectives – Provision of policy guidelines and water quality standards for municipal wastewater reclamation and reuse – Collection and validation of best management practices – Development of reference manuals and as step by step guides for future end-users – Evaluation, selection and standardization of technological concepts and components for wastewater recycling

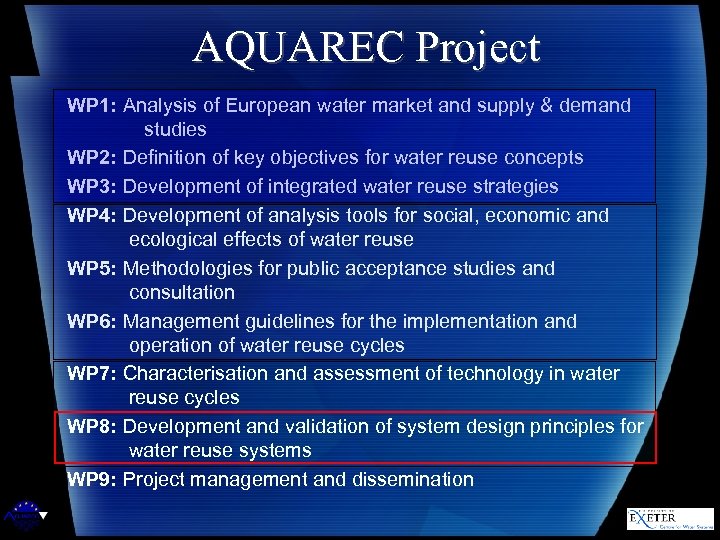

AQUAREC Project WP 1: Analysis of European water market and supply & demand studies WP 2: Definition of key objectives for water reuse concepts WP 3: Development of integrated water reuse strategies WP 4: Development of analysis tools for social, economic and ecological effects of water reuse WP 5: Methodologies for public acceptance studies and consultation WP 6: Management guidelines for the implementation and operation of water reuse cycles WP 7: Characterisation and assessment of technology in water reuse cycles WP 8: Development and validation of system design principles for water reuse systems WP 9: Project management and dissemination

AQUAREC Project WP 1: Analysis of European water market and supply & demand studies WP 2: Definition of key objectives for water reuse concepts WP 3: Development of integrated water reuse strategies WP 4: Development of analysis tools for social, economic and ecological effects of water reuse WP 5: Methodologies for public acceptance studies and consultation WP 6: Management guidelines for the implementation and operation of water reuse cycles WP 7: Characterisation and assessment of technology in water reuse cycles WP 8: Development and validation of system design principles for water reuse systems WP 9: Project management and dissemination

Background • AQUAREC Work Package 8 Objective Develop and validate design principles for water reuse systems by using simulation and optimisation software – Infrastructural aspects of wastewater reuse systems – Integration of distribution and treatment elements – Assess feasibility of decentralised water reuse systems – Systems integration and compatibility with industrial water supply systems

Background • AQUAREC Work Package 8 Objective Develop and validate design principles for water reuse systems by using simulation and optimisation software – Infrastructural aspects of wastewater reuse systems – Integration of distribution and treatment elements – Assess feasibility of decentralised water reuse systems – Systems integration and compatibility with industrial water supply systems

Integrated DSS in Water Reuse Wastewater Influent Reclaimed Water Treatment Train Simulation Model (Synthesis and Evaluation) WWTP - Potential Reclaimed Water Users - Storage Facilities - Pumping Facilities - Distributed Treatment

Integrated DSS in Water Reuse Wastewater Influent Reclaimed Water Treatment Train Simulation Model (Synthesis and Evaluation) WWTP - Potential Reclaimed Water Users - Storage Facilities - Pumping Facilities - Distributed Treatment

Integrated DSS in Water Reuse • Generation and screening of treatment trains – Address limitations of existing tools • Open and user-friendly environment • Suggestions for complete treatment trains • Rules for combining unit processes • Water distribution systems – Network topology – Sizing of pumping, transmission and storage facilities

Integrated DSS in Water Reuse • Generation and screening of treatment trains – Address limitations of existing tools • Open and user-friendly environment • Suggestions for complete treatment trains • Rules for combining unit processes • Water distribution systems – Network topology – Sizing of pumping, transmission and storage facilities

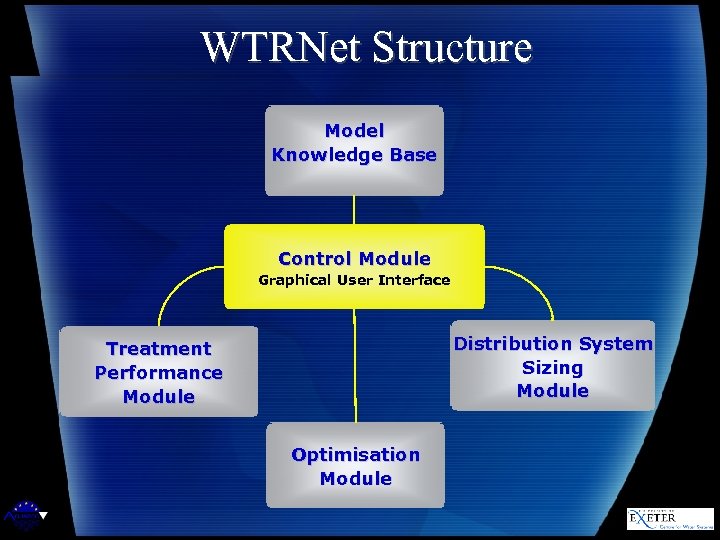

WTRNet Structure Model Knowledge Base Control Module Graphical User Interface Distribution System Sizing Module Treatment Performance Module Optimisation Module

WTRNet Structure Model Knowledge Base Control Module Graphical User Interface Distribution System Sizing Module Treatment Performance Module Optimisation Module

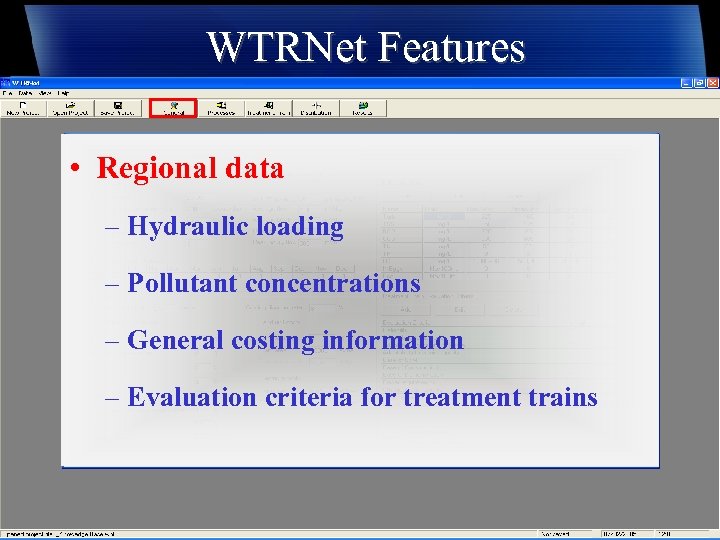

WTRNet Features • Regional data – Hydraulic loading – Pollutant concentrations – General costing information – Evaluation criteria for treatment trains

WTRNet Features • Regional data – Hydraulic loading – Pollutant concentrations – General costing information – Evaluation criteria for treatment trains

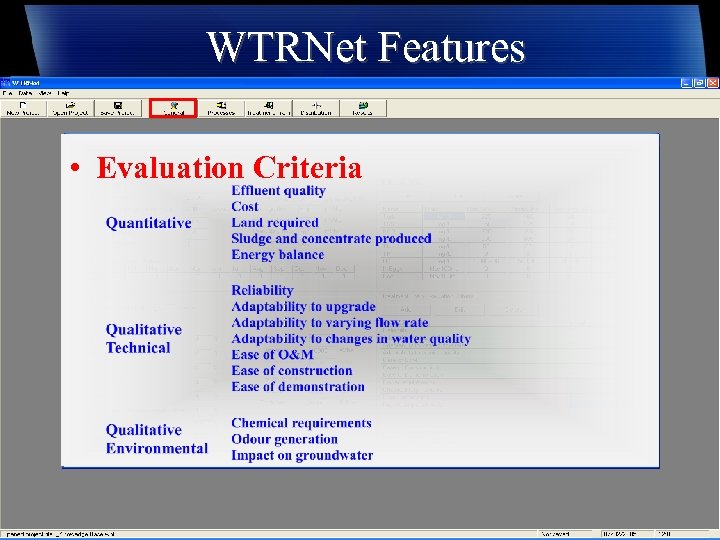

WTRNet Features • Evaluation Criteria

WTRNet Features • Evaluation Criteria

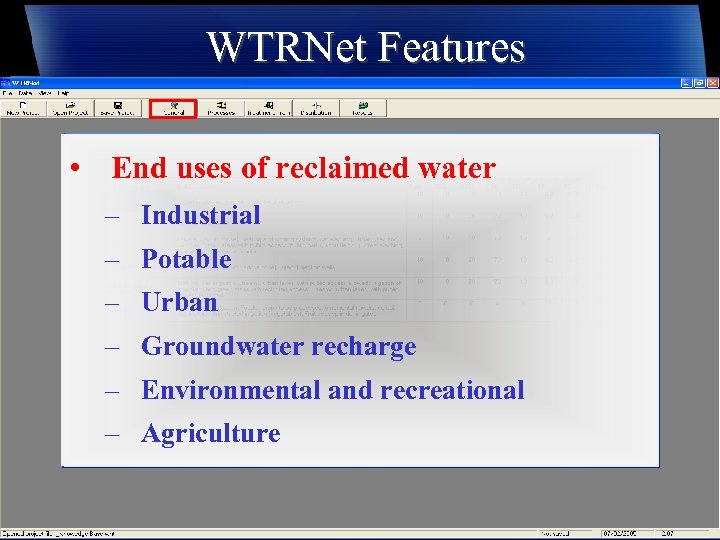

WTRNet Features • End uses of reclaimed water – Industrial – Potable – Urban – Groundwater recharge – Environmental and recreational – Agriculture

WTRNet Features • End uses of reclaimed water – Industrial – Potable – Urban – Groundwater recharge – Environmental and recreational – Agriculture

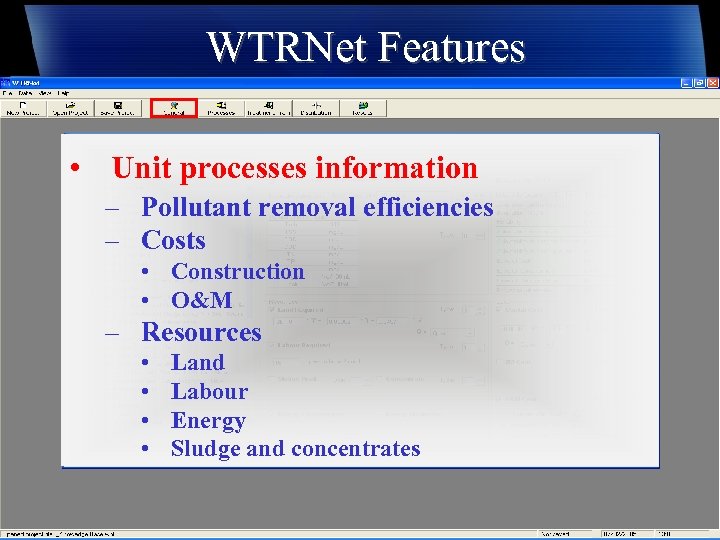

WTRNet Features • Unit processes information – Pollutant removal efficiencies – Costs • Construction • O&M – Resources • • Land Labour Energy Sludge and concentrates

WTRNet Features • Unit processes information – Pollutant removal efficiencies – Costs • Construction • O&M – Resources • • Land Labour Energy Sludge and concentrates

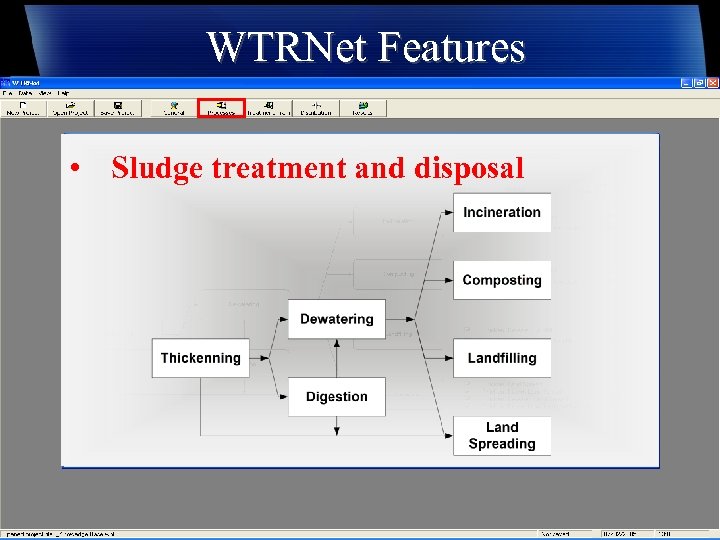

WTRNet Features • Sludge treatment and disposal

WTRNet Features • Sludge treatment and disposal

WTRNet Features

WTRNet Features

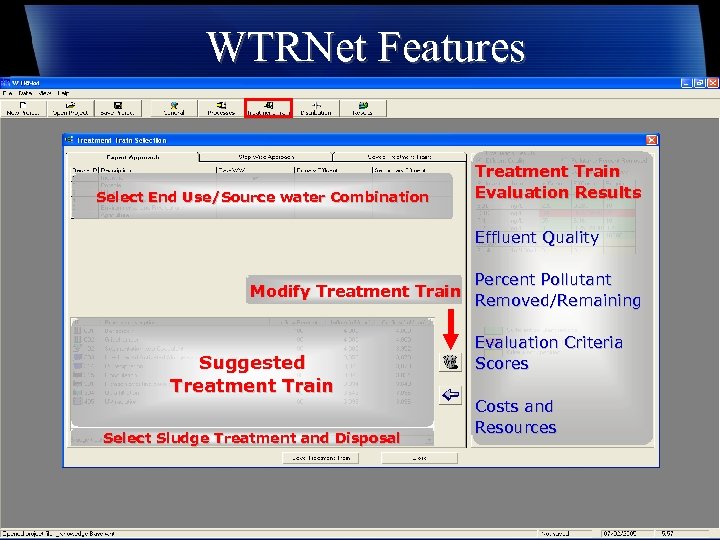

WTRNet Features Select End Use/Source water Combination Treatment Train Evaluation Results Effluent Quality Modify Treatment Train Suggested Treatment Train Select Sludge Treatment and Disposal Percent Pollutant Removed/Remaining Evaluation Criteria Scores Costs and Resources

WTRNet Features Select End Use/Source water Combination Treatment Train Evaluation Results Effluent Quality Modify Treatment Train Suggested Treatment Train Select Sludge Treatment and Disposal Percent Pollutant Removed/Remaining Evaluation Criteria Scores Costs and Resources

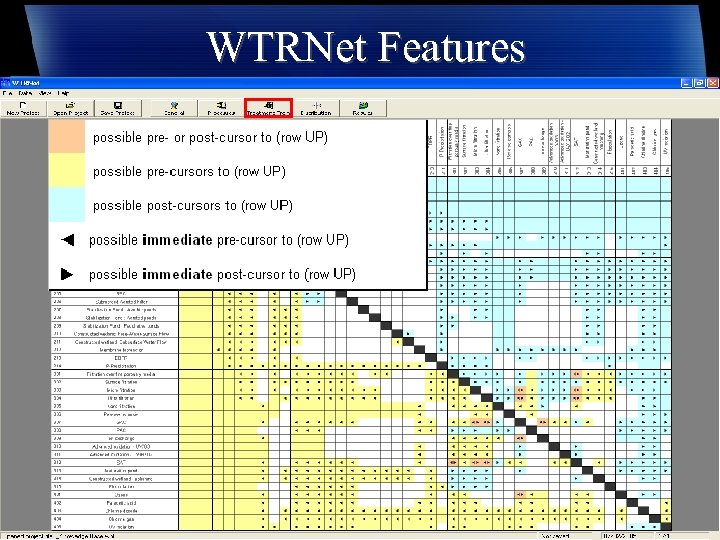

WTRNet Features Select End Use and Source water Add More Processes by Selecting From Lists of Possible Pre- and Post-cursors Add Unit Process to Treatment Train Select Sludge Treatment and Disposal Treatment Train Evaluation Results Effluent Quality Percent Pollutant Removed/Remaining Evaluation Criteria Scores Costs and Resources

WTRNet Features Select End Use and Source water Add More Processes by Selecting From Lists of Possible Pre- and Post-cursors Add Unit Process to Treatment Train Select Sludge Treatment and Disposal Treatment Train Evaluation Results Effluent Quality Percent Pollutant Removed/Remaining Evaluation Criteria Scores Costs and Resources

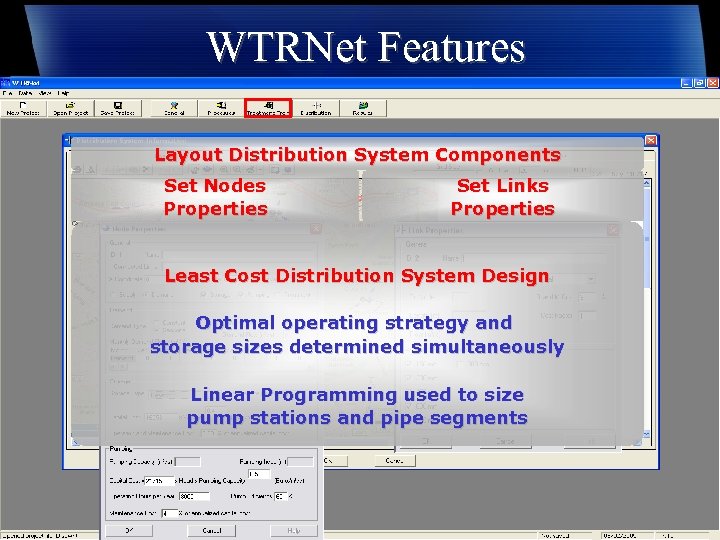

WTRNet Features Layout Distribution System Components Set Nodes Properties Set Links Properties Least Cost Distribution System Design Optimal operating strategy and storage sizes determined simultaneously Linear Programming used to size pump stations and pipe segments

WTRNet Features Layout Distribution System Components Set Nodes Properties Set Links Properties Least Cost Distribution System Design Optimal operating strategy and storage sizes determined simultaneously Linear Programming used to size pump stations and pipe segments

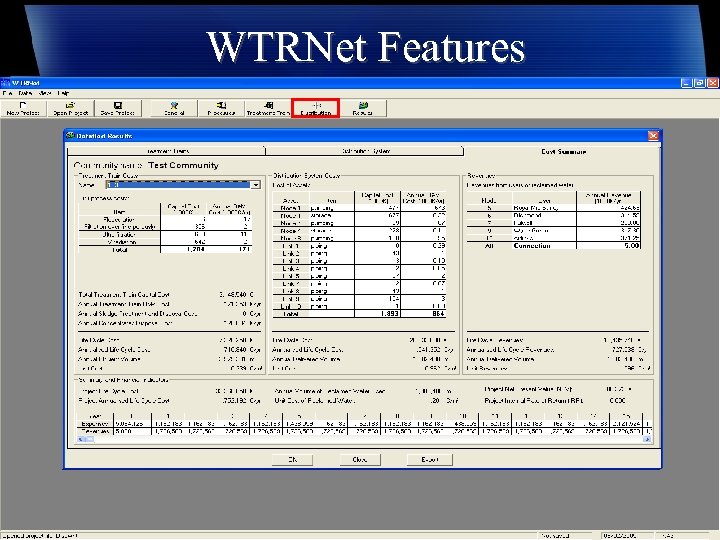

WTRNet Features

WTRNet Features

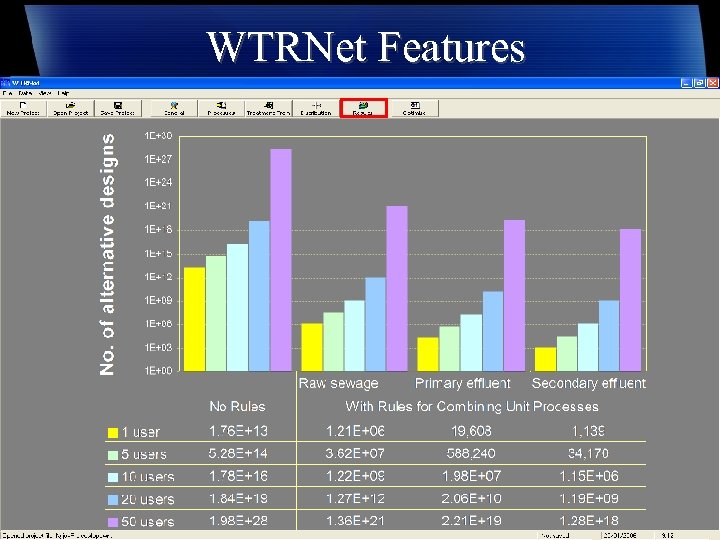

WTRNet Features

WTRNet Features

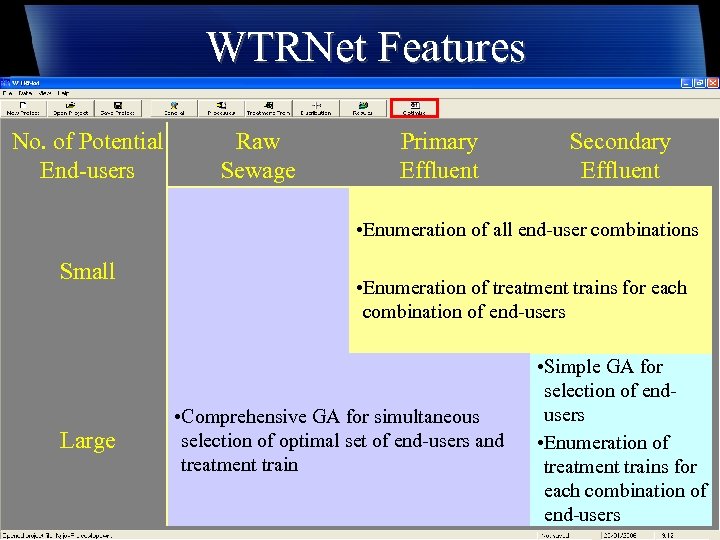

WTRNet Features No. of Potential End-users Raw Sewage Primary Effluent Secondary Effluent • Enumeration of all end-user combinations Small Large • Enumeration of treatment trains for each combination of end-users • Comprehensive GA for simultaneous selection of optimal set of end-users and treatment train • Simple GA for selection of endusers • Enumeration of treatment trains for each combination of end-users

WTRNet Features No. of Potential End-users Raw Sewage Primary Effluent Secondary Effluent • Enumeration of all end-user combinations Small Large • Enumeration of treatment trains for each combination of end-users • Comprehensive GA for simultaneous selection of optimal set of end-users and treatment train • Simple GA for selection of endusers • Enumeration of treatment trains for each combination of end-users

Development of Design Principles • Applied WTRNet to two case studies • Kyjov • London

Development of Design Principles • Applied WTRNet to two case studies • Kyjov • London

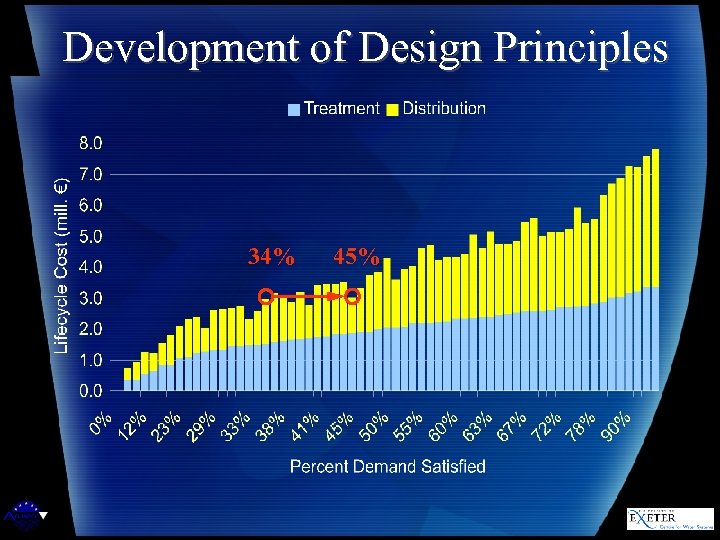

Development of Design Principles 34% 45%

Development of Design Principles 34% 45%

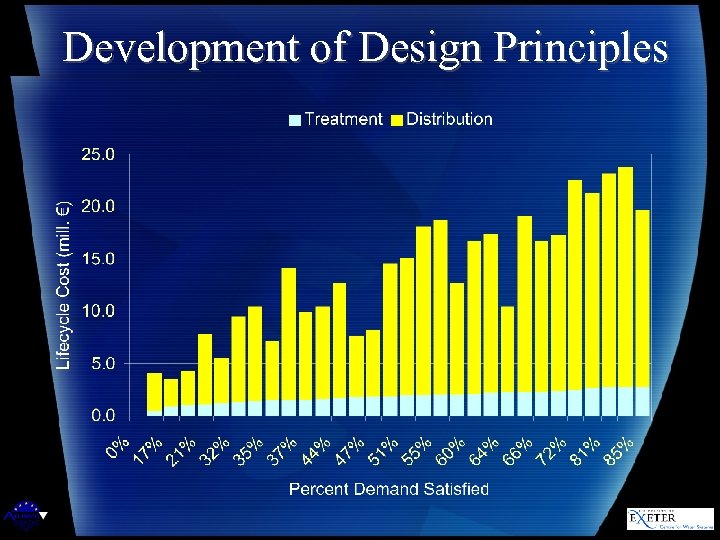

Development of Design Principles

Development of Design Principles

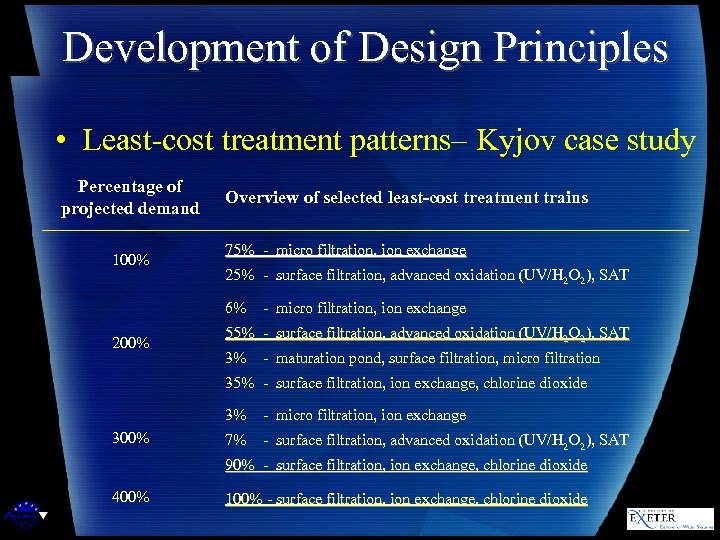

Development of Design Principles • Least-cost treatment patterns– Kyjov case study Percentage of projected demand 100% Overview of selected least-cost treatment trains 75% - micro filtration, ion exchange 25% - surface filtration, advanced oxidation (UV/H 2 O 2), SAT 6% 200% - micro filtration, ion exchange 55% - surface filtration, advanced oxidation (UV/H 2 O 2), SAT 3% - maturation pond, surface filtration, micro filtration 35% - surface filtration, ion exchange, chlorine dioxide 3% 300% - micro filtration, ion exchange 7% - surface filtration, advanced oxidation (UV/H 2 O 2), SAT 90% - surface filtration, ion exchange, chlorine dioxide 400% 100% - surface filtration, ion exchange, chlorine dioxide

Development of Design Principles • Least-cost treatment patterns– Kyjov case study Percentage of projected demand 100% Overview of selected least-cost treatment trains 75% - micro filtration, ion exchange 25% - surface filtration, advanced oxidation (UV/H 2 O 2), SAT 6% 200% - micro filtration, ion exchange 55% - surface filtration, advanced oxidation (UV/H 2 O 2), SAT 3% - maturation pond, surface filtration, micro filtration 35% - surface filtration, ion exchange, chlorine dioxide 3% 300% - micro filtration, ion exchange 7% - surface filtration, advanced oxidation (UV/H 2 O 2), SAT 90% - surface filtration, ion exchange, chlorine dioxide 400% 100% - surface filtration, ion exchange, chlorine dioxide

Conclusions • WTRNet allows efficient planning level evaluation of integrated reuse schemes • Treatment train assembly rules greatly reduce the number of design alternatives • Incorporated optimisation methodologies appropriate for the size of the problem

Conclusions • WTRNet allows efficient planning level evaluation of integrated reuse schemes • Treatment train assembly rules greatly reduce the number of design alternatives • Incorporated optimisation methodologies appropriate for the size of the problem

Conclusions • Variability in total lifecycle cost is a direct result of the distribution system costs • Distribution system - a significant portion of total scheme lifecycle cost • Patterns in selection of least-cost treatment trains

Conclusions • Variability in total lifecycle cost is a direct result of the distribution system costs • Distribution system - a significant portion of total scheme lifecycle cost • Patterns in selection of least-cost treatment trains

Acknowledgements • European Commission • AQUAREC Project partners – RWTH Aachen, Chemical Engineering Department, Germany – Aquafin NV – Water Body of Flanders, Belgium – Centre for Research and Technology, Hellas, Chemical Process Engineering Research Institute, Greece – Technical University Delft, Department of Water Management, Netherlands – Mekorot Water Company Ltd. , Israel

Acknowledgements • European Commission • AQUAREC Project partners – RWTH Aachen, Chemical Engineering Department, Germany – Aquafin NV – Water Body of Flanders, Belgium – Centre for Research and Technology, Hellas, Chemical Process Engineering Research Institute, Greece – Technical University Delft, Department of Water Management, Netherlands – Mekorot Water Company Ltd. , Israel