bf4fdf5b483e5bb5c320ff1e69c5162c.ppt

- Количество слайдов: 54

April 2008 Laird Technologies MMP

April 2008 Laird Technologies MMP

The Laird Group PLC Overview • Founded in mid 1800’s • Headquartered in London, UK • Quoted on the London Stock Exchange (symbol LARD) and a member of the FTSE 250 index • Employer of 10, 000+ people in North America, Europe and Asia • 2006 revenue of approximately $1200 million

The Laird Group PLC Overview • Founded in mid 1800’s • Headquartered in London, UK • Quoted on the London Stock Exchange (symbol LARD) and a member of the FTSE 250 index • Employer of 10, 000+ people in North America, Europe and Asia • 2006 revenue of approximately $1200 million

Laird Technologies • • Founded in mid 1990’s Headquartered in St. Louis, Missouri, USA Annual revenue almost $1 B dollars Over 10, 000 employees globally in engineering, manufacturing and sales • Industry Business Units: – – – Handset Automotive Datacom I&I Consumer

Laird Technologies • • Founded in mid 1990’s Headquartered in St. Louis, Missouri, USA Annual revenue almost $1 B dollars Over 10, 000 employees globally in engineering, manufacturing and sales • Industry Business Units: – – – Handset Automotive Datacom I&I Consumer

Worldwide Locations 50 sites around the world 10, 000 employees Not all sites are represented in this graphic. Some sites are close together

Worldwide Locations 50 sites around the world 10, 000 employees Not all sites are represented in this graphic. Some sites are close together

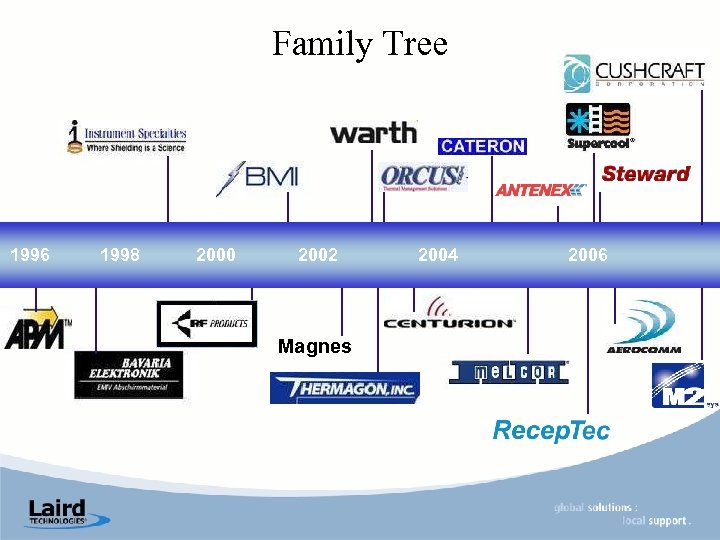

Family Tree 1996 1998 2000 2002 Magnes 2004 2006

Family Tree 1996 1998 2000 2002 Magnes 2004 2006

The Laird Technologies Mission “To be the leader in design and supply of customized performance-critical products for wireless and other advanced electronics applications. ”

The Laird Technologies Mission “To be the leader in design and supply of customized performance-critical products for wireless and other advanced electronics applications. ”

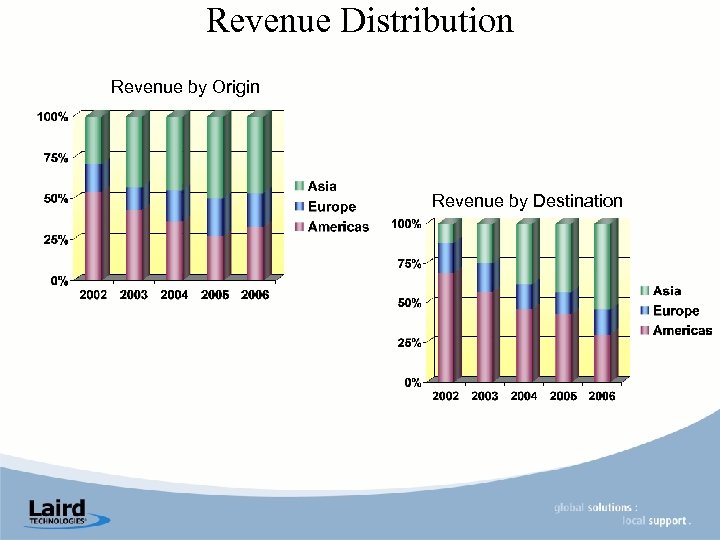

Revenue Distribution Revenue by Origin Revenue by Destination

Revenue Distribution Revenue by Origin Revenue by Destination

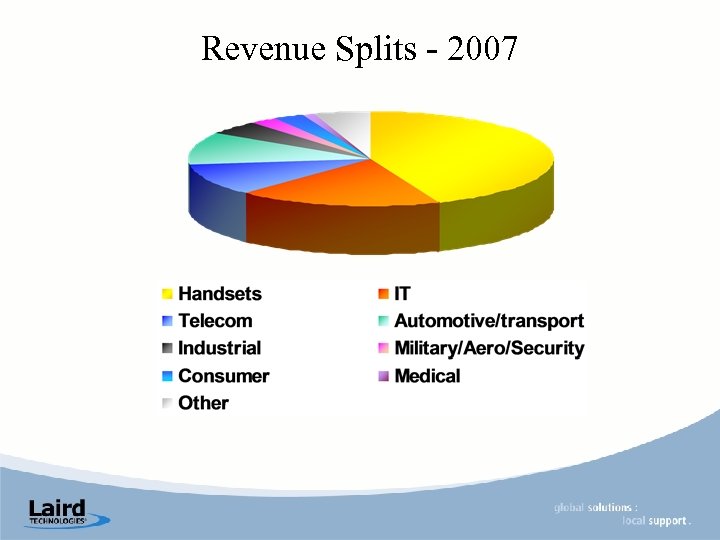

Revenue Splits - 2007

Revenue Splits - 2007

Strategy • Technology leadership in all products offered • Direct support for global and large OEM programs • Broad market coverage • Broad product line within business units • Local manufacturing and engineering • Low cost producer of high volume products • Add complementary product lines global solutions: local support

Strategy • Technology leadership in all products offered • Direct support for global and large OEM programs • Broad market coverage • Broad product line within business units • Local manufacturing and engineering • Low cost producer of high volume products • Add complementary product lines global solutions: local support

Core Competencies • Bias for action – speed of response • Global footprint • Key customer access and relationships • Broad product line to same customers • Ability to bundle technology – “convergence products” • RF design • Identifying, buying, integrating niche segments of high margin, customized electronics components and systems

Core Competencies • Bias for action – speed of response • Global footprint • Key customer access and relationships • Broad product line to same customers • Ability to bundle technology – “convergence products” • RF design • Identifying, buying, integrating niche segments of high margin, customized electronics components and systems

Serving a Diverse Range of Leading Global Companies

Serving a Diverse Range of Leading Global Companies

Topics Today • • • MMP (Mobile Metal Products) Handset Products Technologies Manufacturing Sites Program Support Structure

Topics Today • • • MMP (Mobile Metal Products) Handset Products Technologies Manufacturing Sites Program Support Structure

MMP • Mobile Metal Products – Board Level Shielding – Combo Products – Decorative / Visual Metals – MAP (Hinges)

MMP • Mobile Metal Products – Board Level Shielding – Combo Products – Decorative / Visual Metals – MAP (Hinges)

Technical Characteristics Board Level Shielding Surface Mount Shield Options • 2 Piece pre-assembled frame and cover (Tin Plate CRS not available as cover will reflow to frame) • 2 Piece system surface mount frame with manually installed cover • Multi-Compartmental Shields replace multiple single shields • 1 Piece Surface Mount Shields – Formed and Drawn technologies • 1 Piece Shield w/ Tear-Away Feature (EZ Peel / Pop-Top) • Surface Mount Clips with BLS and MIP shield (Ec. E and TPE types)

Technical Characteristics Board Level Shielding Surface Mount Shield Options • 2 Piece pre-assembled frame and cover (Tin Plate CRS not available as cover will reflow to frame) • 2 Piece system surface mount frame with manually installed cover • Multi-Compartmental Shields replace multiple single shields • 1 Piece Surface Mount Shields – Formed and Drawn technologies • 1 Piece Shield w/ Tear-Away Feature (EZ Peel / Pop-Top) • Surface Mount Clips with BLS and MIP shield (Ec. E and TPE types)

Materials used for BLS • Tin Plated Cold Rolled Steel (CRS) – Cheapest option • Nickel Silver • Stainless Steel Tin Plated • Tin Plate Phos bronze • ALL materials used are Ro. Hs compliant

Materials used for BLS • Tin Plated Cold Rolled Steel (CRS) – Cheapest option • Nickel Silver • Stainless Steel Tin Plated • Tin Plate Phos bronze • ALL materials used are Ro. Hs compliant

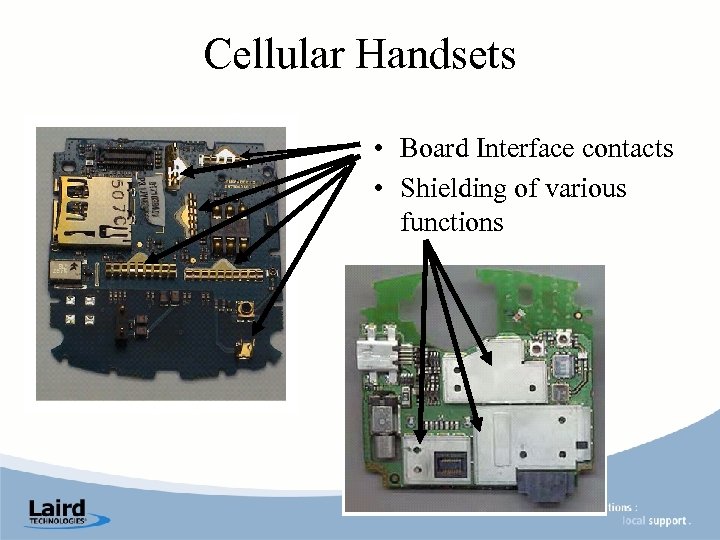

Cellular Handsets • Board Interface contacts • Shielding of various functions

Cellular Handsets • Board Interface contacts • Shielding of various functions

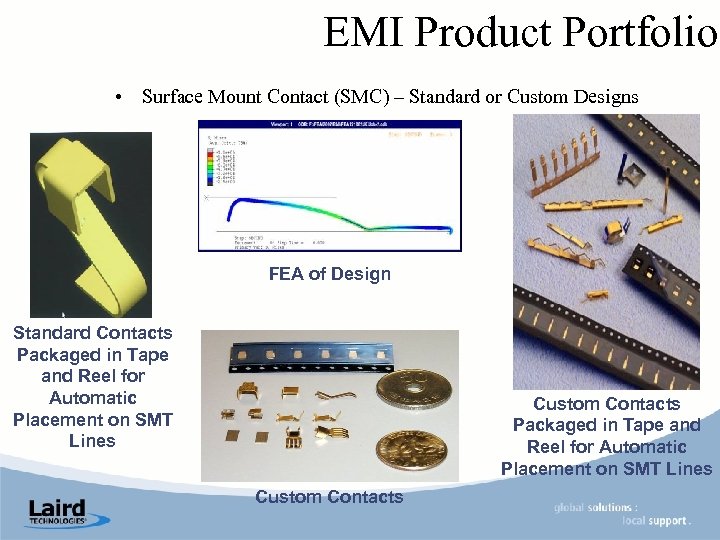

EMI Product Portfolio • Surface Mount Contact (SMC) – Standard or Custom Designs FEA of Design Standard Contacts Packaged in Tape and Reel for Automatic Placement on SMT Lines Custom Contacts

EMI Product Portfolio • Surface Mount Contact (SMC) – Standard or Custom Designs FEA of Design Standard Contacts Packaged in Tape and Reel for Automatic Placement on SMT Lines Custom Contacts

BLS Manufacturing Technology Objectives -Deliver High Quality Parts at the Lowest Cost • Match system productivity to program size • Implement Technologies that maximize yields • In-line and In-Die secondary operations • Technologies to reduce material usages • Real-time Quality Assurance and Quality Control • Match tool life to program size (15 m to 100 m)

BLS Manufacturing Technology Objectives -Deliver High Quality Parts at the Lowest Cost • Match system productivity to program size • Implement Technologies that maximize yields • In-line and In-Die secondary operations • Technologies to reduce material usages • Real-time Quality Assurance and Quality Control • Match tool life to program size (15 m to 100 m)

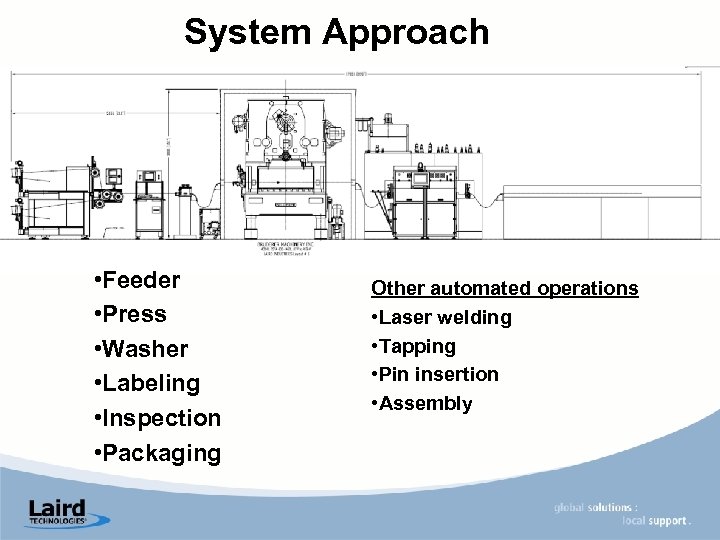

System Approach • Feeder • Press • Washer • Labeling • Inspection • Packaging Other automated operations • Laser welding • Tapping • Pin insertion • Assembly

System Approach • Feeder • Press • Washer • Labeling • Inspection • Packaging Other automated operations • Laser welding • Tapping • Pin insertion • Assembly

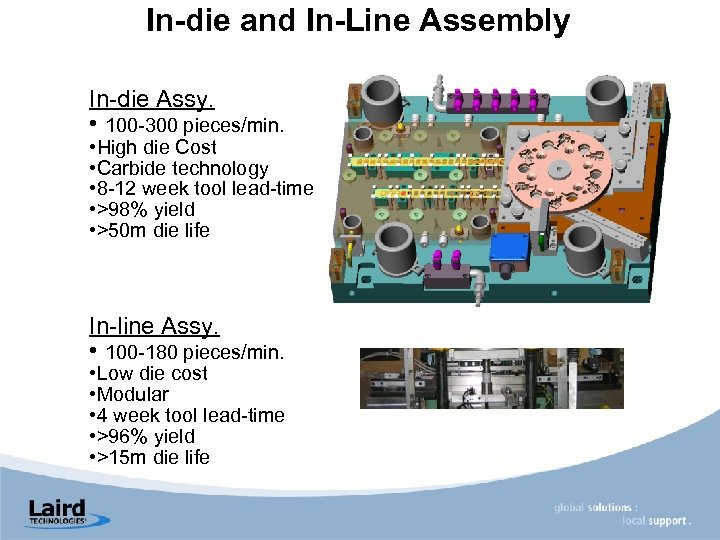

In-die and In-Line Assembly In-die Assy. • 100 -300 pieces/min. • High die Cost • Carbide technology • 8 -12 week tool lead-time • >98% yield • >50 m die life In-line Assy. • 100 -180 pieces/min. • Low die cost • Modular • 4 week tool lead-time • >96% yield • >15 m die life

In-die and In-Line Assembly In-die Assy. • 100 -300 pieces/min. • High die Cost • Carbide technology • 8 -12 week tool lead-time • >98% yield • >50 m die life In-line Assy. • 100 -180 pieces/min. • Low die cost • Modular • 4 week tool lead-time • >96% yield • >15 m die life

100% Automated Co-planarity Inspection PEG AOI

100% Automated Co-planarity Inspection PEG AOI

![Combo Products • Combo (MCS) Drawn Frames with Molding [TPE or Conductive Silicone] Simulation Combo Products • Combo (MCS) Drawn Frames with Molding [TPE or Conductive Silicone] Simulation](https://present5.com/presentation/bf4fdf5b483e5bb5c320ff1e69c5162c/image-22.jpg) Combo Products • Combo (MCS) Drawn Frames with Molding [TPE or Conductive Silicone] Simulation of Draw Forming Drawn Part Molded Part • LT has the internal ability to produce complex metal stampings and insert molded parts. • Molding can be TPE or Ec. E

Combo Products • Combo (MCS) Drawn Frames with Molding [TPE or Conductive Silicone] Simulation of Draw Forming Drawn Part Molded Part • LT has the internal ability to produce complex metal stampings and insert molded parts. • Molding can be TPE or Ec. E

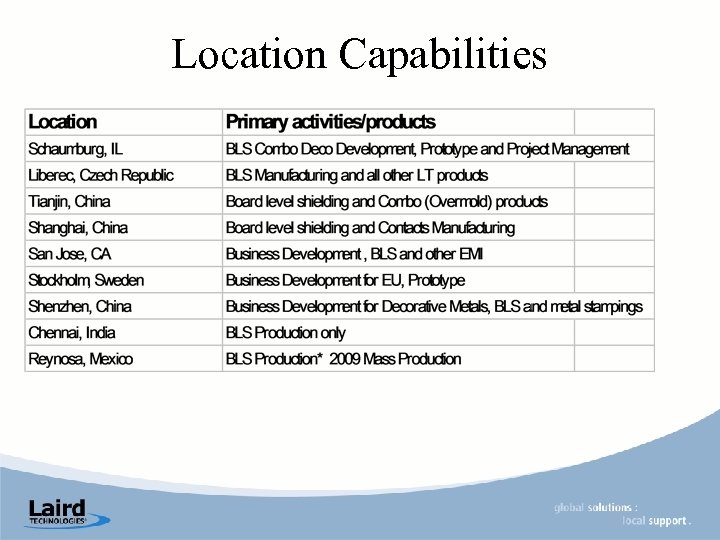

Location Capabilities

Location Capabilities

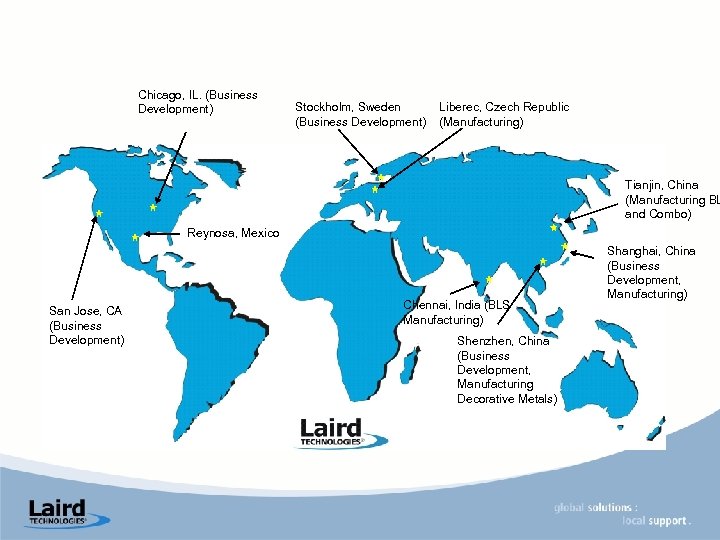

Chicago, IL. (Business Development) Stockholm, Sweden (Business Development) Liberec, Czech Republic (Manufacturing) Tianjin, China (Manufacturing BL and Combo) Reynosa, Mexico San Jose, CA (Business Development) Chennai, India (BLS Manufacturing) Shenzhen, China (Business Development, Manufacturing Decorative Metals) Shanghai, China (Business Development, Manufacturing)

Chicago, IL. (Business Development) Stockholm, Sweden (Business Development) Liberec, Czech Republic (Manufacturing) Tianjin, China (Manufacturing BL and Combo) Reynosa, Mexico San Jose, CA (Business Development) Chennai, India (BLS Manufacturing) Shenzhen, China (Business Development, Manufacturing Decorative Metals) Shanghai, China (Business Development, Manufacturing)

DECORATIVE METALS

DECORATIVE METALS

What is a decorative metal? • • Exterior metals to a customer application. Typically has a class 1 finish. May be plated, colored, etch, etc. Provides ASTHETIC appeal to end customer product • Can also be an enclosure for the application

What is a decorative metal? • • Exterior metals to a customer application. Typically has a class 1 finish. May be plated, colored, etch, etc. Provides ASTHETIC appeal to end customer product • Can also be an enclosure for the application

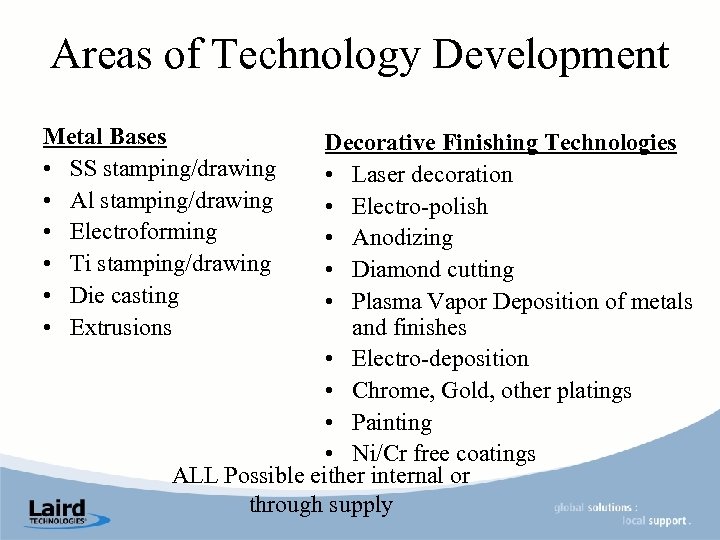

Areas of Technology Development Metal Bases • SS stamping/drawing • Al stamping/drawing • Electroforming • Ti stamping/drawing • Die casting • Extrusions Decorative Finishing Technologies • Laser decoration • Electro-polish • Anodizing • Diamond cutting • Plasma Vapor Deposition of metals and finishes • Electro-deposition • Chrome, Gold, other platings • Painting • Ni/Cr free coatings ALL Possible either internal or through supply

Areas of Technology Development Metal Bases • SS stamping/drawing • Al stamping/drawing • Electroforming • Ti stamping/drawing • Die casting • Extrusions Decorative Finishing Technologies • Laser decoration • Electro-polish • Anodizing • Diamond cutting • Plasma Vapor Deposition of metals and finishes • Electro-deposition • Chrome, Gold, other platings • Painting • Ni/Cr free coatings ALL Possible either internal or through supply

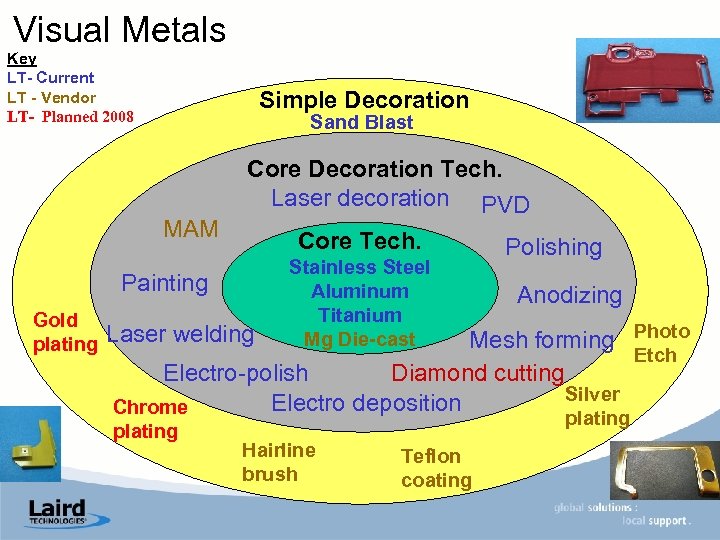

Visual Metals Key LT- Current LT - Vendor LT- Planned 2008 Simple Decoration Sand Blast MAM Core Decoration Tech. Laser decoration PVD Core Tech. Painting Gold plating Stainless Steel Aluminum Titanium Mg Die-cast Polishing Anodizing Mesh forming Photo Etch Electro-polish Diamond cutting Silver Electro deposition Chrome Laser welding plating Hairline brush Teflon coating

Visual Metals Key LT- Current LT - Vendor LT- Planned 2008 Simple Decoration Sand Blast MAM Core Decoration Tech. Laser decoration PVD Core Tech. Painting Gold plating Stainless Steel Aluminum Titanium Mg Die-cast Polishing Anodizing Mesh forming Photo Etch Electro-polish Diamond cutting Silver Electro deposition Chrome Laser welding plating Hairline brush Teflon coating

Digital Imaging Network Infrastructure Handset Computing Platforms Visual Metal & Hinge Market 1 H 08 2 H 08 1 H 09 2 H 10 Roadmap

Digital Imaging Network Infrastructure Handset Computing Platforms Visual Metal & Hinge Market 1 H 08 2 H 08 1 H 09 2 H 10 Roadmap

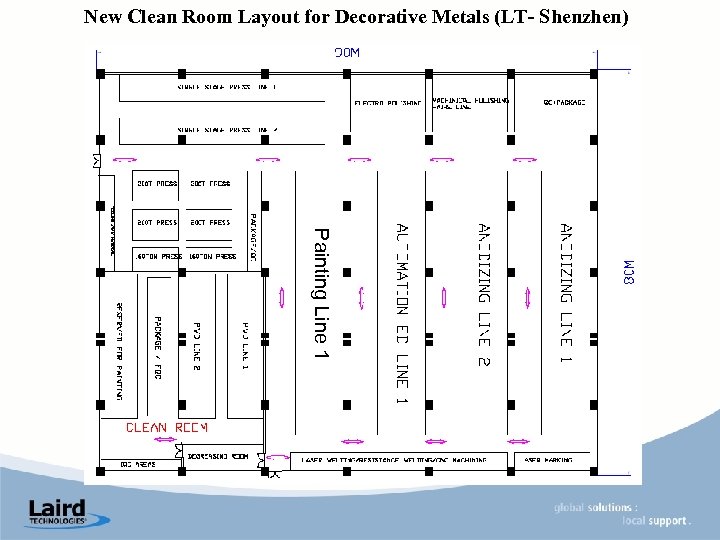

New Clean Room Layout for Decorative Metals (LT- Shenzhen) Painting Line 1

New Clean Room Layout for Decorative Metals (LT- Shenzhen) Painting Line 1

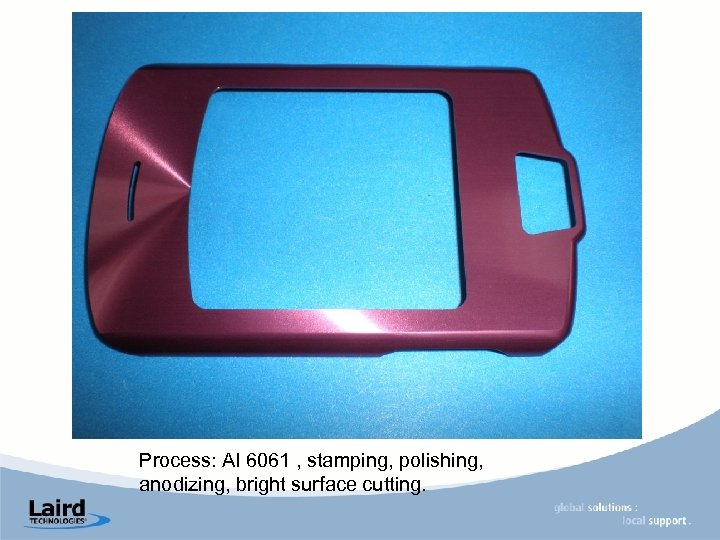

Process: Al 6061 , stamping, polishing, anodizing, bright surface cutting.

Process: Al 6061 , stamping, polishing, anodizing, bright surface cutting.

Process: SUS 304 BA, stamping, electro polishing, selective Hairline.

Process: SUS 304 BA, stamping, electro polishing, selective Hairline.

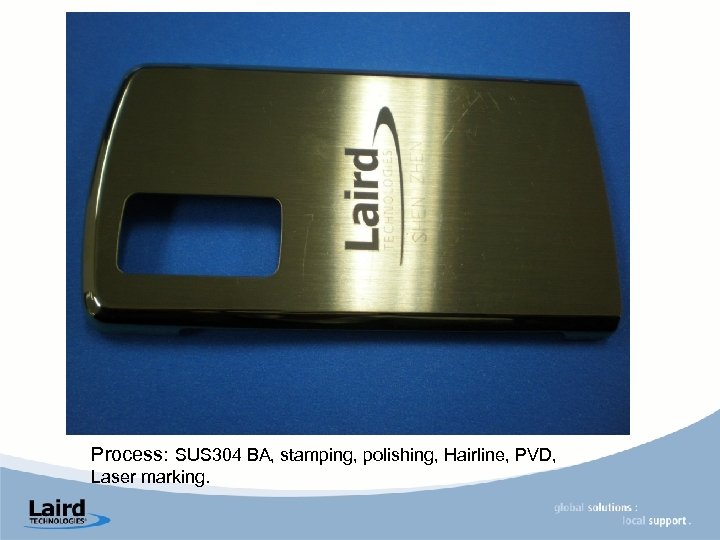

Process: SUS 304 BA, stamping, polishing, Hairline, PVD, Laser marking.

Process: SUS 304 BA, stamping, polishing, Hairline, PVD, Laser marking.

Process: SUS 304 BA, stamping, electro polishing, selective Hairline.

Process: SUS 304 BA, stamping, electro polishing, selective Hairline.

Process: SUS 304 BA, stamping, 3 coatings, soft touch.

Process: SUS 304 BA, stamping, 3 coatings, soft touch.

Decorative Metals • Laser Coloring on Stainless Steel

Decorative Metals • Laser Coloring on Stainless Steel

Decorative Metals • Complex Forming • Electro Polishing

Decorative Metals • Complex Forming • Electro Polishing

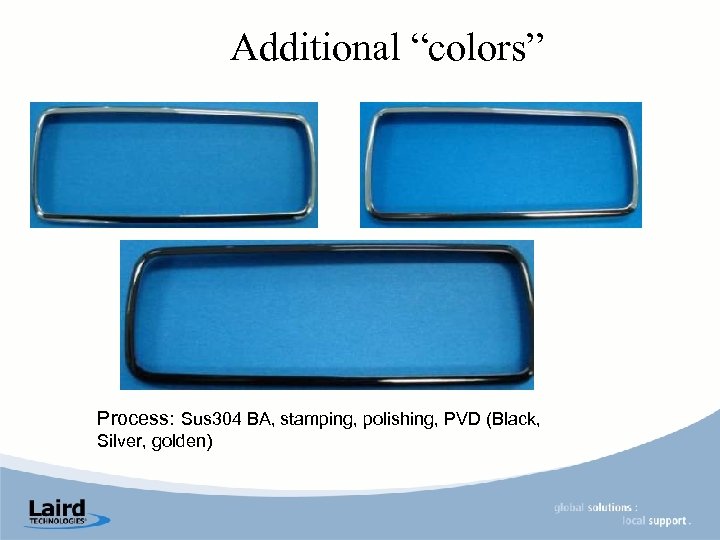

Additional “colors” Process: Sus 304 BA, stamping, polishing, PVD (Black, Silver, golden)

Additional “colors” Process: Sus 304 BA, stamping, polishing, PVD (Black, Silver, golden)

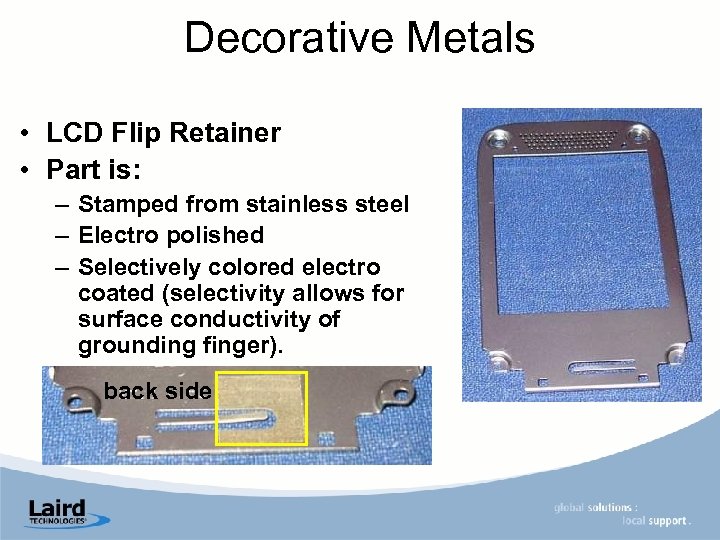

Decorative Metals • LCD Flip Retainer • Part is: – Stamped from stainless steel – Electro polished – Selectively colored electro coated (selectivity allows for surface conductivity of grounding finger). back side

Decorative Metals • LCD Flip Retainer • Part is: – Stamped from stainless steel – Electro polished – Selectively colored electro coated (selectivity allows for surface conductivity of grounding finger). back side

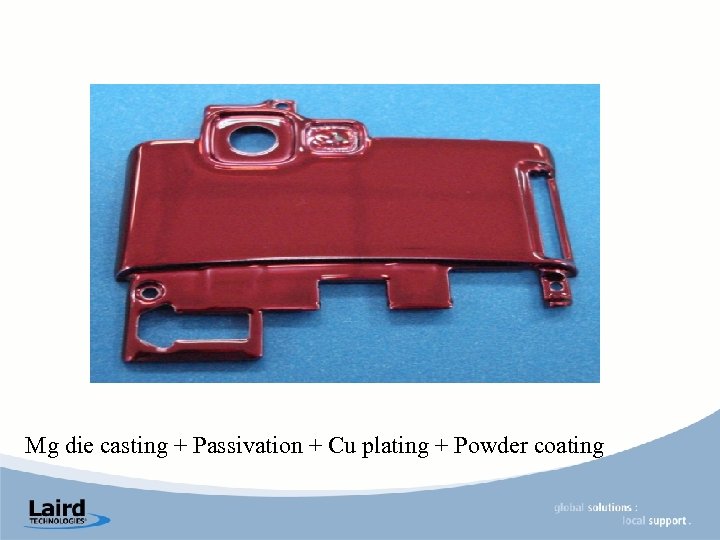

Mg die casting + Passivation + Cu plating + Powder coating

Mg die casting + Passivation + Cu plating + Powder coating

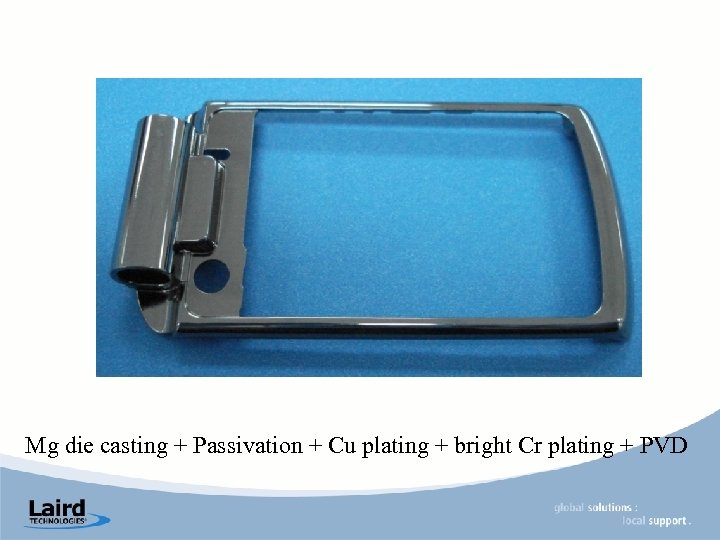

Mg die casting + Passivation + Cu plating + bright Cr plating + PVD

Mg die casting + Passivation + Cu plating + bright Cr plating + PVD

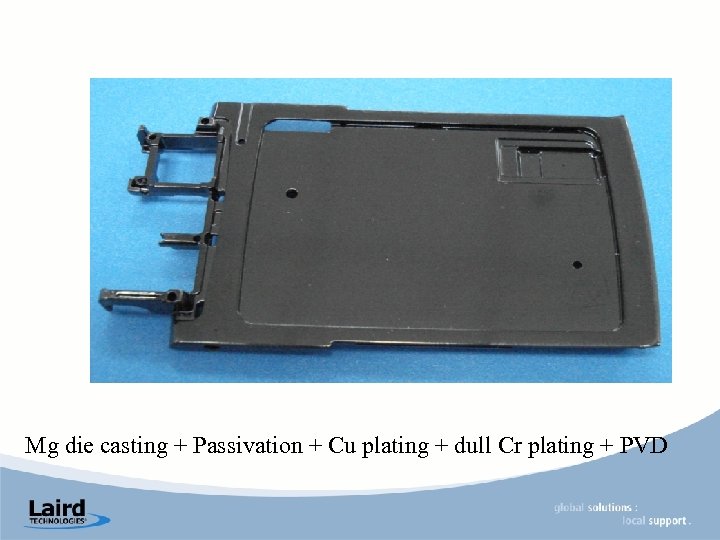

Mg die casting + Passivation + Cu plating + dull Cr plating + PVD

Mg die casting + Passivation + Cu plating + dull Cr plating + PVD

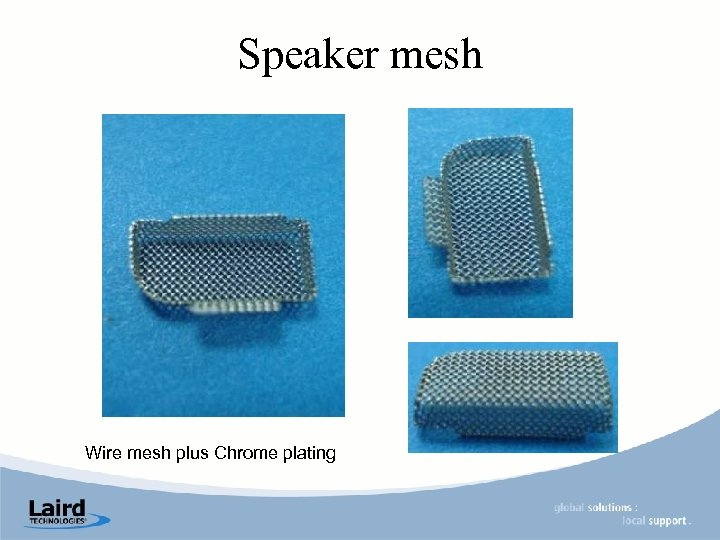

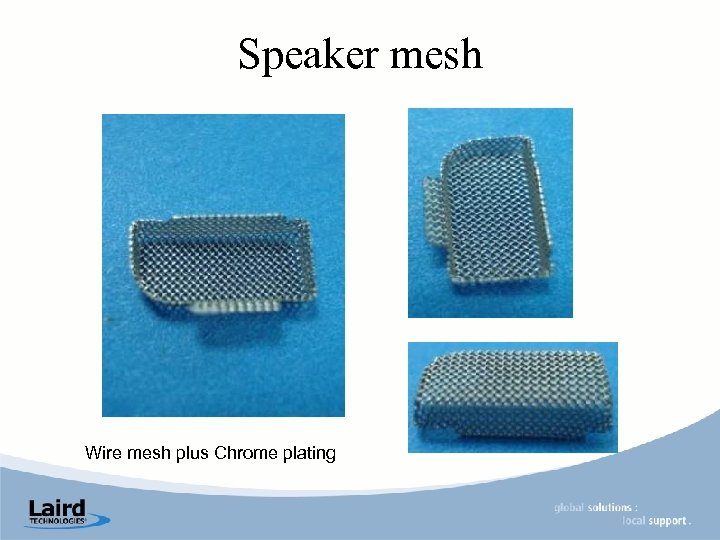

Speaker mesh Wire mesh plus Chrome plating

Speaker mesh Wire mesh plus Chrome plating

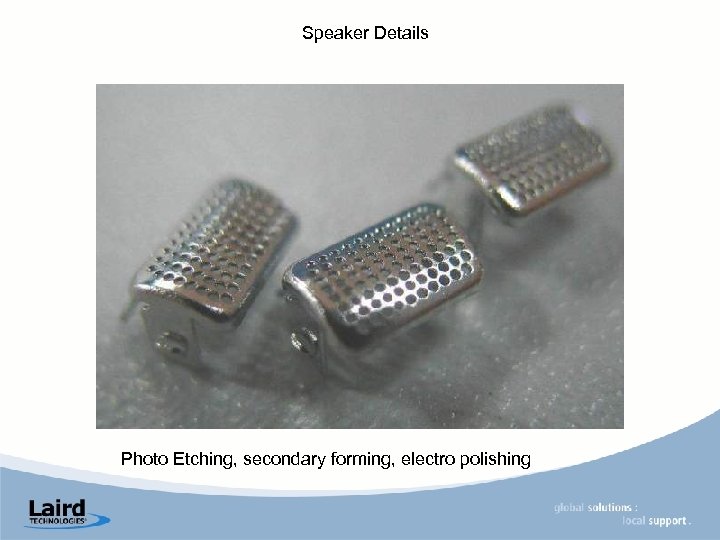

Speaker Details Photo Etching, secondary forming, electro polishing

Speaker Details Photo Etching, secondary forming, electro polishing

Speaker mesh Wire mesh plus Chrome plating

Speaker mesh Wire mesh plus Chrome plating

SIM Tray Stamping + ED coating + laser etching

SIM Tray Stamping + ED coating + laser etching

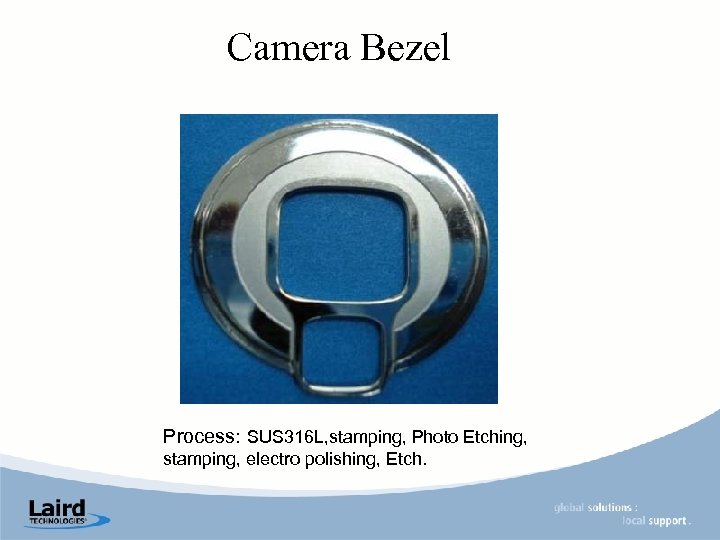

Camera Bezel Process: SUS 316 L, stamping, Photo Etching, stamping, electro polishing, Etch.

Camera Bezel Process: SUS 316 L, stamping, Photo Etching, stamping, electro polishing, Etch.

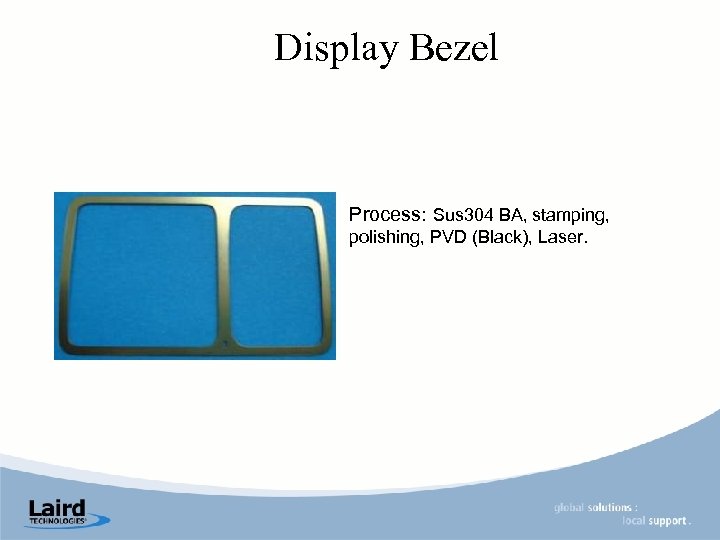

Display Bezel Process: Sus 304 BA, stamping, polishing, PVD (Black), Laser.

Display Bezel Process: Sus 304 BA, stamping, polishing, PVD (Black), Laser.

MAP (Hinges)

MAP (Hinges)

MAP • Mechanical Actuated Products – Hinges provides handheld devices the ability to fold, rotate or slide to allow access to screens or keypads. These capabilities are key aspects to allow these devices to become smaller now and in the future • MAP comes from 2007 Acquisition of M 2 Sys, a Korean company.

MAP • Mechanical Actuated Products – Hinges provides handheld devices the ability to fold, rotate or slide to allow access to screens or keypads. These capabilities are key aspects to allow these devices to become smaller now and in the future • MAP comes from 2007 Acquisition of M 2 Sys, a Korean company.

Locations

Locations

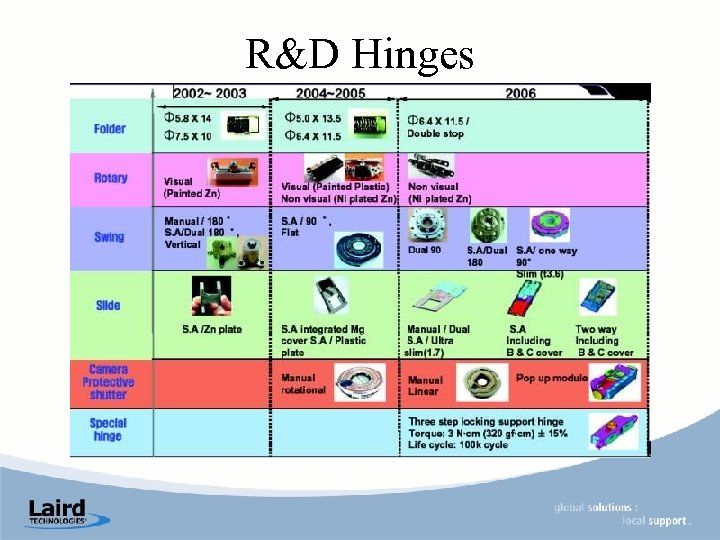

R&D Hinges

R&D Hinges

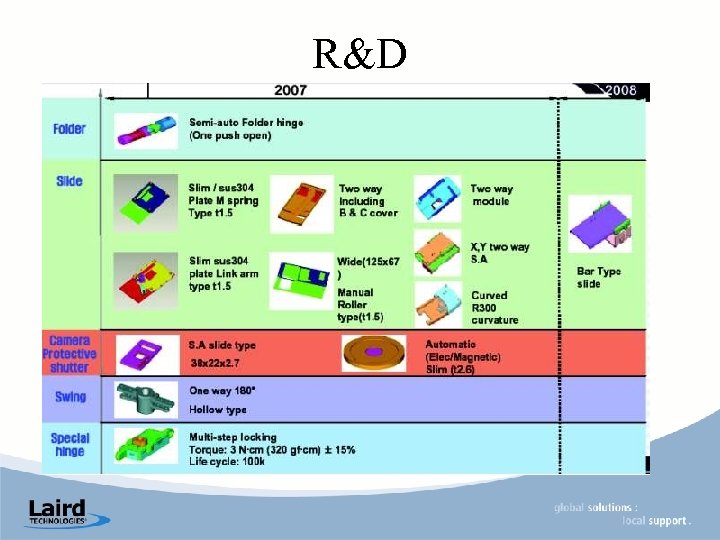

R&D

R&D

Questions

Questions